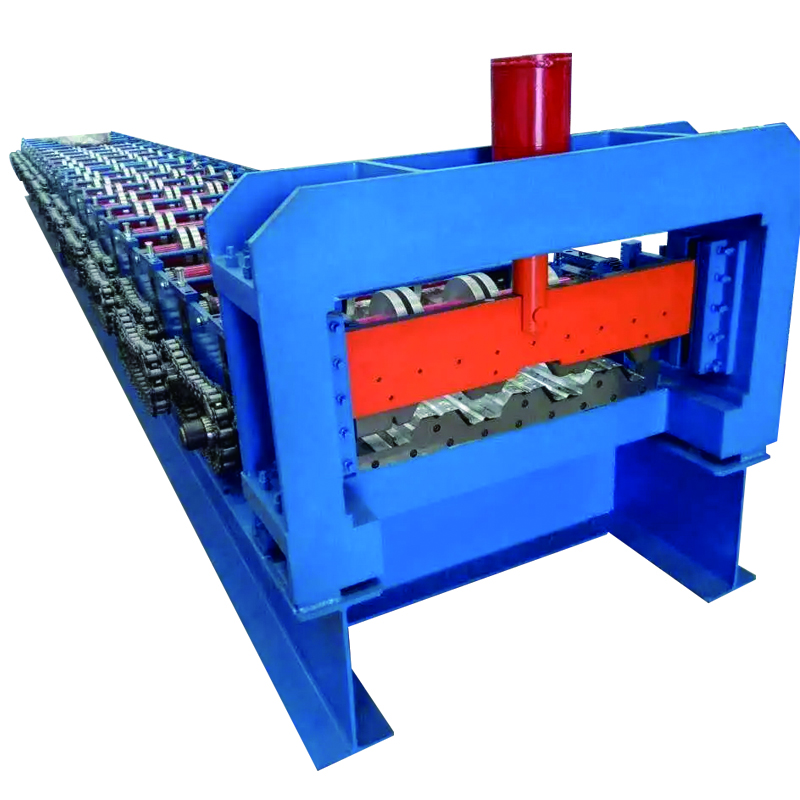

High-Quality Steel Tile Roll Forming Machine for Efficient Roofing Projects

By:Admin

{Company Name}, a renowned manufacturer of {industry or product}, has recently introduced a cutting-edge Color Steel Tile Roll Forming Machine that is set to revolutionize the roofing industry. This state-of-the-art machine is designed to efficiently produce high-quality color steel tiles, catering to the growing demand for durable and aesthetically appealing roofing solutions.

The Color Steel Tile Roll Forming Machine utilizes advanced technology to seamlessly transform raw materials into precision-engineered color steel tiles. With its ability to produce a wide range of tile profiles and sizes, this machine offers unparalleled flexibility and versatility to meet the diverse needs of the roofing market. Whether it’s for residential, commercial, or industrial applications, the Color Steel Tile Roll Forming Machine is capable of delivering exceptional results.

One of the key features of this innovative machine is its high level of automation, significantly reducing the need for manual intervention and streamlining the production process. This not only enhances efficiency but also ensures consistent quality and accuracy in the finished products. Additionally, the machine is equipped with enhanced safety features, making it a reliable and user-friendly solution for manufacturers.

In line with {Company Name}'s commitment to sustainability, the Color Steel Tile Roll Forming Machine is designed to optimize material usage and minimize waste, contributing to a more eco-friendly manufacturing process. By minimizing the environmental footprint of production, {Company Name} is contributing to the global effort towards sustainable and responsible manufacturing practices.

Furthermore, the introduction of this advanced machine is expected to have a positive impact on the roofing industry as a whole. With its ability to streamline production and deliver superior quality color steel tiles, manufacturers can meet the increasing demand for durable and visually appealing roofing solutions. This, in turn, will benefit consumers looking for reliable and long-lasting roofing options for their properties.

The Color Steel Tile Roll Forming Machine is the latest addition to {Company Name}'s extensive portfolio of innovative manufacturing solutions. With a proven track record of delivering cutting-edge machinery to various industries, {Company Name} is poised to set new standards with the introduction of this revolutionary machine. By leveraging their expertise and technological capabilities, {Company Name} is continuously raising the bar for efficiency, quality, and sustainability in the manufacturing sector.

