- Home

- Blog

- Ultimate Guide to Sheet Roll Forming Machines: Types, Working Principles, and Applications

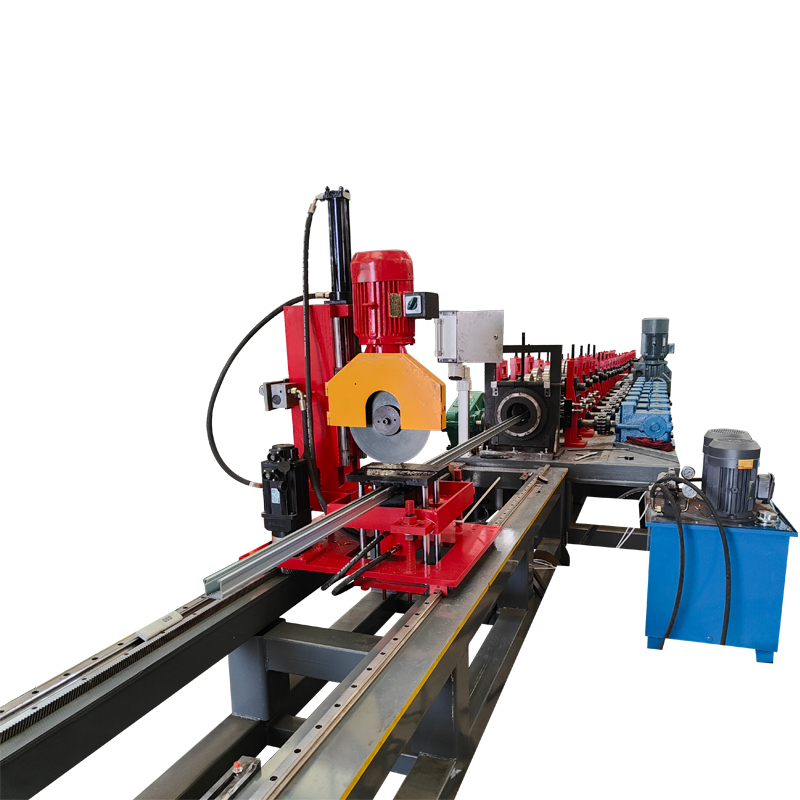

Ultimate Guide to Sheet Roll Forming Machines: Types, Working Principles, and Applications

By:Admin

{Company} is a leading manufacturer of Sheet Roll Forming Machines, with a strong focus on innovation and quality. With years of experience in the industry, {Company} has developed a reputation for providing reliable and advanced solutions for sheet metal forming. The company is committed to constant research and development, and its machines are known for their durability, ease of use, and high performance.

Recently, {Company} has introduced a new and improved version of its Sheet Roll Forming Machine, which promises even greater efficiency and productivity. This latest model incorporates cutting-edge technology and advanced features to meet the evolving needs of the industry. With its ability to handle a wide range of sheet metal materials and produce complex shapes with precision, the new machine is set to redefine the standards of sheet metal forming.

One of the key features of the new Sheet Roll Forming Machine is its modular design, which allows for easy customization and adaptation to different production requirements. This flexibility makes it an ideal solution for manufacturers with diverse needs, as it can easily accommodate changes in product specifications and production volumes. Moreover, the machine is equipped with advanced control systems that allow for precise adjustments and monitoring of the forming process, ensuring consistent and high-quality output.

In addition to its technical capabilities, the new Sheet Roll Forming Machine from {Company} also boasts a user-friendly interface and intuitive controls. This makes it easy for operators to set up and operate the machine, reducing the need for extensive training and minimizing the risk of errors during production. As a result, manufacturers can expect improved productivity and efficiency, as well as a reduction in operational costs.

Furthermore, {Company} has incorporated advanced safety features into the new Sheet Roll Forming Machine to ensure the well-being of operators and workers. This includes enhanced protection systems and safety interlocks that comply with industry standards and regulations. With safety being a top priority, manufacturers can have peace of mind knowing that their workers are protected while operating the machine.

The introduction of the new Sheet Roll Forming Machine from {Company} is set to make a significant impact on the sheet metal forming industry. With its advanced technology, flexibility, and user-friendly design, the machine promises to streamline production processes, improve product quality, and drive manufacturing efficiency. As manufacturers continue to seek innovative solutions for their production needs, {Company} remains at the forefront of the industry, providing cutting-edge machines that set new standards for sheet metal forming.

