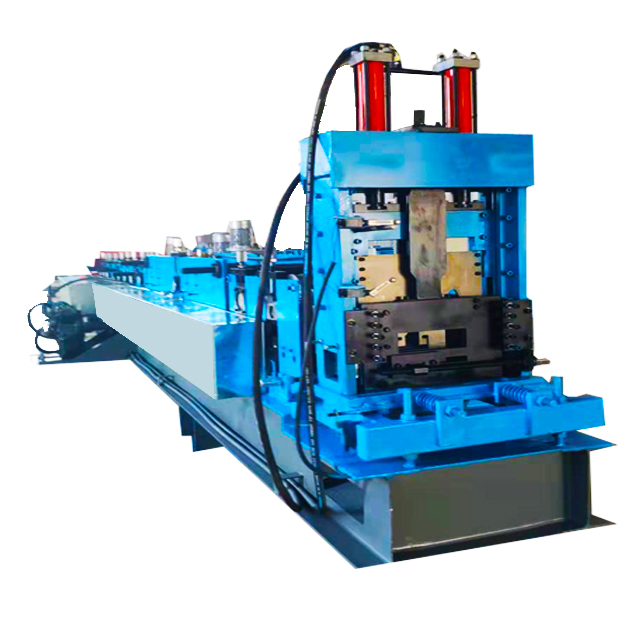

High-Quality Steel Frame Roll Forming Machine for Efficient Production

By:Admin

One company that has been making a significant impact in the roll forming machine industry is {}. They have been leading the way in manufacturing and supplying state-of-the-art roll forming machines for various applications, including steel frame production. Their commitment to innovation and quality has made them a trusted name in the industry.

The Steel Frame Roll Forming Machine produced by {} is designed to meet the specific requirements of the construction industry. It is capable of producing high-quality steel frames with precision and efficiency, making it an ideal choice for construction companies looking to streamline their production processes. The machine is equipped with advanced features such as automatic control systems, quick changeover capabilities, and high-speed production, ensuring superior performance and productivity.

In addition to its impressive technical capabilities, the Steel Frame Roll Forming Machine from {} is also known for its durability and reliability. The machine is built with high-quality materials and components, ensuring long-term performance and low maintenance costs. This makes it a cost-effective investment for construction companies looking to enhance their production capabilities.

Furthermore, {} offers comprehensive support and after-sales services for their Steel Frame Roll Forming Machine, including installation, training, and maintenance. This ensures that their customers can maximize the potential of the machine and achieve the best possible results in their steel frame production.

The company's commitment to customer satisfaction and excellence has earned them a strong reputation in the industry. They work closely with their clients to understand their specific requirements and provide tailored solutions that meet and exceed expectations. Their dedication to quality and innovation has set them apart as a leading provider of roll forming machines for the construction industry.

As the construction industry continues to grow and evolve, the demand for efficient and reliable steel frame production equipment is expected to rise. Companies like {} are well-positioned to meet this demand with their advanced Steel Frame Roll Forming Machine, innovative technologies, and exceptional customer service.

In conclusion, the Steel Frame Roll Forming Machine from {} is a testament to the company's commitment to excellence and innovation. With its advanced features, exceptional performance, and reliable support services, it is no wonder that {} has become a trusted name in the roll forming machine industry. As the construction industry continues to embrace sustainable and cost-effective building solutions, the demand for high-quality steel frame production equipment is expected to grow, and {} is well-prepared to meet this demand with their cutting-edge roll forming machines.

