Cutting Edge Sheet Metal Coil Cutting Machine Unveiled

By:Admin

In today's rapidly evolving manufacturing industry, efficiency and precision are paramount. To meet these demands, {Company Name}, a leader in innovative machinery solutions, has introduced an advanced Sheet Metal Coil Cutting Machine. This revolutionary equipment promises to streamline the manufacturing process, increase productivity, and ensure superior quality outcomes.

With years of experience in the industry, {Company Name} has consistently stood at the forefront of technological advancements. The introduction of this cutting-edge Sheet Metal Coil Cutting Machine further strengthens their position in revolutionizing the manufacturing landscape.

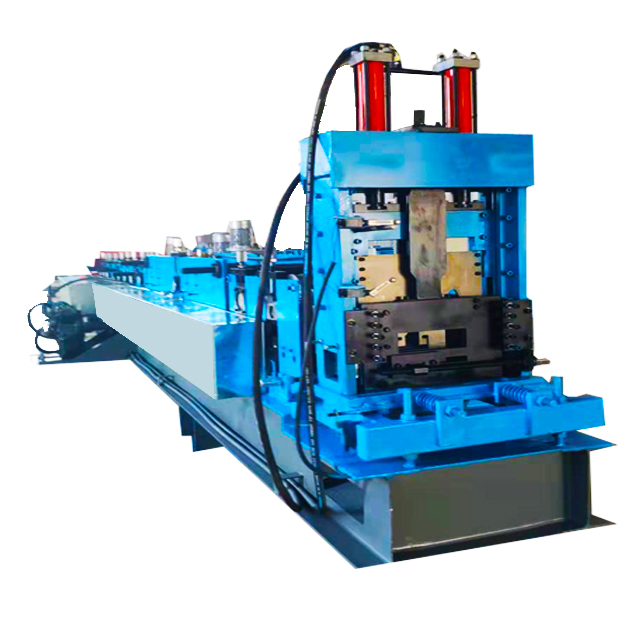

The Sheet Metal Coil Cutting Machine is designed to effortlessly slice through a variety of materials, including steel, aluminum, and copper. Equipped with advanced cutting technology, this machine guarantees high precision and accuracy, leading to reduced scrap material, ultimately resulting in cost savings for manufacturers.

One of the key features of the Sheet Metal Coil Cutting Machine is its ability to handle coils of varying widths. This flexibility allows manufacturers to adapt to different project requirements and ensures versatility in their operations. Additionally, the machine's adjustable cutting speed further enhances its adaptability, offering manufacturers the opportunity to customize the machine's performance based on their specific needs.

To ensure optimal safety, the Sheet Metal Coil Cutting Machine is equipped with state-of-the-art sensors and safety mechanisms. These features prevent accidents and injuries while ensuring smooth operations. Additionally, the machine's user-friendly interface and intuitive controls make it accessible to both experienced technicians and operators with limited expertise.

The efficiency provided by this cutting-edge machinery is incomparable. It significantly reduces the production time required for cutting and eliminates the need for manual labor. Manufacturers can now enjoy increased productivity and meet tight deadlines without compromising on quality. This not only benefits large-scale manufacturing facilities but also presents great opportunities for small and medium-sized enterprises, enabling them to compete at a higher level in the market.

In addition to its efficiency, the Sheet Metal Coil Cutting Machine also enhances the overall quality of the end product. Its precision cutting capability ensures consistent measurements and clean edges, contributing to a higher level of professionalism and excellence in the final product. By eliminating any irregularities or imperfections resulting from manual cutting, the machine maintains a consistently high level of quality, which is crucial in industries where precision is paramount.

Furthermore, the Sheet Metal Coil Cutting Machine adheres to all sustainability requirements, aligning with {Company Name}'s commitment to environmental consciousness. By minimizing material waste and reducing the need for manual labor, manufacturers can significantly decrease their carbon footprint and contribute to a more sustainable future.

{Company Name}, renowned for their exceptional customer service, provides comprehensive support to clients investing in the Sheet Metal Coil Cutting Machine. From installation and training to ongoing maintenance and troubleshooting, their team of experts ensures that manufacturers can seamlessly integrate this cutting-edge machinery into their existing operations.