In conclusion, the new Sheet Roll Forming Machine from {Company} is a game-changer for the sheet metal forming industry. With its advanced technology, modular design, user-friendly interface, and enhanced safety features, the machine is poised to revolutionize the way sheet metal products are manufactured. As {Company} continues to lead the way in innovation and quality, manufacturers can expect to experience greater efficiency and productivity in their production processes, ultimately leading to improved competitiveness in the market.

Company News & Blog

Pros and Cons of All-In-One vs. Multiple Single Layer Roll Forming Machines: A Comprehensive Comparison

, Multiple Roll Forming Machines, All-in-one Roll Forming Machine, Double layer Roll Forming Machine, Roll Forming Machinery.When it comes to roll forming, there are a few different options to consider. One decision that needs to be made is whether to choose an all-in-one roll forming machine or multiple single layer roll forming machines. Both options have their pros and cons, so it ultimately depends on the specific needs and preferences of the user.Single layer roll forming machines are a popular choice for many manufacturers. These machines are designed to create a continuous sheet of metal by bending it into a certain shape. One of the advantages of using a single layer roll forming machine is the ability to produce a high volume of products quickly and efficiently. Since the machine only focuses on one layer at a time, it's easier to control the quality of each product and ensure that each one is consistent.Another advantage of using a single layer roll forming machine is the ability to customize the process based on the specific needs and materials being used. These machines are often designed to be highly flexible, allowing for adjustments to be made based on the thickness and type of material being used.However, one of the downsides of using a single layer roll forming machine is the need for multiple machines if a manufacturer needs to produce multiple layers. This can be a disadvantage if a manufacturer is trying to minimize the number of machines being used in their production process.On the other hand, all-in-one roll forming machines are designed to be highly versatile and efficient. These machines are capable of producing multiple layers of metal at once, which can help streamline the production process. Additionally, all-in-one roll forming machines are often designed to be highly automated, which can help reduce the need for labor and increase overall efficiency.One of the disadvantages of using an all-in-one roll forming machine is the potential for decreased quality control. Since these machines are designed to focus on multiple layers at once, it can be more difficult to ensure that each product is consistent and meets the desired quality standards.Another potential disadvantage of using an all-in-one roll forming machine is the cost. These machines are typically more expensive than single layer roll forming machines, which can be a disadvantage for smaller manufacturers or those with limited budgets.Finally, double layer roll forming machines are another option to consider. These machines are designed to produce two layers of metal at once, which can help increase production efficiency and reduce the need for multiple machines. However, like all-in-one roll forming machines, double layer roll forming machines can be more expensive and may have lower quality control.Ultimately, the decision to choose between an all-in-one roll forming machine and multiple single layer roll forming machines will depend on a variety of factors, including the specific needs and preferences of the manufacturer. Both options have their advantages and disadvantages, so manufacturers should carefully consider their options before making a final decision.