Company News & Blog

Roll Forming and Corrugation Machine for Color Steel Glazed Tile Panels

Title: Innovation in Steel Glazed Tile Panel Roll Forming and Corrugation Machine Revolutionizes Construction IndustryIntroduction:The construction industry has witnessed a remarkable innovation in the form of the Color Steel Glazed Tile Panel Roll Forming and Corrugation Machine. This state-of-the-art machine, developed by a reputable company, is set to transform the way steel glazed tiles are manufactured for roofing applications. With its advanced technology and seamless production process, the machine is poised to revolutionize the industry while offering numerous benefits to construction companies and homeowners alike.Body:1. Industry Challenges and Evolution:The construction industry has always demanded sturdy, efficient, and aesthetically pleasing roofing materials. However, the traditional methods of producing steel glazed tiles posed multiple challenges for manufacturers. These challenges included high production costs, limited design options, and time-consuming installation processes.2. Introducing the Color Steel Glazed Tile Panel Roll Forming and Corrugation Machine:Innovating the market, the Color Steel Glazed Tile Panel Roll Forming and Corrugation Machine eliminates the aforementioned challenges. Developed by a prominent technology company known for its commitment to excellence, this machine streamlines the production process, ensuring cost-effectiveness, flexibility, and enhanced design options.3. Seamless Production Process:The machine's advanced features enable a seamless production process. It is equipped with precision engineering and cutting-edge technology, ensuring high precision in every tile produced. The roll forming and corrugation mechanism guarantees consistent tile dimensions, thus reducing material wastage and costs. With adjustable settings, manufacturers can effortlessly produce a wide range of tile profiles, meeting the diverse design preferences of customers.4. Enhanced Design Options:An exciting aspect of the Color Steel Glazed Tile Panel Roll Forming and Corrugation Machine is its ability to offer an extensive range of design options. Manufacturers can now cater to different architectural styles and market demands. From traditional designs to contemporary aesthetics, this machine facilitates the creation of visually striking steel glazed tiles, making it an attractive choice for builders and homeowners alike.5. Cost-Effective Solution:With its efficient production process and reduced material wastage, the Color Steel Glazed Tile Panel Roll Forming and Corrugation Machine ensures cost-effectiveness for manufacturers. This advantage translates to affordable pricing for consumers without compromising on quality or durability. The machine's productivity significantly increases the overall output, thus enabling companies to meet increased market demands in a shorter timeframe.6. Durability and Longevity:Steel glazed tiles produced using this innovative machine boast exceptional durability and longevity. The use of high-quality materials, combined with precision manufacturing, results in tiles that can withstand harsh weather conditions, UV exposure, and the test of time. This durability ultimately translates into increased customer satisfaction and reduced maintenance costs for homeowners.7. Environmental Sustainability:Recognizing the importance of sustainable practices in the construction industry, the Color Steel Glazed Tile Panel Roll Forming and Corrugation Machine adheres to eco-friendly manufacturing processes. The machine's design ensures minimal energy consumption while reducing the carbon footprint. Additionally, the long lifespan of the tiles reduces the need for frequent replacements, contributing to a more sustainable construction approach.Conclusion:The introduction of the Color Steel Glazed Tile Panel Roll Forming and Corrugation Machine has revolutionized the construction industry. It has addressed the challenges faced by manufacturers, providing them with a cost-effective, flexible, and highly efficient solution to produce high-quality steel glazed tiles. With its seamless production process, enhanced design options, and durability, this innovative machine is set to shape the future of the roofing industry. As construction companies and homeowners continue to seek innovative and sustainable solutions, the machine's technological advancements and environmental benefits position it as a game-changer in the market.

Plastic PVC Colonial Tile/Glazed Roofing Tile Making/Extrusion/Foaming Machine | 2 layers PVC roof tile making machine

