High-Quality Corrugated Roof Sheet Machine for Sale - Complete Guide

By:Admin

Based in [company location], {Company Name} has been a leading manufacturer of various industrial machinery for over two decades. The company has gained a strong reputation for its dedication to innovation, quality, and customer satisfaction.

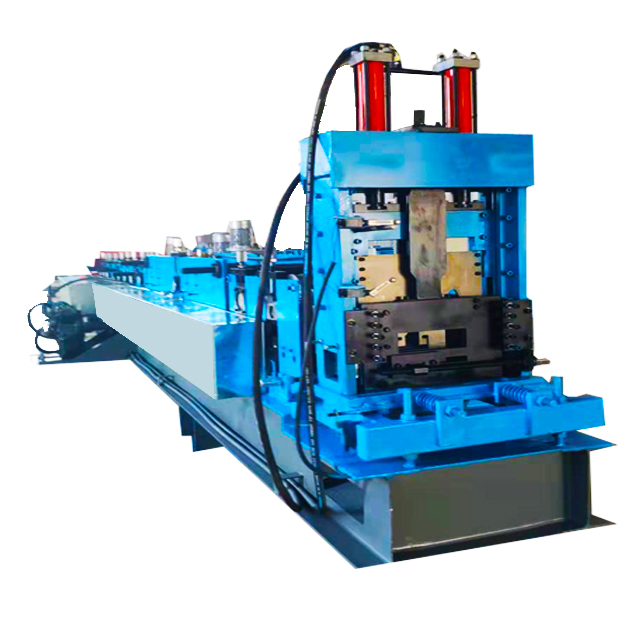

The latest addition to {Company Name}'s impressive line-up of machinery is the cutting-edge Corrugated Roof Sheet Machine. Boasting advanced technology and precision engineering, this machine is designed to meet the growing demand for high-quality corrugated roofing materials. With its ability to produce consistent and reliable results, it is a game-changer for the roofing industry.

One of the key features of the Corrugated Roof Sheet Machine is its efficient production process. The machine is capable of producing a wide range of corrugated roofing sheets at an impressive speed, without compromising on quality. This makes it an ideal choice for businesses looking to enhance their production capabilities and meet tight deadlines.

In addition to its speed and efficiency, the Corrugated Roof Sheet Machine is also known for its versatility. It is designed to accommodate various materials, including galvanized steel, aluminum, and other metals commonly used in corrugated roofing. This flexibility allows businesses to cater to a wide range of customer needs and market demands.

Moreover, the machine's user-friendly interface and intuitive controls make it easy to operate, minimizing the need for extensive training and reducing the risk of errors. This makes it an excellent choice for both experienced operators and those new to the industry.

{Company Name} prides itself on its commitment to sustainability, and the Corrugated Roof Sheet Machine is no exception. It is designed to minimize waste and energy consumption, while maximizing the use of recyclable materials. This not only reduces the environmental impact but also helps businesses save on production costs in the long run.

As a company, {Company Name} has always been dedicated to providing exceptional customer service and support. Their team of expert technicians and engineers are readily available to assist clients with installation, training, and ongoing maintenance to ensure the seamless operation of their machinery.

The company's commitment to excellence has earned it a strong reputation in the industry, with a growing list of satisfied clients from around the world. With a focus on innovation and quality, {Company Name} is poised to continue leading the way in the manufacturing of industrial machinery, including the cutting-edge Corrugated Roof Sheet Machine.

In conclusion, the introduction of the Corrugated Roof Sheet Machine by {Company Name} represents a significant advancement in the roofing industry. With its speed, efficiency, versatility, and sustainability features, this machine is set to revolutionize the production of corrugated roofing materials. As {Company Name} continues to push the boundaries of innovation and quality, it is clear that they will remain a trusted partner for businesses seeking top-of-the-line industrial machinery.