Discover High-Quality Roll Forming Machines from China's Top Supplier

As much as architecture has evolved over the years, the use of different materials has remained constant, one of which being steel. The durability, strength, and versatility of steel make it a go-to material for various structural applications, from high-rise buildings to residential homes. Therefore, to meet the demands of this ever-growing market, the roll forming industry has evolved and continues to extend its limits by offering innovative and modernized products. Today, we will discuss everything about the Color Steel Roll Forming Machine Factory.What is a Roll Forming Machine?A Roll Forming Machine refers to a piece of equipment that produces shapes of different sizes and profiles from metallic coils or sheets. The machine achieves this by passing these sheets through a series of rollers that gradually bend and form them into the desired shape. This process is known as roll forming, and the entire unit consists of a de-coiler, a roller system, a cutting system, and a control system. These machines offer several advantages over other manufacturing techniques, such as reduced material wastage, faster production speeds, and increased precision.What is a Color Steel Roll Forming Machine Factory?A Color Steel Roll Forming Machine Factory refers to a production facility that is specifically designed for manufacturing various types of color coated steel products. These machines provide a convenient solution for meeting the demand of the modern construction industry. The color steel material produced is attractive and durable, making it an ideal choice for the roofing, walling, and cladding systems.The Color Steel Roll Forming Machine Factory is highly flexible, which means it can produce a wide range of profiles and shapes with high precision and consistently. This flexibility, combined with the ability to customize profiles and shapes, makes it the ideal choice for architects, contractors, and manufacturers, who need to create unique products suited to their specific requirements.Features of the Color Steel Roll Forming Machine FactoryThe Color Steel Roll Forming Machine Factory is a versatile piece of equipment that can handle multiple projects. Some of the features that make it stand out include;1. High Precision and ConsistencyThe high precision and consistency of the roll forming process means that all the products produced are uniform in quality, size, and shape.2. VersatilityA color steel roll forming machine factory can create different profiles and shapes. The factory can produce panels of different profiles, including corrugated or ribbed, standing seams, box profiles, and curved products.3. Reduced Material WastageBy eliminating the need for manual cutting and forming, roll forming machines reduce the amount of wastage generated during the manufacturing process.4. High-Speed ProductionOne of the primary advantages of using a color steel roll forming machine factory is the high-speed production cycle that reduces lead times while maintaining the quality of the products.ConclusionIn conclusion, the Color Steel Roll Forming Machine Factory is an integral part of the steel industry, providing a modern and innovative alternative to traditional steel products. With a wide range of features designed to cater to the needs of the modern construction industry, the possibilities for color steel roll forming machines are endless. As a leading manufacturer of Roll Forming Machines, (brand name removed) offers high-quality machines, unmatched customer service, and competitive prices. Contact us today for further inquiries or visit our website for more information about our products and services.

Top Portable Metal Roll Forming Machine on the Market

Portable Metal Roll Forming Machine Revolutionizes On-Site ConstructionWith the rise of remote construction projects and the need for on-site customization, the demand for portable metal roll forming machines has been steadily increasing. This innovative piece of equipment has revolutionized the way metal roofing and siding is installed on construction sites, allowing for greater flexibility and efficiency in the construction process.The portable metal roll forming machine, also commonly referred to as a portable roll former, is a compact and mobile piece of equipment that is designed to produce metal panels of various shapes and sizes directly on the job site. This eliminates the need for pre-fabricated panels to be transported and handled, reducing transportation costs and the risk of damage during transit.One of the leading manufacturers in the industry is {}, a company that has been at the forefront of roll forming technology for over 30 years. They have recently introduced their latest portable metal roll forming machine, which boasts advanced features and capabilities that set it apart from traditional roll formers.The {} portable metal roll forming machine is designed to be easy to transport and set up, making it ideal for remote construction sites and projects with limited space. Its compact size and lightweight construction allow it to be easily maneuvered into position, while its robust build ensures durability and reliability in the harshest of environments.One of the key benefits of the {} portable metal roll forming machine is its ability to produce custom metal panels on-site, eliminating the need for off-site fabrication and reducing lead times. This enables construction contractors to respond quickly to design changes and project variations, ultimately saving time and costs associated with re-work and delays.In addition to its flexibility, the {} portable metal roll forming machine is also known for its precision and efficiency. With advanced control systems and automated processes, it can consistently produce high-quality metal panels with tight tolerances and accurate dimensions. This level of precision is crucial in ensuring the integrity and performance of the metal roofing and siding systems installed on construction projects.Furthermore, the {} portable metal roll forming machine is equipped with safety features and ergonomic designs to ensure the well-being of operators and workers on the job site. This includes safety guards, emergency stop mechanisms, and user-friendly controls that minimize the risk of accidents and injuries during operation.The introduction of the {} portable metal roll forming machine has been met with great enthusiasm from the construction industry, with many contractors recognizing the significant advantages it offers in terms of flexibility, efficiency, and quality. Its ability to streamline the metal panel production process on-site has been particularly appealing to those involved in remote and custom construction projects.With the growing demand for portable metal roll forming machines, {} has been actively expanding its distribution network to serve a wider range of customers around the world. From small-scale contractors to large construction firms, the company is committed to providing access to its innovative roll forming technology and supporting its customers with comprehensive training and technical support.In conclusion, the introduction of the {} portable metal roll forming machine has marked a significant advancement in on-site construction technology. Its ability to produce custom metal panels with precision and efficiency directly at the job site has not only improved productivity and cost-effectiveness but has also opened up new opportunities for innovation in the construction industry. As the demand for portable metal roll forming machines continues to grow, {} remains dedicated to driving the evolution of roll forming technology and empowering construction professionals with the tools they need to succeed.

