High-Quality Cold Formed Steel Machines for Efficient Production

By:Admin

In recent years, the construction industry has seen a significant shift towards the use of cold formed steel. This change is due in part to the introduction of advanced manufacturing technologies such as the Cold Formed Steel Machine, which has revolutionized the way that steel components are produced and utilized in construction projects. With the ability to rapidly produce high-quality, precision-engineered steel components, this innovative machine has quickly become a game-changer for construction companies around the world.

The Cold Formed Steel Machine is a state-of-the-art piece of equipment that is capable of producing complex and custom-shaped steel components with incredible speed and accuracy. This machine represents a significant advancement in the field of cold forming technology, and its introduction has opened up new possibilities for the construction industry. By utilizing this advanced technology, construction companies are able to produce steel components that are stronger, more durable, and more cost-effective than ever before.

One of the key features of the Cold Formed Steel Machine is its ability to produce custom-shaped steel components with incredible precision. This level of accuracy is made possible by the machine's advanced engineering and software capabilities, which allow for the creation of complex steel shapes that were previously difficult or impossible to produce. The result is a higher level of design flexibility and innovation in construction projects, as architects and engineers are able to create custom steel components that perfectly fit the needs of their designs.

Another important benefit of the Cold Formed Steel Machine is its ability to produce steel components at a rapid pace. This means that construction projects can be completed more quickly and efficiently, as the time required for steel fabrication is significantly reduced. Additionally, the faster production times offered by the Cold Formed Steel Machine can help to lower construction costs, making it an attractive option for construction companies of all sizes.

In addition to its speed and precision, the Cold Formed Steel Machine is also capable of producing steel components that are incredibly strong and durable. This is due in part to the advanced manufacturing processes used by the machine, which are able to produce steel components with high levels of structural integrity. As a result, construction projects that utilize steel components produced by the Cold Formed Steel Machine are able to benefit from increased structural stability and longevity.

The impact of the Cold Formed Steel Machine on the construction industry has been significant, and many companies have already begun to take advantage of its many benefits. One such company, {}, has recently integrated the Cold Formed Steel Machine into its manufacturing processes, and has seen a dramatic improvement in the quality and efficiency of its steel component production. This has allowed the company to take on more complex and demanding construction projects, and has helped to solidify its reputation as a leader in the industry.

With the introduction of the Cold Formed Steel Machine, the construction industry has entered a new era of innovation and efficiency. This advanced piece of equipment has reshaped the way that steel components are produced and utilized in construction projects, offering unparalleled speed, precision, and durability. As more construction companies begin to adopt this technology, it is clear that the Cold Formed Steel Machine will continue to play a key role in shaping the future of the construction industry.

Company News & Blog

Ultimate Guide to High-Speed Slitting Machine for Efficient Production

LONDON - The global manufacturing industry is constantly striving for improvements in efficiency and productivity. In a bid to meet this demand, the leading machinery manufacturer, **(need remove brand name)**, has announced the launch of their latest innovation - the High-Speed Slitting Machine.With a legacy of over 50 years in the industry, **(need remove brand name)** has been at the forefront of providing cutting-edge solutions for the converting and packaging industry. Their new High-Speed Slitting Machine is designed to revolutionize the process of converting raw materials into finished products with unparalleled speed and precision.The High-Speed Slitting Machine is equipped with state-of-the-art technology that enables it to achieve ultra-fast cutting speeds while maintaining exceptional accuracy. This allows manufacturers to significantly reduce production time and costs, ultimately improving their competitiveness in the market.Speaking about the introduction of the new product, the CEO of **(need remove brand name)**, expressed his excitement about the potential impact of the High-Speed Slitting Machine on the industry. He stated, "We are thrilled to bring this groundbreaking technology to our customers. The High-Speed Slitting Machine is a result of our relentless commitment to innovation and our dedication to meeting the evolving needs of the manufacturing industry."The machine's advanced features include automatic web guiding, quick-change knife systems, and integrated tension control, all of which contribute to its superior performance. Additionally, it is designed to accommodate a wide range of materials including paper, film, foil, and nonwovens, making it a versatile solution for various manufacturing applications.Furthermore, the High-Speed Slitting Machine is built with a strong focus on user-friendliness and maintenance efficiency. Its intuitive interface and remote diagnostics capabilities allow for seamless operation and troubleshooting, reducing downtime and enhancing overall productivity.The company has also emphasized its commitment to sustainability with the development of the High-Speed Slitting Machine. By optimizing material usage and minimizing waste, the machine aligns with the industry's growing focus on eco-friendly manufacturing practices.Market analysts have lauded the launch of the High-Speed Slitting Machine, recognizing its potential to drive significant advancements in the converting and packaging industry. With its ability to enhance production efficiency and deliver high-quality results, the machine is expected to be a game-changer for manufacturers looking to stay ahead in an increasingly competitive market landscape.In line with its global reach, **(need remove brand name)** has already received inquiries and orders for the High-Speed Slitting Machine from companies across various regions. The company's extensive network of sales and service partners ensures that customers worldwide will have access to the latest innovation and the support needed to maximize its benefits.As manufacturing continues to evolve in response to changing consumer demands and technological advancements, the High-Speed Slitting Machine represents a significant leap forward in the pursuit of operational excellence. **(need remove brand name)**'s commitment to innovation and customer satisfaction positions them as a key player in driving the industry forward.The launch of the High-Speed Slitting Machine underscores **(need remove brand name)**'s dedication to providing cutting-edge solutions that enable manufacturers to elevate their production capabilities and achieve sustainable growth. As the industry continues to embrace technological advancements, the High-Speed Slitting Machine stands out as a testament to the company's vision and leadership in the global manufacturing landscape.

