C Purlin Machine With Punching Hole Device: A Complete Guide

By:Admin

In the ever-evolving world of steel manufacturing, technological advancements continue to provide new and innovative solutions to enhance efficiency and productivity. One such breakthrough comes in the form of the C Purlin Machine with Punching Hole Device, which has been making waves in the industry for its cutting-edge capabilities.

The C Purlin Machine with Punching Hole Device, developed and manufactured by a leading company in the steel manufacturing sector, is a game-changer in the production of C-shaped steel purlins. These purlins, which are widely used in the construction of industrial and commercial buildings, play a crucial role in providing structural support and stability.

One of the key features that sets this machine apart is its punching hole device, which enables the seamless integration of pre-punched holes in the steel purlins during the manufacturing process. This innovative functionality eliminates the need for secondary processes and significantly reduces production time and costs. Moreover, it ensures precise hole placement, resulting in a high-quality end product that meets the specifications of even the most demanding construction projects.

The C Purlin Machine with Punching Hole Device is equipped with advanced technology that allows for seamless operation and precise control. Its user-friendly interface and intuitive design make it easy to operate, while its robust construction ensures durability and longevity, even in the most demanding manufacturing environments.

The machine's versatility and flexibility are further enhanced by its adjustable settings, which allow for the production of a wide range of C purlin sizes and hole configurations. This level of adaptability makes it an invaluable asset for steel manufacturing companies, enabling them to meet the diverse needs of their customers with ease and efficiency.

The company behind this groundbreaking innovation has established itself as a leader in the steel manufacturing industry, with a proven track record of delivering high-quality, reliable solutions to its customers. With a strong focus on research and development, as well as a commitment to continuous improvement, the company has earned a reputation for excellence and innovation.

In addition to its cutting-edge technology, the company is dedicated to providing exceptional customer service and support. Its team of highly skilled technicians and engineers are always on hand to offer assistance and guidance, ensuring that customers can maximize the performance and efficiency of their equipment.

Furthermore, the company places a strong emphasis on sustainability and environmental responsibility, incorporating eco-friendly practices and materials into its manufacturing processes. This commitment to sustainability not only reflects the company's values but also resonates with an industry that is increasingly prioritizing green initiatives and eco-conscious solutions.

In summary, the C Purlin Machine with Punching Hole Device represents a significant advancement in steel manufacturing, offering a level of precision, efficiency, and versatility that is unparalleled in the industry. Its innovative technology, combined with the expertise and support of the company behind it, positions it as a game-changing solution for steel manufacturing companies looking to stay ahead in a competitive market.

As the demand for high-quality steel products continues to grow, this revolutionary machine is set to play a key role in shaping the future of the industry, offering a new standard of excellence in the production of C-shaped steel purlins. With its advanced capabilities and the backing of a reputable company, the C Purlin Machine with Punching Hole Device is poised to make a lasting impact on the world of steel manufacturing.