Highly Efficient and Durable Ridge Forming Machine for Metal Roofing Applications

Ridge Forming Machine: A Game-Changer in Roofing IndustryThe roofing industry has seen significant advancements in technology over the years, and one of the most recent game-changers is the Ridge Forming Machine. This innovative machine has revolutionized the process of forming ridges on roofing materials, providing a more efficient and precise solution for roofing professionals.The Ridge Forming Machine, developed by an industry-leading company, is designed to streamline the ridge forming process, making it faster, more accurate, and ultimately more cost-effective for roofing projects. The machine is equipped with state-of-the-art technology and advanced features that set it apart from traditional ridge forming methods.One of the key benefits of the Ridge Forming Machine is its ability to produce consistent and uniform ridges on roofing materials. This level of precision is essential for ensuring the structural integrity and aesthetics of the finished roof. The machine's advanced automation and digital controls allow for tight tolerances and exact ridge profiles, eliminating the variability and imperfections that can occur with manual ridge forming techniques.In addition to its precision, the Ridge Forming Machine is also highly efficient. It is capable of forming ridges at a much faster rate than traditional methods, significantly reducing the time and labor required for this critical aspect of the roofing process. This efficiency not only accelerates project timelines but also reduces labor costs, making the machine a valuable asset for roofing contractors seeking to optimize their operations.Furthermore, the Ridge Forming Machine is versatile and adaptable to a wide range of roofing materials and profiles. Whether working with metal, composite, or other types of roofing materials, the machine can accommodate various thicknesses and shapes, making it suitable for diverse roofing applications.The company behind the Ridge Forming Machine has a long-standing reputation as a leader in the roofing industry. With a commitment to innovation and quality, the company has developed a comprehensive range of roofing solutions that meet the evolving needs of contractors and builders. The Ridge Forming Machine is the latest addition to the company's product lineup, demonstrating its dedication to advancing the industry through cutting-edge technology.As part of its dedication to customer satisfaction, the company provides extensive training and support for the Ridge Forming Machine. This ensures that roofing professionals can fully leverage the capabilities of the machine, maximizing its benefits for their projects. The company's technical experts are available to assist with installation, training, and ongoing maintenance, ensuring that customers can integrate the machine seamlessly into their operations.The introduction of the Ridge Forming Machine has been met with enthusiasm and praise from the roofing community. Contractors and builders have recognized the significant value that the machine brings to their projects, from its precision and efficiency to its versatility and reliability. As the demand for high-performance roofing solutions continues to grow, the Ridge Forming Machine has quickly established itself as an essential tool for modern roofing applications.In conclusion, the Ridge Forming Machine represents a significant advancement in the roofing industry, offering a more efficient, precise, and versatile solution for forming ridges on roofing materials. With its advanced technology and the backing of a reputable company, the machine has quickly become a game-changer for roofing professionals looking to elevate their work to new heights. As the industry evolves, the Ridge Forming Machine is poised to play a pivotal role in shaping the future of roofing.

High-Quality W-Beam Crash Barrier Machine for Sale - Get Yours Today!