Company News & Blog

Top High-Speed Slitting Machine for Precision Cutting

High-Speed Slitting Machine Revolutionizing the Manufacturing IndustryIn today's fast-paced and technology-driven world, the demand for high-speed and efficient machinery is at an all-time high. With the increasing need for precision and productivity in the manufacturing industry, companies are constantly seeking advanced solutions to meet the market's demands. One such solution that has recently been making waves in the industry is the High-Speed Slitting Machine, developed and manufactured by a leading company in the field of industrial automation.The High-Speed Slitting Machine is a cutting-edge piece of equipment that is designed to revolutionize the way materials such as paper, plastic, and metal are processed and cut. With its cutting-edge technology and high-speed capabilities, this machine has the potential to significantly enhance productivity, reduce costs, and improve overall efficiency in a wide range of manufacturing processes.The company behind this innovative machinery is a renowned leader in the industrial automation sector, with a long-standing reputation for delivering state-of-the-art solutions to meet the evolving needs of the manufacturing industry. With a strong focus on research and development, the company has been at the forefront of technological advancements, consistently pushing the boundaries of what is possible in the world of industrial automation.The High-Speed Slitting Machine is a testament to the company's commitment to innovation and excellence. With its advanced features and high-speed capabilities, it has the potential to transform the way materials are processed in various industries, including packaging, printing, and converting. By providing a reliable and efficient solution for the precise cutting of materials, this machine is poised to significantly enhance the production processes of companies across the globe.One of the key features that sets this High-Speed Slitting Machine apart from other similar equipment is its exceptional speed and accuracy. With its advanced servo motors and cutting-edge control system, the machine can achieve incredibly high speeds while maintaining the highest level of precision. This not only improves the overall efficiency of the manufacturing process but also ensures that the end product meets the strictest quality standards.Furthermore, the High-Speed Slitting Machine is incredibly versatile, capable of handling a wide range of materials and specifications. Whether it's thin plastic films or heavy-duty metal sheets, this machine can be easily customized to meet the specific needs of different industries and applications. This level of flexibility makes it an invaluable asset for companies looking to streamline their production processes and stay ahead of the competition.In addition to its impressive technical capabilities, the High-Speed Slitting Machine is also designed with user-friendliness in mind. The intuitive interface and ergonomic design make it easy for operators to set up and control the machine, minimizing the need for extensive training and maximizing productivity. This, coupled with the machine's low maintenance requirements, makes it a highly cost-effective solution for companies looking to optimize their manufacturing processes.As the manufacturing industry continues to evolve, the demand for advanced machinery that can deliver high-speed, precision, and efficiency will only grow. The High-Speed Slitting Machine, with its cutting-edge technology and versatility, is well-positioned to meet these evolving needs and make a significant impact on the industry. By harnessing the power of this innovative machine, companies can streamline their production processes, reduce costs, and ultimately stay ahead of the competition in an increasingly competitive market.In conclusion, the High-Speed Slitting Machine, developed and manufactured by a leading company in industrial automation, represents a significant leap forward in the manufacturing industry. With its high-speed capabilities, precision cutting, and user-friendly design, this innovative machine has the potential to transform the way materials are processed, setting new standards for productivity and efficiency. As the industry continues to evolve, the High-Speed Slitting Machine is poised to play a pivotal role in shaping the future of manufacturing.

High-Quality Light Gauge Steel Truss Roll Forming Machine for Your Construction Needs

