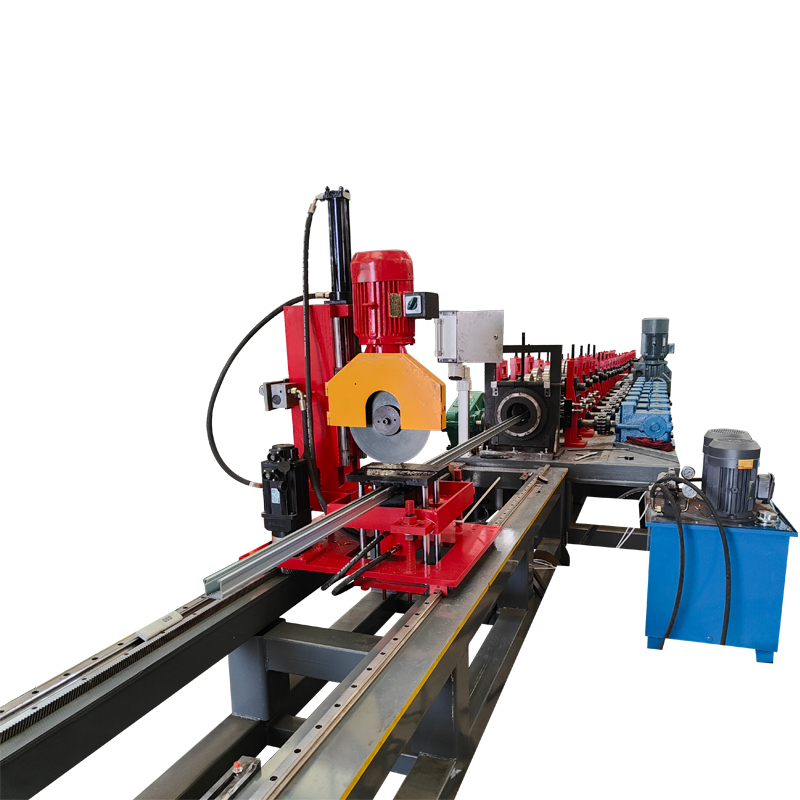

Durable and Efficient Corrugated Roofing Machine for Sale

By:Admin

One of the leading manufacturers of Corrugated Roofing Machines is {}, a renowned company specializing in the production of construction machinery. With a history of excellence spanning over two decades, they have established themselves as a trusted name in the industry.

The Corrugated Roofing Machine manufactured by {} is designed to produce high-quality roofing panels with precision and efficiency. The machine is equipped with advanced technology that allows for seamless operation and consistent output. The company takes pride in the durability and reliability of their machines, ensuring that they can withstand the rigors of continuous use in a demanding construction environment.

The Corrugated Roofing Machine offered by {} is versatile and able to fabricate a variety of roofing panel profiles, catering to the diverse needs of their clients. Whether it's for a large commercial project or a smaller residential application, the machine is capable of delivering consistent results, meeting the highest industry standards.

In addition to the quality of their machinery, {} is also known for their exceptional customer service and technical support. They understand that investing in construction machinery is a significant decision for any business, and they are committed to providing assistance every step of the way. From the initial consultation to after-sales service and maintenance, the company is dedicated to ensuring their clients' satisfaction.

With a global presence, {} has successfully supplied their Corrugated Roofing Machines to clients in various countries, earning a reputation for excellence and reliability. Their commitment to innovation and continuous improvement has allowed them to stay ahead of the competition and meet the evolving needs of the construction industry.

The Corrugated Roofing Machine manufactured by {} is not only efficient but also designed with environmental considerations in mind. The company is committed to sustainability and ensures that their machines are energy-efficient and minimize waste during the manufacturing process. This dedication to environmental responsibility has made them a preferred choice for environmentally conscious construction companies.

As the construction industry continues to expand, the demand for Corrugated Roofing Machines is expected to rise. With a proven track record of delivering superior machinery, {} is well-positioned to meet this growing demand and support the construction of buildings worldwide.