In response to the growing demand for advanced manufacturing solutions, {Company Name} has also expanded its support and service network to ensure that customers receive the necessary assistance and expertise to maximize the performance of the Color Steel Tile Roll Forming Machine. This commitment to customer satisfaction further reinforces {Company Name}'s position as a trusted partner for businesses seeking to elevate their manufacturing capabilities.

As the roofing industry continues to evolve, the introduction of the Color Steel Tile Roll Forming Machine underscores {Company Name}'s dedication to innovation and progress. By providing manufacturers with a cutting-edge solution to produce high-quality color steel tiles, {Company Name} is empowering the industry to meet the demands of modern construction and architectural trends.

In conclusion, the Color Steel Tile Roll Forming Machine represents a significant milestone in the roofing industry, offering a technologically advanced and sustainable solution for the production of color steel tiles. {Company Name}'s commitment to excellence and its ability to deliver innovative manufacturing solutions sets a new benchmark for the industry, and the introduction of this machine is set to have a transformative impact on manufacturers and consumers alike.

Company News & Blog

High-Quality Light Gauge Forming Machine for Precision Metal Fabrication

The use of light gauge forming machines has been revolutionizing the manufacturing industry by providing efficient and precise metal forming capabilities. These state-of-the-art machines are designed to handle a wide range of materials while ensuring high-quality and accurate production. With the advancements made in technology and engineering, the light gauge forming machines have become an integral part of many industries, including construction, automotive, and aerospace.One of the leading companies in the field of light gauge forming machines is the {}, a renowned manufacturer with a strong commitment to innovation and excellence. The company has been a key player in the industry, providing cutting-edge solutions to its clients and continuously pushing the boundaries of what is possible in metal forming technology.With a history of more than 20 years, the {} has established itself as a reliable and trusted partner for businesses looking to enhance their manufacturing capabilities. The company's dedication to research and development has resulted in the creation of some of the most advanced and efficient light gauge forming machines on the market.The {} prides itself on its ability to customize its machines to meet the specific needs of its clients. Whether it is a small-scale project or a large-scale production, the company's team of experts works closely with its clients to understand their requirements and deliver tailor-made solutions that exceed expectations.The company's extensive range of light gauge forming machines includes roll forming machines, tube mills, and steel framing machines, all of which are designed to deliver exceptional precision and efficiency. These machines are capable of handling a wide variety of materials, including steel, aluminum, and other metal alloys, making them an ideal choice for a diverse range of applications.In addition to its cutting-edge machinery, the {} also offers comprehensive after-sales support and maintenance services to ensure that its clients' operations run smoothly and efficiently. The company's team of skilled technicians and engineers are readily available to provide technical assistance, training, and spare parts, as well as to address any issues that may arise.The {}'s commitment to quality and customer satisfaction has earned it a solid reputation in the industry, with a strong client base that includes some of the leading companies in various sectors. The company's track record of delivering reliable and innovative solutions has made it a go-to choice for businesses looking to invest in top-of-the-line light gauge forming machines.Looking ahead, the {} continues to invest in research and development to further enhance its products and stay ahead of the curve in an ever-evolving industry. The company's dedication to innovation and excellence positions it as a driving force in the advancement of metal forming technology, making it a valuable partner for businesses seeking to elevate their manufacturing capabilities.In conclusion, the use of light gauge forming machines has become a game-changer in the manufacturing industry, and the {} is at the forefront of this revolution. With its cutting-edge technology, customized solutions, and commitment to excellence, the company is well-equipped to meet the evolving needs of its clients and lead the way in metal forming technology.

