High-Quality Metal Roof Making Machine for Efficient Production

By:Admin

{Company Name} is a globally renowned manufacturer of construction machinery and equipment, with a strong reputation for delivering high-performance and reliable solutions for the building industry. With a commitment to excellence and innovation, the company has continuously invested in research and development to stay ahead of the curve and meet the evolving needs of its customers.

The Metal Roof Making Machine is the latest addition to {Company Name}'s portfolio of industry-leading products. It is equipped with advanced automation technology and precision engineering, allowing for efficient and accurate production of metal roof panels. The machine is capable of handling various types of metal materials, including steel, aluminum, and copper, and can produce a wide range of profiles and dimensions to meet diverse architectural requirements.

One of the key features of the Metal Roof Making Machine is its versatility and flexibility. It is designed to accommodate custom designs and specifications, enabling customers to create unique and tailored metal roof panels for their projects. This level of customization sets {Company Name}'s machine apart from traditional manufacturing methods, offering increased design freedom and creativity for architects and builders.

Furthermore, the Metal Roof Making Machine is engineered for seamless integration with other processes in the production line, maximizing operational efficiency and reducing lead times. Its user-friendly interface and intuitive controls make it easy to operate and maintain, contributing to a smooth and hassle-free manufacturing experience for businesses.

In addition to its technical capabilities, the Metal Roof Making Machine is also developed with sustainability in mind. It is designed to optimize material usage and minimize waste, aligning with {Company Name}'s commitment to environmental responsibility. By promoting sustainable practices in metal roof production, the machine helps to reduce the carbon footprint of construction projects and support the industry's transition towards greener building solutions.

{Company Name} is dedicated to providing comprehensive support and services for the Metal Roof Making Machine, including training, technical assistance, and aftersales care. This commitment ensures that customers can fully harness the potential of the machine and achieve the best results in their metal roofing projects.

The launch of the Metal Roof Making Machine marks a significant milestone for {Company Name} and underscores its position as a leader in the construction machinery sector. With its advanced technology, versatility, and sustainability benefits, the machine is set to reshape the metal roofing industry and empower businesses to elevate their capabilities in delivering high-quality, customized metal roof solutions.

As {Company Name} continues to drive innovation and progress in the construction industry, the Metal Roof Making Machine stands as a testament to its dedication to pushing boundaries and creating value for its customers. With a strong foundation built on expertise and forward-thinking vision, {Company Name} is poised to shape the future of metal roofing production and inspire new possibilities for the built environment.