In conclusion, the Corrugated Roofing Machine offered by {} is a testament to the company's commitment to excellence, innovation, and sustainability. With a focus on quality, reliability, and customer satisfaction, they have established themselves as a trusted partner for construction companies seeking high-performance machinery. As the industry evolves, {} remains at the forefront, setting the standard for Corrugated Roofing Machines and solidifying their position as a leader in the construction machinery sector.

Company News & Blog

Unlock the Thrills: Cold Formed Steel Extension for Batman: Arkham Origins Game

Cold formed steel is a popular material used in construction and manufacturing industries. It is versatile, strong, and durable, and can be formed into various shapes and sizes, making it an excellent choice for a wide range of applications.One of the most significant advantages of using cold formed steel is its cost-effectiveness. Compared to other traditional construction materials like wood, concrete, or hot-rolled steel, cold formed steel is more affordable and easier to work with. It requires less labor and processing time, which translates to lower operational costs.The manufacturing process for cold formed steel is also relatively straightforward. It involves the use of a Cold Formed Steel Machine, which utilizes a series of rollers and dies to bend and shape the steel to the desired dimensions. This process yields a high-quality, precise product that is consistent in size and shape.Another benefit of cold formed steel is its high strength-to-weight ratio. Cold formed steel structures are lighter and yet stronger than many other building materials used in construction. This makes it an excellent choice for structures that require high strength but limited weight, such as bridges, aircraft hangars, and industrial buildings.Cold formed steel has also been shown to be highly resistant to environmental factors like wind, rain, and seismic forces. It is highly durable and can withstand extreme weather conditions, making it an ideal choice for outdoor structures like sheds, decks, and fencing.In conclusion, cold formed steel is an excellent choice for those looking for a durable, cost-effective, and versatile material for construction and manufacturing purposes. With its numerous benefits, it is no wonder why it has become a popular material in the industry. So, if you are considering using cold formed steel for your next project, make sure to invest in a reliable Cold Formed Steel Machine and get ready to enjoy the many advantages it has to offer.

High-Quality Automatic Wire Length Cutter for Precision Cutting

[Company Logo]Automatic Wire Length Cutter Streamlines Production Process for Manufacturing Industry[Town, Date] – Manufacturing companies and businesses in need of a reliable wire length cutting solution can now turn to the innovative Automatic Wire Length Cutter, developed and produced by [Company Name]. This state-of-the-art machine is designed to revolutionize the wire cutting process, providing unparalleled precision, efficiency, and speed. With its cutting-edge technology and advanced features, the Automatic Wire Length Cutter is set to become a game-changer for the manufacturing industry.[Company Name] is a leading provider of industrial automation and machinery solutions, specializing in the development and production of cutting-edge equipment for a wide range of industries. With a strong focus on innovation and technological advancement, the company is dedicated to providing its clients with the most advanced and reliable solutions to meet their specific needs.The Automatic Wire Length Cutter is the latest addition to [Company Name]'s extensive lineup of industrial automation products. This cutting-edge machine is designed to streamline the wire cutting process, offering unmatched precision and efficiency. With its advanced technology and innovative features, the Automatic Wire Length Cutter is capable of cutting wires of various materials and thicknesses with unparalleled accuracy and speed.One of the key features of the Automatic Wire Length Cutter is its advanced cutting mechanism, which ensures clean and precise cuts without compromising on speed. This is particularly important for manufacturing companies that require high-quality wire cutting solutions to meet the demands of their production processes. In addition, the machine is equipped with a user-friendly interface and intuitive controls, making it easy to operate and highly efficient in a production environment.The Automatic Wire Length Cutter is also designed with versatility in mind, capable of handling a wide range of wire types and sizes. This makes it an ideal solution for manufacturers working with different materials and specifications. With its ability to accommodate various wire cutting requirements, the machine offers a cost-effective and reliable solution for businesses looking to enhance their production processes.Moreover, the Automatic Wire Length Cutter is engineered to meet the highest safety standards, ensuring the protection of operators and personnel in the production environment. With its robust construction and advanced safety features, the machine provides a secure and reliable cutting solution for manufacturing companies and industrial facilities.In addition to its cutting-edge technology and advanced features, the Automatic Wire Length Cutter is backed by [Company Name]'s commitment to customer satisfaction and support. The company's team of experienced professionals is dedicated to providing comprehensive installation, training, and maintenance services to ensure the seamless integration and operation of the machine in a production environment.As a trusted provider of industrial automation solutions, [Company Name] is proud to introduce the Automatic Wire Length Cutter as the latest addition to its lineup of cutting-edge machinery. With its unparalleled precision, efficiency, and reliability, the machine is set to become an indispensable tool for manufacturing companies and businesses in need of a reliable wire cutting solution.For more information about the Automatic Wire Length Cutter and [Company Name]'s complete range of industrial automation solutions, please visit [company website] or contact [contact information].[Company Name] is a leading provider of industrial automation and machinery solutions, specializing in the development and production of cutting-edge equipment for a wide range of industries. With a strong focus on innovation and technological advancement, the company is dedicated to providing its clients with the most advanced and reliable solutions to meet their specific needs.

