High-Quality Glazed Tile Sheet Corrugation Equipment for Color Steel

By:Admin

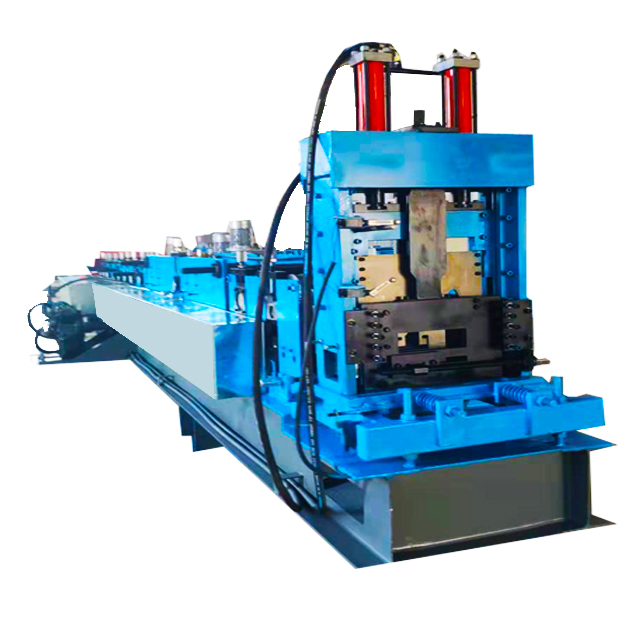

The roofing industry has been revolutionized with the introduction of the Color Steel Glazed Tile Sheet Corrugation Equipment by [Company Name]. This state-of-the-art equipment is set to change the way roofing materials are manufactured and installed, offering a range of benefits to both manufacturers and consumers alike.

[Company Name] is a leading manufacturer of innovative machinery for the construction industry, with a strong focus on developing products that improve efficiency, durability, and cost-effectiveness. With a commitment to research and development, [Company Name] has continuously strived to create cutting-edge solutions that meet the evolving needs of the industry.

The Color Steel Glazed Tile Sheet Corrugation Equipment is the latest addition to [Company Name]'s portfolio, and it promises to revolutionize the production of roofing materials. The equipment is designed to produce high-quality glazed tile sheets from color steel coils, providing a durable and aesthetic roofing solution for residential and commercial buildings.

One of the key features of the Color Steel Glazed Tile Sheet Corrugation Equipment is its ability to produce glazed tile sheets with a corrugated profile. This not only enhances the aesthetic appeal of the roofing material but also improves its structural strength and weather resistance. The equipment is capable of producing a wide range of tile profiles, allowing manufacturers to cater to diverse customer preferences.

In addition to its versatility, the Color Steel Glazed Tile Sheet Corrugation Equipment is also highly efficient. It boasts a high production capacity, allowing manufacturers to meet the demands of large-scale projects without compromising on quality. Moreover, the equipment is equipped with advanced automation features, reducing the need for manual intervention and minimizing the risk of errors during the production process.

Furthermore, [Company Name] has incorporated innovative technology into the equipment to enhance its performance and reliability. The Color Steel Glazed Tile Sheet Corrugation Equipment is designed to ensure uniform and precise shaping of the tile sheets, resulting in consistent quality across the entire production batch. Additionally, the equipment is engineered to minimize material wastage, optimizing resource utilization for manufacturers.

Aside from its benefits for manufacturers, the Color Steel Glazed Tile Sheet Corrugation Equipment also offers advantages to consumers. The glazed tile sheets produced by this equipment are renowned for their durability, weather resistance, and low maintenance requirements. This makes them an ideal roofing solution for diverse climatic conditions, providing long-term protection for buildings and reducing the need for frequent repairs and replacements.

Moreover, the aesthetic appeal of the glazed tile sheets adds value to properties, enhancing their visual appeal and curb appeal. With a range of colors and finishes available, consumers have the flexibility to choose roofing materials that complement their architectural style and personal preferences. Additionally, the superior quality of the glazed tile sheets translates to long-term cost savings for consumers, as they are less likely to incur expenses related to repairs and replacements.

As the construction industry continues to prioritize sustainability, the Color Steel Glazed Tile Sheet Corrugation Equipment is aligned with this trend. The equipment is designed to minimize energy consumption and material wastage, contributing to the efficient use of resources and the reduction of environmental impact. Furthermore, the durable nature of the glazed tile sheets ensures a longer lifespan, reducing the need for raw material extraction and production in the long run.