Company News & Blog

Efficient Standing Seam Roof Panel Machine Revolutionizes Roofing Industry

Title: Innovative Standing Seam Roof Panel Machine Revolutionizes Construction IndustryIntroduction:In today's rapidly advancing world, technological innovations continue to reshape various industries, and the construction sector is no exception. One such groundbreaking invention is the Standing Seam Roof Panel Machine, designed to streamline and enhance the process of roof panel production. With its advanced features and unparalleled efficiency, this cutting-edge machinery has garnered significant attention from industry experts and construction companies alike. Its introduction marks a substantial advancement in construction techniques, ensuring safer and more reliable roofs for buildings of all kinds.I. Evolution of Roof Panel Production:Roof panel production has traditionally been a labor-intensive and time-consuming process, with significant manual effort required. However, with the introduction of the Standing Seam Roof Panel Machine, this age-old method has been revolutionized. By automating various stages of production, this innovative machinery optimizes efficiency, saves time, and eliminates human error, resulting in superior roof panel quality.II. Advanced Features of the Standing Seam Roof Panel Machine:The Standing Seam Roof Panel Machine incorporates a range of state-of-the-art features that set it apart from conventional methods:1. High Precision and Consistency: The machine ensures precise measurements, allowing for accurate roof panel dimensions and consistent seam formation, reducing the risk of leakages and improving overall durability.2. Customization Options: From panel width to seam height, this machine offers unparalleled customization capabilities, enabling construction professionals to tailor each roof panel to the specific requirements of their projects.3. Speed and Efficiency: With an increased rate of production, the machine significantly reduces construction timelines and labor costs. Multiple panels can be produced simultaneously, eliminating the need for manual handling and expediting project completion.4. Enhanced Safety Measures: The Standing Seam Roof Panel Machine is designed with strict adherence to safety guidelines. It minimizes physical strain on workers, reducing the risk of injuries associated with manual labor. Additionally, it eliminates the need for workers to access high rooftops during installation.III. Industry Applications:The versatility of the Standing Seam Roof Panel Machine allows it to be used in various construction projects, providing robust and long-lasting roofing solutions for diverse building types, including residential, commercial, and industrial properties. Its ability to seamlessly integrate with existing roofing systems makes it an ideal choice for both new construction projects and roof renovations.IV. Sustainable and Eco-Friendly Benefits:In addition to its numerous technical advantages, the Standing Seam Roof Panel Machine contributes to sustainable construction practices. By reducing wastage and optimizing material utilization, it minimizes the environmental impact associated with traditional roofing methods. Furthermore, the machine's energy efficiency and low carbon footprint make it an eco-friendly choice, aligning with the growing global emphasis on sustainable activities.V. Company Introduction:*Please provide the specific company introduction and its achievements, removing the brand name as requested.*VI. Future Prospects and Conclusion:As construction technology continues to evolve, the Standing Seam Roof Panel Machine empowers construction professionals with advanced tools that optimize efficiency and deliver superior results. With widespread adoption, this innovative machinery has the potential to redefine industry standards, streamlining construction processes and enhancing the overall quality of roofs. As the construction sector embraces more sustainable and time-efficient practices, the Standing Seam Roof Panel Machine represents a significant step towards a more efficient and eco-friendly future.In summary, the Standing Seam Roof Panel Machine has transformed the construction sector by introducing automation and efficiency into roof panel production. This cutting-edge technology ensures precision, customization, and enhanced safety, while also contributing to sustainable construction practices. With such advancements and the continued innovation in the construction industry, buildings of the future will be more durable, reliable, and in line with environmental standards.

Revolutionary Roof Panel Machine: The Game Changer in Snap Lock Technology

Snap Lock Roof Panel Machine Revolutionizes the Roofing IndustryThe roofing industry has witnessed significant advancements over the years, with the latest innovation being the introduction of the Snap Lock Roof Panel Machine. This groundbreaking technology, developed by an industry-leading company known for its commitment to excellence, has revolutionized the way roofs are built and has quickly gained popularity among contractors and homeowners alike.The Snap Lock Roof Panel Machine, developed by a company that has been at the forefront of roofing machinery for decades, represents a significant leap forward in terms of efficiency, durability, and ease of use. This machine is specifically designed to create snap lock roof panels, a type of standing seam metal roof that offers multiple benefits over traditional roofing options.One of the key advantages of snap lock roof panels is their exceptional weather resistance. The unique design ensures that the seams interlock securely, preventing any water or debris from infiltrating the roof structure. This feature makes snap lock roofs an excellent choice for areas prone to heavy rainfall, snow, or harsh weather conditions.In addition to their superior weather resistance, snap lock roof panels also offer unmatched structural integrity. The interlocking seams provide exceptional stability and prevent the panels from separating, even in extreme wind conditions. This durability ensures peace of mind for homeowners, reducing the need for frequent repairs and maintenance.Another notable advantage of snap lock roof panels is their aesthetic appeal. The clean and streamlined look of these roofs adds a modern touch to any architecture, making them a popular choice for both residential and commercial applications. The Snap Lock Roof Panel Machine allows for customization, enabling contractors to create roofs that perfectly complement the style and design of any structure.The machine itself is a marvel of engineering, combining cutting-edge technology with user-friendly features. It is designed to be easily operated, allowing contractors of all expertise levels to produce high-quality snap lock roof panels with minimal effort. The intuitive controls and automated functions ensure precise panel formation, reducing material waste and maximizing productivity.Furthermore, the company behind the Snap Lock Roof Panel Machine is renowned for its commitment to customer satisfaction and continuous improvement. Their dedicated customer support team provides prompt assistance and guidance, ensuring that every customer has a seamless experience from purchase to operation. This commitment to excellence has earned them a reputation as a trusted industry leader.Contractors who have adopted the Snap Lock Roof Panel Machine have witnessed tremendous benefits in their businesses. The machine's efficiency and versatility have allowed them to expand their operations, complete projects faster, and offer superior products to their clients. The durable and weather-resistant nature of the snap lock roofs has also significantly reduced callbacks, saving both time and money.Homeowners, on the other hand, have praised the longevity and aesthetic appeal of their new snap lock roofs. They appreciate the peace of mind that comes with knowing their investment is protected against the elements, while also enjoying the modern and stylish look that enhances the overall value of their properties.In conclusion, the introduction of the Snap Lock Roof Panel Machine has marked a new era in the roofing industry. Combining exceptional durability, weather resistance, and aesthetic appeal, snap lock roof panels have quickly become the preferred choice for contractors and homeowners seeking a superior roofing solution. The innovative technology behind the machine, coupled with the company's commitment to customer satisfaction, has set a new standard for excellence in the industry. As the demand for snap lock roofs continues to rise, this revolutionary machine is destined to reshape the roofing landscape for years to come.

