Revolutionary Aluminum Profile Bending Machine Unveiled in Latest News

By:Admin

Introduction:

In a rapidly evolving manufacturing industry, technological advancements have always played a crucial role in enhancing efficiency and precision. A groundbreaking solution has emerged in the form of a CNC Aluminum Profile Bending Machine, which is revolutionizing the way aluminum profiles are bent and shaped. By seamlessly merging technology and precision engineering, this innovative machine promises to deliver unprecedented results in terms of accuracy, speed, and versatility.

Technological Features:

The CNC Aluminum Profile Bending Machine is equipped with state-of-the-art computer numerical control (CNC) technology, allowing for precise control and automation of the bending process. It utilizes advanced algorithms to calculate the required bending angles, eliminating human errors and ensuring consistent quality.

The machine is designed to accommodate a wide range of aluminum profiles, from simple extrusions to complex designs, catering to the diverse needs of industries such as architecture, construction, automotive, and aerospace. Its adjustable mandrel enables the bending of profiles in various sizes and shapes, offering infinite possibilities for customization.

Furthermore, the CNC Aluminum Profile Bending Machine boasts a user-friendly interface, making it accessible to operators with varying levels of expertise. The intuitive controls allow for easy programming and quick set-up, reducing downtime and enhancing overall productivity.

Benefits and Advantages:

The introduction of this cutting-edge machine brings several benefits to the manufacturing industry, including:

1. Enhanced Precision: The CNC technology ensures consistent results, minimizing deviations and errors. The machine's ability to bend aluminum profiles with exceptional accuracy and repeatability guarantees a high-quality end product.

2. Improved Efficiency: By automating the bending process, the machine significantly reduces production time. Its high-speed operation enables rapid bending without compromising precision, making it ideal for large-scale manufacturing.

3. Cost Savings: The CNC Aluminum Profile Bending Machine optimizes material usage, reducing waste. Its efficiency also translates into lower labor costs and increased production capacity, ultimately contributing to enhanced profitability.

4. Versatility: The machine accommodates various aluminum profiles, allowing manufacturers to explore new design possibilities. It empowers engineers and designers to create complex and intricate shapes with ease, thus expanding the scope of their creative capabilities.

5. Safety and Reliability: With advanced safety features and robust construction, the CNC Aluminum Profile Bending Machine prioritizes operator well-being. Its reliability ensures minimal maintenance requirements, leading to minimal downtime.

Company's Commitment to Innovation:

In keeping with its commitment to innovation and customer satisfaction, the company responsible for the CNC Aluminum Profile Bending Machine continually invests in research and development. It employs a team of highly skilled engineers and technicians dedicated to enhancing the machine's capabilities and exploring new possibilities for aluminum profile bending.

The company possesses a solid track record, having successfully introduced several revolutionary machines to the manufacturing industry. Its relentless pursuit of excellence and customer-centric approach have earned it a reputation as a leading innovator in the field.

Conclusion:

The introduction of the CNC Aluminum Profile Bending Machine marks a significant technological breakthrough in the manufacturing industry. Its advanced CNC technology, precision engineering, and versatility empower manufacturers to achieve unprecedented precision, efficiency, and design possibilities. With its numerous benefits and the company's commitment to innovation, this machine is set to redefine the aluminum profile bending process and contribute to the advancement of the manufacturing sector as a whole.