Plastic PVC Colonial Tile/Glazed Roofing Tile Making/Extrusion/Foaming Machine: The Perfect Solution for High-Quality PVC TilesJiangsu Acemien Machinery Co., Ltd. (name removed for privacy), a leading manufacturer of plastic extrusion machinery, has launched a state-of-the-art PVC Colonial Tile/Glazed Roofing Tile Making/Extrusion/Foaming Machine that is redefining the standards of quality in the PVC roofing industry. Whether you're a roofing contractor or a manufacturer of PVC roofing tiles, this machine is designed to meet all your needs and exceed your expectations.PVC tiles have gained significant popularity in recent years due to their excellent durability, lightweight, and cost-effectiveness. The PVC Colonial Tile/Glazed Roofing Tile Making/Extrusion/Foaming Machine is a perfect solution for manufacturing high-quality PVC roofing tiles that can withstand harsh weather conditions and provide long-lasting protection for commercial and residential properties.The machine is equipped with advanced technology that allows for the production of two-layer PVC roofing sheets, which are more durable and stronger than single-layer sheets. The top layer is made of PVC, while the bottom layer consists of foamed PVC, making the tiles lighter and more efficient to install than traditional roofing materials.One of the most impressive features of this machine is its speed. The PVC Colonial Tile/Glazed Roofing Tile Making/Extrusion/Foaming Machine is capable of producing up to 6000 tiles per day, which is a significant increase in production capacity compared to traditional tile manufacturing methods. This makes it an ideal choice for large-scale production and roofing contractors looking to complete projects on time and within budget.Moreover, the machine is designed to produce PVC roofing tiles with a variety of colors and textures. The glazed feature of the tiles makes them more attractive and aesthetically pleasing to the eye. This comes in handy in the construction of residential buildings where homeowners are more interested in the visual appeal of their roofs. It also provides a unique selling point for contractors looking to stand out from their competitors.Jiangsu Acemien Machinery Co., Ltd. (name removed for privacy) has an experienced team of engineers and technicians who are always ready to provide technical support and installation services for the PVC Colonial Tile/Glazed Roofing Tile Making/Extrusion/Foaming Machine. The company's commitment to quality is evident in its use of top-quality raw materials and the strict quality control processes that go into every machine produced.In conclusion, if you're in the roofing industry and looking for a reliable and efficient way to manufacture high-quality PVC roofing tiles, the PVC Colonial Tile/Glazed Roofing Tile Making/Extrusion/Foaming Machine is definitely worth considering. It is easy to operate, cost-effective, and produces tiles with excellent durability and strength. Contact Jiangsu Acemien Machinery Co., Ltd. (name removed for privacy) today to learn more about this amazing machine and how it can revolutionize your roofing business.

Precision Coil Cut To Length Machine for Perfect Sheet Metal Cutting

Today, [Company Name] is excited to announce the launch of their new Coil Cut To Length Machine. This state-of-the-art machine is designed to revolutionize the metal processing industry by providing precision cutting and length measurement for a wide range of coil materials.The Coil Cut To Length Machine is the latest addition to [Company Name]'s extensive line of metal processing equipment. With over 20 years of experience in the industry, [Company Name] has earned a reputation for delivering high-quality, innovative solutions for metal fabrication and processing. The introduction of the new Coil Cut To Length Machine further solidifies their commitment to meeting the evolving needs of their customers.This cutting-edge machine offers unparalleled accuracy and efficiency, making it an essential tool for metal processing facilities of all sizes. The Coil Cut To Length Machine is capable of handling a variety of coil materials, including stainless steel, aluminum, copper, and more. Its advanced cutting technology ensures clean, precise cuts, while its length measurement system provides unmatched reliability and consistency.One of the standout features of the Coil Cut To Length Machine is its user-friendly interface. [Company Name] has prioritized ease of use in the design of this machine, ensuring that operators can quickly and effortlessly set up and operate the equipment. This not only enhances productivity but also reduces the potential for errors, ultimately saving time and resources for businesses.Furthermore, the Coil Cut To Length Machine is built to last. [Company Name] has incorporated robust, durable materials and components into the machine's construction, ensuring that it can withstand the rigors of continuous, heavy-duty use. Its longevity and durability make it a sound investment for metal processing facilities looking to optimize their operations for the long term.In addition to its cutting and length measurement capabilities, the Coil Cut To Length Machine also offers flexibility in terms of customization. [Company Name] understands that different businesses have unique requirements, which is why they offer the option to tailor the machine to specific needs. Whether it's adjusting cutting parameters, implementing additional safety features, or integrating the machine into an existing production line, [Company Name] is committed to delivering a solution that perfectly aligns with their customers' needs.The introduction of the Coil Cut To Length Machine represents [Company Name]'s ongoing dedication to innovation and customer satisfaction. By continuously developing and enhancing their product offerings, [Company Name] aims to empower metal processing facilities to achieve new levels of efficiency, productivity, and quality in their operations.In conclusion, the launch of the Coil Cut To Length Machine marks an exciting milestone for [Company Name] and the metal processing industry as a whole. With its cutting-edge technology, user-friendly design, and customizable features, this machine is poised to set a new standard for precision and reliability in coil cutting and length measurement. Businesses can trust [Company Name] to deliver a solution that not only meets but exceeds their expectations, driving success and growth in their metal processing endeavors.