Company News & Blog

Rollforming Machines for Steel Production: Key Features and Benefits

Steel Rollforming Machines are an essential part of the manufacturing process for a wide range of industries, including construction, automotive, and aerospace. These machines are used to shape and manipulate steel into various profiles and shapes, which are then used in the production of a wide range of products.One of the leading manufacturers of Steel Rollforming Machines in the world is {}, a company that has been at the forefront of rollforming technology for over 30 years. With a commitment to innovation and quality, {} has established itself as a trusted name in the industry, providing high-precision rollforming solutions to customers around the globe.{}’s Steel Rollforming Machines are known for their precision, reliability, and efficiency. These machines are designed to meet the specific needs of each customer, with features that allow for quick and easy tooling changes, high-speed production, and accurate forming of steel profiles. Whether it’s for the production of roofing panels, automotive components, or structural steel sections, {}’s rollforming machines are up to the task.One of the key advantages of {}’s Steel Rollforming Machines is their ability to produce high-quality parts with tight tolerances. This is crucial for industries such as automotive and aerospace, where precision is essential for the safety and performance of the finished products. {}’s machines are equipped with advanced control systems and monitoring technologies to ensure that each part produced meets the highest standards of quality.In addition to their precision and reliability, {}’s Steel Rollforming Machines are also designed for ease of use and maintenance. With user-friendly interfaces and intuitive controls, operators can quickly set up and run the machines, minimizing downtime and maximizing productivity. Furthermore, {} provides comprehensive training and support to ensure that customers get the most out of their rollforming equipment.Another key aspect of {}’s rollforming solutions is their versatility. {} offers a wide range of standard machine designs to choose from, as well as the ability to design custom machines for unique applications. This flexibility allows customers to find the perfect rollforming solution for their specific needs, whether they are producing simple profiles or complex, multi-component parts.With a global presence and a reputation for excellence, {} has become the go-to partner for companies looking for high-quality Steel Rollforming Machines. Their commitment to innovation and customer satisfaction sets them apart in the industry, and their machines are trusted by manufacturers around the world to deliver reliable, high-precision rollforming solutions.As the demand for steel components continues to grow across various industries, the need for reliable and efficient rollforming equipment has never been greater. {} continues to lead the way in the development of Steel Rollforming Machines, providing the technology and expertise that manufacturers need to stay ahead in today’s competitive marketplace.Whether it’s for the production of automotive parts, building materials, or any other steel components, {}’s Steel Rollforming Machines are the ideal choice for manufacturers looking for precision, reliability, and efficiency. With a strong track record of delivering high-quality rollforming solutions, {} is poised to remain a leader in the industry for years to come.