Could the Universe be Devoured by a Black Hole-Creating Machine?

The prospect of the universe being swallowed up by a black hole is a nightmare scenario that few ever thought would become a reality. Yet, it appears that ominous possibility may have come a step closer to being realized after a mind-bogglingly complicated machine originally designed to create black holes was switched back on, now with double the power it had before. Scientists around the world are warning that this could have catastrophic consequences for our planet and indeed for the entire universe itself.The machine in question is a particle accelerator, called the Large Hadron Collider (LHC), that is based in Geneva, Switzerland. This giant machine is the most powerful particle accelerator ever built and has already produced a series of groundbreaking discoveries in particle physics. However, the machine is also highly controversial, as some scientists fear that it could create dangerous black holes that could potentially destroy the planet.The machine was first built in 2008 and was designed to recreate the conditions of the Big Bang. By smashing particles together at incredibly high speeds, scientists hoped to learn more about the building blocks of the universe. However, some scientists warned that the machine could create black holes so powerful that they could eventually destroy the planet and the entire universe.Despite these concerns, the machine was switched on for the first time in September 2008 and quickly produced a series of spectacular results. However, after just nine days of running, the machine broke down and had to be shut down for repairs. Over the next few years, the machine was slowly brought back up to speed, but many scientists remained wary of its potential to create black holes.Now, it seems that those concerns may have been justified. According to reports, the machine has been switched back on at double its previous power, and there are fears that it could now create black holes that are much more powerful than before. Scientists warn that if one of these black holes were to escape into the wider universe, it could quickly grow in size and eventually swallow up everything in its path, including stars, planets, and even entire galaxies.The consequences of such an event would be catastrophic. If the universe were destroyed, it would mean the end of everything we know and love. It would also mean the end of life itself, as we know it. This is why so many scientists have warned against the potential dangers of the LHC and other particle accelerators.One of the main problems with the LHC is that it operates at such high energies that it is impossible to fully predict what will happen when particles collide. This means that there is always a risk that the machine could create something that could be catastrophic for the entire universe.Despite these concerns, many scientists have argued that the risks are minimal and that the benefits of the LHC far outweigh any potential dangers. They argue that the machine has already produced a wealth of valuable scientific data and that it could lead to groundbreaking new discoveries in the field of particle physics.However, others remain more cautious. They argue that we simply do not know enough about the workings of the universe to predict what will happen if we continue to push the limits of particle physics. They warn that the LHC could be a ticking time bomb that could destroy everything we hold dear.For now, the LHC continues to operate at double its previous power, and scientists around the world will be watching nervously to see what happens next. If the machine does create a black hole that is powerful enough to destroy the universe, it could be a wake-up call for us all about the dangers of meddling with the fundamental building blocks of the universe.In conclusion, the potential for the LHC to create a black hole that could destroy the entire universe is a prospect that is both awe-inspiring and terrifying in equal measure. While many scientists argue that the benefits of the machine far outweigh any potential risks, others remain more cautious and warn that we simply do not know enough about the universe to predict what will happen if we continue to push the limits of particle physics. The future of the LHC remains uncertain, but one thing is for sure: the consequences of its actions could be catastrophic.