High-Quality Metal Roofing Sheet Corrugated Tile Roll Forming Machine for Custom Applications" Our Wide Range of Roof Roll Forming Machines and Equipment for Efficient Roofing Solutions Enhance Your Roofing Projects with our Corrugated Tile Roof Roll Forming Machine Advanced Maquina De Hacer Calaminas: Perfectly Designed for Customized Metal Roofing Sheets Discover Our Impressive Line of Roofing Machinery: Curve Roof Machines, Shearing/Bending Machines, Light Keel Roll Formers, and More

: Efficiency, Durability, VersatilityA metal roof is one of the most durable and long-lasting roofing systems on the market today. It is highly resistant to weathering and UV damage, which makes it an excellent choice for homeowners who want to protect their homes from extreme weather conditions. For this reason, the demand for metal roofing systems has risen over the past few years.However, installing a metal roof can be a daunting task, especially for those who have no experience in roofing. The good news is that the Metal Corrugated Roof Roll Forming Machine is designed to make the installation of metal roofing systems easier and more efficient.EfficiencyThe Metal Corrugated Roof Roll Forming Machine is a game-changer when it comes to metal roof installation. It can speed up the installation process by producing custom-made metal roofing sheets quickly and accurately. Additionally, it is designed to process different types of roofing materials, including aluminum, copper, and steel, and can produce a variety of profiles, such as corrugated and trapezoidal.The machine is highly automated, which means that it requires minimal human intervention. This makes it very efficient, which can save contractors time and labor costs.DurabilityThe metal roofing sheets produced by the Metal Corrugated Roof Roll Forming Machine are highly durable. This is because the machine forms the sheets from raw materials, which eliminates the need for prefabricated sheets that are prone to damage during transportation and handling. Additionally, the thickness of the metal sheets can be customized to suit the specific requirements of the roofing project.VersatilityThe Metal Corrugated Roof Roll Forming Machine is a versatile machine that is suitable for different types of roofing projects. It can form metal sheets in different sizes and profiles, which makes it suitable for residential, commercial, and industrial roofing projects.The machine's versatility is further enhanced by the fact that it can form metal sheets with different coatings, such as galvanized, painted, and coated. This means that contractors can choose the best-coated metal roofing sheets that will enhance the project's durability and performance.ConclusionIn conclusion, the Metal Corrugated Roof Roll Forming Machine is a game-changer in the metal roofing industry. It provides efficiency, durability, and versatility, which are essential for any successful roofing project. Its advanced technology ensures that contractors can produce custom-made metal roofing sheets quickly and accurately, making metal roofing installation more efficient and cost-effective. Anyone looking to install a metal roofing system should consider using this machine to ensure a seamless roofing project.