High Speed Metal Roof Panel Roll Forming Machine with Hydraulic Control System: Quality Supplier from China

Jiangyin Dingbo Technology CO., Ltd., a leading provider of roofing panel roll forming machines, has recently introduced their latest innovation - a high speed metal roof panel roll forming machine with hydraulic control system. This advanced machine is designed to efficiently produce metal roof panels with precision and speed, offering superior quality and performance.The 380V 50Hz high speed metal roof panel roll forming machine is equipped with a hydraulic control system, which ensures smooth and accurate operation. The hydraulic control system not only enhances the efficiency of the roll forming process but also enables precise control over the shaping and cutting of the metal sheets. This results in high-quality roof panel production that meets the stringent industry standards.One of the key features of this machine is its ability to produce metal roof panels in various sizes and profiles. The roll forming process involves feeding the metal sheets into the machine, where they are gradually shaped and cut into the desired profile. With the hydraulic control system, the machine can easily adjust its settings to accommodate different panel sizes and profiles, making it highly versatile and adaptable to the specific needs of the customers.Another notable feature of this machine is its high-speed production capability. With its efficient hydraulic control system and advanced technology, the roll forming process is significantly accelerated, allowing for faster production rates. This is especially beneficial for large-scale roofing projects where time is of the essence. The high-speed production not only increases efficiency but also reduces labor costs and enhances overall productivity.In addition to its impressive speed, this metal roof panel roll forming machine also ensures uncompromised quality. The advanced hydraulic control system ensures precise shaping and cutting, resulting in panels with smooth edges, consistent dimensions, and superior finish. The machine is designed to operate with utmost precision and accuracy, eliminating any potential errors or imperfections in the production process. This ensures that the produced roof panels meet the highest quality standards, providing customers with durable and aesthetically pleasing roofing solutions.Furthermore, Jiangyin Dingbo Technology CO., Ltd. emphasizes their commitment to customer satisfaction and reliability. As a reputable supplier of roof panel roll forming machines, the company strives to deliver top-notch products that meet and exceed customer expectations. They offer full support and assistance throughout the entire purchasing process, from consultation and customization to installation and after-sales service.Jiangyin Dingbo Technology CO., Ltd. continues to innovate and enhance their products to meet the evolving needs of the roofing industry. Their high-speed metal roof panel roll forming machine with hydraulic control system is a testament to their dedication to providing cutting-edge solutions that optimize efficiency, productivity, and quality. With this advanced machine, customers can benefit from faster production rates, superior panel quality, and enhanced overall performance.In conclusion, the introduction of the 380V 50Hz high speed metal roof panel roll forming machine with hydraulic control system by Jiangyin Dingbo Technology CO., Ltd. showcases their commitment to technological innovation and customer satisfaction. This advanced machine offers versatility, speed, and unmatched quality in the production of metal roof panels. As a trusted supplier, this company continues to revolutionize the roofing industry with their state-of-the-art solutions that enhance productivity and deliver excellence.