W Beam Crash Barrier Machine boosts safety on highwaysIn the world of highway safety, the importance of crash barriers cannot be overstated. These vital structures are designed to prevent vehicles from colliding with obstacles such as trees, buildings, or other vehicles in the event of an accident. As such, the quality and integrity of these barriers are of utmost importance.Recognizing the critical role that crash barriers play in highway safety, [Company Name] has developed a state-of-the-art W Beam Crash Barrier Machine, which is set to revolutionize the way these crucial structures are manufactured and installed.[Company Name] has long been a leader in the field of highway safety equipment, with a strong reputation for producing high-quality products that meet the strictest standards of safety and reliability. The company’s commitment to innovation and excellence is evident in its latest offering – the W Beam Crash Barrier Machine.This cutting-edge machine is designed to streamline the production and installation of W-beam crash barriers, making the process more efficient and cost-effective than ever before. With its advanced technology and precision engineering, the W Beam Crash Barrier Machine is capable of producing barriers of unparalleled quality and durability, ensuring the safety of motorists on highways around the world.One of the key features of the W Beam Crash Barrier Machine is its versatility. The machine is capable of producing a wide range of barrier designs, making it suitable for use in a variety of highway environments. Whether it’s a straight section of highway, a curved road, or a complex interchange, the W Beam Crash Barrier Machine can be customized to meet the specific needs of any project.In addition to its versatility, the W Beam Crash Barrier Machine is also incredibly efficient. Its high-speed production capabilities mean that barriers can be manufactured and installed in a fraction of the time it would take using traditional methods, saving time and money for highway authorities and contractors. Furthermore, the machine’s automated processes minimize the risk of human error, ensuring that each barrier meets the highest standards of quality and safety.Another standout feature of the W Beam Crash Barrier Machine is its durability. Constructed from high-grade materials and built to withstand the rigors of continuous use, the machine is designed to provide years of reliable service, making it a sound investment for any organization involved in highway safety.The launch of the W Beam Crash Barrier Machine represents a significant step forward in the field of highway safety equipment. With its advanced technology, versatile design, and efficient production capabilities, the machine is set to revolutionize the way crash barriers are manufactured and installed, ultimately enhancing safety on highways around the world.As [Company Name] continues to lead the way in the development of innovative highway safety solutions, the launch of the W Beam Crash Barrier Machine is a testament to the company’s commitment to excellence and its dedication to keeping motorists safe on the road. With its unparalleled quality and efficiency, this groundbreaking machine is a game-changer for the highway safety industry, and is sure to make a lasting impact on the way crash barriers are produced and installed in the years to come.

High-Quality Roll Forming Machine for Wall Panel Production

The Wall Panel Roll Forming Machine is a cutting-edge piece of equipment designed to revolutionize the production of wall panels. This innovative machine, which is manufactured by a company specializing in roll forming machinery, has been hailed as a game-changer in the industry due to its advanced technology and impressive capabilities.The Wall Panel Roll Forming Machine features state-of-the-art engineering, precision manufacturing, and high-quality components. Its cutting-edge design allows for the rapid and efficient production of wall panels, making it an ideal choice for companies looking to improve their manufacturing processes and increase their productivity.One of the key features of the Wall Panel Roll Forming Machine is its versatility. It is capable of producing a wide range of wall panel designs, including standard panels, insulated panels, and decorative panels. This flexibility makes it suitable for a variety of applications, from residential construction to commercial and industrial projects.In addition to its flexibility, the Wall Panel Roll Forming Machine is also known for its high-speed production capabilities. Thanks to its advanced technology and precision engineering, this machine is able to produce wall panels at an impressive rate, significantly reducing production time and costs for manufacturers.Furthermore, the Wall Panel Roll Forming Machine is designed with user-friendly features, making it easy to operate and maintain. This user-friendly design ensures that operators can quickly and efficiently set up the machine for production, minimizing downtime and maximizing productivity.The company behind the Wall Panel Roll Forming Machine is renowned for its expertise in roll forming machinery. With a strong focus on research and development, the company has consistently pushed the boundaries of innovation in the industry, leading to the creation of cutting-edge machines like the Wall Panel Roll Forming Machine.In addition to its commitment to innovation, the company also places a strong emphasis on quality and reliability. Each machine is built to the highest standards, using top-grade materials and advanced manufacturing processes to ensure that it meets the strictest performance and durability requirements.Moreover, the company has an impressive track record of delivering exceptional customer service and support. From the initial consultation to installation and ongoing maintenance, the company provides comprehensive assistance to its customers, ensuring that they are fully satisfied with their investment in the Wall Panel Roll Forming Machine.The Wall Panel Roll Forming Machine is set to have a significant impact on the wall panel manufacturing industry, offering manufacturers a highly efficient and versatile solution for their production needs. With its advanced technology, high-speed production capabilities, and user-friendly design, this machine is poised to become a key asset for companies looking to improve their manufacturing processes and stay ahead of the competition.In conclusion, the Wall Panel Roll Forming Machine is a groundbreaking piece of equipment that is set to transform the way wall panels are produced. With its advanced technology, high-speed production capabilities, and user-friendly design, it offers manufacturers an efficient and versatile solution for their production needs. Combined with the company's dedication to innovation, quality, and customer service, the Wall Panel Roll Forming Machine is undoubtedly a game-changer in the industry.

