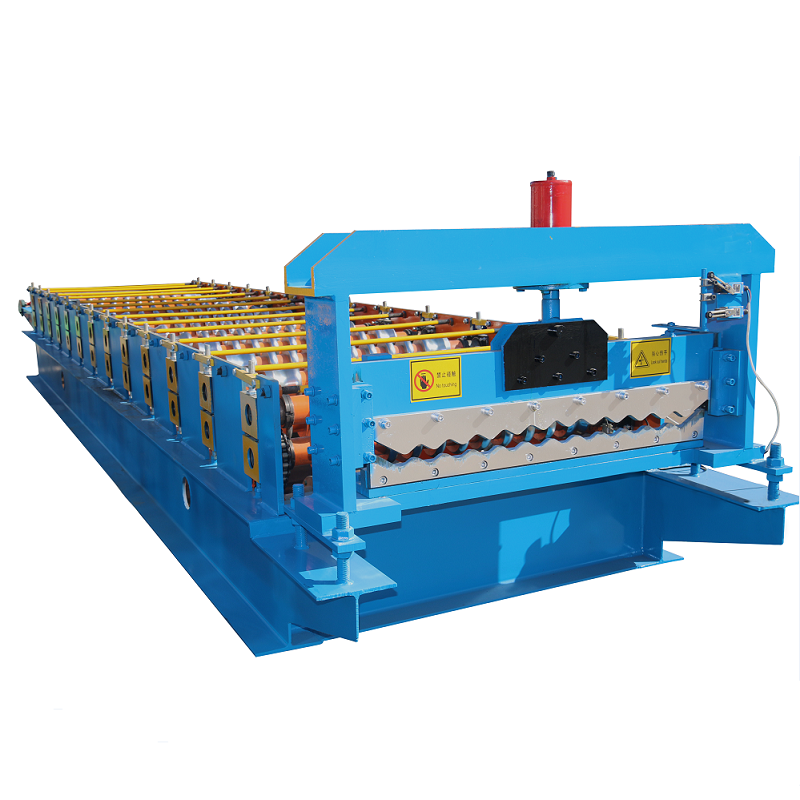

High-quality Glazed Tile Roll Forming And Corrugating Machine for Sale

By:Admin

The Glazed Tile Roll Forming and Corrugating Machine, developed by a leading manufacturing company, offers a range of advanced features that set it apart from traditional manual tile production methods. With its automated process, the machine ensures consistent tile quality and eliminates the risk of human error, resulting in a flawless and uniform finished product.

The machine's roll forming technology allows for the continuous production of glazed tiles, reducing the production time and increasing efficiency. This is a significant advantage in meeting the demands of large-scale construction projects that require a high volume of glazed tiles within a tight timeframe. The ability to produce a continuous stream of tiles also minimizes material waste, making the production process more sustainable and cost-effective.

In addition to its roll forming capabilities, the machine also incorporates corrugating technology, which adds strength and durability to the glazed tiles. This enhances their suitability for various architectural and construction applications, offering a robust and long-lasting solution for modern building designs.

The versatility of the Glazed Tile Roll Forming and Corrugating Machine allows for the customization of tile shapes, sizes, and designs, opening up a world of creative possibilities for architects, designers, and builders. The machine's flexibility in accommodating diverse design requirements makes it a valuable asset for the construction industry, enabling the production of unique and eye-catching glazed tiles that can enhance the aesthetic appeal of any building project.

Furthermore, the machine's user-friendly interface and intuitive controls make it easy to operate, reducing the need for extensive training and specialized skills. This makes it accessible to a wide range of users, from small-scale contractors to large manufacturing facilities, enabling them to incorporate high-quality glazed tiles into their projects with ease.

As a leading manufacturer in the industry, the company behind the Glazed Tile Roll Forming and Corrugating Machine has established a strong reputation for delivering cutting-edge solutions for the construction sector. With a commitment to innovation and quality, the company has consistently introduced advanced technologies that have redefined the standards for building materials production.

