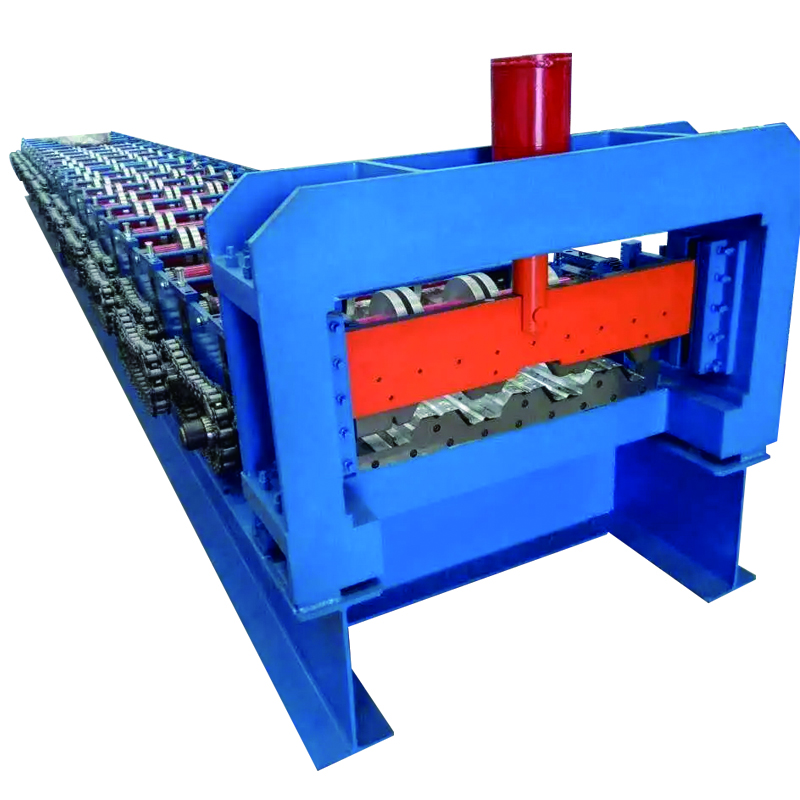

High-Quality Glazed Roofing Sheet Roll Forming Machine for Sale

By:Admin

The Glazed Roofing Sheet Roll Forming Machine is an innovative piece of equipment that allows for the efficient and precise manufacturing of glazed roofing sheets. This machine is a vital tool for businesses involved in the production of roofing materials, as it can greatly increase productivity and ensure high-quality end products. The roll forming process involves feeding a metal sheet through a series of rollers to gradually shape it into the desired profile, making it an ideal solution for producing roofing sheets with a glazed finish.

With a focus on providing advanced solutions for the roofing industry, {Company Name} is a leading manufacturer of roll forming machines. The company is dedicated to delivering cutting-edge technology and reliable equipment to meet the needs of its customers. With years of experience and a commitment to innovation, {Company Name} has established a strong reputation in the market and continues to push the boundaries of roll forming technology.

News Content:

The latest advancement in roll forming technology has arrived with the introduction of the Glazed Roofing Sheet Roll Forming Machine by {Company Name}. This state-of-the-art machine is designed to revolutionize the production of glazed roofing sheets, offering unparalleled precision, efficiency, and quality.

The Glazed Roofing Sheet Roll Forming Machine boasts advanced features that set it apart from traditional roll forming equipment. With a robust frame and a powerful motor, this machine is capable of handling various types of metal sheets with ease. Its precise roller configuration allows for the creation of intricate glazed profiles, ensuring that every roofing sheet meets the highest standards of quality.

One of the key advantages of the Glazed Roofing Sheet Roll Forming Machine is its versatility. Whether producing roofing sheets for residential, commercial, or industrial applications, this machine can accommodate a wide range of requirements. Its adjustable settings and customizable parameters make it suitable for producing roofing sheets of different sizes, profiles, and surface finishes.

Furthermore, the Glazed Roofing Sheet Roll Forming Machine is equipped with advanced control systems that streamline the production process. Operators can easily set and adjust the machine's parameters, monitor its performance, and troubleshoot any issues that may arise. This user-friendly interface allows for efficient operation and reduces the risk of downtime, ensuring continuous productivity.

In addition to its technical capabilities, the Glazed Roofing Sheet Roll Forming Machine is designed with a focus on safety and reliability. With built-in safety features and quality components, this machine offers peace of mind to operators and ensures a long service life with minimal maintenance requirements.

{Company Name} takes great pride in introducing the Glazed Roofing Sheet Roll Forming Machine to the market, as it represents the company's commitment to pushing the boundaries of roll forming technology. With a strong focus on research and development, {Company Name} continues to innovate and improve its product offerings, delivering cutting-edge solutions to meet the evolving needs of the roofing industry.