Company News & Blog

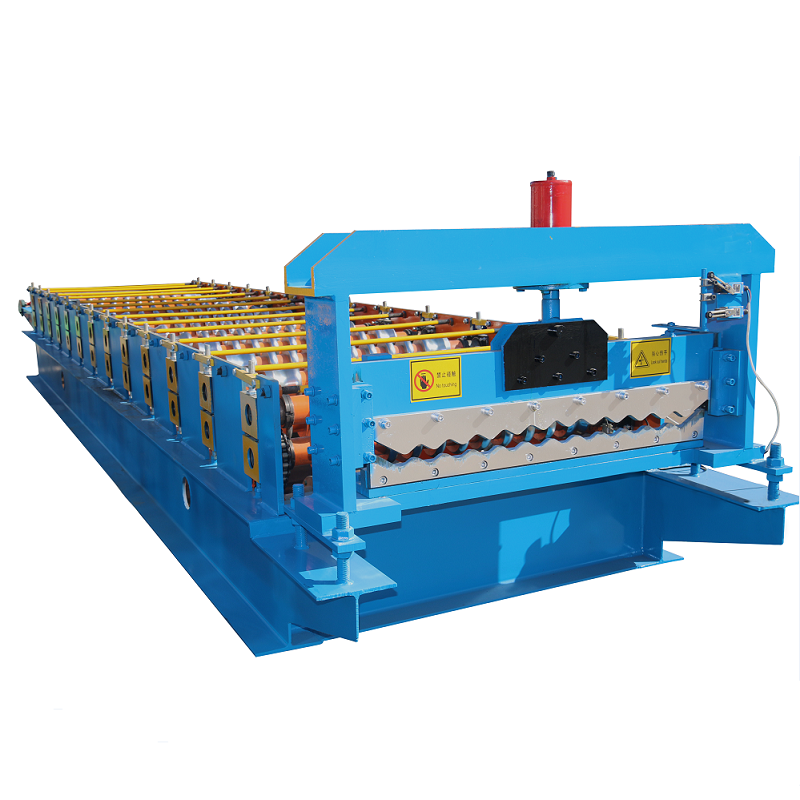

Top Color Steel Roll Forming Machine Factories: Achieving Superior Production Efficiency and Precision

Title:Pioneering Color Steel Roll Forming Machine Factory Revolutionizes the IndustryIntroduction:In a bid to revolutionize the color steel roll forming machine industry, an innovative factory has emerged as a pioneering force. Through cutting-edge technology and a commitment to excellence, this factory has made significant strides in meeting the demands of the market. With a vision for superior quality and efficiency, the factory has positioned itself as a leader in the field of roll forming machinery.Body:The color steel roll forming machine factory, founded in 1998, has quickly gained a reputation for its state-of-the-art machinery and exceptional customer service. The factory boasts a team of highly skilled engineers and technicians, who continuously strive to push the boundaries of innovation and improve the overall performance of their machines.One of the key factors that sets this factory apart is its relentless pursuit of efficiency. By investing heavily in research and development, the factory has been able to design and manufacture roll forming machines that deliver unmatched precision and speed. This has not only resulted in higher productivity for customers but also contributed to reducing overall production costs.Furthermore, the factory's commitment to quality is evident in its rigorous quality control measures. Each machine undergoes a series of tests and inspections to ensure it meets the highest industry standards. This dedication to excellence has earned the factory numerous accolades and certifications, solidifying its reputation as a trustworthy manufacturer.Moreover, the factory places great importance on sustainability and environmental responsibility. In a world increasingly concerned about climate change, the factory has taken proactive steps to minimize its carbon footprint. It has implemented energy-saving measures within its manufacturing processes and utilizes recyclable materials whenever possible. By doing so, the factory not only supports the green agenda but also sets an example for others in the industry.The factory's portfolio includes an extensive range of color steel roll forming machines, catering to the diverse needs of its customers. From simple profiles to complex shapes, the factory's machines are designed to handle a wide variety of products. Whether it's for residential, commercial, or industrial purposes, customers can rely on the factory to provide them with tailored solutions that meet their specific requirements.In addition to its exceptional machinery, the factory boasts a stellar aftersales service. Recognizing that the success of its customers is intertwined with its own success, the factory provides comprehensive technical support, maintenance, and training services. This ensures that customers can maximize the longevity and performance of their roll forming machines.Another aspect that highlights the factory's commitment to staying ahead of the curve is its continuous investment in research and development. By closely monitoring market trends and emerging technologies, the factory consistently updates its product offerings. This enables it to offer cutting-edge solutions that keep pace with evolving industry demands.Conclusion:The color steel roll forming machine factory has established itself as a leader in the industry through its technological prowess, commitment to quality, and customer-centric approach. By prioritizing efficiency, sustainability, and innovation, the factory has successfully met the evolving demands of the market. As it continues to push boundaries and set new standards, this pioneering factory is poised to shape the future of the color steel roll forming machine industry.