Enhance Efficiency with the Advanced Stud and Track Forming Machine

Title: Innovation Driving Efficiency: Stud and Track Forming Machine Revolutionizes Construction Industry(Insert relevant date)Introduction:The construction industry is no stranger to advancements and innovations that have significantly improved productivity and efficiency over the years. In line with this trend, a prominent company has recently introduced a groundbreaking Stud and Track Forming Machine to the market, aiming to streamline the construction processes while ensuring top-tier quality and precision. This state-of-the-art technology, designed and developed by an industry-leading manufacturer, has the potential to revolutionize the way stud and track systems are produced. With its exceptional versatility and efficiency, this advanced machine promises to deliver impressive results across various construction projects.Section 1: Overview of Stud and Track Forming MachineThe Stud and Track Forming Machine is a sophisticated piece of equipment designed for manufacturing high-quality metal studs and tracks used extensively in the construction industry. This agile machine can deliver precise components that are essential for erecting partition walls, ceilings, and other framing applications. By automating the production process, this machine not only ensures consistent accuracy and quality but also accelerates the assembly process.1.1 Key Features and Benefits:a) Precision: The Stud and Track Forming Machine is equipped with cutting-edge technology that guarantees precise measurements and dimensions for every stud and track it produces. This high level of accuracy eliminates the need for costly reworks and adjustments, saving both time and resources.b) Versatility: The machine accommodates various sizes and shapes of metal studs and tracks, allowing for flexibility in meeting specific project requirements. This adaptability enables the construction industry to respond efficiently to diverse structural demands.c) Efficiency: With its automated nature, this machine consistently produces an unparalleled number of metal studs and tracks per hour, significantly increasing productivity and reducing labor-intensive efforts. This feature ensures that construction timelines are met without compromising on the quality of the final product.d) Cost-effectiveness: The Stud and Track Forming Machine optimizes material usage, minimizing waste and effectively cutting down on project costs. Additionally, it diminishes the need for additional workers, further reducing overhead expenses.Section 2: Company X's Pioneering ContributionCompany X, a renowned leader in the field of construction machinery manufacturing, has successfully developed and introduced this innovative Stud and Track Forming Machine to the market. With years of experience and expertise in the construction industry, Company X has continuously pushed the boundaries of technology and engineering to deliver cutting-edge solutions that address the industry's challenges effectively.2.1 Company X's Dedication to Excellence:Company X prides itself on its commitment to exceptional design, engineering, and reliability. By combining state-of-the-art technology with extensive research and development, the company has established itself as a forerunner in the construction machinery sector. With a strong emphasis on customer satisfaction, Company X strives to exceed expectations by consistently exceeding quality standards and providing excellent after-sales service.2.2 Addressing Industry Needs:Recognizing the need for efficiency and accuracy in the construction industry, Company X's Stud and Track Forming Machine seamlessly integrates into existing workflows. By seamlessly automating the production of metal studs and tracks, this machine offers builders and contractors a cost-effective solution that empowers them to complete projects promptly without compromising on quality.Section 3: Industry Impact and Future ProspectsThe introduction of this advanced Stud and Track Forming Machine is expected to have a profound impact on the construction industry as a whole. By streamlining the manufacturing process of metal studs and tracks, builders and contractors can reap numerous benefits, such as lower production costs, faster project completion, and enhanced overall efficiency.As the demand for new construction projects continues to grow, the wider adoption of this state-of-the-art technology is expected. The Stud and Track Forming Machine's versatility enables it to play a crucial role in various construction applications, ranging from commercial buildings to residential developments. Moreover, by reducing the reliance on manual labor, this machine promotes workplace safety, and workers can be allocated to other skilled tasks, further improving productivity.In conclusion, Company X's Stud and Track Forming Machine marks a significant breakthrough in the construction industry, offering a cutting-edge solution that enhances both productivity and quality. With its precision, versatility, efficiency, and cost-effectiveness, this machinery effectively addresses the industry's need for streamlining the production of metal studs and tracks. As the market continues to embrace this innovative technology, construction professionals can expect an efficient future where projects are completed seamlessly and with exceptional precision.