Light Gauge Steel Truss Roll Forming Machine Revolutionizes the Construction IndustryIn recent years, the construction industry has seen a rapid shift towards the use of light gauge steel trusses in construction projects. This shift has been driven by the numerous benefits that light gauge steel trusses offer, including their high strength-to-weight ratio, long spans, and ability to be quickly and accurately installed. To meet the increasing demand for light gauge steel trusses, {Company Name}, a leading manufacturer of roll forming machines, has introduced its state-of-the-art Light Gauge Steel Truss Roll Forming Machine.The Light Gauge Steel Truss Roll Forming Machine is a game-changer in the construction industry, as it allows for the efficient and precise production of light gauge steel trusses. Unlike traditional methods of truss fabrication, which are labor-intensive and time-consuming, this machine is capable of producing trusses at a rapid pace, while maintaining the highest standards of quality and accuracy. This breakthrough technology has significantly reduced the production time of light gauge steel trusses, enabling construction companies to meet tight project deadlines and reduce overall construction costs.Designed with advanced features and cutting-edge technology, the Light Gauge Steel Truss Roll Forming Machine is versatile and adaptable to various truss designs and specifications. This flexibility allows for the customization of trusses to meet the specific requirements of each construction project, while ensuring uniformity and consistency in the manufacturing process. Furthermore, the machine's user-friendly interface and automated controls make it easy to operate, minimizing the need for extensive training and specialized expertise.{Company Name} has a long-standing reputation for delivering high-quality roll forming machines and providing exceptional customer service. With the introduction of the Light Gauge Steel Truss Roll Forming Machine, the company has once again demonstrated its commitment to innovation and excellence in the construction industry. By investing in this cutting-edge technology, construction firms can enhance their production capabilities, streamline their operations, and ultimately, achieve greater efficiency and profitability.In addition to its technological prowess, {Company Name} distinguishes itself through its dedication to customer satisfaction. The company's team of skilled engineers and technical support staff are readily available to provide comprehensive training, ongoing maintenance, and technical assistance to ensure the seamless integration of the Light Gauge Steel Truss Roll Forming Machine into the production process. This level of support is unmatched in the industry, and underscores {Company Name}'s unwavering commitment to its customers' success.The impact of the Light Gauge Steel Truss Roll Forming Machine on the construction industry cannot be overstated. Beyond its ability to enhance productivity and precision in truss fabrication, this innovative machine also upholds sustainability and environmental consciousness in construction practices. By using light gauge steel trusses, construction projects can significantly reduce material waste, promote energy efficiency, and minimize environmental impact, aligning with global efforts to build a more sustainable future.As the construction industry continues to evolve, the demand for light gauge steel trusses will only grow. The introduction of the Light Gauge Steel Truss Roll Forming Machine by {Company Name} has undoubtedly raised the bar for truss manufacturing, setting a new standard for efficiency, quality, and adaptability. This revolutionary technology is not just a machine; it represents a pivotal advancement in the way structures are built, and a testament to the unwavering dedication of {Company Name} to lead the charge towards a more innovative and sustainable construction industry.

Discover the Benefits of Standing Seam Metal Roofing for Your Home

Looking for a roofing solution that will stand the test of time and provide exceptional protection against the elements? Look no further than standing seam metal roofing. This type of roofing has gained immense popularity in recent years due to its outstanding performance and long-lasting durability.At our company, we are proud to be one of the leading standing seam metal roof suppliers in the market. Our standing seam metal roofs are made using the finest quality materials and state-of-the-art manufacturing techniques to ensure that they provide the best possible protection for your home.One of the most significant advantages of standing seam metal roofing is its excellent weather-tightness. These roofs have interlocking seams that are raised above the surface of the roof, providing an impenetrable barrier against rain, snow, and wind. This means that you won't have to worry about leaks or water damage, even during the most extreme weather conditions.Another key benefit of standing seam metal roofing is its fire-resistant properties. Metal is one of the most non-combustible roofing materials available, making it an ideal choice for homes located in fire-prone areas. In addition, standing seam metal roofs are typically coated with a protective layer that further enhances their fire-resistant properties.One of the most attractive features of standing seam metal roofing is its stylish design. These roofs are available in a wide range of colors and finishes, allowing you to choose the perfect look to complement your home's architecture and style. Whether you prefer a sleek and modern look or a more traditional appearance, our standing seam metal roof suppliers can help you find the perfect match for your home.To achieve the best results with your standing seam metal roofing, it's essential to choose a reputable supplier who has the expertise and experience to install your roof properly. Our company has been in the business of providing top-quality roofing solutions for many years, and we pride ourselves on our commitment to customer satisfaction.Our standing seam metal roof suppliers are equipped with all the latest tools and equipment to ensure that your roof is installed with precision and care. We work closely with our customers to understand their specific needs and preferences, and we always strive to exceed their expectations.In conclusion, if you are looking for a roofing solution that will provide outstanding protection, durability, and style for your home, standing seam metal roofing is an excellent option. At our company, we are dedicated to providing you with the best possible products and services to ensure that your roof performs exceptionally for many years to come. Contact our standing seam metal roof suppliers today to learn more about our products and services and get started on your next roofing project!