Driven by a dedication to excellence, the company's team of engineers and technical experts have developed the Glazed Tile Roll Forming and Corrugating Machine to meet the evolving needs of the construction industry. The machine embodies the company's ethos of precision engineering, reliability, and performance, ensuring that it delivers exceptional results in every production run.

In today's competitive construction market, the demand for glazed tiles continues to grow as architects and builders seek to incorporate visually striking and durable materials into their projects. With the introduction of the Glazed Tile Roll Forming and Corrugating Machine, the company is poised to address this demand and set new benchmarks for efficiency, quality, and innovation in the production of glazed tiles.

In conclusion, the Glazed Tile Roll Forming and Corrugating Machine represents a significant advancement in the construction industry, offering a seamless and efficient solution for producing high-quality glazed tiles. With its advanced technology, customization capabilities, and user-friendly design, the machine is poised to elevate the standards of tile production and contribute to the realization of exceptional architectural and building projects. As the company continues to lead the way in innovation, the future of glazed tile production looks brighter than ever.

Company News & Blog

Photos of Cold Rolling Forming Production Line for Stud Profile C Purlin & U Purlin Roll Forming Machine

Zhiye Cold Forming Machinery Co., Ltd. has launched a new product for the construction industry – the Stud Profile C Purlin Cold Rolling Forming Production Line or more commonly known as the stud U purlin roll forming machine.This machine is designed to produce C purlins and U purlins that are commonly used as framing elements in the construction of roofs, walls, and ceilings. The purlins produced by this machine are known for their high strength, versatility, and cost-effectiveness, making them a popular choice for most building projects.The Stud Profile C Purlin Cold Rolling Forming Production Line operates using advanced technology that ensures the production of high-quality purlins with precise dimensions. Its production process involves feeding raw material into the machine where it is pre-cut and fed into the main roll forming machine. The machine then goes through a series of operations such as leveling, punching, cutting, and stacking, before the final product is produced.The C Purlin Profiles Cold Roll Forming Lines produced by Zhiye Cold Forming Machinery Co., Ltd. are all equipped with state-of-the-art control systems that ensure easy operation, smooth production, and high productivity. The machine can produce purlins of different shapes and sizes, ranging from 100mm to 300mm. It can run at speeds of up to 25 meters per minute, making it possible to produce a large volume of purlins in a short period.The Stud Profile C Purlin Cold Rolling Forming Production Line is made using high-quality components and materials, ensuring its durability and long lifespan. The machine is also flexible and can be easily customized to suit specific customer needs. It is designed for ease of maintenance, with minimal downtime required for repairs and servicing.The launch of this new product by Zhiye Cold Forming Machinery Co., Ltd. is expected to have a significant impact on the construction industry, particularly in the roofing and framing sectors. The machine's ability to produce high-quality purlins quickly and efficiently means that construction companies can save time and money on their projects without compromising the quality of the final product. This is essential, given the increasing demand for construction works globally, where cost and time efficiency are critical.In conclusion, the Stud Profile C Purlin Cold Rolling Forming Production Line/stud U purlin roll forming machine from Zhiye Cold Forming Machinery Co., Ltd. is a significant innovation that will revolutionize the construction industry. The machine's advanced technology, coupled with its efficiency and precision, will ensure that construction companies can produce high-quality purlins quickly and cost-effectively. This will ultimately lead to faster project completion times and reduced costs, making it a popular choice in the industry.

Glazed Steel Roofing Tile Corrugating Machine: The Latest in Color Steel Technology