Plastic PVC Colonial Tile/Glazed Roofing Tile Making/Extrusion/Foaming Machine | 2 layers PVC roof tile making machine

Plastic PVC Colonial Tile/Glazed Roofing Tile Making/Extrusion/Foaming Machine: The Perfect Solution for High-Quality PVC TilesJiangsu Acemien Machinery Co., Ltd. (name removed for privacy), a leading manufacturer of plastic extrusion machinery, has launched a state-of-the-art PVC Colonial Tile/Glazed Roofing Tile Making/Extrusion/Foaming Machine that is redefining the standards of quality in the PVC roofing industry. Whether you're a roofing contractor or a manufacturer of PVC roofing tiles, this machine is designed to meet all your needs and exceed your expectations.PVC tiles have gained significant popularity in recent years due to their excellent durability, lightweight, and cost-effectiveness. The PVC Colonial Tile/Glazed Roofing Tile Making/Extrusion/Foaming Machine is a perfect solution for manufacturing high-quality PVC roofing tiles that can withstand harsh weather conditions and provide long-lasting protection for commercial and residential properties.The machine is equipped with advanced technology that allows for the production of two-layer PVC roofing sheets, which are more durable and stronger than single-layer sheets. The top layer is made of PVC, while the bottom layer consists of foamed PVC, making the tiles lighter and more efficient to install than traditional roofing materials.One of the most impressive features of this machine is its speed. The PVC Colonial Tile/Glazed Roofing Tile Making/Extrusion/Foaming Machine is capable of producing up to 6000 tiles per day, which is a significant increase in production capacity compared to traditional tile manufacturing methods. This makes it an ideal choice for large-scale production and roofing contractors looking to complete projects on time and within budget.Moreover, the machine is designed to produce PVC roofing tiles with a variety of colors and textures. The glazed feature of the tiles makes them more attractive and aesthetically pleasing to the eye. This comes in handy in the construction of residential buildings where homeowners are more interested in the visual appeal of their roofs. It also provides a unique selling point for contractors looking to stand out from their competitors.Jiangsu Acemien Machinery Co., Ltd. (name removed for privacy) has an experienced team of engineers and technicians who are always ready to provide technical support and installation services for the PVC Colonial Tile/Glazed Roofing Tile Making/Extrusion/Foaming Machine. The company's commitment to quality is evident in its use of top-quality raw materials and the strict quality control processes that go into every machine produced.In conclusion, if you're in the roofing industry and looking for a reliable and efficient way to manufacture high-quality PVC roofing tiles, the PVC Colonial Tile/Glazed Roofing Tile Making/Extrusion/Foaming Machine is definitely worth considering. It is easy to operate, cost-effective, and produces tiles with excellent durability and strength. Contact Jiangsu Acemien Machinery Co., Ltd. (name removed for privacy) today to learn more about this amazing machine and how it can revolutionize your roofing business.