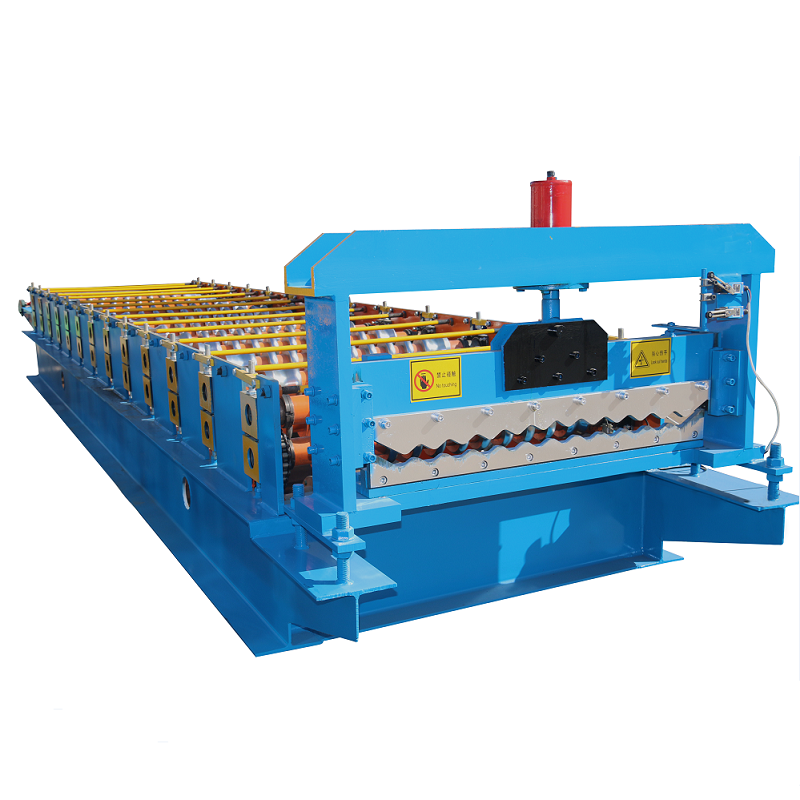

Discover the Innovation of Colored Metal Trapezoidal Sheet Roll Forming Machine

Colored Metal Trapezoidal Sheet Roll Forming Machine Brings Efficiency and Quality to Roofing IndustryThe roofing industry is set to witness a significant boost in efficiency and quality with the introduction of the advanced Colored Metal Trapezoidal Sheet Roll Forming Machine. This innovative machinery, manufactured by a leading company in the industry, aims to revolutionize the way metal roofing sheets are produced.Metal roofing has gained popularity in recent years due to its durability, energy efficiency, and aesthetic appeal. However, the process of manufacturing metal roofing sheets has often been time-consuming, labor-intensive, and prone to errors. The introduction of the Colored Metal Trapezoidal Sheet Roll Forming Machine seeks to address these challenges, ultimately leading to improved productivity and customer satisfaction.The key feature of this roll forming machine is its ability to efficiently produce trapezoidal-shaped metal sheets. This shape is commonly used in roofing applications due to its excellent water drainage capabilities, structural strength, and ease of installation. The machine's precision engineering ensures accurate dimensions, uniformity, and high-quality finishes, meeting the stringent requirements of the roofing industry.Furthermore, the Colored Metal Trapezoidal Sheet Roll Forming Machine can process various types of colored metal sheets, catering to the diverse needs and preferences of customers. It allows for the production of a wide range of colors and coatings, including but not limited to, galvanized steel, galvalume steel, and pre-painted steel sheets. This versatility empowers roofing contractors and manufacturers to meet the specific demands of different projects, further enhancing their competitiveness in the market.The use of this advanced machinery also significantly reduces manual labor and associated costs. The integration of automated procedures and computerized controls ensures precise and consistent results, eliminating the likelihood of human errors. Moreover, the machine's speed and efficiency enable manufacturers to meet tight project deadlines and handle large-scale orders efficiently.The company behind the Colored Metal Trapezoidal Sheet Roll Forming Machine has established itself as a leader in the metal processing industry. With a strong commitment to research and development, their team of experts continually innovate to provide cutting-edge solutions that deliver superior performance and durability. By collaborating with roofing industry professionals, they ensure that their machines meet the specific requirements of the market, ultimately driving the growth and progress of the entire sector.In addition to manufacturing state-of-the-art machinery, the company also offers comprehensive training programs and technical support to its customers. Recognizing the importance of knowledge transfer and skill development, they equip their clients with the necessary expertise to operate the Colored Metal Trapezoidal Sheet Roll Forming Machine optimally. This commitment to customer service further solidifies the company's reputation as a reliable and trusted provider in the industry.The introduction of the Colored Metal Trapezoidal Sheet Roll Forming Machine marks a significant milestone in the roofing industry. By leveraging the capabilities of this efficient and versatile machinery, contractors and manufacturers can enhance productivity, improve product quality, and boost customer satisfaction. This innovative solution showcases the company's dedication to driving progress and innovation in the metal roofing sector, solidifying their position as a leader in the market.

Top Aluminium Profile Bending Machine: Boost Efficiency and Precision

[Company Introduction]With a commitment to innovation and excellence, our company has been a leading manufacturer and supplier of industrial machinery for over two decades. Established in [year], we have consistently delivered top-notch products to various industries worldwide. Our cutting-edge technology, state-of-the-art manufacturing facilities, and a team of experienced professionals enable us to provide reliable and efficient solutions that cater to the diverse needs of our clients.[News Content]Aluminium Profile Bending Machine Sets New Industry Standards[City, Date] - Our company, a global leader in industrial machinery, has recently introduced its latest innovation, the Aluminium Profile Bending Machine. This remarkable machine sets new industry standards by offering precision and efficiency in bending aluminum profiles, revolutionizing the way aluminum fabrication is done.The Aluminium Profile Bending Machine is designed to meet the specific requirements of aluminum profile bending, ensuring accurate and consistent results. Its advanced features and cutting-edge technology make it the ideal choice for industries involved in aluminum fabrication, such as construction, automotive, aerospace, and furniture.Key Features of the Aluminium Profile Bending Machine include:1. Precision Bending: The machine's automated bending process ensures precise and uniform bending of aluminum profiles, eliminating variations and inconsistencies. It offers adjustable bending angles and radius options, allowing for versatile applications and meeting customized specifications.2. High Efficiency: The Aluminium Profile Bending Machine is equipped with a powerful motor and advanced hydraulic system, enabling high-speed and efficient bending operations. It reduces production time and increases overall productivity, leading to substantial cost savings for businesses.3. User-Friendly Interface: The machine is designed with an intuitive and user-friendly interface, making it easy to operate and control. The interface provides various programmable options, allowing operators to store and recall bending profiles quickly. It also features a comprehensive display that provides real-time information on bending processes, ensuring optimum control and monitoring.4. Durability and Reliability: Crafted from high-quality materials and components, the Aluminium Profile Bending Machine is built to last. It undergoes rigorous testing and quality checks to ensure its durability and reliability in demanding industrial environments. This ensures minimum downtime and maintenance costs, providing businesses with a reliable and long-lasting solution.5. Safety Features: Our priority is the safety of operators and the workplace. The Aluminium Profile Bending Machine is equipped with advanced safety features, including emergency stop buttons, safety sensors, and protective guards. These features significantly reduce the risk of accidents and injuries, ensuring a safe working environment.The introduction of the Aluminium Profile Bending Machine marks a significant milestone in our commitment to innovation and providing advanced solutions to our customers. The machine's diverse applications and unmatched precision make it an invaluable asset for industries reliant on aluminum fabrication.We are proud to contribute to the growth and success of our clients worldwide, as they can now enhance their production capabilities and deliver high-quality products with speed and efficiency.For more information about our Aluminium Profile Bending Machine and other industrial machinery, please visit our website or contact our sales team.[Company Name] is dedicated to continuous improvement and remains at the forefront of technological advancements, meeting the ever-evolving needs of the industry. With the Aluminium Profile Bending Machine, we further solidify our position as a trusted partner for industries seeking cutting-edge solutions for their manufacturing processes.