The launch of the Glazed Roofing Sheet Roll Forming Machine marks a significant milestone for {Company Name}, as it further solidifies the company's position as a leading manufacturer of roll forming equipment. With its unparalleled precision, efficiency, and quality, this machine is set to reshape the production of glazed roofing sheets and empower businesses to thrive in a competitive market.

In conclusion, the Glazed Roofing Sheet Roll Forming Machine by {Company Name} represents a leap forward in roll forming technology. With its advanced capabilities, versatility, and focus on safety and reliability, this machine is poised to revolutionize the production of glazed roofing sheets and set new industry standards. As {Company Name} continues to drive innovation and excellence, it is clear that the future of roll forming technology is in capable hands.

Company News & Blog

High-Quality CNC Aluminum Profile Machine for Precision Machining

Aluminum Profile CNC Machine Revolutionizes Manufacturing at [Company Name][City, State] – The manufacturing industry has been revolutionized by the incorporation of advanced technology, and [Company Name] is at the forefront of this innovation with the use of Aluminum Profile CNC Machine in their production process. This state-of-the-art machine has significantly enhanced the precision, efficiency, and flexibility of their manufacturing operations, allowing them to provide high-quality aluminum profiles for a wide range of applications.[Company Name] is a leading manufacturer of aluminum profiles, serving diverse industries such as construction, transportation, electronics, and renewable energy. With a commitment to excellence, they constantly seek ways to improve their manufacturing processes and deliver superior products to their customers. The incorporation of the Aluminum Profile CNC Machine is a testament to their dedication to staying ahead of the curve in the industry.The Aluminum Profile CNC Machine at [Company Name] is a game-changer for their manufacturing capabilities. This advanced equipment allows for the automated machining of aluminum profiles with unparalleled precision. The machine is equipped with a computer numerical control (CNC) system, which ensures that every cut and shaping is executed with utmost accuracy, resulting in consistent and high-quality finished products.One of the key advantages of the Aluminum Profile CNC Machine is its ability to handle complex designs and intricate patterns with ease. This level of precision and flexibility was previously unattainable with traditional machining methods. The machine is capable of producing a wide variety of aluminum profiles, ranging from simple geometries to highly intricate and customized shapes, meeting the unique requirements of different industries and applications.Additionally, the CNC technology enables [Company Name] to streamline their production process, reducing lead times and minimizing material waste. This efficiency not only benefits the company by optimizing their operations but also translates to cost savings for their customers. With the Aluminum Profile CNC Machine, [Company Name] can fulfill orders more efficiently and with greater accuracy, ultimately providing superior value to their clientele.Furthermore, the machine has bolstered the company's capacity to innovate and develop new product offerings. The precision and speed of the CNC machining process allow [Company Name] to prototype and test new designs more rapidly, enabling them to stay at the forefront of market trends and technological advancements. This means that they can quickly respond to new demands and opportunities in the market, driving growth and competitiveness.In terms of quality control, the Aluminum Profile CNC Machine has raised the bar for [Company Name]. The machine's automated processes and built-in quality assurance features ensure that every aluminum profile meets the highest standards for precision, consistency, and surface finish. This means that [Company Name] can confidently deliver products that exceed the expectations of their customers, establishing a reputation for reliability and excellence in the industry.With the incorporation of the Aluminum Profile CNC Machine, [Company Name] is poised to solidify its position as a leader in the aluminum profile manufacturing industry. By embracing advanced technology and leveraging it to enhance their capabilities, they are well-equipped to meet the evolving needs of their customers and the market at large.About [Company Name][Company Name] is a renowned manufacturer of aluminum profiles, serving a diverse range of industries with high-quality and precision-engineered products. With a commitment to excellence and innovation, they are dedicated to pushing the boundaries of manufacturing technology to deliver superior solutions for their customers. [Company Name] is recognized for its expertise, reliability, and customer-centric approach to business, making them a trusted partner in the industry.