High Speed Light Steel Keel Roll Forming Machine: Efficient Building Material Solution

, Stud Truss Roll Forming Machine, High Speed Roll Forming Machine, Metal Stud Roll Forming Machine.With the advancement in technology, the construction industry also has advanced equipment and machines to produce high-quality materials. One such essential machine is the stud truss high speed light steel keel roll forming machine. This machine is used to make light keel studs and trusses that are used for constructing the roof and walls of a building. It is known for its efficiency, reliability, and high speed.The light steel keel machine is designed differently based on the model and the customer's specifications. The metal stud roll-forming machine produces rolls of metal that are used as roofing or wall material in places such as factories, warehouses, garages, gymnasiums, and exhibition centers. These products are popular because of their lightweight, high strength, and easy installation.One of the many advantages of using a stud truss high speed light steel keel roll forming machine is its speed. The machine is designed to produce large quantities of metal strips rapidly, therefore, allowing for mass production, this significantly reduces the time taken to construct a building. The machine is also straightforward to operate, reducing the need for large labor forces on construction sites.Another benefit of using the light steel keel machine is the quality of the material produced; the metal strips produced are of a consistent thickness, length, and size, eliminating the possibility of defects that could lead to the loss of material. The machines are also low-maintenance as they are designed to be robust and long-lasting, thus reducing the operators' servicing costs.In conclusion, the stud truss high speed light steel keel roll forming machine is a must-have piece of equipment in the construction industry. It's easy operation, and high-speed production makes it a favorite among operators globally. The machine's accuracy and quality of the material produced make it an indispensable tool in the construction of buildings. For cost-effective construction materials, the light steel keel machine is the way to go. So if you are in the construction industry, it's essential to invest in a high-quality stud truss roll forming machine that will provide the best results.

Efficient Metal Siding Roll Forming Machine Unveiled in Latest News

Metal Siding Roll Forming Machine Revolutionizes the Construction IndustryThe construction industry is constantly evolving, searching for more efficient and cost-effective solutions to meet the demands of the ever-growing market. One such innovation making waves in the industry is the Metal Siding Roll Forming Machine. This machine, developed by an industry-leading manufacturer, is revolutionizing the way metal siding is produced and installed, offering significant benefits to both contractors and homeowners.The Metal Siding Roll Forming Machine is designed to automate the production process of metal siding, eliminating the need for tedious manual work. With its advanced technology and precise engineering, the machine is capable of producing high-quality metal siding panels quickly and efficiently. This not only saves time but also ensures accuracy and consistency in the final product.The machine operates by guiding a continuous strip of metal through a series of rollers and dies, gradually forming it into the desired shape. The metal strip is fed into the machine, and as it passes through each station, it undergoes various bending and shaping processes. The finished panels are then cut to the required length and can be easily collected for packaging or installation.One of the key advantages of the Metal Siding Roll Forming Machine is its versatility. It can produce a wide range of metal siding profiles, allowing contractors to cater to various architectural and design preferences. Whether it's traditional lap siding, vertical panels, or even custom profiles, the machine can accommodate different specifications. This versatility gives contractors the flexibility to meet the unique demands of each project.Additionally, the Metal Siding Roll Forming Machine offers significant cost savings compared to traditional manual methods. By automating the production process, manufacturers can reduce labor costs and minimize material wastage. The consistency and precision provided by the machine also eliminate the need for rework, further reducing expenses. These cost savings can trickle down to homeowners, making metal siding a more affordable and attractive option for them.Furthermore, the Metal Siding Roll Forming Machine can enhance the overall durability and performance of metal siding. The precise forming process ensures that the panels have consistent dimensions, minimizing the risk of gaps or misalignment during installation. This tight fit increases the siding's resistance to wind, moisture, and other environmental factors, making it a durable and long-lasting option for any building.The machine's efficiency and automation also reduce the manpower required for installation. Contractors can complete projects faster, as the panels are ready to be installed as soon as they are produced. This time-saving aspect not only improves project timelines but also reduces disruptions to homeowners and residents nearby.As an industry-leading manufacturer, [Company Name] has been at the forefront of developing and refining the Metal Siding Roll Forming Machine. With years of experience and expertise in the field, the company has continually improved the machine's design, ensuring optimal performance and reliability. Their commitment to innovation has made the Metal Siding Roll Forming Machine a game-changer in the construction industry.In conclusion, the Metal Siding Roll Forming Machine is revolutionizing the construction industry with its efficiency, versatility, and cost-effectiveness. By automating the production process, contractors can save time, reduce costs, and deliver high-quality metal siding panels. With its precise engineering and durability, the machine ensures that homeowners can enjoy a long-lasting and visually appealing product. Thanks to the innovative efforts of companies like [Company Name], the future of metal siding production and installation looks brighter than ever.