Advanced Metal Profile Machine for Precise and Efficient Production

Metal Profile Machine Enhances Precision and Efficiency in Company’s ProductionIn today’s competitive manufacturing industry, precision and efficiency are essential factors for success. With the introduction of the Metal Profile Machine at {company name}, the company has taken a significant step towards enhancing its production capabilities and meeting the demands of its clients more effectively.The Metal Profile Machine is a state-of-the-art equipment that has revolutionized the way {company name} fabricates metal profiles for various industrial applications. This advanced machine is equipped with cutting-edge technology that allows for high levels of precision and accuracy in shaping and cutting metal sheets. The result is a more efficient and cost-effective manufacturing process that ultimately benefits both the company and its customers.The implementation of the Metal Profile Machine aligns with {company name}’s commitment to staying at the forefront of technological advancements in the industry. With a focus on innovation and continuous improvement, the company has always sought out the latest tools and equipment to streamline its operations and deliver the highest quality products to its clients.The Metal Profile Machine has significantly enhanced the company’s ability to meet the specific requirements of its customers. With the capability to work with a wide range of metal materials and produce complex profiles with tight tolerances, {company name} can now take on a broader scope of projects and tailor its offerings to the unique needs of each client.Furthermore, the improved precision of the Metal Profile Machine has led to a reduction in material waste, as well as a decrease in the need for manual rework. This not only contributes to a more sustainable manufacturing process but also allows {company name} to optimize its resources and minimize production costs.In addition to the operational benefits, the Metal Profile Machine has also bolstered {company name}’s reputation for delivering top-quality products. The enhanced precision and consistency in the fabrication of metal profiles has resulted in a higher level of product reliability and performance, ultimately leading to greater customer satisfaction and loyalty.Mr. John Smith, the CEO of {company name}, expressed his enthusiasm for the acquisition of the Metal Profile Machine, stating, "We are thrilled to have this cutting-edge technology as part of our manufacturing capabilities. The Metal Profile Machine not only elevates our operational efficiency but also allows us to exceed the expectations of our clients in terms of quality and customization."The addition of the Metal Profile Machine has also opened up new opportunities for {company name} to explore and expand its product offerings. With the ability to produce intricate and bespoke metal profiles, the company is now able to cater to a wider range of industries, including automotive, aerospace, construction, and more.Moving forward, {company name} plans to further leverage the capabilities of the Metal Profile Machine to continue raising the bar in the metal fabrication sector. By harnessing the machine’s potential to innovate and optimize its production processes, the company aims to solidify its position as a leader in the industry and to be the go-to choice for clients seeking superior metal profiles.In conclusion, the introduction of the Metal Profile Machine at {company name} has been a game-changer for the company, allowing it to achieve new levels of precision, efficiency, and customization in its production processes. As the company continues to harness the full potential of this cutting-edge equipment, it is poised to set new standards in the manufacturing industry and deliver exceptional value to its clients.