High-Quality Light Gauge Forming Machine for Precision Metal Fabrication

The use of light gauge forming machines has been revolutionizing the manufacturing industry by providing efficient and precise metal forming capabilities. These state-of-the-art machines are designed to handle a wide range of materials while ensuring high-quality and accurate production. With the advancements made in technology and engineering, the light gauge forming machines have become an integral part of many industries, including construction, automotive, and aerospace.One of the leading companies in the field of light gauge forming machines is the {}, a renowned manufacturer with a strong commitment to innovation and excellence. The company has been a key player in the industry, providing cutting-edge solutions to its clients and continuously pushing the boundaries of what is possible in metal forming technology.With a history of more than 20 years, the {} has established itself as a reliable and trusted partner for businesses looking to enhance their manufacturing capabilities. The company's dedication to research and development has resulted in the creation of some of the most advanced and efficient light gauge forming machines on the market.The {} prides itself on its ability to customize its machines to meet the specific needs of its clients. Whether it is a small-scale project or a large-scale production, the company's team of experts works closely with its clients to understand their requirements and deliver tailor-made solutions that exceed expectations.The company's extensive range of light gauge forming machines includes roll forming machines, tube mills, and steel framing machines, all of which are designed to deliver exceptional precision and efficiency. These machines are capable of handling a wide variety of materials, including steel, aluminum, and other metal alloys, making them an ideal choice for a diverse range of applications.In addition to its cutting-edge machinery, the {} also offers comprehensive after-sales support and maintenance services to ensure that its clients' operations run smoothly and efficiently. The company's team of skilled technicians and engineers are readily available to provide technical assistance, training, and spare parts, as well as to address any issues that may arise.The {}'s commitment to quality and customer satisfaction has earned it a solid reputation in the industry, with a strong client base that includes some of the leading companies in various sectors. The company's track record of delivering reliable and innovative solutions has made it a go-to choice for businesses looking to invest in top-of-the-line light gauge forming machines.Looking ahead, the {} continues to invest in research and development to further enhance its products and stay ahead of the curve in an ever-evolving industry. The company's dedication to innovation and excellence positions it as a driving force in the advancement of metal forming technology, making it a valuable partner for businesses seeking to elevate their manufacturing capabilities.In conclusion, the use of light gauge forming machines has become a game-changer in the manufacturing industry, and the {} is at the forefront of this revolution. With its cutting-edge technology, customized solutions, and commitment to excellence, the company is well-equipped to meet the evolving needs of its clients and lead the way in metal forming technology.