European Standard C Z Purlin Machine with Interchangeable Punching Hole Features

In recent years, the construction industry has undergone a significant transformation. New technologies and innovative solutions have made construction projects more efficient, faster, and, most importantly, safer. One such technology is the C Z Purlin Punching Holes Interchangeable Making Machine (CZPM), which has become extremely popular in Europe.This machine is designed to manufacture C and Z-shaped steel channels that are commonly used in building construction. The CZPM is an automated system that can produce C and Z-shaped purlins of varying sizes and lengths, with pre-punched holes that are interchangeable. This system is not only cost-effective and time-saving but also guarantees precision and accuracy.In the past, purlins were produced using traditional methods that were slow, laborious, and often inaccurate. However, with the advent of the CZPM, purlin production has become smoother and more efficient. The machine can produce purlins with widths ranging from 80mm to 300mm, and heights ranging from 30mm to 100mm, making it possible to cater to a wide range of construction needs.The CZPM is equipped with a punching unit that allows for the creation of holes of varying shapes and sizes, according to the requirements of the construction project. This means that purlins can be produced with holes for wiring, plumbing, and other services, without the need for additional drilling or cutting.Another notable feature of the CZPM is its versatility. The machine can produce purlins made of various materials, including galvanized steel, hot-rolled steel, and aluminum. This flexibility makes it an ideal solution for both small and large-scale construction projects.Furthermore, the CZPM is designed to be user-friendly, with an intuitive interface and easy-to-use controls. The machine requires minimal operator training, and the automated system ensures that the purlins produced are of consistent quality.Many construction companies across Europe have already embraced the CZPM, recognizing its numerous benefits and potential impact on the industry. This technology has revolutionized the way purlins are produced and has made construction projects faster, more accurate, and more cost-effective.One company that has adopted this technology is {company name}, a leading manufacturer of steel building products in Europe. Founded in 2002, the company has been at the forefront of innovative steel solutions, serving a wide range of clients in the construction industry.As a company committed to delivering quality steel products, {company name} recognizes the importance of investing in advanced technologies such as the CZPM. With this machine, the company can produce high-quality purlins that meet the specific needs of each client.In addition, {company name} is known for its commitment to sustainability and environmentally-friendly practices. The CZPM aligns with this core value as it minimizes waste and reduces the carbon footprint associated with purlin production.Over the years, {company name} has established itself as a trusted partner for construction companies across Europe, delivering reliable and high-quality products. As the construction industry continues to evolve, {company name} is committed to remaining at the forefront of innovation and providing innovative steel solutions for its clients.In conclusion, the CZPM is a game-changer for the construction industry, making purlin production faster, more efficient, and more precise. Companies like {company name} are embracing this technology and leveraging its benefits to meet the evolving needs of their clients. As the construction industry continues to grow and evolve, the CZPM will undoubtedly play a vital role in shaping its future.

Increase Production Efficiency and Prevent Film Cracking with Advanced Web Tension Control Systems for Slitting Machines

The Slitting and Cutting Machine: An OverviewWhen it comes to manufacturing materials such as paper, plastic film, or even textiles, the slitting and cutting machine is an essential piece of equipment. These machines are designed to take large rolls of material and cut them down into the desired size and shape, allowing for easier handling and processing.One of the most important aspects of a slitting and cutting machine is its ability to maintain proper tension throughout the process. This is where web tension control systems come into play. These systems help prevent film cracking and other issues that can arise when the tension is not properly controlled.There are several different types of slitting and cutting machines available on the market today. Some are designed for specific materials such as paper or plastic film, while others are more versatile and can handle a variety of materials.One common type of slitting and cutting machine is the rotary shear. This machine uses a set of sharp blades that rotate against a stationary blade, effectively cutting the material as it passes through. The blades can be adjusted to vary the width of the cut, allowing for greater flexibility in production.Another type of slitting and cutting machine is the crush cutter. This machine uses a roller with a dull blade that crushes the material against a stationary blade, effectively cutting it in the desired width. Crush cutters are often used for materials that are more delicate or easily damaged.Regardless of the type of slitting and cutting machine being used, proper maintenance is essential to ensure optimal performance and longevity. Routine inspections and cleaning can help prevent issues from arising, while regular calibration can help ensure that the machine is cutting accurately and efficiently.In conclusion, the slitting and cutting machine is a vital piece of equipment in many manufacturing industries. With the right equipment and maintenance, it can help increase efficiency, reduce waste, and improve the overall quality of the finished product. Ensure to also incorporate web tension control systems to prevent film cracking and other similar issues.