Top-rated Roof Panel Machine: A Game-Changer in Construction Industry

Roof Panel Machine Revolutionizes the Manufacturing IndustryThe manufacturing industry has seen a significant breakthrough with the introduction of the state-of-the-art Roof Panel Machine by a leading company. This innovative machine has redefined the process of manufacturing roof panels, making it faster, more efficient, and cost-effective.The Roof Panel Machine is designed to streamline the production of roof panels, providing manufacturers with a high-quality and reliable solution for their production needs. With advanced technology and precision engineering, this machine has the capability to produce a wide range of roof panels with varying thickness, length, and design specifications. This level of flexibility allows manufacturers to meet the diverse needs of their customers, while maintaining a high standard of quality and consistency.One of the key features of the Roof Panel Machine is its automated operation, which minimizes the need for manual labor and reduces the risk of errors in the production process. This automated system is equipped with intelligent controls and sensors that ensure the accurate and precise fabrication of roof panels, resulting in a higher level of efficiency and productivity. As a result, manufacturers can increase their output and meet tight production deadlines without compromising on the quality of their products.In addition, the Roof Panel Machine is designed for ease of use, with a user-friendly interface and intuitive controls that make it accessible to operators of varying skill levels. This allows manufacturers to train their staff quickly and efficiently, reducing the time and resources required for onboarding new employees. The simplified operation of the machine also minimizes the risk of human error, resulting in a more consistent and reliable production process.Furthermore, the Roof Panel Machine is engineered for durability and longevity, ensuring a reliable and long-lasting solution for manufacturers. With robust construction and high-quality components, this machine is designed to withstand the rigors of continuous use in a manufacturing environment, providing a dependable and low-maintenance option for production facilities.The introduction of the Roof Panel Machine has significantly impacted the manufacturing industry, offering a transformative solution for the production of roof panels. With its advanced technology, automated operation, ease of use, and durability, this machine has redefined the standards of manufacturing, setting new benchmarks for efficiency, productivity, and quality.Company Introduction:The company behind the Roof Panel Machine is a leading innovator in the field of manufacturing technology. With a strong focus on research and development, this company has consistently introduced cutting-edge solutions that address the evolving needs of the industry. The Roof Panel Machine is the latest addition to their portfolio of advanced machinery, and it reflects their commitment to driving innovation and excellence in manufacturing.In addition to their dedication to technological advancement, the company is also known for their comprehensive support and service network. They offer a range of services, including installation, training, maintenance, and technical support, to ensure that their customers can fully maximize the benefits of their machinery. This level of support reinforces the company's dedication to customer satisfaction and their commitment to delivering value beyond the sale of their products.With a strong track record of success and a reputation for delivering superior technology, the company is poised to continue leading the way in the manufacturing industry. The Roof Panel Machine is just one example of their innovative solutions, and it serves as a testament to their vision of shaping the future of manufacturing with cutting-edge technology and unmatched expertise.In conclusion, the Roof Panel Machine has ushered in a new era of manufacturing, offering a game-changing solution for the production of roof panels. With its advanced technology, automated operation, ease of use, and durability, this machine has set a new standard for efficiency, productivity, and quality in the industry. As a testament to the company's commitment to innovation and excellence, the Roof Panel Machine stands as a pioneering achievement that is revolutionizing the manufacturing landscape.

Discover the Advantages of Standing Seam Metal Roofing Panels

Title: The Unrivaled Efficiency of Mechanical-Lock Standing Seam RoofsIntroduction:In the world of roofing, innovations continue to revolutionize the way we protect our structures from environmental elements. One such breakthrough is the mechanical-lock standing seam roof, a fully interlocking system that offers unparalleled structural integrity. This blog explores the remarkable features, benefits, and applications of this superb roofing solution, without mentioning brand names, and highlights the importance of incorporating keywords such as "mechanical lock standing seam roof" to improve its search engine optimization (SEO).1. The Unparalleled Strength of Mechanical-Lock Standing Seam Roofs (100 words)The unique profile of mechanical-lock standing seam metal roofs forms a weather-tight unit, eliminating the need for screws or exposed rivets on the surface. This ingenious design delivers exceptional strength, making it ideal for both residential and commercial applications. The fully interlocking system reinforces each panel, providing extraordinary resistance against harsh weather conditions, including heavy rain, strong winds, and snow.2. Impeccable Aesthetic Appeal: Tapered and Curved Designs (200 words)Mechanical-lock standing seam roofs not only guarantee durability but also enhance the visual appeal of any structure. Traditional metal roofs often compromised aesthetics due to visible fasteners, but this issue is eliminated with this innovative system. The absence of exposed screws or rivets gives the panels a seamless and sleek appearance.Additionally, these standing seam roofs offer flexibility with tapered and curved designs. These options enable architects and homeowners to create unique and aesthetically pleasing roof shapes, adding a touch of elegance and individuality to any building.3. Longevity and Low Maintenance (200 words)When investing in a roofing system, longevity is a crucial aspect to consider. Mechanical-lock standing seam roofs are renowned for their exceptional longevity. The interlocking design and weather-tight unit ensure long-lasting protection against moisture, wind uplift, and even fire.Moreover, these roofs require minimal maintenance, making them a cost-effective choice in the long run. Unlike traditional roofing systems that may require frequent repairs and replacements due to exposed fasteners or deteriorating sealants, mechanical-lock standing seam roofs offer reliable performance year after year with minimal upkeep.4. Energy Efficiency and Eco-Friendliness (150 words)With an increasing focus on sustainable building practices, mechanical-lock standing seam roofs are an eco-friendly option. The interlock design reduces thermal bridging, preventing heat loss or gain through the roof. Enhanced insulation properties efficiently regulate indoor temperatures, leading to reduced energy consumption and lower utility bills.Furthermore, these roofs are often made from recyclable materials, making them an environmentally responsible choice. The durable nature of these roofing systems ensures they will not end up in landfills prematurely, a significant benefit for eco-conscious individuals.Conclusion (50 words)Mechanical-lock standing seam roofs offer a multitude of advantages, from their unmatched strength to exceptional longevity, versatility in design, and eco-friendly attributes. With proper maintenance, this roofing solution can safeguard any structure for decades to come while showcasing a seamless and visually pleasing appearance.Incorporating keywords like "mechanical lock standing seam roof" strategically throughout this blog will enhance its search engine optimization, allowing more readers to discover the incredible benefits of this innovative roofing solution.