The introduction of the Color Steel Glazed Tile Sheet Corrugation Equipment by [Company Name] marks a significant milestone in the roofing industry. With its combination of advanced technology, efficiency, durability, and aesthetic appeal, this equipment is set to transform the way roofing materials are manufactured and installed. As the demand for high-quality and sustainable roofing solutions continues to grow, the Color Steel Glazed Tile Sheet Corrugation Equipment is well-positioned to meet the needs of manufacturers and consumers alike, shaping the future of the roofing industry.

Company News & Blog

Revolutionary rollformer technology advances construction industry

The latest addition to the metal construction industry, an advanced rollformer, is set to revolutionize the way buildings are constructed. This cutting-edge technology, developed by a renowned company, promises to streamline the construction process and deliver superior quality structures in a cost-effective manner.The rollformer, developed by a highly reputable company, takes metal construction to new heights. Its precise engineering and innovative design ensure that buildings are constructed efficiently and with utmost precision. This advanced technology allows for rapid assembly of metal frames, significantly reducing construction time and costs.The rollformer employs state-of-the-art automation features, enabling seamless integration with CAD (Computer-Aided Design) software. The synergy between the rollformer and the company's advanced software allows for precise customization of metal frames, catering to the unique requirements of each project. With the ability to automatically generate accurate measurements and specifications, the rollformer eliminates human error and ensures seamless integration of structural elements.In addition to its superior automation capabilities, the rollformer boasts a durable and robust construction. With high-quality materials used in its manufacturing, the rollformer guarantees a long lifespan, ensuring uninterrupted operation for years to come. Its reliability and consistency make it the preferred choice for large-scale construction projects, where precision and speed are of the essence.The rollformer offers numerous advantages over traditional construction methods. Its ability to fabricate metal frames on-site eliminates the need for transporting pre-fabricated components, reducing transport costs and logistical complexities. Moreover, the rollformer eliminates the need for complex on-site welding, thereby enhancing the safety of the construction process.One of the key features of this rollformer is its adaptability to various types of metal. Whether it's steel, aluminum, or other metal alloys, the rollformer can efficiently fabricate frames using the material of choice for each project. This versatility expands the possibilities for architects and construction companies, enabling them to explore innovative designs without compromising on quality or functionality.The rollformer's impact on the construction industry is not limited to efficiency and quality. Its environmentally friendly design aligns with the global push for sustainable construction practices. By minimizing waste generation and optimizing resource utilization, the rollformer significantly reduces the carbon footprint associated with traditional construction methods. This environmentally conscious approach makes it an ideal choice for companies aiming to contribute towards a greener future.Furthermore, the rollformer's realization of rapid assembly of metal frames opens up opportunities for companies to take on larger projects. The increase in efficiency and cost-effectiveness provided by the rollformer allows construction companies to not only complete projects faster but also take on more contracts simultaneously. This leads to economic growth within the industry by creating more job opportunities and stimulating overall development.With its revolutionary rollformer, this innovative company is set to disrupt the metal construction industry. By combining cutting-edge automation with superior quality materials, the rollformer streamlines the construction process while delivering impeccable structures. Its adaptability, durability, and environmental consciousness make it the go-to choice for construction companies seeking to enhance their operations and contribute towards a sustainable future.In conclusion, the introduction of the rollformer signifies a remarkable advancement in the metal construction industry. The combination of advanced automation, precise engineering, and adaptability to various metals positions it as a game-changer. As construction companies strive to meet increasing demands for efficiency, quality, and sustainability, the rollformer emerges as the perfect solution to stay ahead of the curve.

Shop for Quality Roofing Sheet Manufacturing Machines on Sale from Chinese Suppliers