Efficient Roll Forming Machine for Color Steel Glazed Roofing Sheets Unveiled

[Dating], [Geographical Location] - The global construction industry is witnessing a major technological breakthrough as [Company Name], a leading manufacturer of machinery and equipment, introduces its state-of-the-art Color Steel Glazed Roofing Sheet Roll Forming Machine. This innovative product is set to revolutionize the production of glazed roofing sheets, enabling builders and contractors to enhance the durability, aesthetic appeal, and cost-effectiveness of their projects.The Color Steel Glazed Roofing Sheet Roll Forming Machine, designed and manufactured by [Company Name], incorporates cutting-edge technology and premium-quality materials to deliver outstanding performance and unparalleled efficiency. The machine is equipped with advanced automation systems and intelligent controls, ensuring precise and accurate sheet formation. This eliminates human error and reduces production time, thereby enhancing productivity and overall project completion rates.With the global construction industry being increasingly mindful of sustainable practices, the Color Steel Glazed Roofing Sheet Roll Forming Machine offers a sustainable solution. It utilizes recycled materials and minimizes waste generation during the production process. This eco-friendly approach not only aligns with environmental regulations but also positions builders and contractors as responsible industry players, meeting the expectations of environmentally conscious consumers.Additionally, the Color Steel Glazed Roofing Sheet Roll Forming Machine caters to the rising demand for energy-efficient buildings. The machine is engineered to create roofing sheets that effectively reflect heat, reducing the need for excessive cooling measures. This not only lowers energy consumption but also translates into substantial cost savings for building owners. Furthermore, the glazed roofing sheets produced by this machine offer superior insulation, enhancing the overall thermal performance of structures.[Company Name] is renowned for delivering cutting-edge solutions in the construction machinery sector, with a history of successful projects and a growing global client base. The company's commitment to quality and innovation has earned it a reputation as an industry leader. By introducing the Color Steel Glazed Roofing Sheet Roll Forming Machine, [Company Name] reaffirms its dedication to providing market-leading products that meet the evolving needs of the construction industry.The machine's user-friendly interface and streamlined operation make it accessible to both experienced manufacturers and newcomers to the industry. It offers customizable settings and efficient production capabilities, ensuring flexibility and versatility for a wide range of roofing sheet designs. The machine's robust construction and reliable performance guarantee longevity and durability, minimizing maintenance and replacement costs for users.Furthermore, [Company Name]'s dedication to customer satisfaction extends beyond the sale of the Color Steel Glazed Roofing Sheet Roll Forming Machine. The company provides comprehensive training programs and ongoing technical support to ensure users can fully utilize the machine's capabilities. This commitment to empowering its clients with the knowledge and resources required to maximize productivity sets [Company Name] apart from its competitors.As the global construction industry continues to grow and evolve, [Company Name] remains at the forefront of technological advancements. With the introduction of the Color Steel Glazed Roofing Sheet Roll Forming Machine, the company is empowering builders and contractors to construct sustainable, energy-efficient, and visually appealing structures. This groundbreaking product reaffirms [Company Name]'s position as a leading manufacturer of machinery and equipment, committed to driving innovation and improving the construction industry as a whole.In conclusion, the Color Steel Glazed Roofing Sheet Roll Forming Machine introduced by [Company Name] is set to revolutionize the production of glazed roofing sheets, providing builders and contractors with a sustainable, energy-efficient, and cost-effective solution. The machine's cutting-edge technology, eco-friendly approach, and comprehensive customer support make it an essential asset for companies looking to stay ahead in an ever-evolving industry. [Company Name]'s commitment to delivering innovative solutions further cements its reputation as a global leader in the construction machinery sector.