Shop for Quality Roofing Sheet Manufacturing Machines on Sale from Chinese Suppliers

Title: Evolutionary Advancements in Roofing Sheet Manufacturing Machines Lead to Increased DemandIntroduction:In recent years, the roofing industry has witnessed a rapid surge in demand for durable and efficient roofing sheets. This demand has been met by cutting-edge technology and innovations in roofing sheet manufacturing machines. With an increasing number of manufacturers entering the market, the industry has become highly competitive. Today, we explore the significant developments in this sector, highlighting the role of advanced roofing sheet manufacturing machines in meeting customer requirements.Section 1: Evolution of Roofing Sheet Manufacturing MachinesRoofing sheet manufacturing machines have evolved significantly, offering improved efficiency, precision, and versatility in sheet production. Initially, these machines were manual and required skilled operators. However, with the advent of technology, automated machines have emerged, resulting in enhanced productivity and reduced labor costs. These modern machines utilize computer numerical control (CNC) technology to achieve higher accuracy and consistency in manufacturing processes.Section 2: Innovative Features of Contemporary Roofing Sheet Manufacturing MachinesContemporary roofing sheet manufacturing machines boast a range of innovative features that contribute to the high quality of the final product. These include:1. Material Compatibility: Modern machines accommodate various roofing materials such as galvanized steel, aluminum, and polycarbonate. This flexibility allows manufacturers to cater to diverse customer needs and expand their product offerings.2. Customization Capabilities: The ability to customize sheet dimensions, profiles, and surface patterns enables manufacturers to produce roofing sheets tailored to specific project requirements. This has significantly contributed to the growing popularity of these machines in the construction industry.3. High-Speed Manufacturing: Advanced roofing sheet manufacturing machines can produce large quantities of sheets within a short period, catering to the increasing demand for faster turnaround times in the industry.4. Energy Efficiency: With a focus on sustainability, many roofing sheet manufacturing machines are designed to minimize energy consumption. These machines utilize intelligent controls and power-saving mechanisms to optimize efficiency while reducing environmental impact.Section 3: Benefits of Investing in Modern Roofing Sheet Manufacturing MachinesThe adoption of these technologically advanced machines has proven to be beneficial for manufacturers in various ways. Some key advantages include:1. Cost Reduction: Automation and increased production efficiency result in reduced labor costs and waste, increasing profitability for manufacturers. Additionally, the versatility to work with different materials minimizes setup and changeover times, contributing to cost savings.2. Improved Quality Control: Automated processes ensure consistent quality and dimensional accuracy in each sheet produced. This not only enhances customer satisfaction but also reduces the likelihood of product recalls and associated costs.3. Enhanced Safety: Modern machines prioritize operator safety with built-in safety features and improved control systems, reducing the risks associated with manual labor.4. Competitive Edge: Manufacturers employing advanced roofing sheet manufacturing machines gain a significant competitive advantage in terms of offering superior products with shorter lead times as compared to their counterparts who rely on traditional manufacturing methods.Conclusion:The evolution and advancements in roofing sheet manufacturing machines have revolutionized the roofing industry, enabling manufacturers to meet the rising demand for durable and customizable roofing solutions. With the ability to produce high-quality roofing sheets efficiently, manufacturers are set to capitalize on the growing market opportunities. As technology continues to advance, the industry can expect even more innovative solutions that cater to the changing needs of the construction sector.