Metal Steel Sheet Roll Forming Machine for Colored Panels

Colored Metal Steel Sheet Roll Forming Machine: A Revolutionary Solution in the Steel IndustryIn recent years, there has been a growing demand for colored metal steel sheets in various industries, such as construction, automotive, and appliances. These sheets not only provide effective protection against weather conditions but also enhance the aesthetics of the finished products. To cater to this rising demand, several manufacturers have developed advanced machinery. One such groundbreaking innovation is the Colored Metal Steel Sheet Roll Forming Machine, which is quickly gaining popularity across the industry.The roll forming machine, developed by a leading manufacturer in the steel industry, utilizes cutting-edge technology to efficiently produce high-quality colored metal steel sheets. Its unique features enable it to transform metal coils into accurately shaped and colored sheets with exceptional precision and speed. By removing the need for traditional painting or coating methods, this machine revolutionizes the production process, saving both time and costs for manufacturers.One of the key advantages of the Colored Metal Steel Sheet Roll Forming Machine is its versatility. It can be customized to meet the specific requirements of different industries, allowing manufacturers to produce an extensive range of colors, widths, and lengths. This adaptability ensures that the machine caters to the diverse needs of customers, enabling them to create products that align with their design and performance objectives.The machine operates through a multi-step process that starts with the loading of metal coils onto the uncoiler. The material is then fed into the roll forming unit, where it passes through a sequence of carefully designed rolls. These rolls gradually shape the metal into the desired form, ensuring the uniformity and consistency of the final product. Simultaneously, the machine applies the selected color coating to the sheets during the forming process, resulting in a high-quality and visually appealing finish.The Colored Metal Steel Sheet Roll Forming Machine offers numerous advantages over traditional manufacturing techniques. Firstly, it eliminates the need for separate painting or coating processes, which not only simplifies the production line but also reduces the chances of defects and imperfections. Additionally, the machine's high-speed operation significantly increases productivity, enabling manufacturers to meet tight production deadlines and fulfill large orders with ease.Furthermore, the machine incorporates advanced safety features to ensure the well-being of operators. With the integration of sensors, emergency stop buttons, and safety guards, the machine minimizes the risk of accidents, providing a safe working environment. The intuitive control system allows operators to effortlessly monitor and adjust various parameters throughout the production process, further enhancing ease of use and operator efficiency.The introduction of the Colored Metal Steel Sheet Roll Forming Machine has received overwhelmingly positive feedback from manufacturers in the steel industry. Its exceptional performance, efficiency, and reliability have made it an indispensable tool for businesses looking to streamline their operations and enhance their product offerings. Manufacturers using this machine have reported significant improvements in production output, product quality, and customer satisfaction.In conclusion, the Colored Metal Steel Sheet Roll Forming Machine represents a significant breakthrough in the steel industry. Its ability to accurately shape and color metal sheets while eliminating the need for additional painting or coating processes has transformed the production process. By providing manufacturers with a highly efficient, versatile, and safe solution, this machine has revolutionized the way colored metal steel sheets are manufactured. As the industry continues to evolve, it is expected that the Colored Metal Steel Sheet Roll Forming Machine will play a crucial role in meeting the growing demand for high-quality, aesthetically pleasing colored metal sheets.

Spacious and Durable Permanent Structure Garden Tent with Fire Rating: Grade DB1

Title: The Versatility and Value of Permanent Structure Garden TentsIntroduction:In today's fast-paced world, where outdoor events are becoming increasingly popular, the demand for versatile, durable, and eye-catching structures like permanent garden tents is on the rise. These structures not only provide a unique outdoor experience but also offer shelter, space, and unlimited customization possibilities. In this blog, we will explore the features, benefits, and uses of permanent structure garden tents made using high-speed steel roof truss C Z purline making machinery, ensuring their enduring quality and functionality.Size and Steel Structure:One of the key advantages of permanent structure garden tents is their spaciousness. Available in a variety of sizes, the 30M X 50M permanent garden tent provides ample room for any event or gathering. To ensure utmost reliability and durability, the tents are constructed using high-quality Q235 steel, known for its strength and resilience. This steel structure guarantees the safety of occupants and guards against adverse weather conditions, making the garden tent suitable for long-term installations.Membrane Material and Fire Rating:The membrane material used in the construction of permanent structure garden tents is PVDF, which offers exceptional visual appeal and long-lasting performance. PVDF membranes provide high resistance to UV radiation, chemicals, and extreme temperatures, making them ideal for outdoor use. Additionally, these membranes have a fire rating of Grade DB1, ensuring the safety of all occupants. This critical feature makes permanent garden tents suitable for various events, including concerts, exhibitions, weddings, and corporate gatherings.Delivery Time, Port, and Payment Options:Understanding the time constraints that event organizers often face, the delivery time for permanent structure garden tents is 20-30 days. Quick and efficient transportation from the warehouse to the desired location is made possible by convenient access to Huangpu or Nansha ports. To facilitate easy transactions, payments for the tent can be made via T/T (Telegraphic Transfer) or Western Union, providing flexibility and compatibility with various international payment systems.Versatility and Customization:Permanent structure garden tents offer endless possibilities for customization and adaptability to meet specific event requirements. With the help of high-speed steel roof truss C Z purline making machinery, these tents can be easily transformed into outdoor venues or temporary shelter solutions. The machinery enables the construction of strong and durable frameworks that can support lighting fixtures, stage setups, audio-visual equipment, or any other desired fixtures, ensuring a seamless experience for both organizers and attendees.Conclusion:Permanent structure garden tents have become a must-have solution for event organizers, given their versatility, durability, and customization potential. Constructed using high-quality Q235 steel and PVDF membrane material, these tents offer a safe and comfortable environment for various events. With a quick delivery time and flexible payment options, they are a practical choice for anyone looking for a long-term or temporary outdoor shelter solution. By utilizing high-speed steel roof truss C Z purline making machinery, these tents can be tailored to unique requirements, transforming any space into an extraordinary event venue.