Revolutionary Aluminum Profile Bending Machine Unveiled in Latest News

Title: Revolutionary CNC Aluminum Profile Bending Machine Transforming the Manufacturing IndustryIntroduction:In a rapidly evolving manufacturing industry, technological advancements have always played a crucial role in enhancing efficiency and precision. A groundbreaking solution has emerged in the form of a CNC Aluminum Profile Bending Machine, which is revolutionizing the way aluminum profiles are bent and shaped. By seamlessly merging technology and precision engineering, this innovative machine promises to deliver unprecedented results in terms of accuracy, speed, and versatility.Technological Features:The CNC Aluminum Profile Bending Machine is equipped with state-of-the-art computer numerical control (CNC) technology, allowing for precise control and automation of the bending process. It utilizes advanced algorithms to calculate the required bending angles, eliminating human errors and ensuring consistent quality.The machine is designed to accommodate a wide range of aluminum profiles, from simple extrusions to complex designs, catering to the diverse needs of industries such as architecture, construction, automotive, and aerospace. Its adjustable mandrel enables the bending of profiles in various sizes and shapes, offering infinite possibilities for customization.Furthermore, the CNC Aluminum Profile Bending Machine boasts a user-friendly interface, making it accessible to operators with varying levels of expertise. The intuitive controls allow for easy programming and quick set-up, reducing downtime and enhancing overall productivity.Benefits and Advantages:The introduction of this cutting-edge machine brings several benefits to the manufacturing industry, including:1. Enhanced Precision: The CNC technology ensures consistent results, minimizing deviations and errors. The machine's ability to bend aluminum profiles with exceptional accuracy and repeatability guarantees a high-quality end product.2. Improved Efficiency: By automating the bending process, the machine significantly reduces production time. Its high-speed operation enables rapid bending without compromising precision, making it ideal for large-scale manufacturing.3. Cost Savings: The CNC Aluminum Profile Bending Machine optimizes material usage, reducing waste. Its efficiency also translates into lower labor costs and increased production capacity, ultimately contributing to enhanced profitability.4. Versatility: The machine accommodates various aluminum profiles, allowing manufacturers to explore new design possibilities. It empowers engineers and designers to create complex and intricate shapes with ease, thus expanding the scope of their creative capabilities.5. Safety and Reliability: With advanced safety features and robust construction, the CNC Aluminum Profile Bending Machine prioritizes operator well-being. Its reliability ensures minimal maintenance requirements, leading to minimal downtime.Company's Commitment to Innovation:In keeping with its commitment to innovation and customer satisfaction, the company responsible for the CNC Aluminum Profile Bending Machine continually invests in research and development. It employs a team of highly skilled engineers and technicians dedicated to enhancing the machine's capabilities and exploring new possibilities for aluminum profile bending.The company possesses a solid track record, having successfully introduced several revolutionary machines to the manufacturing industry. Its relentless pursuit of excellence and customer-centric approach have earned it a reputation as a leading innovator in the field.Conclusion:The introduction of the CNC Aluminum Profile Bending Machine marks a significant technological breakthrough in the manufacturing industry. Its advanced CNC technology, precision engineering, and versatility empower manufacturers to achieve unprecedented precision, efficiency, and design possibilities. With its numerous benefits and the company's commitment to innovation, this machine is set to redefine the aluminum profile bending process and contribute to the advancement of the manufacturing sector as a whole.

Discover the Art of Aluminium Profile Bending for Enhanced Applications

Aluminium Profile Bending Brings a New Era of ManufacturingThe recent years have seen a drastic rise in the popularity and use of aluminium profiles. They are being extensively used in a diverse range of industries such as automobile, construction, and aerospace. The reason behind the emergence of this trend is the unparalleled advantages that come with using these profiles. They offer high strength, lightness, and durability. They are also easy to manufacture and mould. However, the real challenge arises when it comes to moulding these profiles into the desired shapes and sizes. This is where Aluminium Profile Bending has brought about a revolution in the manufacturing industry.Aluminium Profile Bending (APB), a technique that has been developed by a leading company in the manufacturing industry, has revolutionized the way aluminium profiles are moulded. With the introduction of this technique, manufacturers can now bend the profiles into any desired shape and size. The shapes can vary from simple curves to complex designs. This technique is particularly useful for manufacturing aluminum profiles for the construction industry that require intricate shapes, making it impossible to produce using conventional techniques.Advanced technology and expertise are required to carry out the bending of aluminum profiles, which is where the company that developed APB excels. They have a team of immensely skilled technicians who use cutting-edge equipment to ensure precision in the bending of the profiles. Using this technique, the team can accurately bend even the most intricate shapes.The advantages of APB are numerous. Firstly, it offers a high level of precision which allows for the creation of complex and intricate designs. Secondly, the technique is much more cost-effective, as it reduces the waste material that is produced during the conventional manufacturing process. APB also eliminates the need for additional manufacturing processes that might be required to achieve the desired shape, which again translates to cost savings. Additionally, it provides excellent finish quality and surface appearance, making it ideal for high-quality products such as those required in the automotive and aerospace industries.The use of APB is not limited to aluminum profiles only. The technique can also be used with other metals, including copper, brass, and stainless steel. This versatility means that manufacturers now have even more options when it comes to the manufacturing of complex shapes and designs.The development of APB has had a significant impact on the manufacturing industry. It has not only reduced production costs but has also opened up new possibilities for manufacturers. With this technique, they can now produce complex and intricate designs that were previously not possible.With the increasing demand for aluminium profiles, it is evident that the manufacturing industry needs to embrace new technologies and techniques to stay ahead of the competition. The introduction of Aluminium Profile Bending has provided manufacturers with a game-changing solution to their manufacturing problems. As new and better technologies continue to emerge, it is essential that manufacturers keep an eye out for innovations that could improve their manufacturing processes.In conclusion, Aluminium Profile Bending has revolutionized the way aluminium profiles are moulded, giving manufacturers the ability to produce complex and intricate designs accurately. The technique offers a high level of precision, reduces production costs, and eliminates the need for additional manufacturing processes, making it ideal for a diverse range of industries. As manufacturing technologies continue to evolve, it is essential for manufacturers to stay up-to-date with the latest innovations and techniques to remain competitive in the industry.