Powerful New Forming Machine Poised to Revolutionize the Manufacturing Industry

Forming Machine Revolutionizes the Manufacturing IndustryInnovation has been the driving force behind the manufacturing industry, continually improving the efficiency and quality of production. A recent breakthrough in machinery has once again redefined what is possible in manufacturing. The forming machine, developed by a leading company in the field, has revolutionized the manufacturing industry.The forming machine is a cutting-edge piece of equipment that is used to shape raw materials into the desired form. The process of forming involves using a series of rollers, moulds and dies to turn flat sheets of metal into complex shapes. It has been widely adopted in the automotive, aerospace and construction industries as it significantly reduces production time and increases the precision of the final product.The innovation of the forming machine is that it can now create complex shapes that were not previously possible, allowing manufacturers to easily produce intricate designs and parts. The machine is also highly versatile as it can process a wide range of materials, including aluminium, steel and copper.The development of the forming machine has had a significant impact on efficiency and profitability in the manufacturing industry. Traditionally, complex shapes could only be produced by using a variety of machines, which made the manufacturing process time-consuming and expensive. The forming machine has streamlined this process, allowing parts to be produced faster and more accurately, whilst also reducing the likelihood of mistakes and errors.The company behind the innovation of the forming machine is a leader in its field, with a track record of delivering high-quality machinery to clients across the world. The company has invested heavily in research and development, resulting in a range of products that have changed the face of manufacturing.Founded in 1989, the company has established a reputation for producing high-quality machinery that is tailored to the specific requirements of each client. The company’s team of engineers work closely with clients to develop machinery that is efficient, reliable and cost-effective.The company has developed a range of innovative solutions for the manufacturing industry, including robotics, laser cutting and stamping machines. The forming machine is the latest addition to the company’s portfolio of products that have revolutionized the manufacturing industry.The company has a global presence, with offices in North and South America, Europe, Asia and Africa. Its products are used by manufacturers across a range of industries, including automotive, aerospace, construction, healthcare and food production.The success of the company has been built on its commitment to quality, innovation and customer satisfaction. The forming machine is the perfect example of this commitment, as it represents a technological breakthrough that has changed the way manufacturers operate.The process of forming has been used in manufacturing for centuries, but it was not until the development of the forming machine that it became a truly revolutionary process. The machine has enabled manufacturers to produce complex parts with ease, reducing the time and cost of production whilst increasing accuracy and precision.In conclusion, the forming machine has redefined what is possible in manufacturing, opening up a new world of possibilities for manufacturers across the world. Its impact has been far-reaching, revolutionizing the way complex parts are produced whilst also increasing efficiency and profitability. It is clear that this innovative piece of machinery will continue to shape the manufacturing industry for years to come.

High Speed Light Steel Keel Roll Forming Machine: Efficient Building Material Solution

, Stud Truss Roll Forming Machine, High Speed Roll Forming Machine, Metal Stud Roll Forming Machine.With the advancement in technology, the construction industry also has advanced equipment and machines to produce high-quality materials. One such essential machine is the stud truss high speed light steel keel roll forming machine. This machine is used to make light keel studs and trusses that are used for constructing the roof and walls of a building. It is known for its efficiency, reliability, and high speed.The light steel keel machine is designed differently based on the model and the customer's specifications. The metal stud roll-forming machine produces rolls of metal that are used as roofing or wall material in places such as factories, warehouses, garages, gymnasiums, and exhibition centers. These products are popular because of their lightweight, high strength, and easy installation.One of the many advantages of using a stud truss high speed light steel keel roll forming machine is its speed. The machine is designed to produce large quantities of metal strips rapidly, therefore, allowing for mass production, this significantly reduces the time taken to construct a building. The machine is also straightforward to operate, reducing the need for large labor forces on construction sites.Another benefit of using the light steel keel machine is the quality of the material produced; the metal strips produced are of a consistent thickness, length, and size, eliminating the possibility of defects that could lead to the loss of material. The machines are also low-maintenance as they are designed to be robust and long-lasting, thus reducing the operators' servicing costs.In conclusion, the stud truss high speed light steel keel roll forming machine is a must-have piece of equipment in the construction industry. It's easy operation, and high-speed production makes it a favorite among operators globally. The machine's accuracy and quality of the material produced make it an indispensable tool in the construction of buildings. For cost-effective construction materials, the light steel keel machine is the way to go. So if you are in the construction industry, it's essential to invest in a high-quality stud truss roll forming machine that will provide the best results.