Durable and Efficient Double Deck Roll Forming Machine for High-Volume Production

The Double Deck Roll Forming Machine has recently gained popularity in the metal forming industry, and {} is at the forefront of this innovative technology. This advanced machine has the capability to produce double-layered metal sheets, which offers significant advantages in terms of cost efficiency and production speed.With a focus on providing high-quality roll forming solutions to meet the evolving needs of the industry, {} has been a key player in the development and deployment of the Double Deck Roll Forming Machine. This state-of-the-art equipment is designed to increase productivity and optimize the production process, making it an essential part of modern metal forming operations.One of the key features of the Double Deck Roll Forming Machine is its ability to produce two different profiles simultaneously. This capability enables manufacturers to achieve greater flexibility in their production processes, as well as the ability to meet diverse customer requirements. With this machine, {} has empowered its clients to deliver a wide range of customized metal products, while also improving their overall production efficiency.In addition to its dual-profile capability, the Double Deck Roll Forming Machine also offers enhanced efficiency through its advanced control system. With precise control over the forming process, this machine ensures consistent quality and accuracy in the production of metal sheets. This level of control not only enhances the overall product quality but also minimizes material waste, ultimately leading to cost savings for manufacturers.Moreover, the Double Deck Roll Forming Machine is designed with a modular configuration, allowing for easy customization to suit specific production needs. This flexibility has been a game-changer for many manufacturers, as it enables them to adapt their production lines to accommodate various design requirements and material specifications. As a result, {} has empowered its clients to expand their product offerings and capture new business opportunities in the competitive metal forming market.Furthermore, {} has positioned itself as a leading provider of turnkey solutions for the roll forming industry, offering comprehensive support and expertise in the implementation of the Double Deck Roll Forming Machine. From initial consultation to installation and training, the company is committed to ensuring that its clients fully maximize the potential of this cutting-edge technology. This customer-centric approach has earned {} a reputation for reliability and excellence in the industry.Looking ahead, {} continues to innovate and develop new technologies to further advance the roll forming industry. With a strong focus on research and development, the company is dedicated to staying ahead of market trends and delivering innovative solutions that meet the evolving needs of manufacturers. As the demand for efficient, high-quality metal forming equipment continues to grow, {} remains committed to providing state-of-the-art solutions that drive success for its clients.In conclusion, the Double Deck Roll Forming Machine is a game-changing technology that has revolutionized the metal forming industry, and {} is at the forefront of this innovation. Through its commitment to excellence and customer satisfaction, the company has cemented its position as a trusted partner for manufacturers seeking to optimize their production processes and achieve new levels of efficiency and productivity. As the industry evolves, {} will continue to lead the way in delivering advanced roll forming solutions that empower manufacturers to thrive in the competitive market.