Reliable Sheet Metal Fabrication Services: Stainless Steel, Aluminum & Custom Metal

Title: Streamlining Your Business with Steel Sheet Making Machines: Unleashing the Power of Custom Metal FabricationIntroduction:In today's competitive market, businesses across various industries are increasingly turning to custom metal fabrication services to meet their unique manufacturing requirements. Among the many processes involved in metal fabrication, Steel Sheet Making Machines play a critical role in ensuring high-quality stainless steel and aluminum sheet production. This article aims to explore the significance of Steel Sheet Making Machines in the realm of custom metal fabrication and how they contribute to the manufacturing success of businesses across the globe.1. The Essence of Steel Sheet Making Machines:Steel Sheet Making Machines are advanced manufacturing tools designed to accurately shape and cut steel sheets into desired forms. These machines incorporate various components and mechanisms, including hydraulic systems, feeders, rollers, shears, and cutting devices. By utilizing cutting-edge technologies, these machines streamline the metal fabrication process, enhancing efficiency, precision, and overall productivity.2. Precision and Consistency:One significant advantage of Steel Sheet Making Machines is their ability to consistently produce high-quality steel sheets with utmost precision. The intricate mechanisms and cutting-edge technologies integrated into these machines ensure consistent sheet thickness, tight tolerances, smooth edges, and well-defined shapes. Custom metal fabrication companies can deliver products that meet or even exceed the expectations of their clients, reinforcing their reputation in the market.3. Increased Efficiency and Productivity:Steel Sheet Making Machines revolutionize the manufacturing process, significantly reducing production time and increasing efficiency. These machines can perform multiple operations, such as cutting, bending, and shaping, in a single run, eliminating the need for separate machinery or manual labor. The automated processes of these machines enable businesses to produce larger volumes of steel sheets with minimal human intervention, thereby increasing productivity and reducing labor costs.4. Versatility and Customization:Custom metal fabricators often deal with diverse client requirements, necessitating the ability to produce steel sheets in various shapes, sizes, and thicknesses. Steel Sheet Making Machines offer extensive flexibility and adaptability, allowing businesses to cater to these diverse demands. With adjustable settings and versatile tooling options, these machines can fabricate customized steel sheets to match unique specifications, enabling businesses to deliver tailored solutions to their customers.5. Cost and Resource Optimization:By investing in Steel Sheet Making Machines, businesses can optimize their use of resources and reduce costs in the long run. These machines minimize material wastage through precise cutting and shaping capabilities, ensuring minimal scrap and maximizing yield. Additionally, the automated nature of these machines reduces the reliance on manual labor, saving on labor expenses.Conclusion:In conclusion, Steel Sheet Making Machines have emerged as indispensable tools in the realm of custom metal fabrication. Their ability to deliver precision, consistency, efficiency, and customization has revolutionized the manufacturing industry. By investing in these advanced machines, businesses can streamline their metal fabrication processes, cater to diverse client requirements, minimize costs, and stay ahead in the competitive market. Whether it is stainless steel sheet metal fabrication, aluminum sheet metal fabrication, or any other custom metal fabrication needs, the utilization of Steel Sheet Making Machines ensures successful outcomes and drives the growth of businesses across the globe.Keywords: Steel Sheet Making Machine, custom metal fabrication, stainless steel sheet metal fabrication, aluminum sheet metal fabrication, metal fabrication services, precision manufacturing, increased productivity, cost optimization, versatile tooling options.