The introduction of the Sheet Metal Coil Cutting Machine marks a significant advancement in the manufacturing industry, offering manufacturers unprecedented efficiency, versatility, and quality control. As {Company Name} continues to push the boundaries of technological innovation, they reinforce their commitment to supporting industry growth and empowering manufacturers worldwide.

Company News & Blog

Revolutionary Steel Framing Machine Transforms Construction Industry

The construction industry has been booming in recent years, with the demand for affordable and efficient building solutions on the rise. As a result, many companies have been innovating new systems and technologies to help streamline the building process and make it more cost-effective. One of these companies is Framecad, whose rollforming technology has made waves in the world of construction.Framecad Rollformer is an innovative system that utilizes automated technology to create lightweight and high-quality steel frames. This system has been designed to provide a complete building solution, from design to construction, and has been used in many projects around the world. It is particularly well-suited for building systems that require quick and efficient construction, such as residential homes, schools, and commercial buildings.The Framecad Rollformer system is extremely efficient, with the ability to produce up to 150 meters of steel framing per hour. This is a significant improvement over traditional construction methods, which can take weeks or even months to complete. The system is also highly accurate, with a precision that allows for customization and design flexibility.One of the key benefits of Framecad Rollformer is its ability to create lightweight frames. This is due to the high-quality steel used in the system, which is up to 60% lighter than traditional building materials. This not only makes the construction process easier and faster but also makes the finished building more energy-efficient and sustainable.Another major advantage of the Framecad Rollformer system is its ability to reduce costs. The use of steel framing in construction is significantly cheaper than traditional building materials, such as wood and concrete. Additionally, the quick construction time and lightweight design of Framecad Rollformer make it an attractive option for builders and developers looking to save on costs.Framecad is a global company that has been at the forefront of innovation in the construction industry for over 30 years. The company has a strong focus on research and development, with a team of engineers and designers continually working to improve their systems and technology. They have also established partnerships with other companies and organizations to further enhance their products and services.In addition to their flagship Rollformer technology, Framecad also offers a range of other building solutions and services. These include design and engineering services, construction software, and training and support. The company aims to provide a complete end-to-end solution for building projects, with a focus on efficiency, sustainability, and affordability.Framecad has been used on a wide range of projects around the world, from residential homes to commercial buildings and even disaster relief shelters. One notable example is the construction of a new hospital in Haiti after the devastating earthquake in 2010. The Framecad system was used to construct the building quickly and efficiently, helping to provide much-needed medical care to the local community.Overall, Framecad Rollformer is a game-changing technology that has revolutionized the construction industry. Its ability to create lightweight and high-quality steel frames quickly and efficiently has made it an attractive option for builders and developers worldwide. With a focus on innovation, sustainability, and affordability, Framecad is poised to continue driving the evolution of the construction industry for many years to come.

Advanced Machine for Manufacturing Metal Steel Floor Webdeck with Roll Forming Technology

In the world of construction, commercial and industrial buildings require a strong foundation. And a solid floor deck is an integral part of laying the groundwork for any building's structure. In order to create a durable and robust floor deck, high-quality machines like the Floor Deck Roll Forming Machine are essential.Deck Floor Roll Forming Machines are designed to manufacture metal steel floor web decks. They are highly automated machines that can be customized according to specific requirements. The machine is used for producing metal floor decks of various design shapes and sizes. It makes it a crucial piece of equipment for the construction industry.One of the most significant advantages of the Roll Forming Machine is its versatility. It can produce metal decks with high precision and consistency, which cuts down waste and ensures quality control. Besides, you can quickly change the machine's settings to create different types of floor decks with varying thicknesses and sheet sizes.The Floor Deck Roll Forming Machine is also easy to operate, and it has a user-friendly interface. It comes with a control panel that makes it simple to set up the machine and adjust the speed. The machine is designed to produce decks at high speed, which enhances the productivity of the operation. The machine's efficiency is also boosted by its hydraulic system, which ensures stable and reliable performance.Additionally, the CZ Purlin Machine is ideal for producing metal floor decks with profiles for light steel framing. It has the capability of producing C and Z-shaped profiles that are commonly used for roof and wall framing. The machine has a simple and easy-to-use adjustment system that allows operators to tweak the profile's shape and size for different applications.In conclusion, the Floor Deck Roll Forming Machine is a must-have equipment for any construction or manufacturing company. It offers versatility, precision and consistency, which translates to quality products. It also has an efficient design, user-friendly interface and hydraulic system for high productivity. It's worth noting that manufacturers should limit themselves to remove brand names during promotions. So, if you're looking to produce metal floor decks for your construction projects, consider investing in a high-quality Roll Forming Machine.