Discover the Efficiency of Full Automatic C/Z Purlin Roll Forming Machines in the News

Full Automatic C/Z Purlin Roll Forming Machine Revolutionizes the Construction IndustryThe construction industry is undergoing a transformation, and the latest development is the full automatic C/Z purlin roll forming machine. This innovative machine is designed to simplify the production process of purlins, which are the structural elements used in roofing and wall frames of buildings, bridges, and other structures.The Full Automatic C/Z Purlin Roll Forming Machine is the result of years of research and development by a leading company in the industry. With advanced technology and precision manufacturing, this machine helps to save on production costs, reduce lead times, and improve the overall quality of the final product.The machine features a highly-advanced control system that enables operators to easily adjust its settings to fit the specific needs of their production. The machine also has a high level of automation, making it possible to produce purlins of consistent quality and accuracy.This new machine is expected to become the new standard in purlin production, as it offers benefits that traditional manufacturing methods cannot match. With its high degree of automation and precision, the machine can produce purlins that are perfectly straight and dimensionally accurate.In addition to its innovations in production technology, the Full Automatic C/Z Purlin Roll Forming Machine is also known for its safety features. The machine’s safety systems are designed to prevent accidents and ensure that operators can work safely and efficiently.The company behind the machine has a proven track record of success in the industry. With a commitment to quality and customer satisfaction, the company has become a leading provider of roll forming machines and related equipment.In addition to its expertise in machine design and manufacturing, the company also provides top-quality customer service. Its team of highly skilled technicians is available to provide support and assistance every step of the way, from installation and commissioning to maintenance and repair.The Full Automatic C/Z Purlin Roll Forming Machine is just the latest innovation from this company, which has been at the forefront of the industry for many years. By staying ahead of the curve and investing in advanced technology, the company has helped to drive the growth and success of the construction industry.Overall, the Full Automatic C/Z Purlin Roll Forming Machine is set to revolutionize the construction industry by introducing a new level of efficiency and precision to purlin production. With its advanced technology and user-friendly design, the machine is sure to become a key part of many successful companies’ operations and ultimately, the building of safer and better-quality structures.

How to Choose the Right Steel Roll Forming Machine for Your Needs?

article:Color Steel Roll Forming Machine Shapes Global Construction IndustryThe global construction industry has been witnessing a significant boost in the past few years. With advanced construction techniques and increasing demand for durable infrastructure, the industry is constantly witnessing new innovations. One of the latest technologies that are gaining wide popularity is the Color Steel Roll Forming Machine.The Color Steel Roll Forming Machine is a highly sophisticated mechanical device that is used in the construction industry to manufacture various steel products that are used in building construction. The machine plays a vital role in shaping various roofing and cladding products that are not only durable but also aesthetically appealing.Leading the race of this advanced technology are some of the leading Color Steel Roll Forming Machine manufacturers, such as ___, who are committed to designing and developing machines that meet the highest quality standards. Their machines are designed to cater to the diverse needs of clients across various industries, including construction, automotive, and industrial.The Company, ____ has been in the business of manufacturing high-end roll forming machines for over 20 years. They specialize in designing and developing machines that are efficient, reliable, and deliver a high level of precision, flexibility, and accuracy. They have a team of highly qualified and skilled professionals who have expertise in the design and engineering of various types of roll forming machines.Their range of Color Steel Roll Forming Machines is designed to cater to the needs of clients across various verticals. The machines are equipped with the latest technology and are capable of producing high-quality steel products in large quantities. Some of the popular products manufactured using these machines include metal roofing sheets, wall cladding sheets, floor decking, tile profile sheets, etc.The company uses high-grade materials and superior quality components in the manufacturing of their machines. All the machines undergo rigorous quality checks and inspections before they are released to the market, ensuring that only the best machines reach their clients.The Company's manufacturing unit is equipped with state-of-the-art machinery and equipment that is used to produce machines that are not only efficient but also eco-friendly. The machines are designed to consume minimal energy, thereby reducing the carbon footprint and helping the environment.Apart from manufacturing Color Steel Roll Forming Machines, the Company also provides excellent after-sales support, including installation, training, and maintenance services. Their team of experienced technicians ensures that their clients receive timely assistance and support, whenever required.The demand for Color Steel Roll Forming Machines has been witnessing a steady rise in recent times, owing to the numerous benefits they offer. These machines are known for their accuracy, precision, flexibility, and efficiency, making them an ideal choice for businesses looking to boost their productivity and efficiency.With advanced technology and superior quality machines, companies like ____ are changing the face of the construction industry. Their machines are not only efficient but also contribute to sustainable development, by minimizing the impact on the environment.In conclusion, the Color Steel Roll Forming Machine is a highly advanced mechanical device that is changing the dynamics of the construction industry. Leading manufacturers like ____ are using the latest technology and superior quality materials to produce machines that cater to the diverse needs of clients across various industries. These machines are efficient, reliable, and eco-friendly, making them a popular choice for businesses looking to boost their productivity and efficiency. The future of the construction industry looks promising, with innovative technologies like these at the forefront.