High-Quality C Purlins for Construction Projects: Everything You Need to Know

C Purlins: The Versatile Solution for Construction ProjectsIn the world of construction, it's important to have sturdy and reliable materials that can withstand the test of time. This is where C Purlins come into play, offering a versatile solution for various construction projects. With their unique shape and durable construction, C Purlins have become a popular choice for builders and contractors across the globe.C Purlins are horizontal beams that are used to provide support for a variety of construction projects. They are designed to be strong and durable, making them an ideal choice for applications such as roofing, wall cladding, and structural support. These versatile beams are made from high-quality steel, ensuring that they can withstand the elements and provide long-lasting support for any construction project.One of the key advantages of C Purlins is their ability to be easily installed and customized to fit the specific needs of a project. Whether it's for a small residential building or a large commercial structure, C Purlins can be cut to size and shaped to meet the unique requirements of any construction project. This flexibility and adaptability make them an attractive choice for builders and contractors who are looking for a reliable and cost-effective solution.In addition to their strength and versatility, C Purlins are also known for their lightweight design, making them easy to handle and transport. This can be a significant advantage for construction teams who need to work quickly and efficiently, as the lightweight nature of C Purlins can help to speed up the installation process and reduce labor costs.In recent years, there has been a growing demand for C Purlins in the construction industry, as builders and contractors recognize the many benefits that these versatile beams have to offer. As a result, more and more companies are now offering C Purlins as part of their product lineup, providing builders and contractors with a variety of options to choose from.One such company is {}, a leading supplier of construction materials and solutions. With a strong focus on quality and innovation, {} has established itself as a trusted provider of C Purlins and other construction products. The company offers a wide range of C Purlins in different sizes and specifications, ensuring that builders and contractors can find the right solution for their specific needs.In addition to providing high-quality C Purlins, {} also offers expert guidance and support to help customers find the best products for their construction projects. The company's team of professionals has extensive experience in the construction industry and is committed to delivering top-notch service to every customer. From initial consultations to final installation, {} is dedicated to ensuring that every project is a success.As the demand for C Purlins continues to grow, it's clear that these versatile beams are here to stay. With their strength, durability, and flexibility, C Purlins have become an essential component of modern construction projects, providing reliable support and structural integrity. And with companies like {} leading the way, builders and contractors can rest assured that they have access to the best C Purlins on the market.In conclusion, C Purlins are a versatile and reliable solution for construction projects of all sizes. With their strength, durability, and flexibility, these beams have become a popular choice for builders and contractors around the world. And with companies like {} offering high-quality C Purlins and expert support, it's easier than ever for construction teams to find the perfect solution for their specific needs. Whether it's for roofing, wall cladding, or structural support, C Purlins are sure to continue making a significant impact on the construction industry for many years to come.

High-Quality Floor Production Roll Forming Machine for Efficient Manufacturing

Floor Production Roll Forming Machine: Revolutionizing the Manufacturing IndustryIn the competitive world of manufacturing, efficiency and quality are paramount. Manufacturers are constantly seeking state-of-the-art machinery and equipment to streamline their production processes and improve the overall quality of their products. With this in mind, the industry leader in roll forming machine technology, {Company Name}, is proud to introduce its latest innovation - the Floor Production Roll Forming Machine. This cutting-edge machine is set to revolutionize the production of floor panels, offering unparalleled precision, speed, and reliability.The Floor Production Roll Forming Machine is designed to meet the demands of modern manufacturing, offering a range of features that set it apart from traditional roll forming machines. With its advanced technology and innovative design, this machine is capable of producing high-quality floor panels with exceptional speed and accuracy. Its precision-engineered rollers and cutting tools ensure that each panel is produced to exact specifications, with minimal wastage and defects. This level of precision is essential for manufacturers seeking to meet the stringent quality standards of today's market.One of the key advantages of the Floor Production Roll Forming Machine is its versatility. Whether producing standard floor panels or custom-designed components, this machine is capable of handling a wide range of materials, including steel, aluminum, and other alloys. This flexibility makes it an invaluable asset for manufacturers looking to diversify their product range and meet the unique specifications of their clients. In addition, the machine can be easily reconfigured and adapted to accommodate different panel sizes and designs, further enhancing its versatility.The Floor Production Roll Forming Machine is also renowned for its speed and efficiency. Its high-speed production capabilities enable manufacturers to significantly increase their output, reducing the time and resources required to produce floor panels. This improved efficiency not only reduces production costs but also allows manufacturers to meet tight deadlines and satisfy the demands of their clients. Furthermore, the machine's automated operation minimizes the need for manual intervention, further optimizing the production process and reducing the risk of human error.In addition to its technical features, the Floor Production Roll Forming Machine is backed by {Company Name}'s renowned expertise and support. With years of experience in roll forming technology, the company is dedicated to providing comprehensive customer support, including installation, training, and ongoing maintenance services. This ensures that manufacturers can fully optimize the capabilities of the machine and maximize their return on investment. Furthermore, {Company Name}'s commitment to innovation and continuous improvement means that the machine is regularly updated with the latest advancements in technology, keeping it at the forefront of roll forming innovation.The introduction of the Floor Production Roll Forming Machine marks a significant milestone for {Company Name}, reinforcing its position as a leading provider of roll forming technology. With its state-of-the-art features, versatility, and exceptional performance, this machine is set to transform the manufacturing industry, empowering manufacturers to produce high-quality floor panels with unprecedented speed and precision. As the demands of the market continue to evolve, {Company Name} remains committed to driving innovation and delivering cutting-edge solutions that empower manufacturers to succeed in a competitive industry.