Color Steel Glazed Steel Roofing Tile Corrugating Machine, also known as the CSGL Steel Roofing Tile Corrugating Machine, is a revolutionary piece of technology that is set to transform the roofing industry. This state-of-the-art machine has been developed by a leading company in the field of steel fabrication and construction machinery.The CSGL Steel Roofing Tile Corrugating Machine is designed to produce high-quality, glazed steel roofing tiles with a corrugated profile. These tiles are not only aesthetically pleasing, but also highly durable and weather-resistant. This makes them an ideal choice for roofing applications in both residential and commercial buildings.The machine is fully automated and can produce a large number of roofing tiles in a short amount of time. This not only increases productivity but also reduces labor costs for companies involved in the manufacturing of roofing materials. Additionally, the machine is designed to be user-friendly, with easy-to-use controls and a simple setup process.One of the key features of the CSGL Steel Roofing Tile Corrugating Machine is its ability to produce a wide variety of tile designs and sizes. This flexibility allows companies to meet the diverse needs of their customers and offer a range of options for different roofing projects. Whether it's a traditional or modern design, this machine can cater to all requirements.The company behind this innovative technology has a strong track record in the steel fabrication and construction machinery industry. With years of experience and expertise, they have established themselves as a trusted partner for businesses looking for high-quality and reliable machinery. Their commitment to innovation and continuous improvement has led to the development of the CSGL Steel Roofing Tile Corrugating Machine, which is set to redefine the standards for roofing tile production.In addition to the machine itself, the company also provides comprehensive support and after-sales services to their customers. This includes training and technical assistance to ensure that the machine is operated efficiently and effectively. They also offer maintenance and repair services to keep the machine running smoothly and minimize downtime for their clients.The launch of the CSGL Steel Roofing Tile Corrugating Machine has already generated a lot of interest and excitement within the construction and roofing industry. Many companies are eager to take advantage of this cutting-edge technology to improve their operations and offer better products to their customers. With its advanced features and capabilities, this machine is expected to set new standards for the production of steel roofing tiles.In conclusion, the Color Steel Glazed Steel Roofing Tile Corrugating Machine is a game-changer for the roofing industry. Its advanced technology, flexibility, and reliability make it a valuable asset for companies involved in the manufacturing of roofing materials. With the support of a reputable company behind it, this machine is set to become a go-to solution for businesses looking to stay ahead in the competitive market of roofing materials.

Top Color Steel Roll Forming Machine Factories: Achieving Superior Production Efficiency and Precision

Title:Pioneering Color Steel Roll Forming Machine Factory Revolutionizes the IndustryIntroduction:In a bid to revolutionize the color steel roll forming machine industry, an innovative factory has emerged as a pioneering force. Through cutting-edge technology and a commitment to excellence, this factory has made significant strides in meeting the demands of the market. With a vision for superior quality and efficiency, the factory has positioned itself as a leader in the field of roll forming machinery.Body:The color steel roll forming machine factory, founded in 1998, has quickly gained a reputation for its state-of-the-art machinery and exceptional customer service. The factory boasts a team of highly skilled engineers and technicians, who continuously strive to push the boundaries of innovation and improve the overall performance of their machines.One of the key factors that sets this factory apart is its relentless pursuit of efficiency. By investing heavily in research and development, the factory has been able to design and manufacture roll forming machines that deliver unmatched precision and speed. This has not only resulted in higher productivity for customers but also contributed to reducing overall production costs.Furthermore, the factory's commitment to quality is evident in its rigorous quality control measures. Each machine undergoes a series of tests and inspections to ensure it meets the highest industry standards. This dedication to excellence has earned the factory numerous accolades and certifications, solidifying its reputation as a trustworthy manufacturer.Moreover, the factory places great importance on sustainability and environmental responsibility. In a world increasingly concerned about climate change, the factory has taken proactive steps to minimize its carbon footprint. It has implemented energy-saving measures within its manufacturing processes and utilizes recyclable materials whenever possible. By doing so, the factory not only supports the green agenda but also sets an example for others in the industry.The factory's portfolio includes an extensive range of color steel roll forming machines, catering to the diverse needs of its customers. From simple profiles to complex shapes, the factory's machines are designed to handle a wide variety of products. Whether it's for residential, commercial, or industrial purposes, customers can rely on the factory to provide them with tailored solutions that meet their specific requirements.In addition to its exceptional machinery, the factory boasts a stellar aftersales service. Recognizing that the success of its customers is intertwined with its own success, the factory provides comprehensive technical support, maintenance, and training services. This ensures that customers can maximize the longevity and performance of their roll forming machines.Another aspect that highlights the factory's commitment to staying ahead of the curve is its continuous investment in research and development. By closely monitoring market trends and emerging technologies, the factory consistently updates its product offerings. This enables it to offer cutting-edge solutions that keep pace with evolving industry demands.Conclusion:The color steel roll forming machine factory has established itself as a leader in the industry through its technological prowess, commitment to quality, and customer-centric approach. By prioritizing efficiency, sustainability, and innovation, the factory has successfully met the evolving demands of the market. As it continues to push boundaries and set new standards, this pioneering factory is poised to shape the future of the color steel roll forming machine industry.