Discover the Advantages of Standing Seam Metal Roofing Panels

Title: The Unrivaled Efficiency of Mechanical-Lock Standing Seam RoofsIntroduction:In the world of roofing, innovations continue to revolutionize the way we protect our structures from environmental elements. One such breakthrough is the mechanical-lock standing seam roof, a fully interlocking system that offers unparalleled structural integrity. This blog explores the remarkable features, benefits, and applications of this superb roofing solution, without mentioning brand names, and highlights the importance of incorporating keywords such as "mechanical lock standing seam roof" to improve its search engine optimization (SEO).1. The Unparalleled Strength of Mechanical-Lock Standing Seam Roofs (100 words)The unique profile of mechanical-lock standing seam metal roofs forms a weather-tight unit, eliminating the need for screws or exposed rivets on the surface. This ingenious design delivers exceptional strength, making it ideal for both residential and commercial applications. The fully interlocking system reinforces each panel, providing extraordinary resistance against harsh weather conditions, including heavy rain, strong winds, and snow.2. Impeccable Aesthetic Appeal: Tapered and Curved Designs (200 words)Mechanical-lock standing seam roofs not only guarantee durability but also enhance the visual appeal of any structure. Traditional metal roofs often compromised aesthetics due to visible fasteners, but this issue is eliminated with this innovative system. The absence of exposed screws or rivets gives the panels a seamless and sleek appearance.Additionally, these standing seam roofs offer flexibility with tapered and curved designs. These options enable architects and homeowners to create unique and aesthetically pleasing roof shapes, adding a touch of elegance and individuality to any building.3. Longevity and Low Maintenance (200 words)When investing in a roofing system, longevity is a crucial aspect to consider. Mechanical-lock standing seam roofs are renowned for their exceptional longevity. The interlocking design and weather-tight unit ensure long-lasting protection against moisture, wind uplift, and even fire.Moreover, these roofs require minimal maintenance, making them a cost-effective choice in the long run. Unlike traditional roofing systems that may require frequent repairs and replacements due to exposed fasteners or deteriorating sealants, mechanical-lock standing seam roofs offer reliable performance year after year with minimal upkeep.4. Energy Efficiency and Eco-Friendliness (150 words)With an increasing focus on sustainable building practices, mechanical-lock standing seam roofs are an eco-friendly option. The interlock design reduces thermal bridging, preventing heat loss or gain through the roof. Enhanced insulation properties efficiently regulate indoor temperatures, leading to reduced energy consumption and lower utility bills.Furthermore, these roofs are often made from recyclable materials, making them an environmentally responsible choice. The durable nature of these roofing systems ensures they will not end up in landfills prematurely, a significant benefit for eco-conscious individuals.Conclusion (50 words)Mechanical-lock standing seam roofs offer a multitude of advantages, from their unmatched strength to exceptional longevity, versatility in design, and eco-friendly attributes. With proper maintenance, this roofing solution can safeguard any structure for decades to come while showcasing a seamless and visually pleasing appearance.Incorporating keywords like "mechanical lock standing seam roof" strategically throughout this blog will enhance its search engine optimization, allowing more readers to discover the incredible benefits of this innovative roofing solution.