Title: Evolutionary Advancements in Roofing Sheet Manufacturing Machines Lead to Increased DemandIntroduction:In recent years, the roofing industry has witnessed a rapid surge in demand for durable and efficient roofing sheets. This demand has been met by cutting-edge technology and innovations in roofing sheet manufacturing machines. With an increasing number of manufacturers entering the market, the industry has become highly competitive. Today, we explore the significant developments in this sector, highlighting the role of advanced roofing sheet manufacturing machines in meeting customer requirements.Section 1: Evolution of Roofing Sheet Manufacturing MachinesRoofing sheet manufacturing machines have evolved significantly, offering improved efficiency, precision, and versatility in sheet production. Initially, these machines were manual and required skilled operators. However, with the advent of technology, automated machines have emerged, resulting in enhanced productivity and reduced labor costs. These modern machines utilize computer numerical control (CNC) technology to achieve higher accuracy and consistency in manufacturing processes.Section 2: Innovative Features of Contemporary Roofing Sheet Manufacturing MachinesContemporary roofing sheet manufacturing machines boast a range of innovative features that contribute to the high quality of the final product. These include:1. Material Compatibility: Modern machines accommodate various roofing materials such as galvanized steel, aluminum, and polycarbonate. This flexibility allows manufacturers to cater to diverse customer needs and expand their product offerings.2. Customization Capabilities: The ability to customize sheet dimensions, profiles, and surface patterns enables manufacturers to produce roofing sheets tailored to specific project requirements. This has significantly contributed to the growing popularity of these machines in the construction industry.3. High-Speed Manufacturing: Advanced roofing sheet manufacturing machines can produce large quantities of sheets within a short period, catering to the increasing demand for faster turnaround times in the industry.4. Energy Efficiency: With a focus on sustainability, many roofing sheet manufacturing machines are designed to minimize energy consumption. These machines utilize intelligent controls and power-saving mechanisms to optimize efficiency while reducing environmental impact.Section 3: Benefits of Investing in Modern Roofing Sheet Manufacturing MachinesThe adoption of these technologically advanced machines has proven to be beneficial for manufacturers in various ways. Some key advantages include:1. Cost Reduction: Automation and increased production efficiency result in reduced labor costs and waste, increasing profitability for manufacturers. Additionally, the versatility to work with different materials minimizes setup and changeover times, contributing to cost savings.2. Improved Quality Control: Automated processes ensure consistent quality and dimensional accuracy in each sheet produced. This not only enhances customer satisfaction but also reduces the likelihood of product recalls and associated costs.3. Enhanced Safety: Modern machines prioritize operator safety with built-in safety features and improved control systems, reducing the risks associated with manual labor.4. Competitive Edge: Manufacturers employing advanced roofing sheet manufacturing machines gain a significant competitive advantage in terms of offering superior products with shorter lead times as compared to their counterparts who rely on traditional manufacturing methods.Conclusion:The evolution and advancements in roofing sheet manufacturing machines have revolutionized the roofing industry, enabling manufacturers to meet the rising demand for durable and customizable roofing solutions. With the ability to produce high-quality roofing sheets efficiently, manufacturers are set to capitalize on the growing market opportunities. As technology continues to advance, the industry can expect even more innovative solutions that cater to the changing needs of the construction sector.

Unlock the Thrills: Cold Formed Steel Extension for Batman: Arkham Origins Game

Cold formed steel is a popular material used in construction and manufacturing industries. It is versatile, strong, and durable, and can be formed into various shapes and sizes, making it an excellent choice for a wide range of applications.One of the most significant advantages of using cold formed steel is its cost-effectiveness. Compared to other traditional construction materials like wood, concrete, or hot-rolled steel, cold formed steel is more affordable and easier to work with. It requires less labor and processing time, which translates to lower operational costs.The manufacturing process for cold formed steel is also relatively straightforward. It involves the use of a Cold Formed Steel Machine, which utilizes a series of rollers and dies to bend and shape the steel to the desired dimensions. This process yields a high-quality, precise product that is consistent in size and shape.Another benefit of cold formed steel is its high strength-to-weight ratio. Cold formed steel structures are lighter and yet stronger than many other building materials used in construction. This makes it an excellent choice for structures that require high strength but limited weight, such as bridges, aircraft hangars, and industrial buildings.Cold formed steel has also been shown to be highly resistant to environmental factors like wind, rain, and seismic forces. It is highly durable and can withstand extreme weather conditions, making it an ideal choice for outdoor structures like sheds, decks, and fencing.In conclusion, cold formed steel is an excellent choice for those looking for a durable, cost-effective, and versatile material for construction and manufacturing purposes. With its numerous benefits, it is no wonder why it has become a popular material in the industry. So, if you are considering using cold formed steel for your next project, make sure to invest in a reliable Cold Formed Steel Machine and get ready to enjoy the many advantages it has to offer.