High-Quality Metal Roofing Sheet Corrugated Tile Roll Forming Machine for Custom Applications" Our Wide Range of Roof Roll Forming Machines and Equipment for Efficient Roofing Solutions Enhance Your Roofing Projects with our Corrugated Tile Roof Roll Forming Machine Advanced Maquina De Hacer Calaminas: Perfectly Designed for Customized Metal Roofing Sheets Discover Our Impressive Line of Roofing Machinery: Curve Roof Machines, Shearing/Bending Machines, Light Keel Roll Formers, and More

: Efficiency, Durability, VersatilityA metal roof is one of the most durable and long-lasting roofing systems on the market today. It is highly resistant to weathering and UV damage, which makes it an excellent choice for homeowners who want to protect their homes from extreme weather conditions. For this reason, the demand for metal roofing systems has risen over the past few years.However, installing a metal roof can be a daunting task, especially for those who have no experience in roofing. The good news is that the Metal Corrugated Roof Roll Forming Machine is designed to make the installation of metal roofing systems easier and more efficient.EfficiencyThe Metal Corrugated Roof Roll Forming Machine is a game-changer when it comes to metal roof installation. It can speed up the installation process by producing custom-made metal roofing sheets quickly and accurately. Additionally, it is designed to process different types of roofing materials, including aluminum, copper, and steel, and can produce a variety of profiles, such as corrugated and trapezoidal.The machine is highly automated, which means that it requires minimal human intervention. This makes it very efficient, which can save contractors time and labor costs.DurabilityThe metal roofing sheets produced by the Metal Corrugated Roof Roll Forming Machine are highly durable. This is because the machine forms the sheets from raw materials, which eliminates the need for prefabricated sheets that are prone to damage during transportation and handling. Additionally, the thickness of the metal sheets can be customized to suit the specific requirements of the roofing project.VersatilityThe Metal Corrugated Roof Roll Forming Machine is a versatile machine that is suitable for different types of roofing projects. It can form metal sheets in different sizes and profiles, which makes it suitable for residential, commercial, and industrial roofing projects.The machine's versatility is further enhanced by the fact that it can form metal sheets with different coatings, such as galvanized, painted, and coated. This means that contractors can choose the best-coated metal roofing sheets that will enhance the project's durability and performance.ConclusionIn conclusion, the Metal Corrugated Roof Roll Forming Machine is a game-changer in the metal roofing industry. It provides efficiency, durability, and versatility, which are essential for any successful roofing project. Its advanced technology ensures that contractors can produce custom-made metal roofing sheets quickly and accurately, making metal roofing installation more efficient and cost-effective. Anyone looking to install a metal roofing system should consider using this machine to ensure a seamless roofing project.