Roll Forming Machine for Creating Corrugated Galvanized Steel Roofing

Title: Corrugated Metal Roll Forming Machine: Revolutionizing Modern Roofing SolutionsIntroduction:As the construction industry continues to evolve, it is essential to embrace cutting-edge technologies that enhance efficiency and productivity. One such innovation that has revolutionized the roofing industry is the Corrugated Metal Roll Forming Machine. Specifically designed for producing corrugated galvanized steel, this advanced machine has become indispensable for manufacturers, delivering top-quality metal roofing solutions. In this blog post, we will delve deeper into the benefits and significance of the Corrugated Metal Roll Forming Machine in the modern construction landscape.Exploring the Corrugated Metal Roll Forming Machine:1. Enhanced productivity and efficiency:The Corrugated Metal Roll Forming Machine offers unmatched precision and speed, eliminating wastage and reducing production time. With its automated processes and cutting-edge design, manufacturers can produce more roofing sheets in a shorter span of time, resulting in increased productivity.2. Superior quality products:Equipped with state-of-the-art technology, the Corrugated Metal Roll Forming Machine ensures impeccable finishes and consistent corrugation patterns. This reliability guarantees high-quality roofing solutions that meet and exceed industry standards. The machine's ability to roll galvanized, pre-painted, and galvalume steels into corrugated galvanized steel ensures durability and longevity for the roofs.3. Flexibility in design:Corrugated roofing comes in various shapes, sizes, and profiles. With a versatile Corrugated Metal Roll Forming Machine at their disposal, manufacturers have the freedom to create tailored roofing solutions to cater to diverse customer needs. This adaptability allows for unique designs, providing architects and homeowners with extensive choices for their projects.4. Cost-effective solution:The Corrugated Metal Roll Forming Machine optimizes material usage and minimizes wastage, resulting in cost-effective manufacturing. Its highly efficient processes drastically reduce labor costs and turnaround times, making it an ideal choice for both large-scale production facilities and smaller roofing businesses. The savings accumulated through the use of this machine can be passed on to customers, making metal roofing a more economical option.5. Environmentally friendly:In the era of sustainability, the Corrugated Metal Roll Forming Machine has become a vital player in eco-friendly construction practices. By minimizing the excess material generated during the manufacturing process, this machine contributes to reducing waste and conserving resources. Furthermore, the durability and recyclability of corrugated galvanized steel roofing make it an environmentally conscious choice for builders and homeowners.Keywords and SEO:To maximize the search engine optimization (SEO) of this blog, it is crucial to incorporate relevant keywords ensuring the content aligns with search engine algorithms. By including words such as "corrugated metal roll forming machine," "corrugated metal roofing," "galvanized steel," and "roll forming," we can enhance the visibility of this blog post to the target audience actively searching for information related to metal roofing machinery.Conclusion:The Corrugated Metal Roll Forming Machine has emerged as a game-changer in the roofing industry, providing remarkable benefits such as enhanced productivity, superior quality products, design flexibility, cost-effectiveness, and environmental sustainability. By harnessing the power of this advanced machinery, manufacturers can meet the growing demand for modern, durable, and visually appealing metal roofs. As the construction industry continues to advance, embracing cutting-edge technology like the Corrugated Metal Roll Forming Machine is essential for the success and growth of businesses in the industry.