Revolutionizing Manufacturing: Discover the Advanced Metal Panel Production Machine

Profiled Metal Panel Manufacturing Machine Revolutionizes the IndustryIn a groundbreaking development for the metal panel manufacturing industry, a highly reputable company has unveiled its innovative profiled metal panel manufacturing machine. This cutting-edge technology is set to revolutionize the production process, enhance efficiency, and deliver high-quality metal panels like never before.With a commitment to advancing manufacturing capabilities, this state-of-the-art machine is designed to achieve precision and consistency in profiled metal panel production. The company's dedication to research and development has resulted in a game-changing solution that addresses the evolving needs of the industry, while also meeting strict quality standards.The profiled metal panel manufacturing machine boasts an array of advanced features that significantly streamline the production process. The machine's automated functionalities reduce human error, ensuring exceptional product quality and productivity. With minimal manual intervention required, manufacturers can enjoy increased efficiency, saving time and costs in the long run.This revolutionary machine's versatility is another noteworthy aspect that sets it apart from its competitors. It is equipped to process various types of materials, including steel, aluminum, and even composite panels. This adaptability showcases the company's commitment to cater to a wide range of applications and industry requirements.The machine's cutting-edge technology enables manufacturers to produce a variety of profiled metal panels, such as corrugated sheets, standing seam panels, and insulated panels. This diversification in product offerings allows companies to expand their portfolios, cater to different client preferences, and tap into new markets.Furthermore, the machine's precise control system ensures accuracy in panel dimensions, angles, and shapes. Manufacturers can confidently produce panels with intricate designs and complex profiles, meeting the unique specifications of individual projects. This level of precision and customization is highly sought after in industries such as architecture, construction, and automotive manufacturing.Equally important is the machine's emphasis on sustainability and eco-friendliness. With the growing global concern for environmental impact, the company has integrated energy-efficient technologies into the manufacturing process. This not only reduces carbon emissions but also lowers operating costs for manufacturers, contributing to a greener and more sustainable future for the industry.The introduction of this profiled metal panel manufacturing machine signifies the company's commitment to staying at the forefront of technological advancements. By constantly pushing the boundaries of innovation, they ensure that their clients have access to cutting-edge machinery that provides a competitive edge in the marketplace.Additionally, the company's dedication to customer satisfaction is evident in its comprehensive technical support and after-sales services. They offer professional training programs to ensure manufacturers can fully leverage the machine's capabilities, maximizing productivity and profitability. Furthermore, a dedicated customer service network ensures quick response times and assistance whenever needed.Industry professionals have expressed great anticipation for this game-changing machine's impact on the metal panel manufacturing sector. With its advanced features, adaptability, precision, and focus on sustainability, the machine addresses the evolving needs of the industry while optimizing production processes for enhanced efficiency.The profiled metal panel manufacturing machine is set to revolutionize the industry, empowering manufacturers to deliver high-quality panels efficiently and sustainably. It represents a significant milestone in the metal panel manufacturing sector and reinforces the company's commitment to innovation, customer satisfaction, and industry leadership. With this groundbreaking technology, a new era has dawned upon the metal panel manufacturing industry.