High-Quality Light Gauge Steel Truss Roll Forming Machine for Your Construction Needs

Light Gauge Steel Truss Roll Forming Machine Revolutionizes the Construction IndustryIn recent years, the construction industry has seen a rapid shift towards the use of light gauge steel trusses in construction projects. This shift has been driven by the numerous benefits that light gauge steel trusses offer, including their high strength-to-weight ratio, long spans, and ability to be quickly and accurately installed. To meet the increasing demand for light gauge steel trusses, {Company Name}, a leading manufacturer of roll forming machines, has introduced its state-of-the-art Light Gauge Steel Truss Roll Forming Machine.The Light Gauge Steel Truss Roll Forming Machine is a game-changer in the construction industry, as it allows for the efficient and precise production of light gauge steel trusses. Unlike traditional methods of truss fabrication, which are labor-intensive and time-consuming, this machine is capable of producing trusses at a rapid pace, while maintaining the highest standards of quality and accuracy. This breakthrough technology has significantly reduced the production time of light gauge steel trusses, enabling construction companies to meet tight project deadlines and reduce overall construction costs.Designed with advanced features and cutting-edge technology, the Light Gauge Steel Truss Roll Forming Machine is versatile and adaptable to various truss designs and specifications. This flexibility allows for the customization of trusses to meet the specific requirements of each construction project, while ensuring uniformity and consistency in the manufacturing process. Furthermore, the machine's user-friendly interface and automated controls make it easy to operate, minimizing the need for extensive training and specialized expertise.{Company Name} has a long-standing reputation for delivering high-quality roll forming machines and providing exceptional customer service. With the introduction of the Light Gauge Steel Truss Roll Forming Machine, the company has once again demonstrated its commitment to innovation and excellence in the construction industry. By investing in this cutting-edge technology, construction firms can enhance their production capabilities, streamline their operations, and ultimately, achieve greater efficiency and profitability.In addition to its technological prowess, {Company Name} distinguishes itself through its dedication to customer satisfaction. The company's team of skilled engineers and technical support staff are readily available to provide comprehensive training, ongoing maintenance, and technical assistance to ensure the seamless integration of the Light Gauge Steel Truss Roll Forming Machine into the production process. This level of support is unmatched in the industry, and underscores {Company Name}'s unwavering commitment to its customers' success.The impact of the Light Gauge Steel Truss Roll Forming Machine on the construction industry cannot be overstated. Beyond its ability to enhance productivity and precision in truss fabrication, this innovative machine also upholds sustainability and environmental consciousness in construction practices. By using light gauge steel trusses, construction projects can significantly reduce material waste, promote energy efficiency, and minimize environmental impact, aligning with global efforts to build a more sustainable future.As the construction industry continues to evolve, the demand for light gauge steel trusses will only grow. The introduction of the Light Gauge Steel Truss Roll Forming Machine by {Company Name} has undoubtedly raised the bar for truss manufacturing, setting a new standard for efficiency, quality, and adaptability. This revolutionary technology is not just a machine; it represents a pivotal advancement in the way structures are built, and a testament to the unwavering dedication of {Company Name} to lead the charge towards a more innovative and sustainable construction industry.

Looking for a Quality Horizontal 3D Panel Machine at Factory Price? Check Out Top China Manufacturers Now!