High-Quality Standing Seam Profiling Machine for Efficient Roofing Solutions

In the world of construction and manufacturing, the need for high-quality metal roofing and cladding systems is ever-present. The use of innovative technology and machinery has become a necessity for companies to meet the demand for efficient and effective solutions. One company that has been at the forefront of providing top-of-the-line equipment for the metal roofing industry is [company name].[Company name] is a leading manufacturer of metal roofing and cladding systems, with a focus on providing state-of-the-art machinery to help companies improve their production processes. With a commitment to quality and innovation, [company name] has continuously introduced cutting-edge solutions to the market, including a range of standing seam profiling machines.Standing seam roofing is a popular choice for commercial and industrial buildings due to its durability, weather resistance, and aesthetic appeal. One of the key components in producing standing seam roof panels is the standing seam profiling machine, which is used to form the metal sheets into the desired profile. The precision and efficiency of the machine are crucial for ensuring high-quality end products, and this is where [company name] has excelled with their standing seam profiling machine.The standing seam profiling machine from [company name] is designed to meet the needs of modern metal roofing manufacturers. It is equipped with advanced features and technology to streamline the production process and deliver superior results. The machine is capable of producing a variety of standing seam profiles, allowing for flexibility in design and customization to meet specific project requirements.One of the standout features of the standing seam profiling machine is its user-friendly interface and intuitive controls. This makes it easy for operators to set up and operate the machine, resulting in increased productivity and efficiency. Additionally, the machine is built with robust construction and high-quality components, ensuring reliable performance and longevity.In addition to the advanced technology, [company name] also provides comprehensive support and service for their standing seam profiling machine. This includes installation, training, and ongoing maintenance to ensure optimal performance and minimal downtime for their customers. The company's commitment to customer satisfaction is evident in their dedication to providing top-notch support for their equipment.Furthermore, [company name] understands the importance of staying ahead of the curve in an ever-evolving industry. They continuously invest in research and development to enhance their product offerings and address the changing needs of their customers. This commitment to innovation has enabled [company name] to maintain its position as a leader in the metal roofing and cladding industry.With their standing seam profiling machine, [company name] has set a new standard for precision, efficiency, and reliability in metal roofing production. The machine's advanced features, user-friendly interface, and comprehensive support make it a valuable asset for companies looking to elevate their operations and deliver high-quality standing seam roof panels.As the demand for metal roofing and cladding systems continues to grow, [company name] remains dedicated to providing cutting-edge solutions to meet the needs of their customers. Their standing seam profiling machine is a testament to their commitment to excellence and innovation in the industry. With a strong focus on quality, technology, and customer satisfaction, [company name] is poised to continue leading the way in the metal roofing and cladding market.