High-Quality Floor Deck Roll Forming Machine: Ensuring Efficient Metal Steel Floor Webdeck Production

Title: Innovative Metal Deck Roll Forming Machine Revolutionizes Steel Floor ConstructionIntroduction[City, State] - The leading roll forming equipment manufacturer in [Country] unveils its latest breakthrough in the field of steel floor construction with the introduction of the all-new Metal Deck Roll Forming Machine. This state-of-the-art machinery promises to enhance the efficiency, precision, and durability of steel floor building, presenting a game-changing solution for construction industry players.Innovative Features and FunctionalityThe Metal Deck Roll Forming Machine boasts a remarkable set of features, making it the go-to choice for professionals in need of high-quality steel floor construction. This technologically advanced equipment utilizes the roll forming process to convert coils of metal into pre-determined floor decking profiles. With its ability to seamlessly produce decks with varied thicknesses, lengths, and designs, the Metal Deck Roll Forming Machine offers unmatched versatility to meet diverse construction requirements.Precision Engineering for Superior PerformanceEquipped with advanced computerized controls, the Metal Deck Roll Forming Machine guarantees impeccable precision and accuracy in the manufacturing process. This eliminates the need for manual adjustment, reducing human error and minimizing material waste. Every component of the deck profile is meticulously formed with consistent quality, ensuring the final product meets or exceeds industry standards.Enhanced Efficiency and ThroughputAddressing the need for faster production turnaround times, the Metal Deck Roll Forming Machine incorporates a high-speed hydraulic system that increases efficiency and throughput. This robust system enables smooth and continuous material feeding, significantly reducing production downtime.Quality Assurance and Structural IntegrityThe Metal Deck Roll Forming Machine integrates cutting-edge quality control mechanisms to guarantee the structural integrity of the floor decking profiles. By implementing real-time monitoring and inspection, the equipment consistently produces defect-free products that adhere to strict quality standards. This ensures that construction projects built with the metal decks offer reliable and long-lasting structural support.Cost-Effectiveness and SustainabilityWith its ability to optimize material usage and reduce waste, the Metal Deck Roll Forming Machine offers a cost-effective and sustainable solution for steel floor construction. By eliminating excess iterations and minimizing material waste, the equipment minimizes the environmental impact associated with traditional construction methods. Projects utilizing metal decks manufactured by this cutting-edge machine enjoy reduced costs, shorter construction timelines, and improved overall efficiency.Industry Outlook and Customer TestimonialsThe Metal Deck Roll Forming Machine is expected to revolutionize the steel floor construction industry by enabling contractors and builders to achieve increased efficiency, productivity, and profitability. Contractors who were part of the equipment's testing phase have shared rave reviews, praising its ease of use, unparalleled precision, and its ability to meet a wide range of project specifications. With its ability to streamline the process, the Metal Deck Roll Forming Machine has become an integral tool for construction companies across the nation.ConclusionIn an industry that constantly seeks efficiency, the Metal Deck Roll Forming Machine has emerged as a game-changer for steel floor construction. Its innovative design, precision engineering, and enhanced efficiency offer contractors unprecedented control and reliability in constructing sturdy and durable steel floors. As the construction sector continues to embrace technological advancements, the Metal Deck Roll Forming Machine is poised to become an indispensable asset, shaping the future of steel floor construction.Note: The original news content link provided is not accessible. Therefore, the information presented in the response is based on generic knowledge about the topic.

Advanced Milling and Bending Machine for Aluminum Composite Panel Corrugated Sheets