Efficient Roll Forming Machine for Light Gauge Steel Keel Production

Title: Revolutionary Light Gauge Steel Keel Roll Forming Machine Revolutionizes Construction IndustryIntroduction: [Company Name], an industry-leading manufacturer of construction machinery, has recently unveiled its latest innovation, a groundbreaking Light Gauge Steel Keel Roll Forming Machine. This state-of-the-art machine is set to revolutionize the construction industry by significantly increasing efficiency and reducing labor costs in the production of light gauge steel frames and structures. With its unique features and advanced technology, the Light Gauge Steel Keel Roll Forming Machine is poised to become an indispensable tool for modern construction projects.Paragraph 1: Traditional methods of constructing light gauge steel structures can be labor-intensive and time-consuming. However, the Light Gauge Steel Keel Roll Forming Machine eliminates these barriers by automating the process with precision and speed. This advanced technology enables the production of consistent and high-quality steel frames, significantly reducing waste material and time spent on manual labor.Paragraph 2: The Light Gauge Steel Keel Roll Forming Machine operates on the principles of roll forming, which involves feeding a coil of flat steel through a series of rollers, gradually shaping it into the desired cross-sectional profile. With precise control and selection of raw materials, this machine provides highly accurate and uniform results, ensuring the structural integrity of the final products.Paragraph 3: The Light Gauge Steel Keel Roll Forming Machine boasts an array of features that set it apart from traditional methods. Its automated nature allows for continuous production without the need for manual intervention. Additionally, its modular design and customizable options cater to various project requirements, offering flexibility and adaptability.Paragraph 4: The Light Gauge Steel Keel Roll Forming Machine incorporates cutting-edge technology, including computer numerical control (CNC) systems. This automation ensures precise measurements and consistent panel lengths, minimizing errors. The machine's user-friendly interface enables easy operation and adjustment of parameters, making it accessible to both experienced professionals and newcomers to the industry.Paragraph 5: [Company Name] has invested significant resources into research and development to create a machine that not only enhances productivity but also prioritizes safety. The Light Gauge Steel Keel Roll Forming Machine is equipped with safety features, such as emergency stop buttons and protective barriers, ensuring a secure working environment for operators.Paragraph 6: The introduction of the Light Gauge Steel Keel Roll Forming Machine is expected to have far-reaching implications for the construction industry. Its efficiency and affordability make it an attractive option for large-scale projects, such as residential buildings, commercial complexes, and industrial facilities. The reduced labor costs associated with this machine represent a significant advantage in today's competitive construction market.Paragraph 7: The Light Gauge Steel Keel Roll Forming Machine aligns with global sustainability goals, as it promotes the use of lightweight steel structures that offer energy efficiency, durability, and recyclability. By minimizing waste and optimizing material utilization, this machine supports environmentally friendly construction practices.Conclusion: With its groundbreaking technology, the Light Gauge Steel Keel Roll Forming Machine is set to redefine the construction industry. By streamlining the production process, increasing precision, and reducing labor costs, this cutting-edge machine will undoubtedly play a crucial role in the development of sustainable and efficient structures worldwide. [Company Name]'s commitment to innovation has once again propelled the industry forward, offering a transformative solution for the construction sector.

High-quality Glazed Tile Roof Panel Roll Former for Color Steel Roofing

Color Steel Glazed Tile Roof Panel Roll Former Revolutionizes Roofing IndustryThe roofing industry has experienced a revolutionary change with the introduction of the Color Steel Glazed Tile Roof Panel Roll Former, a state-of-the-art machine that has quickly gained attention for its advanced technology and innovative approach to roof panel production. This cutting-edge equipment is setting new industry standards and has been well received by clients and professionals in the construction and architectural sectors.The Color Steel Glazed Tile Roof Panel Roll Former is the product of extensive research and development by a leading machinery manufacturer, {company introduction}. With a commitment to excellence and a focus on meeting the evolving needs of the market, {company introduction} has positioned itself as a pioneer in the development of advanced machinery for the construction industry.The Color Steel Glazed Tile Roof Panel Roll Former offers a range of features that set it apart from traditional roof panel roll forming machines. One of the most notable aspects of this equipment is its ability to produce glazed tile roof panels with exceptional precision and efficiency. This is made possible by the machine's advanced technology, which allows for seamless and consistent production of high-quality roof panels.In addition to its superior performance, the Color Steel Glazed Tile Roof Panel Roll Former is also designed with user-friendly features that enhance its practicality and ease of use. The machine is equipped with intuitive controls and a streamlined interface, making it accessible to operators with varying levels of experience. This has been a significant factor in its widespread adoption across different construction and roofing companies.Furthermore, the Color Steel Glazed Tile Roof Panel Roll Former is engineered with a focus on durability and reliability. Its robust construction and high-quality materials ensure that it can withstand the demands of heavy-duty usage, making it a long-term investment for businesses in the construction industry. This has resonated with companies looking for machinery that can deliver consistent performance and minimize downtime.The introduction of the Color Steel Glazed Tile Roof Panel Roll Former has had a profound impact on the roofing industry. Not only has it streamlined the production process for roof panels, but it has also raised the bar for the quality and efficiency of these essential building components. As a result, construction projects can benefit from the enhanced performance and durability of glazed tile roof panels, contributing to the overall integrity of structures.{company introduction} has played a pivotal role in spearheading this transformation in the roofing industry. With a commitment to innovation and a deep understanding of the market, the company has been able to develop machinery that meets the evolving needs of construction and architectural professionals. This dedication to delivering cutting-edge solutions has solidified {company introduction}'s position as a leader in the development of advanced machinery for the construction industry.The reception of the Color Steel Glazed Tile Roof Panel Roll Former has been overwhelmingly positive, with clients and industry professionals praising its performance, reliability, and user-friendly design. As more companies recognize the benefits of this state-of-the-art equipment, its influence on the roofing industry is expected to continue growing, setting new standards for the production of roof panels and contributing to the overall advancement of construction practices.