Reliable Sheet Metal Fabrication Services: Stainless Steel, Aluminum & Custom Metal

Title: Streamlining Your Business with Steel Sheet Making Machines: Unleashing the Power of Custom Metal FabricationIntroduction:In today's competitive market, businesses across various industries are increasingly turning to custom metal fabrication services to meet their unique manufacturing requirements. Among the many processes involved in metal fabrication, Steel Sheet Making Machines play a critical role in ensuring high-quality stainless steel and aluminum sheet production. This article aims to explore the significance of Steel Sheet Making Machines in the realm of custom metal fabrication and how they contribute to the manufacturing success of businesses across the globe.1. The Essence of Steel Sheet Making Machines:Steel Sheet Making Machines are advanced manufacturing tools designed to accurately shape and cut steel sheets into desired forms. These machines incorporate various components and mechanisms, including hydraulic systems, feeders, rollers, shears, and cutting devices. By utilizing cutting-edge technologies, these machines streamline the metal fabrication process, enhancing efficiency, precision, and overall productivity.2. Precision and Consistency:One significant advantage of Steel Sheet Making Machines is their ability to consistently produce high-quality steel sheets with utmost precision. The intricate mechanisms and cutting-edge technologies integrated into these machines ensure consistent sheet thickness, tight tolerances, smooth edges, and well-defined shapes. Custom metal fabrication companies can deliver products that meet or even exceed the expectations of their clients, reinforcing their reputation in the market.3. Increased Efficiency and Productivity:Steel Sheet Making Machines revolutionize the manufacturing process, significantly reducing production time and increasing efficiency. These machines can perform multiple operations, such as cutting, bending, and shaping, in a single run, eliminating the need for separate machinery or manual labor. The automated processes of these machines enable businesses to produce larger volumes of steel sheets with minimal human intervention, thereby increasing productivity and reducing labor costs.4. Versatility and Customization:Custom metal fabricators often deal with diverse client requirements, necessitating the ability to produce steel sheets in various shapes, sizes, and thicknesses. Steel Sheet Making Machines offer extensive flexibility and adaptability, allowing businesses to cater to these diverse demands. With adjustable settings and versatile tooling options, these machines can fabricate customized steel sheets to match unique specifications, enabling businesses to deliver tailored solutions to their customers.5. Cost and Resource Optimization:By investing in Steel Sheet Making Machines, businesses can optimize their use of resources and reduce costs in the long run. These machines minimize material wastage through precise cutting and shaping capabilities, ensuring minimal scrap and maximizing yield. Additionally, the automated nature of these machines reduces the reliance on manual labor, saving on labor expenses.Conclusion:In conclusion, Steel Sheet Making Machines have emerged as indispensable tools in the realm of custom metal fabrication. Their ability to deliver precision, consistency, efficiency, and customization has revolutionized the manufacturing industry. By investing in these advanced machines, businesses can streamline their metal fabrication processes, cater to diverse client requirements, minimize costs, and stay ahead in the competitive market. Whether it is stainless steel sheet metal fabrication, aluminum sheet metal fabrication, or any other custom metal fabrication needs, the utilization of Steel Sheet Making Machines ensures successful outcomes and drives the growth of businesses across the globe.Keywords: Steel Sheet Making Machine, custom metal fabrication, stainless steel sheet metal fabrication, aluminum sheet metal fabrication, metal fabrication services, precision manufacturing, increased productivity, cost optimization, versatile tooling options.