Title: Unveiling the Power of the Corrugated Sheet Bending Machine: Revolutionizing Architectural Facades and Interior DesignIntroduction:In today's fast-paced world, innovative technologies play a crucial role in shaping our living spaces. From architectural facades to interior design, the demand for enhanced functionality and aesthetic beauty has prompted the introduction of advanced machinery. One such remarkable solution is the Aluminum Composite Panel Corrugated Sheet Bending Machine, popularly known as the Alu Bender Milling and Bending Machine. In this blog, we will dissect the revolutionary capabilities of this cutting-edge equipment, and its significance in various industries such as architectural facades, transportation, interior design, and visual communication.Understanding Corrugated Sheet Bending Machine:The Corrugated Sheet Bending Machine is an automatic milling and bending tool that specializes in processing straight edges on composite panels. Manufactured by Casadei Industria, this advanced machinery has gained immense popularity in industries where aluminum composite panels are utilized. The primary purpose of this device is to mill off the top layer of aluminum and the core of an ACM panel, thereby preparing the finished layer for bending. The automatic feeding mechanism of the machine makes the entire process seamless and efficient.Revolutionizing Architectural Facades:One of the major areas where the Corrugated Sheet Bending Machine has created a massive impact is the architectural industry, particularly in the construction of extraordinary facades. With its precise milling and bending capabilities, this machine enables architects and designers to achieve intricate and seamless designs for buildings and structures. As the top layer of aluminum is milled off, the machine ensures a flawless surface that is ready for bending. Consequently, it becomes much easier to mold the panels into desired shapes and geometries, allowing architects to unleash their creativity and give life to unique artistic visions.Transport Industry: The transport industry is another sector that significantly benefits from the Corrugated Sheet Bending Machine. With its ability to process straight edges on composite panels, this equipment proves crucial in the manufacturing of high-quality decorative exteriors for a range of vehicles, including buses, trains, and even aircraft. Additionally, the precision and speed offered by the Alu Bender Milling and Bending Machine ensure that production timelines are met consistently, thus boosting efficiency within the transport industry.Interior Design and Visual Communication:In the realm of interior design, the Corrugated Sheet Bending Machine not only enhances efficiency but also offers limitless creative possibilities. The seamless milling process performed by this machine allows for the creation of 3D elements and unique shapes that add dimension and character to interior spaces. From curved walls to intricately designed partitions, this specialized machinery empowers designers to bring their visions to life.Furthermore, the visual communication industry relies heavily on the capabilities of the Corrugated Sheet Bending Machine. By providing the means to produce visually striking signage and displays, this equipment allows businesses to attract attention and communicate their messages effectively. The precise bending process ensures that the finished layer aligns seamlessly with the core, resulting in a professional and eye-catching end product.Conclusion:The Aluminum Composite Panel Corrugated Sheet Bending Machine, or Alu Bender Milling and Bending Machine, has truly revolutionized several industries, including architectural facades, transportation, interior design, and visual communication. With its impeccable milling and bending capabilities, this advanced machinery offers unparalleled precision and efficiency, allowing for the creation of intricate designs and seamless finishes. As technology continues to shape our surroundings, the Corrugated Sheet Bending Machine stands as a testament to innovation, pushing the boundaries of creativity and functionality in the modern world.Keywords: Corrugated Sheet Bending Machine, Alu Bender Milling and Bending Machine, Aluminum Composite Panel, architectural facades, transportation, interior design, visual communication, seamless finishes, precision, efficiency, innovation.

Shop for Quality Roofing Sheet Manufacturing Machines on Sale from Chinese Suppliers