High-Quality Automatic Wire Cut To Length Machine for Efficient Cutting

Precision Machinery Co., Ltd. is proud to announce the release of their latest innovation, the Automatic Wire Cut To Length Machine. This cutting-edge machine is designed to streamline and optimize the wire cutting process, providing unparalleled precision and efficiency in wire length cutting for various industrial applications.The newly developed Automatic Wire Cut To Length Machine is equipped with advanced technology and features that set it apart from traditional wire cutting machines. With its high-speed cutting capability and precise length control, this machine is able to cut multiple wires with different lengths in a single operation, saving time and increasing productivity for businesses. Additionally, the machine's user-friendly interface and programmable settings make it simple for operators to set up and adjust cutting parameters, reducing the risk of human error and ensuring consistent results.The Automatic Wire Cut To Length Machine is also designed to accommodate a wide range of wire diameters, making it a versatile solution for businesses that work with various types of wire. This flexibility allows companies to streamline their wire cutting operations and minimize the need for multiple machines, ultimately reducing costs and increasing efficiency.In addition to its cutting capabilities, the Automatic Wire Cut To Length Machine also offers a compact and durable design, making it suitable for use in various industrial settings. The machine's robust construction and high-quality components ensure reliable performance and longevity, allowing businesses to invest in a solution that will continue to deliver exceptional results for years to come.As a leading manufacturer of precision machinery, Precision Machinery Co., Ltd. has a long-standing reputation for delivering high-quality, innovative solutions to meet the evolving needs of the industry. With a focus on research and development, the company is committed to staying ahead of the curve and continuously improving its products to provide customers with the best possible solutions for their wire cutting needs."We are thrilled to introduce the Automatic Wire Cut To Length Machine to the market," said Mr. Zhang, the CEO of Precision Machinery Co., Ltd. "This machine represents the culmination of our dedication to innovation and excellence in precision machinery technology. We believe that it will revolutionize the wire cutting process for businesses, providing them with a reliable and efficient solution that will ultimately contribute to their success."Precision Machinery Co., Ltd. is dedicated to providing top-notch customer service and technical support to ensure that businesses can integrate the Automatic Wire Cut To Length Machine seamlessly into their operations. From initial installation and training to ongoing maintenance and support, the company is committed to helping its customers maximize the potential of this cutting-edge machine.The Automatic Wire Cut To Length Machine is now available for purchase, and Precision Machinery Co., Ltd. is excited to work with businesses to tailor the solution to their specific wire cutting needs. With its cutting-edge technology, precision performance, and versatile capabilities, this machine is poised to become an indispensable tool for businesses looking to optimize their wire cutting operations and drive greater efficiency and productivity.In conclusion, the release of the Automatic Wire Cut To Length Machine underscores Precision Machinery Co., Ltd.'s commitment to delivering cutting-edge solutions that empower businesses to thrive in a competitive market. With its advanced technology, unparalleled precision, and user-friendly design, this machine is set to revolutionize the wire cutting process, providing businesses with a reliable and efficient solution to meet their wire cutting needs.