Revolutionary Roof Panel Machine: The Game Changer in Snap Lock Technology

Snap Lock Roof Panel Machine Revolutionizes the Roofing IndustryThe roofing industry has witnessed significant advancements over the years, with the latest innovation being the introduction of the Snap Lock Roof Panel Machine. This groundbreaking technology, developed by an industry-leading company known for its commitment to excellence, has revolutionized the way roofs are built and has quickly gained popularity among contractors and homeowners alike.The Snap Lock Roof Panel Machine, developed by a company that has been at the forefront of roofing machinery for decades, represents a significant leap forward in terms of efficiency, durability, and ease of use. This machine is specifically designed to create snap lock roof panels, a type of standing seam metal roof that offers multiple benefits over traditional roofing options.One of the key advantages of snap lock roof panels is their exceptional weather resistance. The unique design ensures that the seams interlock securely, preventing any water or debris from infiltrating the roof structure. This feature makes snap lock roofs an excellent choice for areas prone to heavy rainfall, snow, or harsh weather conditions.In addition to their superior weather resistance, snap lock roof panels also offer unmatched structural integrity. The interlocking seams provide exceptional stability and prevent the panels from separating, even in extreme wind conditions. This durability ensures peace of mind for homeowners, reducing the need for frequent repairs and maintenance.Another notable advantage of snap lock roof panels is their aesthetic appeal. The clean and streamlined look of these roofs adds a modern touch to any architecture, making them a popular choice for both residential and commercial applications. The Snap Lock Roof Panel Machine allows for customization, enabling contractors to create roofs that perfectly complement the style and design of any structure.The machine itself is a marvel of engineering, combining cutting-edge technology with user-friendly features. It is designed to be easily operated, allowing contractors of all expertise levels to produce high-quality snap lock roof panels with minimal effort. The intuitive controls and automated functions ensure precise panel formation, reducing material waste and maximizing productivity.Furthermore, the company behind the Snap Lock Roof Panel Machine is renowned for its commitment to customer satisfaction and continuous improvement. Their dedicated customer support team provides prompt assistance and guidance, ensuring that every customer has a seamless experience from purchase to operation. This commitment to excellence has earned them a reputation as a trusted industry leader.Contractors who have adopted the Snap Lock Roof Panel Machine have witnessed tremendous benefits in their businesses. The machine's efficiency and versatility have allowed them to expand their operations, complete projects faster, and offer superior products to their clients. The durable and weather-resistant nature of the snap lock roofs has also significantly reduced callbacks, saving both time and money.Homeowners, on the other hand, have praised the longevity and aesthetic appeal of their new snap lock roofs. They appreciate the peace of mind that comes with knowing their investment is protected against the elements, while also enjoying the modern and stylish look that enhances the overall value of their properties.In conclusion, the introduction of the Snap Lock Roof Panel Machine has marked a new era in the roofing industry. Combining exceptional durability, weather resistance, and aesthetic appeal, snap lock roof panels have quickly become the preferred choice for contractors and homeowners seeking a superior roofing solution. The innovative technology behind the machine, coupled with the company's commitment to customer satisfaction, has set a new standard for excellence in the industry. As the demand for snap lock roofs continues to rise, this revolutionary machine is destined to reshape the roofing landscape for years to come.

High-quality Glazed Metal Tile Roll Forming Machine for Efficient Tile Production

The demand for construction materials continues to grow as the construction industry booms. With this in mind, a leading manufacturer in the construction machinery industry has introduced a new product that promises to revolutionize the way glazed metal tiles are produced. The company, which has been in the business for over 20 years, is proud to unveil their latest innovation - the Glazed Metal Tile Roll Forming Machine.The Glazed Metal Tile Roll Forming Machine is a state-of-the-art equipment that is designed to produce glazed metal tiles with high precision and efficiency. This machine is equipped with advanced technology and features, making it the perfect solution for companies looking to increase their production capacity and improve the quality of their products.One of the key features of the Glazed Metal Tile Roll Forming Machine is its ability to produce glazed metal tiles with different profiles and sizes. This flexibility allows companies to meet the varying demands of their clients and expand their product offerings. Additionally, the machine is easy to operate and maintain, reducing downtime and increasing productivity.Another standout feature of the Glazed Metal Tile Roll Forming Machine is its high-speed production capability. With a speed of up to 20 meters per minute, this machine can produce a large number of glazed metal tiles in a short amount of time. This not only helps companies meet tight deadlines but also reduces labor costs, making it a cost-effective solution for businesses.The Glazed Metal Tile Roll Forming Machine is also equipped with a cutting-edge control system, allowing for precise control of the production process. This ensures that each glazed metal tile is produced to the highest quality standards, meeting the stringent requirements of the construction industry. With this level of precision, companies can deliver superior products to their customers, enhancing their reputation and competitiveness in the market.In addition to its advanced features, the Glazed Metal Tile Roll Forming Machine is also designed with durability and reliability in mind. The machine is made of high-quality materials and components, ensuring long-term performance and minimal maintenance requirements. This reliability gives companies the peace of mind that their production line will run smoothly and efficiently, without unexpected downtime or costly repairs.Upon its launch, the Glazed Metal Tile Roll Forming Machine has received positive feedback from industry experts and customers alike. Many have praised its cutting-edge technology, high-speed production, and exceptional quality of output. Companies that have integrated this machine into their production line have reported significant improvements in their operational efficiency and product quality, leading to increased customer satisfaction and business growth.With the introduction of the Glazed Metal Tile Roll Forming Machine, this leading manufacturer has reaffirmed its commitment to driving innovation in the construction machinery industry. The company's dedication to research and development has resulted in a product that not only meets the current demands of the market but also sets new standards for quality and performance in glazed metal tile production.As the construction industry continues to expand, the demand for high-quality construction materials, such as glazed metal tiles, will only increase. The Glazed Metal Tile Roll Forming Machine offers companies a competitive edge, allowing them to meet the growing demand and deliver superior products to their customers. With its advanced technology, high-speed production, and exceptional quality, this machine is set to become a game-changer in the construction machinery industry.