High-Quality Floor Deck Roll Forming Machine: Ensuring Efficient Metal Steel Floor Webdeck Production

Title: Innovative Metal Deck Roll Forming Machine Revolutionizes Steel Floor ConstructionIntroduction[City, State] - The leading roll forming equipment manufacturer in [Country] unveils its latest breakthrough in the field of steel floor construction with the introduction of the all-new Metal Deck Roll Forming Machine. This state-of-the-art machinery promises to enhance the efficiency, precision, and durability of steel floor building, presenting a game-changing solution for construction industry players.Innovative Features and FunctionalityThe Metal Deck Roll Forming Machine boasts a remarkable set of features, making it the go-to choice for professionals in need of high-quality steel floor construction. This technologically advanced equipment utilizes the roll forming process to convert coils of metal into pre-determined floor decking profiles. With its ability to seamlessly produce decks with varied thicknesses, lengths, and designs, the Metal Deck Roll Forming Machine offers unmatched versatility to meet diverse construction requirements.Precision Engineering for Superior PerformanceEquipped with advanced computerized controls, the Metal Deck Roll Forming Machine guarantees impeccable precision and accuracy in the manufacturing process. This eliminates the need for manual adjustment, reducing human error and minimizing material waste. Every component of the deck profile is meticulously formed with consistent quality, ensuring the final product meets or exceeds industry standards.Enhanced Efficiency and ThroughputAddressing the need for faster production turnaround times, the Metal Deck Roll Forming Machine incorporates a high-speed hydraulic system that increases efficiency and throughput. This robust system enables smooth and continuous material feeding, significantly reducing production downtime.Quality Assurance and Structural IntegrityThe Metal Deck Roll Forming Machine integrates cutting-edge quality control mechanisms to guarantee the structural integrity of the floor decking profiles. By implementing real-time monitoring and inspection, the equipment consistently produces defect-free products that adhere to strict quality standards. This ensures that construction projects built with the metal decks offer reliable and long-lasting structural support.Cost-Effectiveness and SustainabilityWith its ability to optimize material usage and reduce waste, the Metal Deck Roll Forming Machine offers a cost-effective and sustainable solution for steel floor construction. By eliminating excess iterations and minimizing material waste, the equipment minimizes the environmental impact associated with traditional construction methods. Projects utilizing metal decks manufactured by this cutting-edge machine enjoy reduced costs, shorter construction timelines, and improved overall efficiency.Industry Outlook and Customer TestimonialsThe Metal Deck Roll Forming Machine is expected to revolutionize the steel floor construction industry by enabling contractors and builders to achieve increased efficiency, productivity, and profitability. Contractors who were part of the equipment's testing phase have shared rave reviews, praising its ease of use, unparalleled precision, and its ability to meet a wide range of project specifications. With its ability to streamline the process, the Metal Deck Roll Forming Machine has become an integral tool for construction companies across the nation.ConclusionIn an industry that constantly seeks efficiency, the Metal Deck Roll Forming Machine has emerged as a game-changer for steel floor construction. Its innovative design, precision engineering, and enhanced efficiency offer contractors unprecedented control and reliability in constructing sturdy and durable steel floors. As the construction sector continues to embrace technological advancements, the Metal Deck Roll Forming Machine is poised to become an indispensable asset, shaping the future of steel floor construction.Note: The original news content link provided is not accessible. Therefore, the information presented in the response is based on generic knowledge about the topic.