Complete Roll Forming Solution for Various Applications in China

Roll forming machines have become increasingly popular in the manufacturing industry, thanks to their ability to produce high-quality and consistent products. There are various roll forming machine manufacturers across the globe, but one that stands out is MTC, a leading Cold Roll Former Manufacturer in China. The company provides one-stop roll forming solutions, from consultation to final training for many different applications where roll forming machines can do their best.MTC has been in the roll forming machine industry for over 15 years and has grown to become a highly respected manufacturer. The company specializes in producing a wide range of roll forming machines, including roof panel forming machines, floor decking roll forming machines, C/Z purlin roll forming machines, door frame forming machines, and more. The team at MTC is dedicated to providing innovative solutions that meet the unique needs of their clients.MTC provides clients with an end-to-end service, starting with a consultation. During this stage, MTC experts work together with clients to identify their requirements and recommend the most appropriate roll forming machine for their needs. The company takes into consideration factors such as the application, material used, cost, and desired results, among others. This ensures that clients get the best possible solution that meets their unique requirements.Once the consultation stage is complete and the ideal roll forming machine has been selected, the manufacturing process begins. MTC uses state-of-the-art equipment and technology to produce high-quality roll forming machines that meet international standards. The machines are built using top-grade materials to ensure their durability, and the company guarantees their quality.After the machine has been manufactured, MTC provides installation, testing, and training services. The company has a team of experienced engineers who work with clients to ensure that the machine is installed and tested correctly. The team also provides training services to clients to ensure that they can operate the machine safely and effectively. This ensures that clients get the most out of their investment and can produce high-quality products consistently.One of the popular products produced by MTC is the Roofing Sheet Forming Machine. This machine is designed to produce a variety of roofing sheets, including corrugated sheets. The Roofing Sheet Forming Machine is highly efficient, producing high-quality sheets at a remarkable speed. The machine is versatile and can be customized to meet the specific needs of clients. The machine is also easy to operate, making it ideal for both seasoned and beginner manufacturers.The Roofing Sheet Forming Machine is made using high-quality materials, ensuring its durability. The machine is also low maintenance, making it cost-effective in the long run. Clients who choose this machine can enjoy increased productivity, reduced production time, and a superior quality end-product. The machine is ideal for manufacturing roofing sheets for industrial, commercial, and even residential applications.In conclusion, MTC is a leading Cold Roll Former Manufacturer in China, providing one-stop roll forming solutions to clients worldwide. The company's commitment to delivering innovative solutions, coupled with its dedication to producing high-quality roll forming machines, sets it apart from the competition. The Roofing Sheet Forming Machine is one of the many products produced by MTC that demonstrates the company's commitment to excellence. Clients who choose MTC can enjoy a range of benefits, including increased productivity, reduced production time, and a superior quality end-product.

Revolutionary Steel Framing Machine Transforms Construction Industry

The construction industry has been booming in recent years, with the demand for affordable and efficient building solutions on the rise. As a result, many companies have been innovating new systems and technologies to help streamline the building process and make it more cost-effective. One of these companies is Framecad, whose rollforming technology has made waves in the world of construction.Framecad Rollformer is an innovative system that utilizes automated technology to create lightweight and high-quality steel frames. This system has been designed to provide a complete building solution, from design to construction, and has been used in many projects around the world. It is particularly well-suited for building systems that require quick and efficient construction, such as residential homes, schools, and commercial buildings.The Framecad Rollformer system is extremely efficient, with the ability to produce up to 150 meters of steel framing per hour. This is a significant improvement over traditional construction methods, which can take weeks or even months to complete. The system is also highly accurate, with a precision that allows for customization and design flexibility.One of the key benefits of Framecad Rollformer is its ability to create lightweight frames. This is due to the high-quality steel used in the system, which is up to 60% lighter than traditional building materials. This not only makes the construction process easier and faster but also makes the finished building more energy-efficient and sustainable.Another major advantage of the Framecad Rollformer system is its ability to reduce costs. The use of steel framing in construction is significantly cheaper than traditional building materials, such as wood and concrete. Additionally, the quick construction time and lightweight design of Framecad Rollformer make it an attractive option for builders and developers looking to save on costs.Framecad is a global company that has been at the forefront of innovation in the construction industry for over 30 years. The company has a strong focus on research and development, with a team of engineers and designers continually working to improve their systems and technology. They have also established partnerships with other companies and organizations to further enhance their products and services.In addition to their flagship Rollformer technology, Framecad also offers a range of other building solutions and services. These include design and engineering services, construction software, and training and support. The company aims to provide a complete end-to-end solution for building projects, with a focus on efficiency, sustainability, and affordability.Framecad has been used on a wide range of projects around the world, from residential homes to commercial buildings and even disaster relief shelters. One notable example is the construction of a new hospital in Haiti after the devastating earthquake in 2010. The Framecad system was used to construct the building quickly and efficiently, helping to provide much-needed medical care to the local community.Overall, Framecad Rollformer is a game-changing technology that has revolutionized the construction industry. Its ability to create lightweight and high-quality steel frames quickly and efficiently has made it an attractive option for builders and developers worldwide. With a focus on innovation, sustainability, and affordability, Framecad is poised to continue driving the evolution of the construction industry for many years to come.

C Z Channel Shaped Steel Roof Purlin Roll Forming Machine - Find High-Quality Suppliers