Efficient Standing Seam Roof Panel Machine Revolutionizes Roofing Industry

Title: Innovative Standing Seam Roof Panel Machine Revolutionizes Construction IndustryIntroduction:In today's rapidly advancing world, technological innovations continue to reshape various industries, and the construction sector is no exception. One such groundbreaking invention is the Standing Seam Roof Panel Machine, designed to streamline and enhance the process of roof panel production. With its advanced features and unparalleled efficiency, this cutting-edge machinery has garnered significant attention from industry experts and construction companies alike. Its introduction marks a substantial advancement in construction techniques, ensuring safer and more reliable roofs for buildings of all kinds.I. Evolution of Roof Panel Production:Roof panel production has traditionally been a labor-intensive and time-consuming process, with significant manual effort required. However, with the introduction of the Standing Seam Roof Panel Machine, this age-old method has been revolutionized. By automating various stages of production, this innovative machinery optimizes efficiency, saves time, and eliminates human error, resulting in superior roof panel quality.II. Advanced Features of the Standing Seam Roof Panel Machine:The Standing Seam Roof Panel Machine incorporates a range of state-of-the-art features that set it apart from conventional methods:1. High Precision and Consistency: The machine ensures precise measurements, allowing for accurate roof panel dimensions and consistent seam formation, reducing the risk of leakages and improving overall durability.2. Customization Options: From panel width to seam height, this machine offers unparalleled customization capabilities, enabling construction professionals to tailor each roof panel to the specific requirements of their projects.3. Speed and Efficiency: With an increased rate of production, the machine significantly reduces construction timelines and labor costs. Multiple panels can be produced simultaneously, eliminating the need for manual handling and expediting project completion.4. Enhanced Safety Measures: The Standing Seam Roof Panel Machine is designed with strict adherence to safety guidelines. It minimizes physical strain on workers, reducing the risk of injuries associated with manual labor. Additionally, it eliminates the need for workers to access high rooftops during installation.III. Industry Applications:The versatility of the Standing Seam Roof Panel Machine allows it to be used in various construction projects, providing robust and long-lasting roofing solutions for diverse building types, including residential, commercial, and industrial properties. Its ability to seamlessly integrate with existing roofing systems makes it an ideal choice for both new construction projects and roof renovations.IV. Sustainable and Eco-Friendly Benefits:In addition to its numerous technical advantages, the Standing Seam Roof Panel Machine contributes to sustainable construction practices. By reducing wastage and optimizing material utilization, it minimizes the environmental impact associated with traditional roofing methods. Furthermore, the machine's energy efficiency and low carbon footprint make it an eco-friendly choice, aligning with the growing global emphasis on sustainable activities.V. Company Introduction:*Please provide the specific company introduction and its achievements, removing the brand name as requested.*VI. Future Prospects and Conclusion:As construction technology continues to evolve, the Standing Seam Roof Panel Machine empowers construction professionals with advanced tools that optimize efficiency and deliver superior results. With widespread adoption, this innovative machinery has the potential to redefine industry standards, streamlining construction processes and enhancing the overall quality of roofs. As the construction sector embraces more sustainable and time-efficient practices, the Standing Seam Roof Panel Machine represents a significant step towards a more efficient and eco-friendly future.In summary, the Standing Seam Roof Panel Machine has transformed the construction sector by introducing automation and efficiency into roof panel production. This cutting-edge technology ensures precision, customization, and enhanced safety, while also contributing to sustainable construction practices. With such advancements and the continued innovation in the construction industry, buildings of the future will be more durable, reliable, and in line with environmental standards.