C Purlin Machine With Punching Hole Device: A Complete Guide

C Purlin Machine With Punching Hole Device Revolutionizes Steel ManufacturingIn the ever-evolving world of steel manufacturing, technological advancements continue to provide new and innovative solutions to enhance efficiency and productivity. One such breakthrough comes in the form of the C Purlin Machine with Punching Hole Device, which has been making waves in the industry for its cutting-edge capabilities.The C Purlin Machine with Punching Hole Device, developed and manufactured by a leading company in the steel manufacturing sector, is a game-changer in the production of C-shaped steel purlins. These purlins, which are widely used in the construction of industrial and commercial buildings, play a crucial role in providing structural support and stability.One of the key features that sets this machine apart is its punching hole device, which enables the seamless integration of pre-punched holes in the steel purlins during the manufacturing process. This innovative functionality eliminates the need for secondary processes and significantly reduces production time and costs. Moreover, it ensures precise hole placement, resulting in a high-quality end product that meets the specifications of even the most demanding construction projects.The C Purlin Machine with Punching Hole Device is equipped with advanced technology that allows for seamless operation and precise control. Its user-friendly interface and intuitive design make it easy to operate, while its robust construction ensures durability and longevity, even in the most demanding manufacturing environments.The machine's versatility and flexibility are further enhanced by its adjustable settings, which allow for the production of a wide range of C purlin sizes and hole configurations. This level of adaptability makes it an invaluable asset for steel manufacturing companies, enabling them to meet the diverse needs of their customers with ease and efficiency.The company behind this groundbreaking innovation has established itself as a leader in the steel manufacturing industry, with a proven track record of delivering high-quality, reliable solutions to its customers. With a strong focus on research and development, as well as a commitment to continuous improvement, the company has earned a reputation for excellence and innovation.In addition to its cutting-edge technology, the company is dedicated to providing exceptional customer service and support. Its team of highly skilled technicians and engineers are always on hand to offer assistance and guidance, ensuring that customers can maximize the performance and efficiency of their equipment.Furthermore, the company places a strong emphasis on sustainability and environmental responsibility, incorporating eco-friendly practices and materials into its manufacturing processes. This commitment to sustainability not only reflects the company's values but also resonates with an industry that is increasingly prioritizing green initiatives and eco-conscious solutions.In summary, the C Purlin Machine with Punching Hole Device represents a significant advancement in steel manufacturing, offering a level of precision, efficiency, and versatility that is unparalleled in the industry. Its innovative technology, combined with the expertise and support of the company behind it, positions it as a game-changing solution for steel manufacturing companies looking to stay ahead in a competitive market.As the demand for high-quality steel products continues to grow, this revolutionary machine is set to play a key role in shaping the future of the industry, offering a new standard of excellence in the production of C-shaped steel purlins. With its advanced capabilities and the backing of a reputable company, the C Purlin Machine with Punching Hole Device is poised to make a lasting impact on the world of steel manufacturing.