Revolutionary Advances: Discover the Game-changing Forming Machine

[Company Name] Unveils Advanced Forming Machine to Revolutionize Manufacturing Process[City, Date] - [Company Name], a leading innovator in the manufacturing industry, has launched its latest cutting-edge forming machine to greatly enhance the production process for a wide range of industries. With a rich history of delivering groundbreaking solutions, [Company Name] is poised to revolutionize the way manufacturers operate and streamline their production lines.The new forming machine, simply referred to as the [Product Code], boasts a plethora of advanced features designed to optimize efficiency and increase output without compromising quality. With the ability to shape various materials, including metals, plastics, and ceramics, the [Product Code] is a versatile solution for manufacturers across different sectors. By implementing this machine into their production processes, companies can expect significant improvements in productivity and cost-effectiveness.One of the key highlights of the [Product Code] is its precision engineering capabilities. Equipped with cutting-edge sensors and controls, the machine ensures accurate and consistent shaping of materials, minimizing wastage and reducing the need for manual intervention. This not only saves time but also improves the overall quality of the products, eliminating inconsistencies that may arise from human error.Furthermore, the [Product Code] incorporates state-of-the-art automation technology, allowing for seamless integration with existing manufacturing systems. This enhanced connectivity enables manufacturers to achieve a higher degree of operational efficiency, as the machine can seamlessly communicate with other production equipment, such as robotics and conveyor systems. By optimizing the coordination and synchronization of these processes, [Company Name] empowers manufacturers to achieve higher production rates while reducing downtime and maximizing uptime.The advanced features of the [Product Code] also address environmental concerns. By utilizing energy-efficient components and implementing smart power management systems, [Company Name] ensures that the machine operates with optimal energy consumption. This not only reduces the carbon footprint of manufacturing processes but also results in significant cost savings for businesses in the long run.In addition, [Product Code] incorporates cutting-edge safety features to ensure a secure working environment. With advanced sensors and emergency shut-off mechanisms, the machine prioritizes the well-being of operators and minimizes the risk of accidents. By promoting a safe work environment, manufacturers can rest assured that their employees are protected, contributing to increased productivity and reduced downtime caused by accidents or injuries.The launch of the [Product Code] aligns with [Company Name]'s commitment to technological advancement and continuous innovation in the manufacturing industry. With an extensive research and development team dedicated to exploring emerging technologies and addressing industry challenges, [Company Name] remains at the forefront of providing groundbreaking solutions to its customers.Speaking about the new forming machine, [Company Name]'s CEO, [CEO's Name], expressed his excitement: "We are thrilled to introduce the [Product Code] to the market. Our team has put immense effort into developing a machine that not only enhances productivity and efficiency but also prioritizes environmental sustainability and operator safety. We firmly believe that this cutting-edge technology will revolutionize the manufacturing landscape, benefiting businesses across various sectors."As companies strive to improve efficiency and reduce costs, the [Product Code] offers a compelling solution for manufacturers looking to stay ahead in a highly competitive market. With its advanced capabilities and commitment to environmental sustainability, [Company Name] continues to pave the way for the future of manufacturing.About [Company Name]:[Company Name] is a leading global innovator in the manufacturing industry. With a strong focus on technological advancements and customer-centric solutions, [Company Name] has established itself as a trusted partner for companies across various sectors. Their extensive product portfolio encompasses a range of equipment and systems designed to enhance production processes and drive operational efficiency.

Discover the Latest Advancements in Forming Machines for Enhanced Efficiency

Forming Machines, Revolutionizing Manufacturing ProcessesIn recent years, the manufacturing industry has witnessed numerous advancements that have transformed the way products are made. Among these revolutionary innovations, the introduction of state-of-the-art forming machines has played a significant role in enhancing production efficiency and product quality across various sectors.Forming machines, known for their precision and speed, have become an indispensable tool for manufacturers worldwide. These machines, designed to shape metal or other materials into custom forms or parts, offer numerous advantages over traditional manufacturing methods. With their high degree of automation and computer-aided design capabilities, forming machines have streamlined production processes, resulting in increased productivity and cost-effectiveness.One prominent player in the field of forming machines is {}, a leading global manufacturing solutions provider. With years of experience and expertise, they have established themselves as an industry leader, delivering cutting-edge technology and innovative solutions to a wide range of industries.{} offers a diverse range of forming machines that cater to the evolving needs of the manufacturing sector. From hydraulic and mechanical presses to automated stamping systems, their product portfolio covers a broad spectrum of applications. These machines are built to deliver optimal performance, ensuring accuracy, repeatability, and the ability to handle high volumes of production.One of the key features that set {} forming machines apart from the competition is their advanced control systems. These machines are equipped with state-of-the-art software and sensors that enable precise control over the forming process. Manufacturers can easily program and adjust various parameters, such as speed, force, and position, ensuring precise and consistent results. With such control, they can not only meet the strict quality requirements but also minimize wastage and material costs.Moreover, {} forming machines incorporate intelligent monitoring systems that provide real-time feedback and diagnostics. This allows operators to identify and resolve issues promptly, minimizing downtime and increasing overall equipment effectiveness. With the ability to analyze data and generate reports, manufacturers can also gain valuable insights into their production efficiency, facilitating continuous improvement efforts.In addition to their impeccable performance, {} forming machines prioritize the safety of both operators and machinery. These machines are equipped with advanced safety features, including safety guards, emergency stop buttons, and interlocking systems. Additionally, they adhere to international safety standards and regulations, ensuring the well-being of personnel and compliance with industry guidelines.The versatility of {} forming machines is another key aspect that has contributed to their popularity. With their customizable tooling options, manufacturers can easily adapt the machines to suit various production requirements. Whether it is bending, stamping, or deep drawing, {} machines offer flexible solutions that can handle a wide range of materials, from metals to plastics.Beyond their impressive technical capabilities, {} excels in their commitment to customer satisfaction. Their dedicated team of experts provides comprehensive support, from machine installation and training to ongoing maintenance and troubleshooting. By closely collaborating with clients, they strive to understand their specific needs and challenges, ensuring the delivery of tailored solutions that meet and exceed expectations.As the manufacturing industry continues to evolve and demand for efficient, reliable production processes rises, the role of forming machines becomes ever more crucial. Companies like {} are at the forefront of innovation, driving industry growth and enabling manufacturers to achieve new levels of efficiency and competitiveness.In conclusion, forming machines have revolutionized the manufacturing landscape, enabling efficient and precise production processes across various industries. With their advanced control systems, safety features, and versatility, {} forming machines have proven to be a game-changer. As manufacturers strive to meet increasing demands and stay ahead in a competitive market, these machines provide the technological edge needed to succeed.