Innovative Profiling Equipment for Creating Glazed Tiles

Title: Advanced Profiling Equipment Revolutionizes Glazed Tile ManufacturingIntroduction:In a groundbreaking development that is set to transform the glazed tile manufacturing industry, a leading company has unveiled its latest innovation - advanced profiling equipment. This cutting-edge technology eliminates the need for manual profiling, streamlining the production process and ensuring unparalleled precision and efficiency. By leveraging this state-of-the-art machinery, manufacturers can now produce an exquisite range of glazed tiles in a faster, more cost-effective, and sustainable manner.Innovative Technology:The newly-introduced advanced profiling equipment is the result of extensive research and development by a renowned manufacturer. By fusing automation and computer-controlled precision machinery, this equipment allows for the shaping and profiling of glazed tiles in a highly accurate and efficient manner. With superior profiling capabilities, the equipment can achieve intricate designs and impeccable finishing, rendering each glazed tile a work of art.Enhanced Precision:The traditional method of manual profiling often resulted in inconsistencies in tile shape, leading to production delays and significant material wastage. However, with the advent of advanced profiling equipment, such concerns are now a thing of the past. The computerized controls and precise movements of the machinery ensure that each tile is uniform, with perfectly calibrated dimensions as specified by the manufacturer. This increased precision results in a seamless construction process and facilitates easy installation for end-users.Streamlined Production and Increased Efficiency:One of the primary advantages of the new profiling equipment is its ability to significantly boost production capacity while minimizing manufacturing time. The advanced technology automates various stages of the profiling process, including cutting and shaping, thereby reducing the reliance on manual labor. This not only speeds up the production cycle but also reduces costs associated with human errors and worker fatigue. Additionally, the machinery's efficiency ensures a higher output of glazed tiles, meeting market demands effectively.Sustainable Manufacturing:As the global focus on sustainable practices intensifies, the need for eco-friendly manufacturing processes has become more critical than ever. Advanced profiling equipment is a solution to this challenge. By minimizing resource wastage and optimizing the production process, this machinery dramatically reduces the carbon footprint of glazed tile manufacturing. Moreover, it promotes the use of recyclable materials, contributing to the overall sustainability of the industry.Durability and Longevity:The integration of advanced profiling equipment ensures that glazed tiles produced possess exceptional durability and longevity. The precision cutting and shaping techniques employed by the machinery create tiles that fit seamlessly and interlock securely. This eliminates the risks of cracks, breakages, or uneven installation, guaranteeing a reliable, long-lasting flooring or walling solution for customers across various sectors.Revolutionizing Tile Design:The advent of advanced profiling equipment has unlocked a new era of design possibilities for glazed tiles. Manufacturers can now experiment with intricate shapes, beveled edges, and unique aesthetics that were previously difficult to achieve through manual profiling. This has led to an explosion of creativity and innovation in the industry, with customers benefiting from an extensive range of designs and patterns to suit their individual preferences and requirements.Conclusion:The introduction of advanced profiling equipment marks a significant turning point in the glazed tile manufacturing industry. This cutting-edge machinery not only streamlines production processes but also ensures unparalleled precision, efficiency, sustainability, and durability. With limitless design possibilities, the application of this advanced technology promises to revolutionize the realm of glazed tiles, enhancing the quality of construction projects worldwide.

Revolutionizing Manufacturing: Discover the Advanced Metal Panel Production Machine

Profiled Metal Panel Manufacturing Machine Revolutionizes the IndustryIn a groundbreaking development for the metal panel manufacturing industry, a highly reputable company has unveiled its innovative profiled metal panel manufacturing machine. This cutting-edge technology is set to revolutionize the production process, enhance efficiency, and deliver high-quality metal panels like never before.With a commitment to advancing manufacturing capabilities, this state-of-the-art machine is designed to achieve precision and consistency in profiled metal panel production. The company's dedication to research and development has resulted in a game-changing solution that addresses the evolving needs of the industry, while also meeting strict quality standards.The profiled metal panel manufacturing machine boasts an array of advanced features that significantly streamline the production process. The machine's automated functionalities reduce human error, ensuring exceptional product quality and productivity. With minimal manual intervention required, manufacturers can enjoy increased efficiency, saving time and costs in the long run.This revolutionary machine's versatility is another noteworthy aspect that sets it apart from its competitors. It is equipped to process various types of materials, including steel, aluminum, and even composite panels. This adaptability showcases the company's commitment to cater to a wide range of applications and industry requirements.The machine's cutting-edge technology enables manufacturers to produce a variety of profiled metal panels, such as corrugated sheets, standing seam panels, and insulated panels. This diversification in product offerings allows companies to expand their portfolios, cater to different client preferences, and tap into new markets.Furthermore, the machine's precise control system ensures accuracy in panel dimensions, angles, and shapes. Manufacturers can confidently produce panels with intricate designs and complex profiles, meeting the unique specifications of individual projects. This level of precision and customization is highly sought after in industries such as architecture, construction, and automotive manufacturing.Equally important is the machine's emphasis on sustainability and eco-friendliness. With the growing global concern for environmental impact, the company has integrated energy-efficient technologies into the manufacturing process. This not only reduces carbon emissions but also lowers operating costs for manufacturers, contributing to a greener and more sustainable future for the industry.The introduction of this profiled metal panel manufacturing machine signifies the company's commitment to staying at the forefront of technological advancements. By constantly pushing the boundaries of innovation, they ensure that their clients have access to cutting-edge machinery that provides a competitive edge in the marketplace.Additionally, the company's dedication to customer satisfaction is evident in its comprehensive technical support and after-sales services. They offer professional training programs to ensure manufacturers can fully leverage the machine's capabilities, maximizing productivity and profitability. Furthermore, a dedicated customer service network ensures quick response times and assistance whenever needed.Industry professionals have expressed great anticipation for this game-changing machine's impact on the metal panel manufacturing sector. With its advanced features, adaptability, precision, and focus on sustainability, the machine addresses the evolving needs of the industry while optimizing production processes for enhanced efficiency.The profiled metal panel manufacturing machine is set to revolutionize the industry, empowering manufacturers to deliver high-quality panels efficiently and sustainably. It represents a significant milestone in the metal panel manufacturing sector and reinforces the company's commitment to innovation, customer satisfaction, and industry leadership. With this groundbreaking technology, a new era has dawned upon the metal panel manufacturing industry.