High Speed Light Steel Keel Roll Forming Machine: Efficient Building Material Solution

, Stud Truss Roll Forming Machine, High Speed Roll Forming Machine, Metal Stud Roll Forming Machine.With the advancement in technology, the construction industry also has advanced equipment and machines to produce high-quality materials. One such essential machine is the stud truss high speed light steel keel roll forming machine. This machine is used to make light keel studs and trusses that are used for constructing the roof and walls of a building. It is known for its efficiency, reliability, and high speed.The light steel keel machine is designed differently based on the model and the customer's specifications. The metal stud roll-forming machine produces rolls of metal that are used as roofing or wall material in places such as factories, warehouses, garages, gymnasiums, and exhibition centers. These products are popular because of their lightweight, high strength, and easy installation.One of the many advantages of using a stud truss high speed light steel keel roll forming machine is its speed. The machine is designed to produce large quantities of metal strips rapidly, therefore, allowing for mass production, this significantly reduces the time taken to construct a building. The machine is also straightforward to operate, reducing the need for large labor forces on construction sites.Another benefit of using the light steel keel machine is the quality of the material produced; the metal strips produced are of a consistent thickness, length, and size, eliminating the possibility of defects that could lead to the loss of material. The machines are also low-maintenance as they are designed to be robust and long-lasting, thus reducing the operators' servicing costs.In conclusion, the stud truss high speed light steel keel roll forming machine is a must-have piece of equipment in the construction industry. It's easy operation, and high-speed production makes it a favorite among operators globally. The machine's accuracy and quality of the material produced make it an indispensable tool in the construction of buildings. For cost-effective construction materials, the light steel keel machine is the way to go. So if you are in the construction industry, it's essential to invest in a high-quality stud truss roll forming machine that will provide the best results.

Metal Step Tile Forming Machine with Filming Capabilities

Metal Step Tile With Filming Forming Machine Showcases Cutting-Edge TechnologyIn the world of construction and manufacturing, technological advancements are constantly changing the landscape of the industry. One such advancement is the introduction of the Metal Step Tile With Filming Forming Machine, a revolutionary piece of equipment that is poised to revolutionize the way metal step tiles are produced.The Metal Step Tile With Filming Forming Machine is a product of cutting-edge technology and innovation. It is designed to streamline the process of manufacturing metal step tiles, in order to make it more efficient and cost-effective. The machine is equipped with state-of-the-art features that enable it to produce high-quality metal step tiles with precision and consistency.One of the key features of the Metal Step Tile With Filming Forming Machine is its ability to produce metal step tiles with a variety of profiles and dimensions. This flexibility allows manufacturers to cater to a wide range of customer needs and preferences, and to produce custom metal step tiles that are tailored to specific project requirements.Another notable feature of the Metal Step Tile With Filming Forming Machine is its use of filming technology, which allows for the application of protective coatings to the metal step tiles during the production process. This not only enhances the aesthetic appeal of the tiles, but also provides a layer of protection against corrosion and wear, making them more durable and long-lasting.The company behind this innovative piece of technology, {}, has established itself as a leader in the field of manufacturing equipment and machinery. With a strong focus on research and development, the company has been able to stay at the forefront of technological advancements in the industry, and has earned a reputation for producing high-quality and reliable products.{} has a team of highly skilled engineers and technicians who are dedicated to pushing the boundaries of innovation, and who work tirelessly to develop new and improved manufacturing solutions. The Metal Step Tile With Filming Forming Machine is a testament to the company's commitment to excellence and its ability to deliver cutting-edge technology to its customers.The introduction of the Metal Step Tile With Filming Forming Machine has generated a significant amount of excitement and interest within the construction and manufacturing industries. Manufacturers are eager to take advantage of the machine's capabilities in order to improve their production processes and to enhance the quality of their metal step tiles.In addition to its technological advantages, the Metal Step Tile With Filming Forming Machine is also being lauded for its potential to reduce production costs and increase efficiency. By streamlining the manufacturing process and minimizing waste, the machine allows manufacturers to maximize their productivity and to operate more sustainably.The Metal Step Tile With Filming Forming Machine is already making waves in the industry, and it is expected to have a significant impact on the way metal step tiles are produced in the future. As technology continues to advance, it is innovations like this that will shape the future of manufacturing, and contribute to the ongoing evolution of the construction and building materials industries.In conclusion, the Metal Step Tile With Filming Forming Machine represents a major advancement in the field of manufacturing technology. With its cutting-edge features and capabilities, this machine has the potential to revolutionize the way metal step tiles are produced, and to drive significant improvements in the efficiency, quality, and sustainability of the manufacturing process. As the construction and manufacturing industries continue to evolve, the Metal Step Tile With Filming Forming Machine stands as a testament to the power of innovation and the potential for technological advancements to shape the future of the industry.