article as follows:A breakthrough technology in the construction industry has taken the market by surprise. The Horizontal Barrel Vault Panel Manufacturing Machine has revolutionized the way buildings are made. With its innovative design and high-quality production, it has become the new standard for construction.The Horizontal Barrel Vault Panel Manufacturing Machine was created by industry experts to address the growing demand for more efficient and reliable building solutions. It produces a unique and durable product that significantly reduces construction time, labor, and cost. It is a game-changer in the construction industry that has been waiting for a new, more efficient way to build.The technology behind the Horizontal Barrel Vault Panel Manufacturing Machine is state-of-the-art, incorporating the latest in manufacturing technologies. It uses horizontal 3D panel technology, which results in panels that are extremely strong, rigid, and lightweight. This means that builders can construct taller, more extensive structures faster and with less cost.The Horizontal Barrel Vault Panel Manufacturing Machine was developed with a focus on energy efficiency, and environmental sustainability. It uses eco-friendly materials that are environmentally friendly, making it a go-to choice for architects and engineers. It has a low carbon footprint, uses less energy, and reduces waste, making it a cost-effective and sustainable solution.The machine’s use of horizontal 3D panels makes it more versatile and adaptable than traditional construction methods. The panels can be used to create long spans, and the machine can produce panels of various shapes and sizes. This flexibility opens up a whole new world of possibilities for architects and builders to create complex and visually appealing structures.The Horizontal Barrel Vault Panel Manufacturing Machine is user-friendly and efficient, with excellent automation features that reduce the likelihood of human error. It has an integrated control system that allows users to input specific measurements, produces the desired panels, and reduces waste. The intuitive interface makes it easy for beginners to operate, and the machine requires minimal maintenance.Several companies in China manufacture and supply the Horizontal Barrel Vault Panel Manufacturing Machine. The cost of the machine varies. However, buyers should expect a higher initial investment in exchange for long-term cost savings and faster construction. The suppliers offer after-sale services such as installation, training, and maintenance, ensuring a seamless switch to the new construction method.The Horizontal Barrel Vault Panel Manufacturing Machine has proved its value in several projects worldwide. It has been used in the construction of commercial buildings, residential homes, and industrial facilities. Its use reduces construction time by up to 50 percent, lowers labor costs, and produces more durable buildings that withstand earthquakes and natural disasters.In conclusion, the Horizontal Barrel Vault Panel Manufacturing Machine is the future of the construction industry. It offers innovative and sustainable solutions that make construction cheaper, faster, and safer. Its benefits are immense, and it’s only a matter of time before it becomes the norm in the construction industry. As the market becomes more competitive and demanding, the Horizontal Barrel Vault Panel Manufacturing Machine offers a significant edge, providing builders with the tools they need to build better, more sustainable, and efficient structures.

High-Quality Steel Frame Roll Forming Machine for Efficient Production

Steel Frame Roll Forming Machine has become an essential equipment in the construction industry, especially for the production of steel frames for buildings. With the increasing demand for sustainable and cost-effective building solutions, the importance of efficient and high-quality roll forming machines cannot be overstated.One company that has been making a significant impact in the roll forming machine industry is {}. They have been leading the way in manufacturing and supplying state-of-the-art roll forming machines for various applications, including steel frame production. Their commitment to innovation and quality has made them a trusted name in the industry.The Steel Frame Roll Forming Machine produced by {} is designed to meet the specific requirements of the construction industry. It is capable of producing high-quality steel frames with precision and efficiency, making it an ideal choice for construction companies looking to streamline their production processes. The machine is equipped with advanced features such as automatic control systems, quick changeover capabilities, and high-speed production, ensuring superior performance and productivity.In addition to its impressive technical capabilities, the Steel Frame Roll Forming Machine from {} is also known for its durability and reliability. The machine is built with high-quality materials and components, ensuring long-term performance and low maintenance costs. This makes it a cost-effective investment for construction companies looking to enhance their production capabilities.Furthermore, {} offers comprehensive support and after-sales services for their Steel Frame Roll Forming Machine, including installation, training, and maintenance. This ensures that their customers can maximize the potential of the machine and achieve the best possible results in their steel frame production.The company's commitment to customer satisfaction and excellence has earned them a strong reputation in the industry. They work closely with their clients to understand their specific requirements and provide tailored solutions that meet and exceed expectations. Their dedication to quality and innovation has set them apart as a leading provider of roll forming machines for the construction industry.As the construction industry continues to grow and evolve, the demand for efficient and reliable steel frame production equipment is expected to rise. Companies like {} are well-positioned to meet this demand with their advanced Steel Frame Roll Forming Machine, innovative technologies, and exceptional customer service.In conclusion, the Steel Frame Roll Forming Machine from {} is a testament to the company's commitment to excellence and innovation. With its advanced features, exceptional performance, and reliable support services, it is no wonder that {} has become a trusted name in the roll forming machine industry. As the construction industry continues to embrace sustainable and cost-effective building solutions, the demand for high-quality steel frame production equipment is expected to grow, and {} is well-prepared to meet this demand with their cutting-edge roll forming machines.