High-Quality C Purlins for Construction Projects: Everything You Need to Know

C Purlins: The Versatile Solution for Construction ProjectsIn the world of construction, it's important to have sturdy and reliable materials that can withstand the test of time. This is where C Purlins come into play, offering a versatile solution for various construction projects. With their unique shape and durable construction, C Purlins have become a popular choice for builders and contractors across the globe.C Purlins are horizontal beams that are used to provide support for a variety of construction projects. They are designed to be strong and durable, making them an ideal choice for applications such as roofing, wall cladding, and structural support. These versatile beams are made from high-quality steel, ensuring that they can withstand the elements and provide long-lasting support for any construction project.One of the key advantages of C Purlins is their ability to be easily installed and customized to fit the specific needs of a project. Whether it's for a small residential building or a large commercial structure, C Purlins can be cut to size and shaped to meet the unique requirements of any construction project. This flexibility and adaptability make them an attractive choice for builders and contractors who are looking for a reliable and cost-effective solution.In addition to their strength and versatility, C Purlins are also known for their lightweight design, making them easy to handle and transport. This can be a significant advantage for construction teams who need to work quickly and efficiently, as the lightweight nature of C Purlins can help to speed up the installation process and reduce labor costs.In recent years, there has been a growing demand for C Purlins in the construction industry, as builders and contractors recognize the many benefits that these versatile beams have to offer. As a result, more and more companies are now offering C Purlins as part of their product lineup, providing builders and contractors with a variety of options to choose from.One such company is {}, a leading supplier of construction materials and solutions. With a strong focus on quality and innovation, {} has established itself as a trusted provider of C Purlins and other construction products. The company offers a wide range of C Purlins in different sizes and specifications, ensuring that builders and contractors can find the right solution for their specific needs.In addition to providing high-quality C Purlins, {} also offers expert guidance and support to help customers find the best products for their construction projects. The company's team of professionals has extensive experience in the construction industry and is committed to delivering top-notch service to every customer. From initial consultations to final installation, {} is dedicated to ensuring that every project is a success.As the demand for C Purlins continues to grow, it's clear that these versatile beams are here to stay. With their strength, durability, and flexibility, C Purlins have become an essential component of modern construction projects, providing reliable support and structural integrity. And with companies like {} leading the way, builders and contractors can rest assured that they have access to the best C Purlins on the market.In conclusion, C Purlins are a versatile and reliable solution for construction projects of all sizes. With their strength, durability, and flexibility, these beams have become a popular choice for builders and contractors around the world. And with companies like {} offering high-quality C Purlins and expert support, it's easier than ever for construction teams to find the perfect solution for their specific needs. Whether it's for roofing, wall cladding, or structural support, C Purlins are sure to continue making a significant impact on the construction industry for many years to come.

How to Choose the Right Steel Roll Forming Machine for Your Needs?