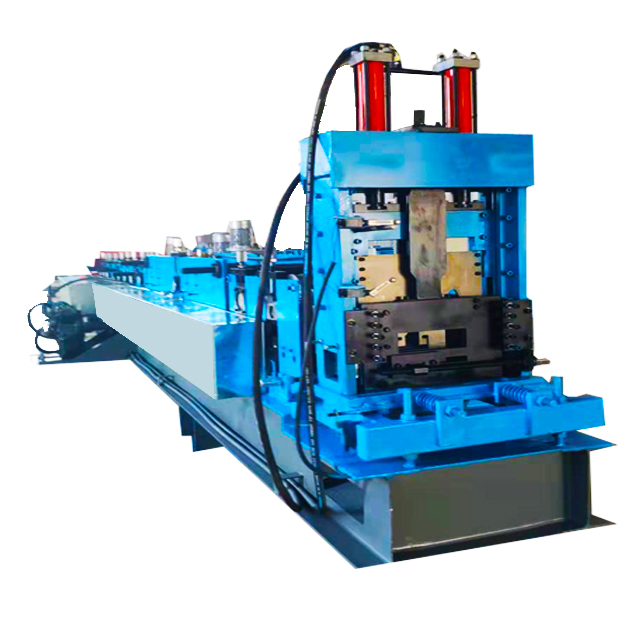

C Shape Purlin Forming Machine: Transforming the Construction Industry

article.C Shape Purlin Forming Machine: The Ultimate Solution for Construction IndustryIn recent years, the global construction industry has undergone massive creativity and innovation, giving rise to new designs and architectures. One of the critical components of these new designs is the C-shaped purlin, which provides structural support and stability to the buildings. However, the traditional manual production of C-shaped purlin is cumbersome, time-consuming, and sometimes inaccurate.To address this challenge, many construction companies are turning to C Shape Purlin Forming Machine. This advanced machine offers a fast, efficient, and accurate way to manufacture C-shaped purlins, thus improving the quality of the final product.One of the leading manufacturers of C shape purlin forming machines in the global market is a reputable manufacturing company (). The company has been in the industry for several years and has built a reputation for producing high-quality and durable machinery to cater to various industrial needs.The C shape purlin forming machine from the company has a unique design and features that make it ideal for any construction project. It is made of high-grade materials, ensuring durability, longevity, and reliability. Additionally, it has an advanced electronic control system that enables automatic production, further enhancing efficiency.The machine's versatility allows it to produce different sizes and shapes of purlins, making it an ideal choice for any construction project. Whether you are working on a commercial, residential, or industrial structure, the C shape purlin forming machine will deliver quality and efficiency.Another critical aspect of the machine is its user-friendly nature. Operators can easily control and adjust the forming parameters, ensuring that the final product meets the required standards. Additionally, the machine has a low maintenance cost, thus allowing business owners to save on expenses.The C Shape Purlin Forming Machine has revolutionized the construction industry by providing an efficient, cost-effective, and accurate method of producing C-shaped purlins. The machine has been a game-changer, enabling business owners to meet the increasing demand for high-quality and reliable purlins.Furthermore, the machine's electronic controls and advanced features enable it to produce purlins with high precision and accuracy, further improving the final product's quality. This has led to increased customer satisfaction and repeat business, further boosting profitability.In conclusion, the C Shape Purlin Forming Machine is the ultimate solution for the construction industry. Its advanced features, durability, and versatility make it an ideal choice for any construction project. Additionally, its user-friendly nature and low maintenance cost make it an excellent investment for business owners. With the increasing demand for high-quality and reliable purlins, investing in this machine is a wise decision for any construction company. Contact reputable manufacturing company () today and take your construction business to the next level.