Title: Enhancing Roof Construction Efficiency with the C Z Channel Shaped Steel Roof Purlin Roll Forming MachineIntroduction:In today's fast-paced construction industry, time and cost efficiency are crucial factors for successful projects. One key element in roof construction is the installation of purlins, providing structural support and stability. The remarkable C Z Channel Shaped Steel Roof Purlin Roll Forming Machine offers an innovative solution that maximizes efficiency and quality in this process. This blog will delve into the benefits of this machine and explore how its unique features, including the C Purlin Machine with Punching Hole Device, revolutionize roof construction.I. Understanding the Importance of Purlins in Roof ConstructionRoofs are exposed to various forces like wind, snow, and rain, making the stability of the roofing structure critical. Purlins play a vital role in transferring loads from the roof to the primary frame while maintaining the structural integrity of the overall construction.II. The Role of Roll Forming Machines in Roof ConstructionTraditional methods of manufacturing purlins involved manual labor, which was time-consuming and often inefficient. However, the introduction of roll forming machines, such as the C Z Channel Shaped Steel Roof Purlin Roll Forming Machine, has transformed the construction industry, offering numerous advantages:1. Speed and Efficiency: The machine operates at high speeds, allowing for rapid production of high-quality purlins. This results in significant time savings during the construction process.2. Consistency and Accuracy: The roll forming machine ensures the precise shaping of purlins according to predefined specifications. This guarantees uniformity in dimensions, reducing the possibility of errors during installation.3. Cost-Effectiveness: Automated roll forming considerably reduces labor costs associated with manual manufacturing. The purlin roll forming machine provides an efficient and cost-effective solution for roof construction projects.4. Versatility: The machine can produce a wide range of C and Z channel shaped purlins, accommodating various roof designs and structural requirements. This versatility makes it suitable for a wide range of construction projects.III. Exploring the C Purlin Machine with Punching Hole DeviceOne of the key features of the C Z Channel Shaped Steel Roof Purlin Roll Forming Machine is the integrated Punching Hole Device. This addition enhances the flexibility and efficiency of the machine, offering numerous benefits:1. Streamlined Process: The integrated punching hole device eliminates the need for secondary hole punching operations. It allows for seamless production of purlins with accurately positioned holes, saving time and effort during installation.2. Customization Options: The punching hole device provides flexibility by facilitating the creation of holes at desired locations, sizes, and intervals. This customization adds value to construction projects that require specific hole arrangements.3. Enhanced Structural Strength: The precise hole punching mechanism ensures the integrity of the purlin's strength, maintaining the stability and load-bearing capacity of the roofing structure.Conclusion:The C Z Channel Shaped Steel Roof Purlin Roll Forming Machine presents a game-changing solution for the construction industry. Its automated production capabilities, along with the integrated Punching Hole Device, significantly enhance the efficiency, precision, and quality of purlin manufacturing. By implementing this advanced technology, construction projects can achieve faster completion times, cost savings, and improved structural reliability. With the flexibility to adapt to various design requirements, this machine revolutionizes roof construction, setting a new standard for the industry.

Efficient Standing Seam Roof Panel Machine Revolutionizes Roofing Industry

Title: Innovative Standing Seam Roof Panel Machine Revolutionizes Construction IndustryIntroduction:In today's rapidly advancing world, technological innovations continue to reshape various industries, and the construction sector is no exception. One such groundbreaking invention is the Standing Seam Roof Panel Machine, designed to streamline and enhance the process of roof panel production. With its advanced features and unparalleled efficiency, this cutting-edge machinery has garnered significant attention from industry experts and construction companies alike. Its introduction marks a substantial advancement in construction techniques, ensuring safer and more reliable roofs for buildings of all kinds.I. Evolution of Roof Panel Production:Roof panel production has traditionally been a labor-intensive and time-consuming process, with significant manual effort required. However, with the introduction of the Standing Seam Roof Panel Machine, this age-old method has been revolutionized. By automating various stages of production, this innovative machinery optimizes efficiency, saves time, and eliminates human error, resulting in superior roof panel quality.II. Advanced Features of the Standing Seam Roof Panel Machine:The Standing Seam Roof Panel Machine incorporates a range of state-of-the-art features that set it apart from conventional methods:1. High Precision and Consistency: The machine ensures precise measurements, allowing for accurate roof panel dimensions and consistent seam formation, reducing the risk of leakages and improving overall durability.2. Customization Options: From panel width to seam height, this machine offers unparalleled customization capabilities, enabling construction professionals to tailor each roof panel to the specific requirements of their projects.3. Speed and Efficiency: With an increased rate of production, the machine significantly reduces construction timelines and labor costs. Multiple panels can be produced simultaneously, eliminating the need for manual handling and expediting project completion.4. Enhanced Safety Measures: The Standing Seam Roof Panel Machine is designed with strict adherence to safety guidelines. It minimizes physical strain on workers, reducing the risk of injuries associated with manual labor. Additionally, it eliminates the need for workers to access high rooftops during installation.III. Industry Applications:The versatility of the Standing Seam Roof Panel Machine allows it to be used in various construction projects, providing robust and long-lasting roofing solutions for diverse building types, including residential, commercial, and industrial properties. Its ability to seamlessly integrate with existing roofing systems makes it an ideal choice for both new construction projects and roof renovations.IV. Sustainable and Eco-Friendly Benefits:In addition to its numerous technical advantages, the Standing Seam Roof Panel Machine contributes to sustainable construction practices. By reducing wastage and optimizing material utilization, it minimizes the environmental impact associated with traditional roofing methods. Furthermore, the machine's energy efficiency and low carbon footprint make it an eco-friendly choice, aligning with the growing global emphasis on sustainable activities.V. Company Introduction:*Please provide the specific company introduction and its achievements, removing the brand name as requested.*VI. Future Prospects and Conclusion:As construction technology continues to evolve, the Standing Seam Roof Panel Machine empowers construction professionals with advanced tools that optimize efficiency and deliver superior results. With widespread adoption, this innovative machinery has the potential to redefine industry standards, streamlining construction processes and enhancing the overall quality of roofs. As the construction sector embraces more sustainable and time-efficient practices, the Standing Seam Roof Panel Machine represents a significant step towards a more efficient and eco-friendly future.In summary, the Standing Seam Roof Panel Machine has transformed the construction sector by introducing automation and efficiency into roof panel production. This cutting-edge technology ensures precision, customization, and enhanced safety, while also contributing to sustainable construction practices. With such advancements and the continued innovation in the construction industry, buildings of the future will be more durable, reliable, and in line with environmental standards.