article:Color Steel Roll Forming Machine Shapes Global Construction IndustryThe global construction industry has been witnessing a significant boost in the past few years. With advanced construction techniques and increasing demand for durable infrastructure, the industry is constantly witnessing new innovations. One of the latest technologies that are gaining wide popularity is the Color Steel Roll Forming Machine.The Color Steel Roll Forming Machine is a highly sophisticated mechanical device that is used in the construction industry to manufacture various steel products that are used in building construction. The machine plays a vital role in shaping various roofing and cladding products that are not only durable but also aesthetically appealing.Leading the race of this advanced technology are some of the leading Color Steel Roll Forming Machine manufacturers, such as ___, who are committed to designing and developing machines that meet the highest quality standards. Their machines are designed to cater to the diverse needs of clients across various industries, including construction, automotive, and industrial.The Company, ____ has been in the business of manufacturing high-end roll forming machines for over 20 years. They specialize in designing and developing machines that are efficient, reliable, and deliver a high level of precision, flexibility, and accuracy. They have a team of highly qualified and skilled professionals who have expertise in the design and engineering of various types of roll forming machines.Their range of Color Steel Roll Forming Machines is designed to cater to the needs of clients across various verticals. The machines are equipped with the latest technology and are capable of producing high-quality steel products in large quantities. Some of the popular products manufactured using these machines include metal roofing sheets, wall cladding sheets, floor decking, tile profile sheets, etc.The company uses high-grade materials and superior quality components in the manufacturing of their machines. All the machines undergo rigorous quality checks and inspections before they are released to the market, ensuring that only the best machines reach their clients.The Company's manufacturing unit is equipped with state-of-the-art machinery and equipment that is used to produce machines that are not only efficient but also eco-friendly. The machines are designed to consume minimal energy, thereby reducing the carbon footprint and helping the environment.Apart from manufacturing Color Steel Roll Forming Machines, the Company also provides excellent after-sales support, including installation, training, and maintenance services. Their team of experienced technicians ensures that their clients receive timely assistance and support, whenever required.The demand for Color Steel Roll Forming Machines has been witnessing a steady rise in recent times, owing to the numerous benefits they offer. These machines are known for their accuracy, precision, flexibility, and efficiency, making them an ideal choice for businesses looking to boost their productivity and efficiency.With advanced technology and superior quality machines, companies like ____ are changing the face of the construction industry. Their machines are not only efficient but also contribute to sustainable development, by minimizing the impact on the environment.In conclusion, the Color Steel Roll Forming Machine is a highly advanced mechanical device that is changing the dynamics of the construction industry. Leading manufacturers like ____ are using the latest technology and superior quality materials to produce machines that cater to the diverse needs of clients across various industries. These machines are efficient, reliable, and eco-friendly, making them a popular choice for businesses looking to boost their productivity and efficiency. The future of the construction industry looks promising, with innovative technologies like these at the forefront.

Discover the Innovation of Colored Metal Trapezoidal Sheet Roll Forming Machine

Colored Metal Trapezoidal Sheet Roll Forming Machine Brings Efficiency and Quality to Roofing IndustryThe roofing industry is set to witness a significant boost in efficiency and quality with the introduction of the advanced Colored Metal Trapezoidal Sheet Roll Forming Machine. This innovative machinery, manufactured by a leading company in the industry, aims to revolutionize the way metal roofing sheets are produced.Metal roofing has gained popularity in recent years due to its durability, energy efficiency, and aesthetic appeal. However, the process of manufacturing metal roofing sheets has often been time-consuming, labor-intensive, and prone to errors. The introduction of the Colored Metal Trapezoidal Sheet Roll Forming Machine seeks to address these challenges, ultimately leading to improved productivity and customer satisfaction.The key feature of this roll forming machine is its ability to efficiently produce trapezoidal-shaped metal sheets. This shape is commonly used in roofing applications due to its excellent water drainage capabilities, structural strength, and ease of installation. The machine's precision engineering ensures accurate dimensions, uniformity, and high-quality finishes, meeting the stringent requirements of the roofing industry.Furthermore, the Colored Metal Trapezoidal Sheet Roll Forming Machine can process various types of colored metal sheets, catering to the diverse needs and preferences of customers. It allows for the production of a wide range of colors and coatings, including but not limited to, galvanized steel, galvalume steel, and pre-painted steel sheets. This versatility empowers roofing contractors and manufacturers to meet the specific demands of different projects, further enhancing their competitiveness in the market.The use of this advanced machinery also significantly reduces manual labor and associated costs. The integration of automated procedures and computerized controls ensures precise and consistent results, eliminating the likelihood of human errors. Moreover, the machine's speed and efficiency enable manufacturers to meet tight project deadlines and handle large-scale orders efficiently.The company behind the Colored Metal Trapezoidal Sheet Roll Forming Machine has established itself as a leader in the metal processing industry. With a strong commitment to research and development, their team of experts continually innovate to provide cutting-edge solutions that deliver superior performance and durability. By collaborating with roofing industry professionals, they ensure that their machines meet the specific requirements of the market, ultimately driving the growth and progress of the entire sector.In addition to manufacturing state-of-the-art machinery, the company also offers comprehensive training programs and technical support to its customers. Recognizing the importance of knowledge transfer and skill development, they equip their clients with the necessary expertise to operate the Colored Metal Trapezoidal Sheet Roll Forming Machine optimally. This commitment to customer service further solidifies the company's reputation as a reliable and trusted provider in the industry.The introduction of the Colored Metal Trapezoidal Sheet Roll Forming Machine marks a significant milestone in the roofing industry. By leveraging the capabilities of this efficient and versatile machinery, contractors and manufacturers can enhance productivity, improve product quality, and boost customer satisfaction. This innovative solution showcases the company's dedication to driving progress and innovation in the metal roofing sector, solidifying their position as a leader in the market.