High-quality Metal Roll Forming Machine for Efficient Manufacturing

Metal Roll Forming Machine Revolutionizing the Manufacturing IndustryOver the years, the manufacturing industry has seen significant advancements in technology and machinery, leading to increased efficiency and precision in production processes. One such groundbreaking innovation is the Metal Roll Forming Machine, which has revolutionized the way metal components are produced.Metal roll forming is a continuous metal shaping process that involves passing a metal strip through a series of rollers to gradually bend and shape the material into a desired profile. This process is widely used in various industries such as automotive, construction, and aerospace to create components like panels, beams, and tubing.With the introduction of the Metal Roll Forming Machine by the industry leader {Company Name}, manufacturers are now able to achieve higher levels of productivity and cost-effectiveness in their production processes. The machine is designed to handle a wide range of metal materials including steel, aluminum, and copper, making it a versatile solution for a diverse set of manufacturing needs.{Company Name} has been at the forefront of developing cutting-edge metal forming technologies for over three decades, and their Metal Roll Forming Machine is a testament to their commitment to innovation and excellence. The machine is equipped with state-of-the-art automation and control systems, enabling precise and consistent forming of metal profiles with minimal human intervention.One of the key advantages of the Metal Roll Forming Machine is its ability to produce complex and intricate metal profiles with high accuracy and repeatability. This level of precision is essential for industries that require tight tolerances and geometrically challenging components, such as the aerospace and automotive sectors.Furthermore, the machine’s high-speed forming capabilities allow for increased production output, making it an ideal choice for manufacturers looking to streamline their operations and meet growing demand. The efficiency and speed of the Metal Roll Forming Machine significantly reduce lead times and production costs, ultimately improving the overall bottom line for manufacturers.In addition to its technological capabilities, the Metal Roll Forming Machine also boasts a user-friendly interface and ergonomic design, ensuring ease of operation and maintenance for the machine operators. This focus on user experience aligns with {Company Name}’s commitment to delivering solutions that not only enhance productivity but also prioritize the wellbeing of the workforce.As the manufacturing industry continues to evolve, the demand for advanced metal forming technologies like the Metal Roll Forming Machine is expected to grow. Manufacturers are increasingly seeking solutions that can offer higher production efficiency, cost-effectiveness, and flexibility, all of which are key benefits provided by {Company Name}’s innovative machine.The Metal Roll Forming Machine has already garnered significant interest from industry leaders and is poised to set new standards in metal forming technology. Its ability to transform raw metal materials into precise and complex profiles with unprecedented speed and accuracy positions it as a game-changer in the manufacturing landscape.In conclusion, the Metal Roll Forming Machine by {Company Name} represents a significant leap forward in metal forming technology, offering manufacturers a competitive edge in today’s fast-paced and demanding market. With its advanced capabilities and user-centric design, this machine is poised to revolutionize the manufacturing industry and drive the next wave of innovation.