High-Quality Machinery for Making Glazed Roof Tiles at an Affordable Price

[A generic image of a tile making machinery can be added here]In today's fast-paced world, it's crucial for businesses to stay ahead of the game by utilizing the latest technology and machinery. One industry that has seen significant advancements in recent years is the construction industry. With the demand for sustainable and durable building materials on the rise, companies are constantly innovating and improving their manufacturing processes. One such company that is leading the way in this regard is {Company Name}.{Company Name} is a renowned manufacturer of construction machinery and equipment. With a strong focus on innovation and quality, the company has earned a reputation for delivering cutting-edge solutions to its customers. One of its flagship products is the Glazed Roof Tile Making Machinery.The Glazed Roof Tile Making Machinery developed by {Company Name} is a state-of-the-art solution for manufacturing high-quality glazed roof tiles. The machinery is designed to streamline the production process, ensuring efficiency and precision at every stage. With its advanced technology and superior craftsmanship, the machinery is capable of producing a wide range of glazed roof tiles with varying designs and specifications.The key features of the Glazed Roof Tile Making Machinery include its automated operation, high production capacity, and energy efficiency. The machinery is equipped with advanced sensors and control systems that allow for seamless operation without any manual intervention. This not only reduces the labor costs but also ensures consistent output quality. Additionally, the machinery is designed to maximize productivity, with a high production capacity that can meet the demands of large-scale projects. Furthermore, the energy-efficient design of the machinery helps in reducing the overall operational costs, making it an economical choice for businesses.In addition to its technical capabilities, the Glazed Roof Tile Making Machinery is also known for its user-friendly interface and easy maintenance. The machinery is designed with the end-user in mind, with intuitive controls and a user-friendly interface that allows for easy operation. Furthermore, the machinery is built to withstand the rigors of continuous use, with minimal maintenance requirements, ensuring maximum uptime and productivity for the customers.{Company Name}'s Glazed Roof Tile Making Machinery has already gained significant traction in the market, with several successful installations and satisfied customers. The machinery has been widely praised for its performance, reliability, and cost-effectiveness, making it a preferred choice for businesses looking to enhance their production capabilities.With the global construction industry witnessing a surge in demand for sustainable and aesthetically appealing building materials, the Glazed Roof Tile Making Machinery by {Company Name} is well-positioned to capitalize on this trend. The machinery offers a perfect blend of technology, quality, and efficiency, making it an ideal choice for businesses looking to stay ahead of the competition.In conclusion, the Glazed Roof Tile Making Machinery developed by {Company Name} is a testament to the company's commitment to innovation and excellence. With its advanced technology, superior craftsmanship, and customer-centric approach, the machinery has set a new standard in the construction industry. As the demand for high-quality glazed roof tiles continues to grow, {Company Name} is well-positioned to emerge as a key player in the market, offering innovative solutions that cater to the evolving needs of its customers.