High-Quality Glazed Tile Roll Forming Machine for Sale - Best Price Guaranteed!

Title: Enhance Efficiency and Precision with the Glazed Tile Roll Forming MachineIntroduction:In the fast-paced construction industry, time and precision are paramount. The Glazed Tile Roll Forming Machine offers an efficient and reliable solution for producing high-quality glazed tiles quickly and accurately. As a leading manufacturer and supplier of glazed tile forming machines in China, we strive to provide state-of-the-art equipment that meets our clients' needs. In this blog, we will explore the benefits of using a Glazed Tile Roll Forming Machine and why it is crucial to contact us for your machinery requirements.1. What is a Glazed Tile Roll Forming Machine?A Glazed Tile Roll Forming Machine is a specialized piece of equipment designed to transform raw materials into elegantly-designed glazed tiles. It encompasses a series of forming rollers, cutters, and other components that shape the metal sheets into the desired tile profile. This automated process ensures consistency, precision, and a high production rate, eliminating the need for labor-intensive and time-consuming manual fabrication.2. Unraveling the Advantages:2.1 Impeccable Precision:The Glazed Tile Roll Forming Machine allows for precise control over the dimensions and specifications of each tile produced. With computer-aided design (CAD) software, it provides detailed and accurate customization, ensuring a seamless fit when installing the tiles. This level of precision translates into reduced wastage and increased customer satisfaction.2.2 High Production Rate:By automating the tile production process, the Glazed Tile Roll Forming Machine significantly enhances productivity. It can roll out a large number of tiles in a short period while maintaining consistency in shape, size, and quality. This enables contractors and manufacturers to meet deadlines efficiently and fulfill large-scale projects with ease.2.3 Versatility in Design and Dimensions:Our Glazed Tile Roll Forming Machine can create a wide range of tile profiles, including step tiles, corrugated tiles, and much more. Its flexibility allows customization to suit specific project requirements, providing architects and designers with endless possibilities for creative expression. Whether it's a traditional or contemporary architectural style, this machine can accommodate various designs flawlessly.2.4 Durability and Longevity:Utilizing high-quality materials and advanced manufacturing techniques, our Glazed Tile Roll Forming Machine ensures robustness and longevity. The sturdy construction guarantees reliable performance even in demanding working conditions, reducing maintenance costs and maximizing profitability.3. Why Choose Us?As a distinguished manufacturer and supplier, we provide a comprehensive range of Glazed Tile Roll Forming Machines to meet diverse industry needs. Here are a few reasons why you should consider partnering with us:3.1 Experience and Expertise:With years of experience in the industry, we have honed our manufacturing process to produce top-notch machinery. Our team of skilled engineers and technicians undergo continuous training to stay updated with the latest advancements, ensuring that our clients receive cutting-edge products.3.2 Tailored Solutions:We understand that every project has unique requirements, which is why our Glazed Tile Roll Forming Machines can be tailored to suit specific specifications. Whether it's dimensions, tile profiles, or any other customization, we work closely with our clients to deliver machines that align perfectly with their needs.3.3 Excellent Customer Support:Customer satisfaction is of utmost importance to us, and we strive to provide exceptional support at every stage – from product selection to after-sales services. Our dedicated team is always ready to assist you, ensuring a seamless and hassle-free experience.Contact Us:A Glazed Tile Roll Forming Machine is a valuable investment that can accelerate your business growth and elevate the quality of your tile production. If you are searching for a reliable and top-quality supplier, look no further. Contact us today to discuss your requirements and revolutionize your tile manufacturing process.