Coil-fed Cutting Machine for Metal and Sheet Metal - Efficient and Precise Solution

Sheet metal coil cutting machines have revolutionized the way sheet metal fabrication was done earlier. These machines use highly advanced laser cutting technology to cut sheet metal coils of various thicknesses with ease. A staunch player in this industry is the DANOBAT LB coil-fed cutting machine, offered by the renowned DANOBATGROUP.The DANOBAT LB coil-fed cutting machine is an efficient and high-quality equipment specially designed for the sheet metal cutting industry. It offers advanced precision in cutting operations, enabling the production of high-quality products with elevated efficiency. The machine can cut coil sheets of various materials such as steel, aluminum, brass, copper, and other alloys.The machine has a cutting speed of up to 150 meters per minute and can handle sheets of thickness ranging from 0.4mm to 16 mm. This coil-fed cutting machine features a robust structure that can withstand intense workload for years, making it one of the most reliable sheet metal cutting machines on the market.Equipped with a fiber laser, the DANOBAT LB coil-fed cutting machine is an extremely precise machine that delivers remarkable cuts on various materials. The laser facilitates high cutting speeds with a minimal kerf width, thus reducing the amount of scrap and maximizing the yield.Moreover, DANOBATGROUP's coil-fed cutting machine is incredibly easy to operate and maintain. The machine's user-friendly interface makes it possible to control the cutting processes and communicate with the machine directly. The intuitive software technology integrated into the machine enables operators to modify cutting parameters and prepare the cutting process quickly and efficiently.The DANOBAT LB coil-fed cutting machine is ideal for the production of various products, including automotive components, industrial equipment, and construction materials, among others. The machine ensures efficient production, improved automation, and enhanced product quality.DANOBATGROUP is not only known for its cutting-edge sheet metal coil cutting machines but also for providing excellent customer service. The company has a team of professionals who are always ready to offer technical support and assistance. With a worldwide presence, DANOBATGROUP ensures that its customers receive timely assistance and a reliable after-sales service.In summary, the DANOBAT LB coil-fed cutting machine is a top-of-the-line equipment that offers high-precision, efficiency, and reliability to the sheet metal cutting industry. Its excellent cutting speed, user-friendly interface, and optimal usage of materials result in minimized production costs and high-quality products. To learn more about this cutting-edge technology and to request a quote, contact DANOBATGROUP, a reputed provider of sheet metal processing solutions.

High-Quality Sheet Making Machine for Metro Systems

(Metro Area) - The demand for efficient and high-quality sheet making machines has been on the rise in recent years, and (company name) is leading the way with their innovative Metro Sheet Making Machine. This state-of-the-art machine is designed to produce top-quality sheets with precision and speed, meeting the needs of businesses in various industries.The Metro Sheet Making Machine is equipped with advanced technology that sets it apart from other sheet making machines on the market. It boasts a user-friendly interface, allowing operators to easily control the machine and monitor its performance. With its high-speed production capabilities, the Metro Sheet Making Machine can produce a large volume of sheets in a short amount of time, making it ideal for businesses with high production demands.In addition to its speed, the Metro Sheet Making Machine is also known for its precision and accuracy. It is designed to produce sheets with consistent thickness and dimensions, ensuring that each sheet meets the highest quality standards. This level of precision is crucial for businesses that require uniform and reliable sheets for their products.The Metro Sheet Making Machine is also designed with durability and reliability in mind. It is built with high-quality materials and components that can withstand the demands of continuous production. This ensures that businesses can rely on the machine to deliver consistent performance day after day, minimizing downtime and maximizing productivity.Furthermore, the Metro Sheet Making Machine is designed to be versatile and adaptable to different production needs. It can accommodate a wide range of materials, including paper, cardboard, and plastic, allowing businesses to use the machine for various applications. This flexibility makes the Metro Sheet Making Machine a valuable investment for businesses looking to expand their production capabilities.In addition to its cutting-edge technology, (company name) is also known for its commitment to customer satisfaction. The company offers comprehensive support and service for the Metro Sheet Making Machine, ensuring that businesses can maximize the machine's performance and longevity. This includes installation, training, and ongoing maintenance to keep the machine in optimal condition.Furthermore, (company name) takes pride in its dedication to innovation and continuous improvement. The Metro Sheet Making Machine is the result of extensive research and development, and the company is constantly exploring new ways to enhance its performance and capabilities. This commitment to innovation ensures that the Metro Sheet Making Machine remains at the forefront of the industry.With its advanced technology, precision, durability, and versatility, the Metro Sheet Making Machine from (company name) is a game-changer for businesses that require high-quality sheets for their products. Its innovative features and reliable performance make it a valuable asset for businesses in various industries, setting a new standard for sheet making machines.As the demand for efficient and high-quality sheet making machines continues to grow, (company name) is poised to lead the industry with their innovative Metro Sheet Making Machine. With its advanced technology, precision, durability, and versatility, the Metro Sheet Making Machine is a game-changer for businesses looking to enhance their production capabilities and meet the needs of their customers.For more information about the Metro Sheet Making Machine and other products from (company name), visit their website or contact their team for a consultation.