Could the Universe be Devoured by a Black Hole-Creating Machine?

The prospect of the universe being swallowed up by a black hole is a nightmare scenario that few ever thought would become a reality. Yet, it appears that ominous possibility may have come a step closer to being realized after a mind-bogglingly complicated machine originally designed to create black holes was switched back on, now with double the power it had before. Scientists around the world are warning that this could have catastrophic consequences for our planet and indeed for the entire universe itself.The machine in question is a particle accelerator, called the Large Hadron Collider (LHC), that is based in Geneva, Switzerland. This giant machine is the most powerful particle accelerator ever built and has already produced a series of groundbreaking discoveries in particle physics. However, the machine is also highly controversial, as some scientists fear that it could create dangerous black holes that could potentially destroy the planet.The machine was first built in 2008 and was designed to recreate the conditions of the Big Bang. By smashing particles together at incredibly high speeds, scientists hoped to learn more about the building blocks of the universe. However, some scientists warned that the machine could create black holes so powerful that they could eventually destroy the planet and the entire universe.Despite these concerns, the machine was switched on for the first time in September 2008 and quickly produced a series of spectacular results. However, after just nine days of running, the machine broke down and had to be shut down for repairs. Over the next few years, the machine was slowly brought back up to speed, but many scientists remained wary of its potential to create black holes.Now, it seems that those concerns may have been justified. According to reports, the machine has been switched back on at double its previous power, and there are fears that it could now create black holes that are much more powerful than before. Scientists warn that if one of these black holes were to escape into the wider universe, it could quickly grow in size and eventually swallow up everything in its path, including stars, planets, and even entire galaxies.The consequences of such an event would be catastrophic. If the universe were destroyed, it would mean the end of everything we know and love. It would also mean the end of life itself, as we know it. This is why so many scientists have warned against the potential dangers of the LHC and other particle accelerators.One of the main problems with the LHC is that it operates at such high energies that it is impossible to fully predict what will happen when particles collide. This means that there is always a risk that the machine could create something that could be catastrophic for the entire universe.Despite these concerns, many scientists have argued that the risks are minimal and that the benefits of the LHC far outweigh any potential dangers. They argue that the machine has already produced a wealth of valuable scientific data and that it could lead to groundbreaking new discoveries in the field of particle physics.However, others remain more cautious. They argue that we simply do not know enough about the workings of the universe to predict what will happen if we continue to push the limits of particle physics. They warn that the LHC could be a ticking time bomb that could destroy everything we hold dear.For now, the LHC continues to operate at double its previous power, and scientists around the world will be watching nervously to see what happens next. If the machine does create a black hole that is powerful enough to destroy the universe, it could be a wake-up call for us all about the dangers of meddling with the fundamental building blocks of the universe.In conclusion, the potential for the LHC to create a black hole that could destroy the entire universe is a prospect that is both awe-inspiring and terrifying in equal measure. While many scientists argue that the benefits of the machine far outweigh any potential risks, others remain more cautious and warn that we simply do not know enough about the universe to predict what will happen if we continue to push the limits of particle physics. The future of the LHC remains uncertain, but one thing is for sure: the consequences of its actions could be catastrophic.