Efficient and Precise Horizontal Barrel Vault Panel Cutting Machine for Improved Productivity

Horizontal Barrel Vault Panel Cutting Machine, the Latest Innovation in Industrial Cutting TechnologyIn the constantly evolving world of industrial cutting technology, one company is at the forefront of innovation with their latest product, the Horizontal Barrel Vault Panel Cutting Machine. This state-of-the-art machine is designed to revolutionize the way industrial cutting is done, providing unmatched accuracy and efficiency for a wide range of applications.With over 20 years of experience in the industry, {Company Name} has built a reputation for delivering cutting-edge solutions to meet the ever-changing needs of their clients. The company's commitment to innovation and excellence has led to the development of the Horizontal Barrel Vault Panel Cutting Machine, a machine that is set to redefine the standards of industrial cutting.The Horizontal Barrel Vault Panel Cutting Machine is designed to cut a wide range of materials with precision and speed. Its innovative design allows for the cutting of various materials such as metal, plastic, and composite materials with ease, making it an ideal solution for industries such as automotive, aerospace, and construction.One of the key features of the Horizontal Barrel Vault Panel Cutting Machine is its ability to cut panels with a barrel vault shape. This unique capability opens up new possibilities for designers and manufacturers, allowing them to create complex and intricate designs that were previously difficult to achieve. The machine's advanced cutting technology ensures that the barrel vault panels are cut with unparalleled precision, resulting in high-quality finished products.In addition to its cutting capabilities, the Horizontal Barrel Vault Panel Cutting Machine also boasts a user-friendly interface that makes it easy to operate. The machine is equipped with intuitive controls and advanced software that allows operators to program cutting patterns and make adjustments with ease. This not only increases efficiency but also reduces the need for extensive training, making it an ideal solution for companies looking to streamline their production processes.Furthermore, the Horizontal Barrel Vault Panel Cutting Machine is designed with productivity in mind. Its high-speed cutting capabilities enable manufacturers to increase their output significantly, while maintaining the highest level of accuracy. This not only improves efficiency but also reduces production time, ultimately leading to cost savings for businesses.Another noteworthy aspect of the Horizontal Barrel Vault Panel Cutting Machine is its versatility. The machine is capable of cutting panels of various sizes and thicknesses, making it a valuable asset for manufacturers with diverse cutting needs. Whether it's large-scale production or custom fabrication, this machine is designed to handle a wide range of cutting tasks, making it a versatile and cost-effective solution for businesses.The Horizontal Barrel Vault Panel Cutting Machine is backed by {Company Name}'s commitment to providing exceptional customer support. The company offers comprehensive training and technical assistance to ensure that clients can maximize the potential of their investment. Additionally, the machine is designed with durability in mind, ensuring that it can withstand the rigors of industrial use for years to come.In conclusion, the Horizontal Barrel Vault Panel Cutting Machine represents a significant leap forward in industrial cutting technology. With its cutting-edge capabilities, user-friendly interface, and unmatched versatility, this machine is set to become a game-changer for manufacturers across a wide range of industries. Thanks to {Company Name}'s dedication to innovation and excellence, the Horizontal Barrel Vault Panel Cutting Machine is poised to set new standards for industrial cutting, providing businesses with the tools they need to thrive in today's competitive market.