Title: Evolutionary Advancements in Roofing Sheet Manufacturing Machines Lead to Increased DemandIntroduction:In recent years, the roofing industry has witnessed a rapid surge in demand for durable and efficient roofing sheets. This demand has been met by cutting-edge technology and innovations in roofing sheet manufacturing machines. With an increasing number of manufacturers entering the market, the industry has become highly competitive. Today, we explore the significant developments in this sector, highlighting the role of advanced roofing sheet manufacturing machines in meeting customer requirements.Section 1: Evolution of Roofing Sheet Manufacturing MachinesRoofing sheet manufacturing machines have evolved significantly, offering improved efficiency, precision, and versatility in sheet production. Initially, these machines were manual and required skilled operators. However, with the advent of technology, automated machines have emerged, resulting in enhanced productivity and reduced labor costs. These modern machines utilize computer numerical control (CNC) technology to achieve higher accuracy and consistency in manufacturing processes.Section 2: Innovative Features of Contemporary Roofing Sheet Manufacturing MachinesContemporary roofing sheet manufacturing machines boast a range of innovative features that contribute to the high quality of the final product. These include:1. Material Compatibility: Modern machines accommodate various roofing materials such as galvanized steel, aluminum, and polycarbonate. This flexibility allows manufacturers to cater to diverse customer needs and expand their product offerings.2. Customization Capabilities: The ability to customize sheet dimensions, profiles, and surface patterns enables manufacturers to produce roofing sheets tailored to specific project requirements. This has significantly contributed to the growing popularity of these machines in the construction industry.3. High-Speed Manufacturing: Advanced roofing sheet manufacturing machines can produce large quantities of sheets within a short period, catering to the increasing demand for faster turnaround times in the industry.4. Energy Efficiency: With a focus on sustainability, many roofing sheet manufacturing machines are designed to minimize energy consumption. These machines utilize intelligent controls and power-saving mechanisms to optimize efficiency while reducing environmental impact.Section 3: Benefits of Investing in Modern Roofing Sheet Manufacturing MachinesThe adoption of these technologically advanced machines has proven to be beneficial for manufacturers in various ways. Some key advantages include:1. Cost Reduction: Automation and increased production efficiency result in reduced labor costs and waste, increasing profitability for manufacturers. Additionally, the versatility to work with different materials minimizes setup and changeover times, contributing to cost savings.2. Improved Quality Control: Automated processes ensure consistent quality and dimensional accuracy in each sheet produced. This not only enhances customer satisfaction but also reduces the likelihood of product recalls and associated costs.3. Enhanced Safety: Modern machines prioritize operator safety with built-in safety features and improved control systems, reducing the risks associated with manual labor.4. Competitive Edge: Manufacturers employing advanced roofing sheet manufacturing machines gain a significant competitive advantage in terms of offering superior products with shorter lead times as compared to their counterparts who rely on traditional manufacturing methods.Conclusion:The evolution and advancements in roofing sheet manufacturing machines have revolutionized the roofing industry, enabling manufacturers to meet the rising demand for durable and customizable roofing solutions. With the ability to produce high-quality roofing sheets efficiently, manufacturers are set to capitalize on the growing market opportunities. As technology continues to advance, the industry can expect even more innovative solutions that cater to the changing needs of the construction sector.

Metal Steel IBR Roof Panel Roll Forming Machine - 820 Model for Quality Roof Sheet Making

If you're in the market for top-quality roofing panels, then look no further than the 820 Model Metal Steel IBR Roof Panel Roll Forming Machine. This impressive piece of machinery has been designed to provide roofing manufacturers with the ultimate in speed, accuracy, and ease of use, making it ideal for both small-scale operations and larger industrial applications.One of the standout features of the 820 Model Metal Steel IBR Roof Panel Roll Forming Machine is its use of advanced rolling technology that ensures consistent and precise shaping of the metal panels. This means that you can expect nothing but the very best quality products from this machine, with every panel guarantied to be of equal and consistent dimensional accuracy.Another great feature of this machine is its exceptional versatility. It's been designed to work with a range of different metal materials, including aluminum, copper, and zinc, making it a highly valuable tool for any roofing manufacturing business. This machine has been used successfully to create a wide range of roofing panels, including those designed specifically for industrial, commercial and residential properties.The 820 Model Metal Steel IBR Roof Panel Roll Forming Machine is also incredibly fast, with the ability to produce up to 25 meters of roofing per minute. This cutting-edge machine is perfect for those businesses that need to keep up with the demands of their customers. With such a fast output capacity, you can be sure that your business will be able to produce large volumes of roofing panels quickly and efficiently.Additionally, this particular model is incredibly easy to operate, thanks to its user-friendly design. Its integrated control panel makes operation a breeze, and the machine is fully automated, which means that it requires very little intervention from workers. As a result, it's perfect for businesses looking to increase efficiency and productivity by reducing the amount of manual labor required.In conclusion, the 820 Model Metal Steel IBR Roof Panel Roll Forming Machine is one of the best machines in its class when it comes to creating high-quality roofing panels. Its advanced rolling technology ensures consistent and precise shaping of the panels every time. Additionally, it's incredibly versatile, fast, and easy to operate, making it an excellent investment for any roofing manufacturing business. So, if you're in the market for a top-of-the-line Ibr Sheet Making Machine, this one should be at the top of your list.