Efficient Automatic Length Cutting Machine for Various Applications

Automatic Length Cutting Machine Revolutionizing Precision Cutting in Manufacturing IndustryIn today's fast-paced manufacturing industry, precision cutting plays a crucial role in ensuring the quality and accuracy of the final product. To meet the demand for high-precision cutting in various industries, the introduction of the Automatic Length Cutting Machine has revolutionized the way manufacturers produce cut-to-length products. This state-of-the-art machine, developed and manufactured by {Company Name}, is setting new standards for precision cutting in the manufacturing industry.{Company Name} has been at the forefront of manufacturing innovative machinery and equipment for various industries for over two decades. With a commitment to excellence and a strong focus on technological advancements, the company has established itself as a leading provider of cutting-edge solutions for precision cutting and manufacturing processes. The Automatic Length Cutting Machine is a testament to their dedication to delivering high-quality, efficient, and reliable equipment to their clients.The Automatic Length Cutting Machine is designed to provide unmatched precision and accuracy in cutting various materials, including metal sheets, plastic, rubber, and other industrial materials. The machine's advanced cutting technology ensures consistent and uniform cuts, enabling manufacturers to produce high-quality products with minimal waste and maximum efficiency. This level of precision is critical for industries such as automotive, aerospace, construction, and metal fabrication, where the quality of the cut directly impacts the performance and reliability of the final product.One of the key features of the Automatic Length Cutting Machine is its advanced automation system, which allows for easy programming and set-up of cutting parameters. This significantly reduces the time and effort required for manual adjustments, while also minimizing the risk of human error. Additionally, the machine's intuitive interface and user-friendly controls make it accessible to operators of all skill levels, further streamlining the manufacturing process and increasing overall productivity.The versatility of the Automatic Length Cutting Machine is another standout feature, as it is capable of handling a wide range of materials and dimensions. Whether it's a small batch of custom-sized parts or large-scale production runs, the machine can accommodate varying lengths and thicknesses with precision and consistency. This flexibility makes it an invaluable asset for manufacturers looking to optimize their production processes and meet the diverse demands of their clients.Furthermore, the Automatic Length Cutting Machine is equipped with advanced safety features to ensure the well-being of operators and minimize the risk of accidents. The machine's enclosure and safety interlocks provide a secure operating environment, while its built-in sensors and monitoring systems enhance overall operational safety. This commitment to safety reflects {Company Name}'s dedication to not only providing cutting-edge technology but also prioritizing the well-being of its clients and their personnel.In addition to its technical capabilities, the Automatic Length Cutting Machine is backed by {Company Name}'s comprehensive support and service network. From initial installation and commissioning to ongoing maintenance and technical assistance, the company's team of experts is committed to providing exceptional support to ensure the seamless operation of their equipment. This dedication to customer satisfaction has earned {Company Name} a reputation for reliability and trustworthiness in the manufacturing industry.The introduction of the Automatic Length Cutting Machine by {Company Name} is poised to reshape the landscape of precision cutting in the manufacturing industry. By combining cutting-edge technology, unmatched precision, and exceptional versatility, this machine is redefining the standard for high-quality, efficient, and reliable cutting solutions. As manufacturers continue to seek ways to optimize their production processes and enhance their competitive edge, the Automatic Length Cutting Machine stands as a testament to {Company Name}'s commitment to innovation and excellence in the manufacturing sector.