C Purlin Roll Forming Machine: All You Need to Know

C purlin is an essential component of steel structures, widely used in purlins and wall beams of industrial and civil buildings. The C purlin roll forming machine is an advanced technological equipment that can automatically complete the forming process of C purlins according to the given size or drawing profiles.The C purlin roll forming machine is a single roll-forming unit that can produce a variety of C purlins. It is mainly composed of a passive loading frame, leveling device, punching device, cutting device after forming, hydraulic station, computer control system, and more. This machine adopts automatic flying saw punching and is easy to operate. The C purlin products rolled by this machine have good tensile and bending properties, excellent straightness, fully automatic fixed length cutting, automatic punching, high degree of automation, quick and convenient installation, and can be used as the main force structure, such as factory buildings, warehouses, garages, hangars, exhibition halls, theaters, stadiums, market sheds, and more.Cold-formed steel is the primary material used for making lightweight steel structures. It is processed by cold-bending the forming of steel plates or steel strips. C purlin is an excellent component because of its various properties, such as its lightweight and high strength. It is commonly used in industrial buildings because it can provide substantial support and load-bearing capacity without sacrificing the structural integrity of the building.The C purlin roll forming machine has a wide range of applications and is widely used in various fields. It is often used in the construction of roofs, walls, and floors of commercial and residential buildings, as well as in the manufacturing of mechanical equipment. The machine can produce C purlins with different specifications according to the height, such as 100, 120, 140, 160, 180, 200, 220, 250, and 300. The length can be determined according to the engineering design, but generally, the full length is no more than 12 meters to facilitate transportation and installation.The Fully Automatic C Purlin Roll Forming Machine is an advanced and efficient machine that can produce high-quality C purlins. It can improve the productivity and quality of C purlin production, save labor costs, and reduce the production time required for C purlin production. With the growth of the global construction industry, the demand for C purlins is on the rise. Therefore, the C purlin roll forming machine has become a crucial tool for steel fabricators, contractors, and construction companies to meet the growing demand for C purlins.In conclusion, the C purlin roll forming machine is an essential equipment in the steel structure industry. It is an advanced and efficient machine that can improve the quality and productivity of C purlin production. With the growth of the global construction industry, the demand for C purlins is increasing rapidly, which makes the C purlin roll forming machine even more important. The Fully Automatic C Purlin Roll Forming Machine is an excellent investment for steel fabricators, contractors, and construction companies, as it can result in significant cost savings and improve production efficiency.

Cable Tray Pultrusion Machine: Advancements in FRP Technology Shake Up the Industry

Title: Cutting-Edge FRP Cable Tray Pultrusion Machine Revolutionizes the IndustryIntroduction:Pushing the boundaries of innovation, a leading company in the manufacturing sector has recently unveiled its latest breakthrough - an advanced FRP (Fiber Reinforced Plastic) Cable Tray Pultrusion Machine. This cutting-edge technology showcases the company's commitment to providing state-of-the-art machinery solutions for the cable management industry. With a focus on enhanced productivity, efficiency, and durability, this new machine is set to revolutionize the sector in numerous ways.Paragraph 1:The FRP Cable Tray Pultrusion Machine is a result of extensive research and development, combined with the company's years of experience in the field. Pultrusion is a continuous manufacturing process that produces fiber-reinforced polymer composites with superior mechanical properties. By utilizing this innovative approach, the machine is designed to create cable trays with exceptional strength, rigidity, and resistance to environmental factors such as corrosion and fire.Paragraph 2:Implementing this advanced equipment brings forth a multitude of benefits for industries relying on cable management systems. Firstly, the FRP Cable Tray Pultrusion Machine guarantees high productivity due to its continuous and automated manufacturing process. This allows for the production of cable trays at a much faster rate compared to conventional methods, resulting in significant time and cost savings.Paragraph 3:Furthermore, the FRP Cable Tray Pultrusion Machine ensures precise and uniform product dimensions. By controlling variables such as resin content, fiber density, and temperature throughout the manufacturing process, the machine delivers cable trays with consistent quality and reliability. This feature eliminates the need for excess materials or rework, leading to further cost reduction and waste minimization.Paragraph 4:One of the most significant advantages of the FRP Cable Tray Pultrusion Machine is its durability and resistance to external influences. Traditional metal cable trays are prone to rust, corrosion, and degradation over time, affecting their performance and longevity. However, the implementation of FRP materials provides excellent resistance to corrosive substances, moisture, UV radiation, and extreme temperatures. This makes the cable trays suitable for both outdoor and indoor applications, including industrial facilities, power plants, transportation infrastructure, and more.Paragraph 5:Moreover, the FRP Cable Tray Pultrusion Machine promotes environmental sustainability by utilizing lightweight, recyclable, and non-toxic materials. The reduction in weight compared to traditional metal cable trays significantly reduces transportation costs and energy consumption during installation. Additionally, the longevity of FRP cable trays minimizes the need for replacements, preventing unnecessary waste generation.Paragraph 6:The company's commitment to customer satisfaction is reflected in the FRP Cable Tray Pultrusion Machine's user-friendly features. With its intuitive control panel and automated operation, the machine ensures ease of use and minimal training requirements for operators. This not only improves overall efficiency but also reduces human errors during the production process, leading to enhanced product quality.Conclusion:In conclusion, the introduction of the FRP Cable Tray Pultrusion Machine marks a significant milestone in the cable management industry. Through its advanced technology, this innovative machinery brings improved productivity, cost-effectiveness, and durability to cable tray manufacturing. With its ability to withstand diverse environmental conditions and promote sustainability, the FRP Cable Tray Pultrusion Machine is set to redefine the standard for cable management systems across various sectors.