Steel Sheet Metal Cut To Length Machine: The Latest in Color Technology

Color Steel Sheet Metal Cut To Length Machine Boosts Production EfficiencyIn today's fast-paced and demanding market, efficiency in production processes can often be the difference between success and failure for many businesses. With this in mind, {Company Name} is proud to announce the acquisition of the latest state-of-the-art Color Steel Sheet Metal Cut To Length Machine, a cutting-edge addition to their advanced manufacturing facility.The new Color Steel Sheet Metal Cut To Length Machine is a highly efficient and precise piece of equipment that is designed to streamline the process of cutting steel sheets to specific lengths. This innovative machine is capable of handling a wide range of steel sheets, and its advanced technology ensures clean and accurate cuts every time. With the ability to cut large volumes of steel sheets in a fraction of the time it would take using traditional methods, the Color Steel Sheet Metal Cut To Length Machine is set to revolutionize {Company Name}'s production capabilities.The acquisition of this cutting-edge technology reflects {Company Name}'s commitment to staying ahead of the curve and continuously investing in the latest advancements in manufacturing. By incorporating the Color Steel Sheet Metal Cut To Length Machine into their production operations, {Company Name} aims to significantly enhance their production efficiency and output, ultimately translating into improved product quality and customer satisfaction.Not only does the Color Steel Sheet Metal Cut To Length Machine streamline the production process, but it also offers a level of precision and consistency that is unparalleled. With its advanced cutting mechanisms and integrated quality control systems, the machine ensures that each steel sheet is cut to the exact specifications, leaving no room for error. This level of precision not only increases the overall quality of the products manufactured by {Company Name}, but also minimizes material wastage, leading to cost savings and a more sustainable manufacturing process.Additionally, the Color Steel Sheet Metal Cut To Length Machine is designed to be user-friendly and easily customizable. This means that {Company Name}'s skilled technicians can quickly and efficiently set up the machine to handle various sheet sizes and thicknesses, allowing for seamless transitions between different production runs. The versatility of the machine further enhances {Company Name}'s ability to meet the diverse needs of their clients and adapt to changing market demands with ease.With the installation of the Color Steel Sheet Metal Cut To Length Machine, {Company Name} is poised to significantly increase their production capacity and shorten lead times. By automating and optimizing the cutting process, the company can fulfill orders more efficiently and respond to customer demands in a timelier manner. This increased agility and responsiveness will undoubtedly set {Company Name} apart in the competitive manufacturing landscape, giving them a distinct edge in meeting the evolving needs of their clients.The investment in the Color Steel Sheet Metal Cut To Length Machine aligns with {Company Name}'s overarching goal of delivering top-tier products and services to their customers. By incorporating this cutting-edge technology into their manufacturing operations, the company is not only positioning itself for future growth, but also solidifying its reputation as a reliable and innovative partner in the industry.As {Company Name} continues to push the boundaries of manufacturing excellence, the acquisition of the Color Steel Sheet Metal Cut To Length Machine stands as a testament to their unwavering dedication to continuous improvement and advancement. With this cutting-edge addition to their production facility, {Company Name} is well-positioned to drive productivity, efficiency, and quality to new heights, setting a standard for excellence in the industry.

Quality Light Steel Roll Forming Machine for Sale - Get Your Project Done Right!

In recent years, there has been a growing demand for light steel roll forming machines in the construction industry. These machines are used to produce high-quality, precise and durable light steel frames, which are then used in various construction projects. One company that has been at the forefront of this technology is {}. With their state-of-the-art technology and innovative solutions, they have been providing their customers with top-notch light steel roll forming machines that have been revolutionizing the construction industry.{} has been in the business for over a decade, specializing in the design, manufacturing, and distribution of light steel roll forming machines. They have a team of highly skilled engineers and technicians who are dedicated to developing cutting-edge technology that meets the needs of their clients. Their machines are known for their high efficiency, accuracy, and reliability, making them an ideal choice for construction companies looking to enhance their productivity and quality of work.One of the key features of {}'s light steel roll forming machines is their ability to produce a wide range of steel profiles with different sizes and shapes, meeting the diverse needs of the construction industry. These machines are also equipped with advanced control systems, ensuring precise and consistent production of steel frames. Furthermore, {} offers customized solutions to their clients, tailoring their machines to meet specific requirements and preferences, providing a competitive edge in the market.The company's commitment to innovation and quality has earned them a solid reputation in the industry. They have a strong focus on research and development, continuously striving to improve their machines and develop new technologies to stay ahead of the competition. This dedication to innovation has allowed {} to expand their market reach and serve clients globally, making them a trusted partner for construction companies worldwide.In addition to their cutting-edge technology, {} also prides themselves on their excellent customer service. They believe in building long-term relationships with their clients, providing them with comprehensive support and maintenance services for their machines. This commitment to customer satisfaction has helped them build a loyal customer base, with many clients choosing {} as their preferred supplier for light steel roll forming machines.As the construction industry continues to evolve, the demand for efficient and reliable light steel roll forming machines is expected to grow. With their years of experience and expertise in the field, {} is well-positioned to capitalize on this trend and further solidify their position as a leading provider of light steel roll forming machines.With a focus on quality, innovation, and customer satisfaction, {} is setting new benchmarks in the industry and shaping the future of construction technology. Their dedication to providing top-notch machines and excellent service has made them a trusted partner for construction companies around the world, and they are poised to continue leading the way in the light steel roll forming machine industry.