High-Quality Automatic Wire Length Cutter for Precision Cutting

[Company Logo]Automatic Wire Length Cutter Streamlines Production Process for Manufacturing Industry[Town, Date] – Manufacturing companies and businesses in need of a reliable wire length cutting solution can now turn to the innovative Automatic Wire Length Cutter, developed and produced by [Company Name]. This state-of-the-art machine is designed to revolutionize the wire cutting process, providing unparalleled precision, efficiency, and speed. With its cutting-edge technology and advanced features, the Automatic Wire Length Cutter is set to become a game-changer for the manufacturing industry.[Company Name] is a leading provider of industrial automation and machinery solutions, specializing in the development and production of cutting-edge equipment for a wide range of industries. With a strong focus on innovation and technological advancement, the company is dedicated to providing its clients with the most advanced and reliable solutions to meet their specific needs.The Automatic Wire Length Cutter is the latest addition to [Company Name]'s extensive lineup of industrial automation products. This cutting-edge machine is designed to streamline the wire cutting process, offering unmatched precision and efficiency. With its advanced technology and innovative features, the Automatic Wire Length Cutter is capable of cutting wires of various materials and thicknesses with unparalleled accuracy and speed.One of the key features of the Automatic Wire Length Cutter is its advanced cutting mechanism, which ensures clean and precise cuts without compromising on speed. This is particularly important for manufacturing companies that require high-quality wire cutting solutions to meet the demands of their production processes. In addition, the machine is equipped with a user-friendly interface and intuitive controls, making it easy to operate and highly efficient in a production environment.The Automatic Wire Length Cutter is also designed with versatility in mind, capable of handling a wide range of wire types and sizes. This makes it an ideal solution for manufacturers working with different materials and specifications. With its ability to accommodate various wire cutting requirements, the machine offers a cost-effective and reliable solution for businesses looking to enhance their production processes.Moreover, the Automatic Wire Length Cutter is engineered to meet the highest safety standards, ensuring the protection of operators and personnel in the production environment. With its robust construction and advanced safety features, the machine provides a secure and reliable cutting solution for manufacturing companies and industrial facilities.In addition to its cutting-edge technology and advanced features, the Automatic Wire Length Cutter is backed by [Company Name]'s commitment to customer satisfaction and support. The company's team of experienced professionals is dedicated to providing comprehensive installation, training, and maintenance services to ensure the seamless integration and operation of the machine in a production environment.As a trusted provider of industrial automation solutions, [Company Name] is proud to introduce the Automatic Wire Length Cutter as the latest addition to its lineup of cutting-edge machinery. With its unparalleled precision, efficiency, and reliability, the machine is set to become an indispensable tool for manufacturing companies and businesses in need of a reliable wire cutting solution.For more information about the Automatic Wire Length Cutter and [Company Name]'s complete range of industrial automation solutions, please visit [company website] or contact [contact information].[Company Name] is a leading provider of industrial automation and machinery solutions, specializing in the development and production of cutting-edge equipment for a wide range of industries. With a strong focus on innovation and technological advancement, the company is dedicated to providing its clients with the most advanced and reliable solutions to meet their specific needs.

High-Quality Glazed Roofing Sheet Roll Forming Machine for Sale

Introduction:The Glazed Roofing Sheet Roll Forming Machine is an innovative piece of equipment that allows for the efficient and precise manufacturing of glazed roofing sheets. This machine is a vital tool for businesses involved in the production of roofing materials, as it can greatly increase productivity and ensure high-quality end products. The roll forming process involves feeding a metal sheet through a series of rollers to gradually shape it into the desired profile, making it an ideal solution for producing roofing sheets with a glazed finish.With a focus on providing advanced solutions for the roofing industry, {Company Name} is a leading manufacturer of roll forming machines. The company is dedicated to delivering cutting-edge technology and reliable equipment to meet the needs of its customers. With years of experience and a commitment to innovation, {Company Name} has established a strong reputation in the market and continues to push the boundaries of roll forming technology.News Content:The latest advancement in roll forming technology has arrived with the introduction of the Glazed Roofing Sheet Roll Forming Machine by {Company Name}. This state-of-the-art machine is designed to revolutionize the production of glazed roofing sheets, offering unparalleled precision, efficiency, and quality.The Glazed Roofing Sheet Roll Forming Machine boasts advanced features that set it apart from traditional roll forming equipment. With a robust frame and a powerful motor, this machine is capable of handling various types of metal sheets with ease. Its precise roller configuration allows for the creation of intricate glazed profiles, ensuring that every roofing sheet meets the highest standards of quality.One of the key advantages of the Glazed Roofing Sheet Roll Forming Machine is its versatility. Whether producing roofing sheets for residential, commercial, or industrial applications, this machine can accommodate a wide range of requirements. Its adjustable settings and customizable parameters make it suitable for producing roofing sheets of different sizes, profiles, and surface finishes.Furthermore, the Glazed Roofing Sheet Roll Forming Machine is equipped with advanced control systems that streamline the production process. Operators can easily set and adjust the machine's parameters, monitor its performance, and troubleshoot any issues that may arise. This user-friendly interface allows for efficient operation and reduces the risk of downtime, ensuring continuous productivity.In addition to its technical capabilities, the Glazed Roofing Sheet Roll Forming Machine is designed with a focus on safety and reliability. With built-in safety features and quality components, this machine offers peace of mind to operators and ensures a long service life with minimal maintenance requirements.{Company Name} takes great pride in introducing the Glazed Roofing Sheet Roll Forming Machine to the market, as it represents the company's commitment to pushing the boundaries of roll forming technology. With a strong focus on research and development, {Company Name} continues to innovate and improve its product offerings, delivering cutting-edge solutions to meet the evolving needs of the roofing industry.The launch of the Glazed Roofing Sheet Roll Forming Machine marks a significant milestone for {Company Name}, as it further solidifies the company's position as a leading manufacturer of roll forming equipment. With its unparalleled precision, efficiency, and quality, this machine is set to reshape the production of glazed roofing sheets and empower businesses to thrive in a competitive market.In conclusion, the Glazed Roofing Sheet Roll Forming Machine by {Company Name} represents a leap forward in roll forming technology. With its advanced capabilities, versatility, and focus on safety and reliability, this machine is poised to revolutionize the production of glazed roofing sheets and set new industry standards. As {Company Name} continues to drive innovation and excellence, it is clear that the future of roll forming technology is in capable hands.