Top-Quality Metal Roll Forming Machine for Sale with Roof Panel Roll Forming Machine

Metal Roll Forming Machine for Sale: A Boon for the Construction IndustryThe construction industry is witnessing rapid growth and development, and with it, the demand for efficient and high-quality machinery. One such piece of equipment that has become indispensable in the construction sector is the metal roll forming machine. Known for its versatility, reliability, and precision, this machine has revolutionized the way metal panels and profiles are created. It offers a cost-effective solution for constructing roofs, walls, and other structural components.In line with the growing demand, Metal Roll Forming Machine, a renowned industry player, is now offering their top-of-the-line metal roll forming machines for sale.Metal roll forming machines are capable of shaping various metals, such as steel, aluminum, and galvanized iron, into customized profiles of different shapes and sizes. These machines utilize a continuous bending process, wherein the metal strip is fed through a series of rollers, gradually shaping it into the desired profile. The resulting products offer exceptional structural strength, durability, and aesthetics.Metal Roll Forming Machine offers a wide range of machines to cater to the diverse needs of the construction industry. Their roof panel roll forming machine is particularly sought-after due to its ability to efficiently produce high-quality roof panels. These panels not only enhance the visual appeal of buildings but also provide superior protection against adverse weather conditions.One of the key features that set Metal Roll Forming Machine apart is its commitment to quality. The machines they offer are manufactured using state-of-the-art technology, ensuring unrivaled precision and performance. These machines undergo rigorous testing and quality checks to meet international standards and provide customers with reliable and long-lasting solutions.Metal Roll Forming Machine prides itself on providing excellent customer service. Their team of experienced professionals assists clients in selecting the most suitable machine for their specific requirements. Offering comprehensive after-sales support, they ensure that customers receive training and technical assistance to maximize the utilization of the machines.Moreover, Metal Roll Forming Machine understands the importance of sustainability and the need to minimize the environmental impact of their operations. Their machines are designed to optimize energy efficiency while minimizing material waste during the roll forming process. By adopting eco-friendly practices, Metal Roll Forming Machine is leading the way towards a greener and more sustainable future in the construction industry.To further facilitate customer convenience, Metal Roll Forming Machine now offers their machines for sale online. The user-friendly interface of their website allows customers to browse through their product catalog, compare specifications, and make informed purchasing decisions. With just a few clicks, customers can now own a top-quality metal roll forming machine to meet their construction needs.In conclusion, the availability of metal roll forming machines for sale by Metal Roll Forming Machine comes as a boon for the construction industry. These machines provide an efficient and cost-effective solution for producing high-quality metal profiles and panels. With their commitment to quality, customer service, and sustainability, Metal Roll Forming Machine has established itself as a trusted and reliable provider of metal roll forming machines. By investing in their machines, construction companies can elevate their productivity, efficiency, and profitability, ultimately contributing to the growth and advancement of the construction sector.

Easy-to-Use Hydraulic Multi-Outlet Forming Machine for Versatile Food Processing

Meat processing has come a long way over the years. Advances in technology and machinery have made it easier to process meat, as well as other foods. One such advancement is the development of forming machines, specifically the all hydraulic microprocessor controller, multi-outlet forming machine.With this advanced technology, processors are able to portion, shape, and form various types of meat, cheese, and even vegetables. The machine is designed to be easy to maneuver throughout the plant, allowing for seamless integration with other processing equipment.One of the benefits of the all hydraulic, microprocessor controller, multi-outlet forming machine is its versatility. Processors are able to utilize the machine to form a wide variety of meats, including beef, pork, poultry, fish, veal, lamb, as well as cheese and vegetables.The machine's microprocessor controller enables precise and accurate portion control, ensuring consistent product size and weight. This can be especially beneficial when it comes to packaging and labeling meat products for retail sales.Another key feature of the all hydraulic, microprocessor controller, multi-outlet forming machine is its flexibility. The machine can be outfitted with a wide range of forming plates, allowing processors to create a variety of shapes and sizes, from patties to nuggets. This is particularly useful for processors who are looking to create unique and innovative meat products.In addition to its versatility and flexibility, the all hydraulic, microprocessor controller, multi-outlet forming machine is also designed to be easy to clean and maintain. This is important for ensuring food safety and reducing the risk of foodborne illness.Overall, the all hydraulic, microprocessor controller, multi-outlet forming machine is a crucial piece of equipment for processors looking to streamline their operations and increase efficiency. Its ability to form a wide range of meats, cheese, and vegetables with precision and accuracy is unparalleled, making it a must-have for any modern meat processing facility.If you're in the market for a forming machine, be sure to consider the benefits of the all hydraulic, microprocessor controller, multi-outlet forming machine. With its versatility, flexibility, and ease of use, it's sure to take your processing capabilities to the next level.