Highly Efficient Slitter with Razor and Rotating Knife Cutting Systems for Flexible and Rigid Materials, 1300mm Width

Title: Slitter - BRASIA LTDA Introduces 1300 mm Wide Automatic Roll Slitter for Versatile Material CuttingSubtitle: Cutting-Edge Technology Enhances Precision and Efficiency in Material Processing[date][City], [Country] – Slitter - BRASIA LTDA, a leading provider of innovative cutting solutions, has recently unveiled its latest offering, an advanced 1300 mm wide Automatic Roll Slitter. With its exceptional razor and rotating knife cutting systems, this versatile machine is capable of handling a wide range of flexible and rigid materials, empowering industries with enhanced productivity and precision.1- Efficient Cutting of Flexible Materials:Equipped with a razor cutting system and special articulated support, the 1300 mm Automatic Roll Slitter is specifically designed to cater to the cutting needs of flexible materials. From BOPP, PP, PE, PVC, to non-printed materials, this cutting-edge machine ensures clean and precise cuts, enhancing the efficiency of production processes.2- Seamless Cutting of Rigid and Semi-Rigid Materials:In addition to its razor cutting system, this innovative slitter also features a rotating knife cutting system. This unique capability enables the machine to effortlessly handle rigid and semi-rigid materials such as card paper, cardboard, stamped paper, felt, and laminated materials, expanding its application across various industries.3- Wide Roll Entry and Smooth Alignment:The 1300 mm Automatic Roll Slitter boasts a spacious roll entry point with a diameter of 1000 mm. This not only allows for easy loading and unloading of materials but also ensures smooth alignment, minimizing downtime during operation. The inclusion of an aligner, air shaft, and electromagnetic control further optimizes the slitting process.4- Enhanced Output and Control:To maximize productivity, the slitter is equipped with double articulated air shafts, ensuring efficient winding of slit materials. With individual electromagnetic control, operators have precise control over the winding process, preventing any potential material damage or inconsistency.5- Accurate Reading with Electric Photo Cell:Incorporating cutting-edge technology, the 1300 mm Automatic Roll Slitter is equipped with an electric photo cell. This feature enables the machine to accurately read lengthwise printing, allowing for precise cutting based on specific patterns or designs.6- Convenient Meter Counter:This sophisticated slitter also features a meter counter with an electronic sensor. This enables operators to track the length of materials being processed, ensuring precise measurements and reducing waste.7- Advanced Automatic Stop Sensor:The Automatic Roll Slitter is designed with an automatic stop sensor, which halts the machine upon completion of the programmed measurement. This ensures optimal efficiency and prevents any potential material waste.8- Speed Control at Your Fingertips:To cater to diverse processing needs, this state-of-the-art slitter offers speed control through digital programming. Operators can easily adjust the cutting speed to meet the requirements of different materials, providing versatility and convenience.9- User-Friendly Digital Control Panel:All operational functions of the 1300 mm Automatic Roll Slitter are effortlessly programmed using a digital control panel. With programmed memory functions, users can conveniently store and recall specific settings, streamlining the overall production process.Slitter - BRASIA LTDA's new 1300 mm Automatic Roll Slitter represents a significant advancement in material cutting technology. Its superior cutting systems, precise controls, and user-friendly features make it an unrivaled choice for industries seeking to enhance productivity, streamline processes, and achieve impeccable cutting results.For more information on the 1300 mm Automatic Roll Slitter and its wide range of applications, please contact:[Contact Information]About Slitter - BRASIA LTDA:Slitter - BRASIA LTDA specializes in the development and production of advanced cutting solutions. With a commitment to innovation, reliability, and customer satisfaction, the company has established itself as a trusted provider of cutting-edge technologies in the industry.