High-Quality Steel Roof Making Machine for Industrial Applications

Steel Roof Making Machine Revolutionizing the Roofing IndustryThe introduction of the groundbreaking Steel Roof Making Machine by [Company Name] has been heralded as a game-changer in the roofing industry. This innovative machine is set to revolutionize the way steel roofs are manufactured, offering a wide range of benefits for both manufacturers and consumers alike.The Steel Roof Making Machine is a state-of-the-art piece of equipment that is designed to streamline the manufacturing process for steel roofing panels. With its advanced technology and precision engineering, the machine is capable of producing high-quality and durable steel roof panels in a fraction of the time it takes with traditional methods. This not only improves efficiency but also allows for greater production capacity, meeting the growing demand for steel roofs in the construction industry.One of the key features of the Steel Roof Making Machine is its versatility. It is capable of producing a wide variety of steel roof panel profiles, from corrugated to standing seam, with customizable options for panel width and length. This flexibility allows for greater customization and innovation in the design of steel roofs, meeting the unique needs and preferences of different markets and consumers.In addition to its versatility, the Steel Roof Making Machine is also equipped with advanced automation and control systems, minimizing the need for manual labor and reducing the risk of human error. This not only improves the overall quality of the steel roof panels but also enhances workplace safety for employees.Furthermore, the machine is designed for easy maintenance and operation, with user-friendly interfaces and intuitive controls. This ensures that manufacturers can maximize their productivity with minimal downtime and training requirements, ultimately leading to cost savings and improved profitability.The Steel Roof Making Machine also incorporates sustainable and environmentally friendly practices, such as energy-efficient processes and the use of recyclable materials. This aligns with the growing demand for eco-friendly building materials and construction practices, positioning manufacturers as responsible and forward-thinking leaders in the industry.As a result, the Steel Roof Making Machine has been met with a positive reception from manufacturers and consumers alike. The machine has already been adopted by leading steel roofing manufacturers, who have praised its performance, efficiency, and reliability. In turn, consumers can expect to benefit from a wider range of high-quality steel roof options that are cost-effective and sustainable.[Company Name] is at the forefront of this innovation. As a leading manufacturer of machinery and equipment for the construction industry, the company has a strong track record of delivering cutting-edge solutions that improve productivity, quality, and safety. With the introduction of the Steel Roof Making Machine, [Company Name] is further solidifying its position as a trusted partner for manufacturers seeking to stay ahead in a competitive market.Looking ahead, [Company Name] is committed to ongoing research and development, ensuring that the Steel Roof Making Machine continues to set new standards in the roofing industry. The company is also dedicated to providing comprehensive support and service for its customers, helping them maximize the potential of the machine and stay ahead of market demands.In conclusion, the Steel Roof Making Machine by [Company Name] represents a significant advancement in the manufacturing of steel roofs. With its advanced technology, versatility, efficiency, and sustainability, the machine is poised to drive innovation and growth in the roofing industry, benefiting manufacturers, consumers, and the environment as a whole.