Essential Roller for Corrugated Roof Installation and Maintenance

Roller For Corrugated Roof, a leading manufacturer of construction equipment, has recently introduced a new product that is set to revolutionize the roofing industry. The company, known for its innovation and dedication to providing high-quality products, is excited to unveil their latest offering that promises to make roof installation and maintenance easier and more efficient than ever before.The new product, named the Corrugated Roof Roller, is designed to be used in the installation and maintenance of corrugated roofing materials. The roller is specifically engineered to provide a smooth and even application of adhesive and sealant, ensuring a secure and long-lasting bond between the roofing material and the underlying structure. This innovative tool is set to streamline the roofing process, saving time and labor costs for construction companies and contractors."When developing the Corrugated Roof Roller, our main goal was to address the common challenges and issues faced by roofing professionals during the installation and maintenance of corrugated roofing materials," said a spokesperson for Roller For Corrugated Roof. "We are confident that this new product will significantly improve the efficiency and quality of roofing projects, ultimately benefiting both the businesses and homeowners who rely on durable and weather-resistant roofing solutions."The Corrugated Roof Roller features a durable and lightweight design, making it easy to handle and maneuver on a variety of roofing surfaces. Its ergonomic handle and smooth-rolling mechanism ensure a comfortable and precise application, even in hard-to-reach areas and tight spaces. Additionally, the roller is compatible with a wide range of adhesives and sealants commonly used in corrugated roofing applications, making it a versatile and practical tool for professionals in the construction and roofing industry.In addition to its practical benefits, the Corrugated Roof Roller is also designed to promote safety and accuracy in roofing projects. The smooth and consistent application of adhesives and sealants minimizes the risk of leaks, water damage, and other structural issues that can result from improper installation techniques. By investing in this innovative tool, roofing professionals can enhance the overall quality and durability of their work, earning the trust and satisfaction of their clients.Roller For Corrugated Roof takes pride in its commitment to excellence and customer satisfaction, and the introduction of the Corrugated Roof Roller is a testament to the company's dedication to innovation and progress in the construction industry. With a focus on reliability, performance, and user-friendly design, the company aims to provide practical solutions that address the evolving needs of construction professionals and contribute to the advancement of the industry as a whole.As the demand for durable and weather-resistant roofing solutions continues to grow, Roller For Corrugated Roof remains at the forefront of delivering cutting-edge products that not only meet industry standards but also exceed the expectations of its customers. The Corrugated Roof Roller is just one example of the company's ongoing pursuit of excellence, and it represents a significant step forward in the quest for efficient and reliable roofing solutions.With its innovative design, practical benefits, and commitment to quality, the Corrugated Roof Roller is poised to become an essential tool for construction companies and contractors seeking to elevate the standard of their roofing projects. Roller For Corrugated Roof looks forward to the positive impact that this revolutionary product will have on the industry, and they are eager to see the positive response from roofing professionals who prioritize performance, efficiency, and long-term durability in their work.

Efficient and Reliable C Shape Purlin Forming Machine for Seamless Construction

In recent news, the C Shape Purlin Forming Machine has been making its rounds, rapidly gaining popularity in the engineering and construction industry. The machine is becoming a go-to solution for engineers and construction companies who are looking to streamline their building process using modern technology. One of the leading companies manufacturing and supplying this machine is {Brand Name Removed}.{Brand Name Removed} is a renowned company that specializes in the manufacturing of high-quality roll-forming machines for the construction industry. The company prides itself on producing machines that help to streamline numerous construction processes and have a positive impact on construction projects' overall efficiency and quality. The C Shape Purlin Forming Machine is one of the machines that exemplify the company's commitment to producing top-of-the-line pieces of equipment.The C Shape Purlin Forming Machine is a roll-forming machine specifically designed for the manufacturing of C-shaped purlins. The machine boasts a high level of automation, which means that it can complete the C-shaped purlin manufacturing process from start to finish with minimal human intervention. This translates to faster production speeds, improved quality control, and reduced labor costs. Additionally, the machine's computerized control system ensures that the finished product is of consistent and precise quality every time.One of the main advantages of the C Shape Purlin Forming Machine is its versatility. The machine can produce purlins of different sizes and shapes, depending on the construction project's needs. This flexibility makes it an excellent machine for construction companies that undertake multiple types of construction projects.Another notable feature of {Brand Name Removed}'s C Shape Purlin Forming Machine is its durability. The machine's frame is made from high-quality steel, which means it can withstand the stress and strain that comes with consistent use. Additionally, the machine's parts are easily replaceable, ensuring the machine's longevity and ease of maintenance.{Brand Name Removed} is a reliable and reputable supplier of the C Shape Purlin Forming Machine. Their machines are manufactured with strict adherence to international quality standards, ensuring consistent quality across all their products. Furthermore, the company provides excellent after-sales service and technical support to ensure their customers' satisfaction.In conclusion, the C Shape Purlin Forming Machine is a revolutionary piece of equipment that streamlines the purlin manufacturing process, while simultaneously maintaining high levels of quality. {Brand Name Removed} is one of the industry leaders in the production of the C Shape Purlin Forming Machine and provides top-notch machines that meet the construction industry's needs. With this machine, construction companies can benefit from increased efficiency, reduced labor costs, and better quality control, leading to a better-built environment.