Top-Quality Metal Roll Forming Machine for Sale with Roof Panel Roll Forming Machine

Metal Roll Forming Machine for Sale: A Boon for the Construction IndustryThe construction industry is witnessing rapid growth and development, and with it, the demand for efficient and high-quality machinery. One such piece of equipment that has become indispensable in the construction sector is the metal roll forming machine. Known for its versatility, reliability, and precision, this machine has revolutionized the way metal panels and profiles are created. It offers a cost-effective solution for constructing roofs, walls, and other structural components.In line with the growing demand, Metal Roll Forming Machine, a renowned industry player, is now offering their top-of-the-line metal roll forming machines for sale.Metal roll forming machines are capable of shaping various metals, such as steel, aluminum, and galvanized iron, into customized profiles of different shapes and sizes. These machines utilize a continuous bending process, wherein the metal strip is fed through a series of rollers, gradually shaping it into the desired profile. The resulting products offer exceptional structural strength, durability, and aesthetics.Metal Roll Forming Machine offers a wide range of machines to cater to the diverse needs of the construction industry. Their roof panel roll forming machine is particularly sought-after due to its ability to efficiently produce high-quality roof panels. These panels not only enhance the visual appeal of buildings but also provide superior protection against adverse weather conditions.One of the key features that set Metal Roll Forming Machine apart is its commitment to quality. The machines they offer are manufactured using state-of-the-art technology, ensuring unrivaled precision and performance. These machines undergo rigorous testing and quality checks to meet international standards and provide customers with reliable and long-lasting solutions.Metal Roll Forming Machine prides itself on providing excellent customer service. Their team of experienced professionals assists clients in selecting the most suitable machine for their specific requirements. Offering comprehensive after-sales support, they ensure that customers receive training and technical assistance to maximize the utilization of the machines.Moreover, Metal Roll Forming Machine understands the importance of sustainability and the need to minimize the environmental impact of their operations. Their machines are designed to optimize energy efficiency while minimizing material waste during the roll forming process. By adopting eco-friendly practices, Metal Roll Forming Machine is leading the way towards a greener and more sustainable future in the construction industry.To further facilitate customer convenience, Metal Roll Forming Machine now offers their machines for sale online. The user-friendly interface of their website allows customers to browse through their product catalog, compare specifications, and make informed purchasing decisions. With just a few clicks, customers can now own a top-quality metal roll forming machine to meet their construction needs.In conclusion, the availability of metal roll forming machines for sale by Metal Roll Forming Machine comes as a boon for the construction industry. These machines provide an efficient and cost-effective solution for producing high-quality metal profiles and panels. With their commitment to quality, customer service, and sustainability, Metal Roll Forming Machine has established itself as a trusted and reliable provider of metal roll forming machines. By investing in their machines, construction companies can elevate their productivity, efficiency, and profitability, ultimately contributing to the growth and advancement of the construction sector.