High-Quality Corrugated Metal Sheet Roll Forming Machine for Sale

Corrugated Metal Sheet Roll Forming Machine, a New Milestone in the Field of Metal FormingIn the fast-paced world of metal manufacturing, staying ahead of the competition is crucial. That's why the unveiling of the new Corrugated Metal Sheet Roll Forming Machine by [Company Name] has caused quite a stir in the industry. This state-of-the-art machine promises to revolutionize the way corrugated metal sheets are produced, making the process faster, more efficient, and more cost-effective than ever before.The Corrugated Metal Sheet Roll Forming Machine is the result of years of research and development by the team at [Company Name]. Leveraging their extensive experience in the field of metal forming, the engineers at [Company Name] have come up with a machine that is truly groundbreaking. By incorporating the latest advancements in technology and design, they have created a product that sets a new standard for quality and performance.One of the key features of the Corrugated Metal Sheet Roll Forming Machine is its versatility. It is capable of producing a wide range of corrugated metal sheet profiles, giving manufacturers the flexibility to meet the unique requirements of their customers. Whether it's for roofing, siding, or other applications, this machine can handle the job with ease.But perhaps the most impressive aspect of the Corrugated Metal Sheet Roll Forming Machine is its speed and efficiency. Thanks to its advanced automation and precision engineering, this machine is able to produce corrugated metal sheets at a rate that was previously unheard of. This means that manufacturers can now fulfill large orders in a fraction of the time it would have taken with traditional methods.In addition to its speed, the Corrugated Metal Sheet Roll Forming Machine also boasts an impressive level of accuracy and consistency. This is crucial for ensuring that the finished products meet the highest standards of quality. With this machine, manufacturers can have complete confidence that every corrugated metal sheet produced will be of the utmost precision and uniformity.Of course, an innovative product like the Corrugated Metal Sheet Roll Forming Machine is only as good as the company behind it. In the case of [Company Name], customers can rest assured that they are dealing with a reputable and reliable partner. With a long track record of delivering top-notch metal forming solutions, [Company Name] has earned a strong reputation in the industry.Furthermore, [Company Name] doesn't just stop at selling the Corrugated Metal Sheet Roll Forming Machine. They also offer comprehensive support and service to ensure that their customers get the most out of their investment. From installation and training to ongoing maintenance and technical assistance, [Company Name] is dedicated to helping their clients succeed.With the introduction of the Corrugated Metal Sheet Roll Forming Machine, [Company Name] has truly raised the bar for the entire industry. This machine represents a new milestone in the field of metal forming, offering a level of performance and efficiency that was previously unimaginable. As manufacturers around the world seek to stay competitive in a rapidly evolving market, this innovative product is poised to make a significant impact.In conclusion, the Corrugated Metal Sheet Roll Forming Machine by [Company Name] is a game-changer for the metal forming industry. Its cutting-edge technology, versatility, speed, and precision are testament to the ingenuity and expertise of the team at [Company Name]. With this machine, manufacturers can expect to improve their productivity, reduce costs, and deliver exceptional quality products to their customers. It's clear that the future of metal forming is here, and it's being shaped by the innovative solutions of [Company Name].