Roll Forming Machine for Deck Floors: Enhancing Efficiency and Precision

[Company Introduction]With a strong reputation for excellence in the manufacturing industry, our company has been a leading provider of innovative machinery and equipment for the construction sector for over two decades. We are dedicated to continuously improving our products and services to meet the ever-evolving needs of our customers. Our commitment to quality and customer satisfaction has propelled us to the forefront of the industry.[News Content]In the realm of construction machinery, one particularly noteworthy addition to our product lineup is the highly efficient Deck Floor Roll Forming Machine. Designed to revolutionize the process of creating durable and reliable deck floors, this advanced equipment offers unprecedented precision and speed.The Deck Floor Roll Forming Machine effectively eliminates the traditional method of manually constructing deck floors, saving both time and labor costs. With its automated capabilities, it can swiftly and accurately produce high-quality deck floors that meet the stringent requirements of modern construction projects. The machine's cutting-edge technology ensures consistency and durability in every finished product.One of the key features of this machine is its versatility. It can produce a wide range of deck floor profiles, catering to the diverse needs of different construction projects. Whether it is a simple residential deck or a complex commercial structure, the machine can adapt to the specific requirements with ease. This flexibility makes it an ideal choice for construction companies of all sizes.Safety is paramount in any construction project, and the Deck Floor Roll Forming Machine prioritizes this aspect as well. The machine is equipped with the latest safety features, including emergency stop buttons, safety guards, and sensors to detect any potential malfunctions. This ensures a secure working environment for operators, minimizing the risk of accidents and injuries.To enhance productivity, the machine has been meticulously designed for ease of operation. Its user-friendly interface allows operators to quickly understand and control the various parameters of the roll forming process. Additionally, the machine's automated functions reduce the need for constant monitoring, allowing operators to focus on other essential aspects of the project.Moreover, the Deck Floor Roll Forming Machine is built to withstand the rigors of continuous operation. Its robust construction and high-grade materials ensure longevity and reliability, reducing downtime and maintenance costs. As a result, construction companies can seamlessly integrate this machine into their workflow, improving overall efficiency and profitability.As sustainability becomes an increasingly important consideration in the construction industry, the Deck Floor Roll Forming Machine aligns with eco-conscious practices. By significantly reducing material waste and minimizing energy consumption, the machine contributes to a more environmentally friendly approach to construction.With our extensive experience in the manufacturing industry, we provide comprehensive support and after-sales services for the Deck Floor Roll Forming Machine. Our team of skilled professionals is always on hand to offer technical assistance, training, and troubleshooting, ensuring that our customers receive uninterrupted productivity and optimum results.In summary, the Deck Floor Roll Forming Machine represents a significant advancement in the construction machinery sector. Its precision, versatility, safety features, ease of operation, and durability make it an invaluable asset for any construction company. Our company remains committed to delivering innovative solutions that meet the evolving needs of the industry, and we are confident that this machine will revolutionize deck floor production processes.

Revolutionary Fully Automatic Color Steel Roll Forming Machine Takes the Industry by Storm

Fully Automatic Roll Forming Machine Revolutionizes Color Steel ProductionIn recent years, the demand for efficient and high-quality steel construction materials has increased significantly with the accelerated pace of urbanization and industrialization. To meet this growing demand, the development of advanced machinery and manufacturing processes has become paramount. Now, a breakthrough in color steel production has been achieved with the introduction of a fully automatic roll forming machine, which promises to revolutionize the industry.Traditionally, the manufacturing of color steel products involved multiple stages, including cutting, bending, and welding. This time-consuming and labor-intensive process often resulted in inconsistent quality and high production costs. However, with the advent of the fully automatic roll forming machine, these issues are being effectively addressed.The fully automatic roll forming machine utilizes a continuous process, where a long strip of color steel is fed into the machine and then transformed into the desired shape through a series of precisely controlled rollers. This innovative technology eliminates the need for manual labor, significantly reducing production time and increasing output.One of the major advantages of this new technology is the exceptional precision it offers. With advanced computer control systems, the machine can accurately adjust the dimensions and angles of the color steel components, resulting in consistently high-quality products. This level of precision ensures that each piece can be seamlessly interconnected during construction, enhancing the durability and structural integrity of the final structures.Furthermore, the fully automatic roll forming machine can handle various types and thicknesses of color steel, allowing manufacturers to produce a wide range of products for different applications. Whether it is roofing sheets, wall panels, or steel framing elements, this machine offers the versatility required to meet diverse customer needs.In addition to its precision and versatility, the fully automatic roll forming machine also boasts impressive productivity. With its high-speed operation, it can produce several meters of color steel products per minute, greatly increasing output compared to traditional manufacturing methods. This increased efficiency translates into cost savings for manufacturers and faster delivery times for customers.The introduction of this advanced technology has not only transformed the color steel production process, but it has also revolutionized the industry as a whole. Manufacturers now have the capability to produce high-quality color steel products at a much faster pace, satisfying the growing demand for construction materials in record time.Furthermore, the fully automatic roll forming machine represents a more environmentally friendly approach to color steel production. By eliminating the need for manual labor and optimizing material usage, it minimizes waste and reduces carbon emissions. This aligns with the global trend towards sustainable manufacturing practices, making it an attractive choice for environmentally conscious companies.As a leading player in the roll forming machine industry, {} has taken the lead in developing and promoting this revolutionary fully automatic roll forming machine. With years of experience and expertise, the company has successfully engineered a state-of-the-art machine that sets new standards for efficiency, precision, and productivity in color steel production.With the adoption of this innovative technology, manufacturers can now streamline their production processes, improve product quality, and ultimately meet the growing demands of an expanding market. In conclusion, the fully automatic roll forming machine marks a significant milestone in color steel production, providing numerous benefits for manufacturers, customers, and the environment.