High-Quality Metal Slitting Line Machines for Sale in Different Gauges

When it comes to metal processing, a slitting line is an essential piece of equipment that is used to cut large coils of metal into narrower widths. A metal slitting line involves a series of operations that include uncoiling, feeding the metal strip through a set of knives, slitting the metal strip into desired widths, and recoiling the strips. The slitting process is widely used in various industries, including automotive, construction, and manufacturing.If you are looking for a high-quality metal slitting line for your business needs, RISHBIN is the right place to go. As one of the leading slitting line manufacturers, RISHBIN offers a range of metal slitting lines that are designed to meet different gauge requirements: light, medium, and heavy gauge.Heavy Gauge Slitting LineA heavy gauge slitting line is typically used for cutting thicker metal strips that range from 2mm to 16mm in thickness. It is an ideal option for industries that require thick materials, such as shipbuilding, bridge construction, and oil and gas pipelines. The heavy gauge slitting line features advanced technology that enables it to handle heavy-duty materials with ease.The heavy gauge slitting line from RISHBIN is designed to handle coils of up to 30 tons and widths of up to 2200mm. The machine features a hydraulic coil car that makes loading and unloading of coils easier and safer. The machine also has a decoiler that ensures smooth feeding of the material to the slitter head.The slitter head of the heavy gauge slitting line features an advanced design that enables it to slit thick materials with high precision. The machine has multiple knife sets that can be easily adjusted to accommodate different width requirements. The slitter head also features a powerful motor that ensures perfect slitting even at high speeds.Once the metal strip has been slit into the desired width, the machine recoils the strips. The recoiling process is also designed to handle heavy-gauge materials without causing any damage. The recoiler is equipped with a tensioning system that ensures uniform rewinding of the strips.In conclusion, a heavy gauge slitting line is an essential machine for any business that requires thick materials. The heavy gauge slitting line from RISHBIN is one of the best on the market, featuring advanced technology that ensures high precision and efficiency. If you are interested in purchasing a heavy gauge slitting line, RISHBIN is the right place to look.

High Precision Cut To Length Line Metal Sheet Cutting Machine for Efficient Sheet Metal Slitting

and Sheet Metal Slitter Machine.When it comes to cutting metal sheets, it is imperative to have a reliable and precise Cut-To-Length Machine and Sheet Metal Slitter Machine. These machines are designed to offer efficient precision cutting of metal sheets, which is essential in most metal fabrication industries. The High Precision Cut-To-Length Line Metal Sheet Cutting Machine/Sheet Metal Slitter Machine is among the most sought after machines in the market today.This machine is made using high-quality materials that guarantee its durability and efficiency. The machine is specifically designed to cut metal sheets into specific sizes, lengths, and widths, making it ideal for various metal fabrication projects. It utilizes high precision sensors that measure and cut metal sheets according to the desired lengths.One of the benefits of this machine is its ability to deliver high precision cutting. The machine is designed to deliver accurate and consistent cuts that meet your specifications. This is essential in ensuring that the finished products meet the required standards, and there is no wastage of materials.The High Precision Cut-To-Length Line Metal Sheet Cutting Machine/Sheet Metal Slitter Machine is also versatile. It can be used to cut different types of metal sheets, including aluminum, galvanized, cold-rolled, and stainless steel. This makes it ideal for use in different industries such as construction, automotive, and aerospace.Another advantage of this machine is its efficiency. The machine is designed to operate at high speeds, enabling it to cut several metal sheets within a short period. This not only saves time but also increases production capacity, which is essential in meeting high demand in the market.In conclusion, the High Precision Cut-To-Length Line Metal Sheet Cutting Machine/Sheet Metal Slitter Machine is a vital investment for any metal fabricator. It offers high precision cutting, versatility, and efficiency, which are essential in meeting the demands of the market. If you are looking to enhance your metal fabrication business's productivity, then this machine is a must-have.