How to Choose the Best Horizontal Corrugated Roofing Tile for Your Home

[Title]Horizontal Corrugated Roof Tile: A Revolutionary Addition to the Roofing Industry[Introduction]In recent times, the roofing industry has witnessed a remarkable invention that is set to transform the way we approach roofing solutions. Horizontal Corrugated Roof Tile, an innovative product brought to you by a leading manufacturer in the industry, is here to revolutionize the roofing landscape. With its unique features and superior quality, this new addition offers numerous advantages over traditional roofing options. Let us delve deeper into the world of Horizontal Corrugated Roof Tiles and explore how they are paving the way for a brighter and more sustainable future.[Body]1. The Concept behind Horizontal Corrugated Roof Tile:Horizontal Corrugated Roof Tile is the result of years of research and development by a dedicated team of experts in the field. This roofing solution aims to provide a durable, aesthetically pleasing, and environmentally friendly alternative to conventional roofing options. The concept behind this innovative product stems from the need to address the limitations of traditional roofing materials and to provide a superior solution that caters to the evolving demands of the industry.2. Unparalleled Durability:One of the key features of Horizontal Corrugated Roof Tile is its unmatched durability. Made from high-quality materials, these tiles can withstand extreme weather conditions, including strong winds, heavy rain, and even hailstorms. Unlike traditional roofing options that often suffer from structural damage and require frequent repairs, Horizontal Corrugated Roof Tiles have been engineered to last for decades, reducing maintenance costs significantly.3. Aesthetics and Design:Not only does Horizontal Corrugated Roof Tile provide exceptional durability, but it also offers a wide range of design options to suit different architectural styles. The sleek and modern design of these tiles adds a touch of sophistication to any building, making it an ideal choice for both residential and commercial projects. With a variety of color options available, customers can select the perfect shade to complement their overall building design.4. Environmental Benefits:In today's world, sustainability plays a pivotal role in decision-making when it comes to construction materials. Horizontal Corrugated Roof Tile aligns perfectly with this mindset, as it is made from recycled and recyclable materials. By opting for this eco-friendly roofing solution, customers can contribute to reducing their carbon footprint, while also enjoying the numerous benefits it offers.5. Easy Installation and Cost-Effectiveness:Horizontal Corrugated Roof Tile not only saves time but also money during the installation process. Thanks to its lightweight design, these tiles are easier to handle and require less labor compared to traditional materials. This results in reduced installation costs and quicker project completion times. Moreover, the long lifespan of these tiles means that customers can enjoy significant long-term savings by minimizing the need for frequent repairs or replacements.6. Testimonials and Success Stories:Since its introduction to the market, Horizontal Corrugated Roof Tile has received high praise from contractors, architects, and customers alike. Numerous success stories have emerged, showcasing the transformation of buildings and the immense satisfaction of customers who have opted for this innovative roofing solution. Whether it's residential complexes, commercial buildings, or industrial structures, the versatility of Horizontal Corrugated Roof Tile shines through in all applications.[Conclusion]In conclusion, Horizontal Corrugated Roof Tile represents a significant advancement in the roofing industry. With its durability, sustainability, and aesthetic design, this revolutionary product is redefining the standards for roofing solutions. The innovative concept, combined with the company's commitment to quality and customer satisfaction, ensures that customers receive a superior product that surpasses their expectations. As the roofing industry continues to evolve, Horizontal Corrugated Roof Tile stands tall as a testament to the ingenuity and potential for positive change within the field.

High-Quality Automatic Corrugated Tile Roll Forming Machine for Metal Roofing and Colored Steel Sheets

Title: Enhancing Efficiency and Quality with the Colored Metal Corrugated Sheet Roll Forming MachineIntroduction:In the rapidly evolving construction industry, keeping up with the latest technological advancements is crucial. When it comes to roofing materials, the demand for colored metal corrugated sheets has significantly increased due to their durability and aesthetic appeal. To meet the rising need for these sheets, the Automatic Metal Roofing Corrugated Tile Roll Forming Machine, also known as the Colored Steel Sheet Roll Forming Machine, has emerged as a game-changer. This blog post will delve into the key features, benefits, and applications of this advanced machine that has revolutionized the manufacturing process.1. Features of the Automatic Metal Roofing Corrugated Tile Roll Forming Machine:The Automatic Metal Roofing Corrugated Tile Roll Forming Machine is designed with cutting-edge technology to ensure seamless production of colored metal corrugated sheets. Some notable features include:a) High-Speed Performance: This machine boasts an exceptional production speed that enables efficient manufacturing without compromising the product's quality. Its advanced automation capabilities contribute to enhanced productivity and a significant reduction in labor costs.b) Precision and Accuracy: Equipped with advanced PLC control systems and digital displays, the machine guarantees precise and accurate sheet dimensions, angles, and curves. This ensures that the final product meets the required specifications, resulting in superior quality roofing sheets.c) Versatile Design: The machine's versatility allows it to handle various raw materials such as galvanized steel, aluminum, and stainless steel. This flexibility enables manufacturers to cater to a wide range of customer preferences, expanding their market reach.d) Durability and Longevity: The machine is built with robust materials, ensuring its durability and longevity. Its reliable performance minimizes downtime and maintenance, contributing to uninterrupted manufacturing operations.2. Benefits of the Colored Metal Corrugated Sheet Roll Forming Machine:a) Enhanced Efficiency: The high-speed performance of the machine significantly reduces the manufacturing time, enabling manufacturers to meet customer demands promptly. Its precision and accuracy eliminate the need for manual adjustments, resulting in increased productivity.b) Cost-Effectiveness: With its automation capabilities, the machine reduces labor costs and minimizes errors caused by human intervention. Its durable construction ensures longevity, reducing maintenance expenses and enhancing the return on investment.c) Customization and Design Flexibility: The machine's versatility allows manufacturers to produce colored metal corrugated sheets in various sizes, shapes, and colors. This flexibility enables them to cater to the unique design preferences and requirements of their customers.d) Superior Quality: The machine's advanced technology ensures the production of high-quality roofing sheets with accurate dimensions and excellent finishes. This quality assurance leads to satisfied customers and increased brand reputation.3. Applications of the Colored Metal Corrugated Sheet Roll Forming Machine:The Colored Metal Corrugated Sheet Roll Forming Machine finds extensive applications in the construction industry. Some notable uses include:a) Residential Roofing: The machine is used to manufacture corrugated metal roofing sheets for residential buildings. These sheets provide durability, weather resistance, and aesthetically pleasing options for homeowners.b) Commercial and Industrial Roofs: Manufacturing large quantities of colored metal corrugated sheets using this machine is ideal for commercial and industrial roofing projects. The sheets' strength, longevity, and low maintenance make them a cost-effective solution.c) Agricultural Structures: The machine caters to the specific requirements of the agricultural sector, enabling the production of corrugated metal sheets for barns, sheds, and other farm structures. These sheets provide a durable and weather-resistant solution for protecting livestock and equipment.Conclusion:The Automatic Metal Roofing Corrugated Tile Roll Forming Machine, also known as the Colored Metal Corrugated Sheet Roll Forming Machine, is a game-changer in the manufacturing of roofing sheets. Its high-speed performance, precision, versatility, and durability have significantly enhanced the efficiency and quality of production. By investing in this advanced machine, manufacturers can cater to customer demands promptly, reduce costs, and produce high-quality colored metal corrugated sheets for various applications in the construction industry.