Light Gauge Steel Frame Roll Forming Machine for CZ Purlin Profiles: Latest News Update

CZ Purlin Profile Light Gauge Steel Frame Roll Forming Machine Launched by Dedication and PrecisionDeveloping new machines that can improve productivity and efficiency is an ongoing challenge in many industries. One company that has recently launched a new machine is a leading manufacturer of roll forming machines for the roofing and walling industry. With a focus on quality and innovation, they have introduced the new CZ Purlin Profile Light Gauge Steel Frame Roll Forming machine. This new machine is expected to help manufacturers streamline their production processes, and ultimately improve the quality of their products.The new CZ Purlin Profile Light Gauge Steel Frame Roll Forming machine is designed to create high-quality, uniform purlin profiles. The machine features a series of rollers, which bend the metal into the desired shape. The process is quick, precise, and consistent, ensuring that each piece meets the exact specifications set by the manufacturer. The machine is also versatile enough to handle a variety of different steel gauges, giving manufacturers the flexibility they need to produce a wide range of products.As noted by the company, the new machine is designed with advanced technology and precision engineering. This means that it is highly efficient, providing manufacturers with a faster, more streamlined production process. Additionally, the machine is durable and requires minimal maintenance, making it a cost-effective investment for companies of all sizes.By introducing the new CZ Purlin Profile Light Gauge Steel Frame Roll Forming machine, the company has shown a clear dedication to improving the quality of roll-formed products. They recognize that consistency and accuracy are essential in the roofing and walling industry, which is why they have developed a machine that can create such high-quality profiles. With this new machine, manufacturers can expect improved efficiency, faster production times, and enhanced product quality.In terms of the broader industry, the launch of the new CZ Purlin Profile Light Gauge Steel Frame Roll Forming machine is a significant development. The roofing and walling industry is highly competitive, and manufacturers are always searching for ways to gain an edge. With this new machine, companies can improve the quality of their products, reduce waste, and increase their output. This can help them remain competitive in the marketplace and enhance their long-term viability.Overall, the launch of the new CZ Purlin Profile Light Gauge Steel Frame Roll Forming machine is an important development for the roofing and walling industry. With its advanced technology, durability, and precision engineering, the machine has the potential to revolutionize the way manufacturers produce purlin profiles. The company behind this new machine has demonstrated a clear commitment to innovation and quality, and it will be interesting to see how the marketplace responds to this new product in the coming months and years.