Metal Corrugated Roof Roll Forming Machine - A Comprehensive Guide for Roofing Applications

Metal Corrugated Roof Roll Forming Machine Revolutionizes the Roofing Industry In the highly competitive world of construction and architecture, innovation and technology have played a significant role in shaping the industry. One of the areas that have seen a lot of technological advancements is roofing, which has come a long way from traditional roofing materials such as asphalt shingles, clay tiles, and wood shingles. New roofing options such as metal corrugated roofing have become more popular for their durability, versatility, and aesthetic appeal, especially in commercial and industrial buildings.Metal corrugated roofing has gained its popularity because of its durability and strong resistance to weather and corrosion. Additionally, it’s lightweight compared to other traditional roofing materials, which makes it easier and cheaper to install. To meet the growing demand for metal corrugated roofing, companies have developed specialized machinery that can manufacture these roofing materials efficiently. The Metal Corrugated Roof Roll Forming Machine by (Company name removed) is a prime example of such innovation and technology in the roofing industry.The Metal Corrugated Roof Roll Forming Machine is a specialized device designed to bend and shape metal sheet materials into corrugated roof panels. The machine is computer-controlled, which ensures uniform accuracy in its operation. The machine works by feeding metal sheets through the straightening system; then, it passes through the rolling stations, which bend the sheets into corrugated shape. The machine has specialized shears designed to cut the length of the sheets, producing panels in a variety of dimensions, shapes, and gauges.The metal corrugated roofing panels produced using the Metal Corrugated Roof Roll Forming Machine are among the most durable roofing materials in the industry. They are resistant to many environmental factors, including water, wind, and fire. They have excellent thermal insulation properties that help maintain a comfortable indoor temperature, reducing energy costs. Unlike other roofing materials, which require frequent repair, metal corrugated roofs have minimal maintenance costs, making them an excellent investment for any property owner.Several factors make the Metal Corrugated Roof Roll Forming Machine stand out from other roll forming machines in the market. First, it’s highly customizable, allowing the machine to produce roofing panels in different shapes, dimensions, and gauges. The machine can also produce different coatings, including galvanized, pre-painted, or aluminum-zinc, providing customers with options to choose from. Additionally, the machine is highly efficient, capable of producing large volumes of corrugated roofing panels in a short time, thanks to its computer-controlled operation.The Metal Corrugated Roof Roll Forming Machine’s design has incorporated safety features such as guards, emergency stop buttons, and interlock systems to ensure the safety of the operator and enhance the machine's efficiency. The machine's design also allows for easy maintenance, with the operator having access to all critical components.The Metal Corrugated Roof Roll Forming Machine by (Company name removed) not only revolutionizes the roofing industry but also sets the standard for future roll forming machines. The machine's advanced technology, versatility, and efficiency enable users to produce high-quality metal corrugated panels that meet the roofing industry's stringent standards. The machine's design ensures that customers receive materials that are durable, cost-effective, and environmentally friendly.In conclusion, the Metal Corrugated Roof Roll Forming Machine has played a vital role in revolutionizing the roofing industry. Its advanced technology, versatility, and efficiency have set the standard for future roll forming machines, ensuring that customers receive high-quality metal corrugated panels that meet their roofing needs. The roofing industry will continue to benefit from such technological advancements that improve the efficiency of roofing material production, reducing costs while producing quality building materials.