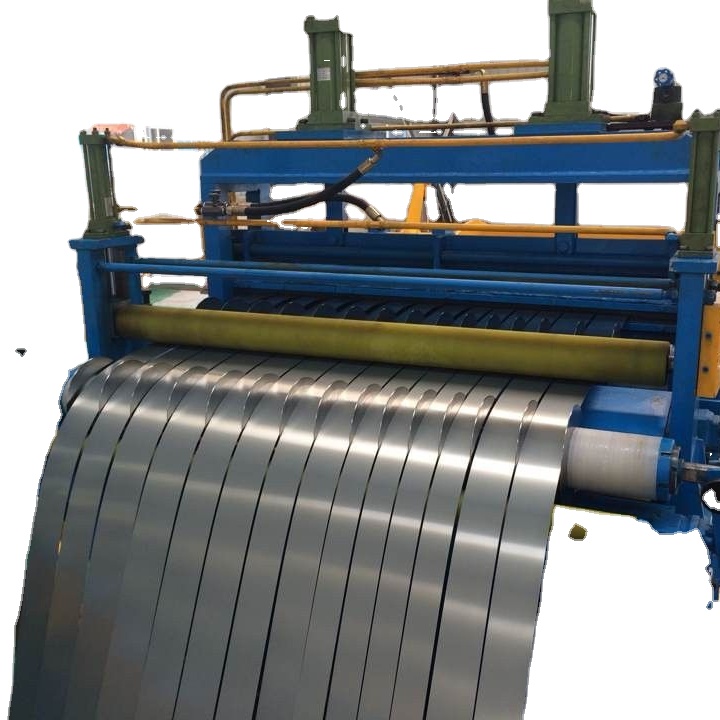

High-quality Slitting Line for CR Metal Processing

Cr Slitting Line, a cutting-edge new technology for sheet metal processing, is set to revolutionize the manufacturing industry. With its advanced features and efficient operation, this innovative equipment is already making waves in the market.The Cr Slitting Line is designed and manufactured by a leading company in the field of metal processing equipment. This company has a strong reputation for delivering high-quality, reliable and cost-effective solutions to its customers. With years of experience and expertise in the industry, the company has continuously pushed the boundaries of innovation to meet the evolving needs of its clients.The introduction of the Cr Slitting Line is a significant milestone for the company and for the manufacturing industry as a whole. This state-of-the-art equipment is designed to streamline the process of slitting metal sheets, making it faster, more accurate and highly efficient. Its cutting-edge technology and precision engineering ensure superior performance and consistent results, setting a new benchmark in the industry.One of the key features of the Cr Slitting Line is its ability to handle a wide range of materials and thicknesses, making it a versatile solution for various applications. Whether it's stainless steel, aluminum, carbon steel or other types of metal, this equipment can efficiently process them with ease. Its flexibility and adaptability make it an ideal choice for manufacturers looking to expand their capabilities and improve their production efficiency.Furthermore, the Cr Slitting Line is equipped with advanced automation and control systems, ensuring optimal performance and ease of operation. Its intuitive interface and user-friendly controls allow operators to set up and run the equipment with minimal effort, reducing the risk of errors and increasing productivity. This makes it an ideal solution for both small-scale and large-scale manufacturers, offering a competitive advantage in today's fast-paced and competitive market.In addition to its cutting-edge technology, the Cr Slitting Line is also designed with practicality in mind. Its compact footprint and modular design make it easy to integrate into existing production lines, saving valuable floor space and minimizing installation time. Its robust construction and durable components ensure long-term reliability and low maintenance requirements, maximizing uptime and reducing operational costs for manufacturers.The introduction of the Cr Slitting Line has already garnered widespread attention and positive feedback from industry professionals and customers. Its performance and reliability have been put to the test in real-world applications, demonstrating its ability to deliver consistent and high-quality results. As a result, demand for this innovative equipment is on the rise, with manufacturers keen to take advantage of its benefits and stay ahead of the competition.Looking ahead, the company behind the Cr Slitting Line remains committed to pushing the boundaries of innovation and delivering cutting-edge solutions to its customers. Its ongoing investment in research and development, combined with its strong focus on customer satisfaction, positions it as a leading provider of metal processing equipment. As the manufacturing industry continues to evolve, the company is well-positioned to meet the changing needs of its clients and drive the industry forward with its advanced technologies.In conclusion, the introduction of the Cr Slitting Line marks a significant advancement in sheet metal processing technology. With its advanced features, versatile capabilities and exceptional performance, this innovative equipment is set to revolutionize the manufacturing industry. As demand for efficient and reliable metal processing solutions continues to grow, the company behind the Cr Slitting Line is poised to lead the way with its commitment to innovation and customer satisfaction.