High-Quality Automatic Wire Cut To Length Machine for Efficient Cutting

Precision Machinery Co., Ltd. is proud to announce the release of their latest innovation, the Automatic Wire Cut To Length Machine. This cutting-edge machine is designed to streamline and optimize the wire cutting process, providing unparalleled precision and efficiency in wire length cutting for various industrial applications.The newly developed Automatic Wire Cut To Length Machine is equipped with advanced technology and features that set it apart from traditional wire cutting machines. With its high-speed cutting capability and precise length control, this machine is able to cut multiple wires with different lengths in a single operation, saving time and increasing productivity for businesses. Additionally, the machine's user-friendly interface and programmable settings make it simple for operators to set up and adjust cutting parameters, reducing the risk of human error and ensuring consistent results.The Automatic Wire Cut To Length Machine is also designed to accommodate a wide range of wire diameters, making it a versatile solution for businesses that work with various types of wire. This flexibility allows companies to streamline their wire cutting operations and minimize the need for multiple machines, ultimately reducing costs and increasing efficiency.In addition to its cutting capabilities, the Automatic Wire Cut To Length Machine also offers a compact and durable design, making it suitable for use in various industrial settings. The machine's robust construction and high-quality components ensure reliable performance and longevity, allowing businesses to invest in a solution that will continue to deliver exceptional results for years to come.As a leading manufacturer of precision machinery, Precision Machinery Co., Ltd. has a long-standing reputation for delivering high-quality, innovative solutions to meet the evolving needs of the industry. With a focus on research and development, the company is committed to staying ahead of the curve and continuously improving its products to provide customers with the best possible solutions for their wire cutting needs."We are thrilled to introduce the Automatic Wire Cut To Length Machine to the market," said Mr. Zhang, the CEO of Precision Machinery Co., Ltd. "This machine represents the culmination of our dedication to innovation and excellence in precision machinery technology. We believe that it will revolutionize the wire cutting process for businesses, providing them with a reliable and efficient solution that will ultimately contribute to their success."Precision Machinery Co., Ltd. is dedicated to providing top-notch customer service and technical support to ensure that businesses can integrate the Automatic Wire Cut To Length Machine seamlessly into their operations. From initial installation and training to ongoing maintenance and support, the company is committed to helping its customers maximize the potential of this cutting-edge machine.The Automatic Wire Cut To Length Machine is now available for purchase, and Precision Machinery Co., Ltd. is excited to work with businesses to tailor the solution to their specific wire cutting needs. With its cutting-edge technology, precision performance, and versatile capabilities, this machine is poised to become an indispensable tool for businesses looking to optimize their wire cutting operations and drive greater efficiency and productivity.In conclusion, the release of the Automatic Wire Cut To Length Machine underscores Precision Machinery Co., Ltd.'s commitment to delivering cutting-edge solutions that empower businesses to thrive in a competitive market. With its advanced technology, unparalleled precision, and user-friendly design, this machine is set to revolutionize the wire cutting process, providing businesses with a reliable and efficient solution to meet their wire cutting needs.