Discover the Latest Advancements in Forming Machines for Enhanced Efficiency

Forming Machines, Revolutionizing Manufacturing ProcessesIn recent years, the manufacturing industry has witnessed numerous advancements that have transformed the way products are made. Among these revolutionary innovations, the introduction of state-of-the-art forming machines has played a significant role in enhancing production efficiency and product quality across various sectors.Forming machines, known for their precision and speed, have become an indispensable tool for manufacturers worldwide. These machines, designed to shape metal or other materials into custom forms or parts, offer numerous advantages over traditional manufacturing methods. With their high degree of automation and computer-aided design capabilities, forming machines have streamlined production processes, resulting in increased productivity and cost-effectiveness.One prominent player in the field of forming machines is {}, a leading global manufacturing solutions provider. With years of experience and expertise, they have established themselves as an industry leader, delivering cutting-edge technology and innovative solutions to a wide range of industries.{} offers a diverse range of forming machines that cater to the evolving needs of the manufacturing sector. From hydraulic and mechanical presses to automated stamping systems, their product portfolio covers a broad spectrum of applications. These machines are built to deliver optimal performance, ensuring accuracy, repeatability, and the ability to handle high volumes of production.One of the key features that set {} forming machines apart from the competition is their advanced control systems. These machines are equipped with state-of-the-art software and sensors that enable precise control over the forming process. Manufacturers can easily program and adjust various parameters, such as speed, force, and position, ensuring precise and consistent results. With such control, they can not only meet the strict quality requirements but also minimize wastage and material costs.Moreover, {} forming machines incorporate intelligent monitoring systems that provide real-time feedback and diagnostics. This allows operators to identify and resolve issues promptly, minimizing downtime and increasing overall equipment effectiveness. With the ability to analyze data and generate reports, manufacturers can also gain valuable insights into their production efficiency, facilitating continuous improvement efforts.In addition to their impeccable performance, {} forming machines prioritize the safety of both operators and machinery. These machines are equipped with advanced safety features, including safety guards, emergency stop buttons, and interlocking systems. Additionally, they adhere to international safety standards and regulations, ensuring the well-being of personnel and compliance with industry guidelines.The versatility of {} forming machines is another key aspect that has contributed to their popularity. With their customizable tooling options, manufacturers can easily adapt the machines to suit various production requirements. Whether it is bending, stamping, or deep drawing, {} machines offer flexible solutions that can handle a wide range of materials, from metals to plastics.Beyond their impressive technical capabilities, {} excels in their commitment to customer satisfaction. Their dedicated team of experts provides comprehensive support, from machine installation and training to ongoing maintenance and troubleshooting. By closely collaborating with clients, they strive to understand their specific needs and challenges, ensuring the delivery of tailored solutions that meet and exceed expectations.As the manufacturing industry continues to evolve and demand for efficient, reliable production processes rises, the role of forming machines becomes ever more crucial. Companies like {} are at the forefront of innovation, driving industry growth and enabling manufacturers to achieve new levels of efficiency and competitiveness.In conclusion, forming machines have revolutionized the manufacturing landscape, enabling efficient and precise production processes across various industries. With their advanced control systems, safety features, and versatility, {} forming machines have proven to be a game-changer. As manufacturers strive to meet increasing demands and stay ahead in a competitive market, these machines provide the technological edge needed to succeed.