Efficient Roll Forming Machine for Light Gauge Steel Keel Production

Title: Revolutionary Light Gauge Steel Keel Roll Forming Machine Revolutionizes Construction IndustryIntroduction: [Company Name], an industry-leading manufacturer of construction machinery, has recently unveiled its latest innovation, a groundbreaking Light Gauge Steel Keel Roll Forming Machine. This state-of-the-art machine is set to revolutionize the construction industry by significantly increasing efficiency and reducing labor costs in the production of light gauge steel frames and structures. With its unique features and advanced technology, the Light Gauge Steel Keel Roll Forming Machine is poised to become an indispensable tool for modern construction projects.Paragraph 1: Traditional methods of constructing light gauge steel structures can be labor-intensive and time-consuming. However, the Light Gauge Steel Keel Roll Forming Machine eliminates these barriers by automating the process with precision and speed. This advanced technology enables the production of consistent and high-quality steel frames, significantly reducing waste material and time spent on manual labor.Paragraph 2: The Light Gauge Steel Keel Roll Forming Machine operates on the principles of roll forming, which involves feeding a coil of flat steel through a series of rollers, gradually shaping it into the desired cross-sectional profile. With precise control and selection of raw materials, this machine provides highly accurate and uniform results, ensuring the structural integrity of the final products.Paragraph 3: The Light Gauge Steel Keel Roll Forming Machine boasts an array of features that set it apart from traditional methods. Its automated nature allows for continuous production without the need for manual intervention. Additionally, its modular design and customizable options cater to various project requirements, offering flexibility and adaptability.Paragraph 4: The Light Gauge Steel Keel Roll Forming Machine incorporates cutting-edge technology, including computer numerical control (CNC) systems. This automation ensures precise measurements and consistent panel lengths, minimizing errors. The machine's user-friendly interface enables easy operation and adjustment of parameters, making it accessible to both experienced professionals and newcomers to the industry.Paragraph 5: [Company Name] has invested significant resources into research and development to create a machine that not only enhances productivity but also prioritizes safety. The Light Gauge Steel Keel Roll Forming Machine is equipped with safety features, such as emergency stop buttons and protective barriers, ensuring a secure working environment for operators.Paragraph 6: The introduction of the Light Gauge Steel Keel Roll Forming Machine is expected to have far-reaching implications for the construction industry. Its efficiency and affordability make it an attractive option for large-scale projects, such as residential buildings, commercial complexes, and industrial facilities. The reduced labor costs associated with this machine represent a significant advantage in today's competitive construction market.Paragraph 7: The Light Gauge Steel Keel Roll Forming Machine aligns with global sustainability goals, as it promotes the use of lightweight steel structures that offer energy efficiency, durability, and recyclability. By minimizing waste and optimizing material utilization, this machine supports environmentally friendly construction practices.Conclusion: With its groundbreaking technology, the Light Gauge Steel Keel Roll Forming Machine is set to redefine the construction industry. By streamlining the production process, increasing precision, and reducing labor costs, this cutting-edge machine will undoubtedly play a crucial role in the development of sustainable and efficient structures worldwide. [Company Name]'s commitment to innovation has once again propelled the industry forward, offering a transformative solution for the construction sector.

High-Quality Light Gauge Forming Machine for Precision Metal Fabrication

The use of light gauge forming machines has been revolutionizing the manufacturing industry by providing efficient and precise metal forming capabilities. These state-of-the-art machines are designed to handle a wide range of materials while ensuring high-quality and accurate production. With the advancements made in technology and engineering, the light gauge forming machines have become an integral part of many industries, including construction, automotive, and aerospace.One of the leading companies in the field of light gauge forming machines is the {}, a renowned manufacturer with a strong commitment to innovation and excellence. The company has been a key player in the industry, providing cutting-edge solutions to its clients and continuously pushing the boundaries of what is possible in metal forming technology.With a history of more than 20 years, the {} has established itself as a reliable and trusted partner for businesses looking to enhance their manufacturing capabilities. The company's dedication to research and development has resulted in the creation of some of the most advanced and efficient light gauge forming machines on the market.The {} prides itself on its ability to customize its machines to meet the specific needs of its clients. Whether it is a small-scale project or a large-scale production, the company's team of experts works closely with its clients to understand their requirements and deliver tailor-made solutions that exceed expectations.The company's extensive range of light gauge forming machines includes roll forming machines, tube mills, and steel framing machines, all of which are designed to deliver exceptional precision and efficiency. These machines are capable of handling a wide variety of materials, including steel, aluminum, and other metal alloys, making them an ideal choice for a diverse range of applications.In addition to its cutting-edge machinery, the {} also offers comprehensive after-sales support and maintenance services to ensure that its clients' operations run smoothly and efficiently. The company's team of skilled technicians and engineers are readily available to provide technical assistance, training, and spare parts, as well as to address any issues that may arise.The {}'s commitment to quality and customer satisfaction has earned it a solid reputation in the industry, with a strong client base that includes some of the leading companies in various sectors. The company's track record of delivering reliable and innovative solutions has made it a go-to choice for businesses looking to invest in top-of-the-line light gauge forming machines.Looking ahead, the {} continues to invest in research and development to further enhance its products and stay ahead of the curve in an ever-evolving industry. The company's dedication to innovation and excellence positions it as a driving force in the advancement of metal forming technology, making it a valuable partner for businesses seeking to elevate their manufacturing capabilities.In conclusion, the use of light gauge forming machines has become a game-changer in the manufacturing industry, and the {} is at the forefront of this revolution. With its cutting-edge technology, customized solutions, and commitment to excellence, the company is well-equipped to meet the evolving needs of its clients and lead the way in metal forming technology.