High-Quality Automatic Wire Cut To Length Machine for Efficient Cutting

Precision Machinery Co., Ltd. is proud to announce the release of their latest innovation, the Automatic Wire Cut To Length Machine. This cutting-edge machine is designed to streamline and optimize the wire cutting process, providing unparalleled precision and efficiency in wire length cutting for various industrial applications.The newly developed Automatic Wire Cut To Length Machine is equipped with advanced technology and features that set it apart from traditional wire cutting machines. With its high-speed cutting capability and precise length control, this machine is able to cut multiple wires with different lengths in a single operation, saving time and increasing productivity for businesses. Additionally, the machine's user-friendly interface and programmable settings make it simple for operators to set up and adjust cutting parameters, reducing the risk of human error and ensuring consistent results.The Automatic Wire Cut To Length Machine is also designed to accommodate a wide range of wire diameters, making it a versatile solution for businesses that work with various types of wire. This flexibility allows companies to streamline their wire cutting operations and minimize the need for multiple machines, ultimately reducing costs and increasing efficiency.In addition to its cutting capabilities, the Automatic Wire Cut To Length Machine also offers a compact and durable design, making it suitable for use in various industrial settings. The machine's robust construction and high-quality components ensure reliable performance and longevity, allowing businesses to invest in a solution that will continue to deliver exceptional results for years to come.As a leading manufacturer of precision machinery, Precision Machinery Co., Ltd. has a long-standing reputation for delivering high-quality, innovative solutions to meet the evolving needs of the industry. With a focus on research and development, the company is committed to staying ahead of the curve and continuously improving its products to provide customers with the best possible solutions for their wire cutting needs."We are thrilled to introduce the Automatic Wire Cut To Length Machine to the market," said Mr. Zhang, the CEO of Precision Machinery Co., Ltd. "This machine represents the culmination of our dedication to innovation and excellence in precision machinery technology. We believe that it will revolutionize the wire cutting process for businesses, providing them with a reliable and efficient solution that will ultimately contribute to their success."Precision Machinery Co., Ltd. is dedicated to providing top-notch customer service and technical support to ensure that businesses can integrate the Automatic Wire Cut To Length Machine seamlessly into their operations. From initial installation and training to ongoing maintenance and support, the company is committed to helping its customers maximize the potential of this cutting-edge machine.The Automatic Wire Cut To Length Machine is now available for purchase, and Precision Machinery Co., Ltd. is excited to work with businesses to tailor the solution to their specific wire cutting needs. With its cutting-edge technology, precision performance, and versatile capabilities, this machine is poised to become an indispensable tool for businesses looking to optimize their wire cutting operations and drive greater efficiency and productivity.In conclusion, the release of the Automatic Wire Cut To Length Machine underscores Precision Machinery Co., Ltd.'s commitment to delivering cutting-edge solutions that empower businesses to thrive in a competitive market. With its advanced technology, unparalleled precision, and user-friendly design, this machine is set to revolutionize the wire cutting process, providing businesses with a reliable and efficient solution to meet their wire cutting needs.