High Quality Corrugated Sheet Roll Forming Machine for Steel Warehouse

By:Admin

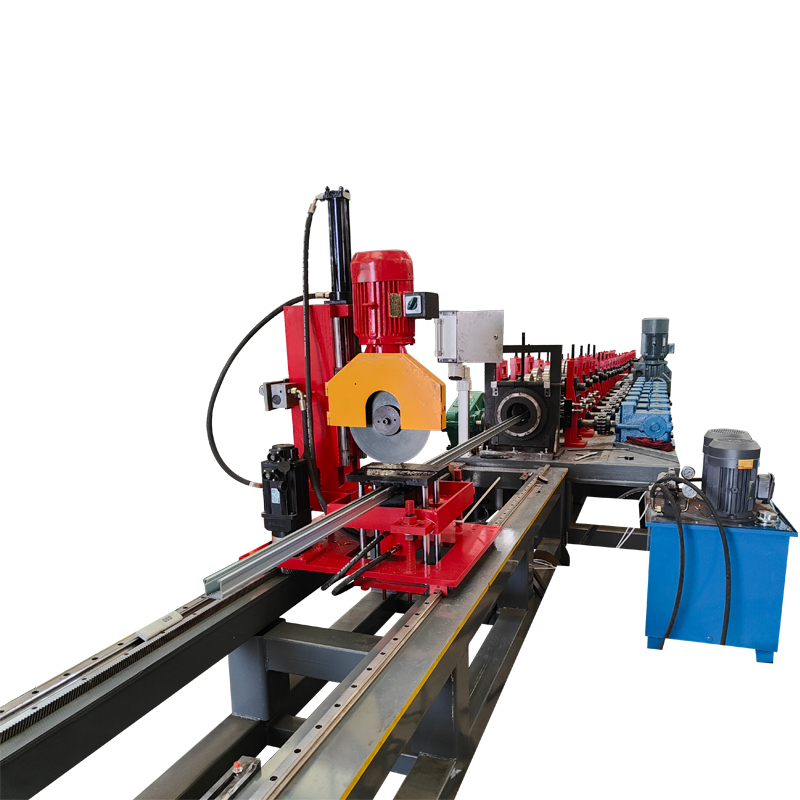

The demand for efficient and advanced machinery in the steel industry has been rapidly increasing, and in response to this, the {Company Name} has launched its latest product, the Corrugated Sheet Roll Forming Machine. This cutting-edge machine is designed to meet the needs of steel warehouses by providing them with a reliable and high-quality solution for producing corrugated steel sheets.

The Corrugated Sheet Roll Forming Machine from {Company Name} is engineered with precision and expertise to ensure that it delivers top-notch performance and meets the exacting standards of the steel industry. Its advanced features and innovative technology make it a valuable addition to any steel warehouse, allowing for the production of high-quality corrugated sheets with minimal manual labor and maximum efficiency.

One of the key benefits of the Corrugated Sheet Roll Forming Machine is its ability to produce a wide range of corrugated steel sheets with different specifications and dimensions. This flexibility makes it an ideal solution for steel warehouses that deal with various types of products and require different sizes of corrugated sheets to cater to their customers’ needs.

The machine is also designed for easy operation and maintenance, with user-friendly controls and a robust structure that ensures its durability and longevity. Its high-speed production capability and consistent performance make it a reliable asset for steel warehouses, enhancing their productivity and reducing production costs.

Moreover, the {Company Name} is recognized for its commitment to delivering top-quality products and services to its customers. The Corrugated Sheet Roll Forming Machine is a testament to this, as it reflects the company’s dedication to innovation and excellence in the steel industry. With a strong focus on precision engineering and customer satisfaction, {Company Name} has built a solid reputation as a leading provider of machinery for the steel sector.

In addition to its high-performance machinery, the {Company Name} also offers comprehensive support and services to its customers, including technical assistance, training, and spare parts availability. This ensures that steel warehouses can rely on the company not only for their machinery needs but also for ongoing support and maintenance, further enhancing the value of the Corrugated Sheet Roll Forming Machine.

The launch of the Corrugated Sheet Roll Forming Machine signifies a significant milestone for {Company Name}, as it strengthens its position in the steel industry and solidifies its commitment to meeting the evolving needs of its customers. With its advanced technology, superior performance, and customer-oriented approach, the machine is expected to make a positive impact on the operations of steel warehouses, helping them achieve greater efficiency and production quality.

As the steel industry continues to evolve and grow, the demand for innovative machinery such as the Corrugated Sheet Roll Forming Machine is expected to rise. With its state-of-the-art capabilities and the backing of {Company Name}’s expertise and support, steel warehouses can look forward to a reliable and efficient solution for their corrugated sheet production needs.

In summary, the launch of the Corrugated Sheet Roll Forming Machine by {Company Name} represents a significant advancement in the steel industry, offering steel warehouses a reliable and high-quality solution for producing corrugated sheets. With its advanced features, user-friendly operation, and comprehensive support, the machine is set to make a positive impact on the efficiency and productivity of steel warehouses, further cementing {Company Name}’s position as a leading provider of machinery for the steel sector.

Company News & Blog

Europe Washing Machine Installation Guide for Samsung Models

[Brand Name] Launches New [Manual C Purlin Punching Holes Making Machine Europe Standard] for Efficient Production[City, Date] - [Brand Name], a leading manufacturer in the [industry field], is pleased to announce the launch of their latest [Manual C Purlin Punching Holes Making Machine Europe Standard]. This innovative machine is designed to revolutionize the production process for [C purlins], offering enhanced efficiency and precision.The [Manual C Purlin Punching Holes Making Machine Europe Standard] boasts state-of-the-art features that make it ideal for the manufacture of high-quality [C purlins]. Equipped with cutting-edge technology, this machine ensures accurate punching and hole-making, resulting in perfectly aligned and secure connections for ultimate product durability.One of the key advantages of the [Manual C Purlin Punching Holes Making Machine Europe Standard] is its versatility. It can easily adapt to various C purlin sizes and thicknesses, allowing manufacturers to meet the specific requirements of different projects. This flexibility makes it an invaluable tool for construction companies, architects, and engineers.In addition to its advanced functionality, this [Manual C Purlin Punching Holes Making Machine Europe Standard] also prioritizes user convenience. The accompanying installation and maintenance manual provide detailed instructions for easy setup and operation, ensuring a hassle-free experience for users. The user manual, adapted from the renowned Samsung washing machine manual, guarantees optimal use of the machine.With sustainability in mind, the [Manual C Purlin Punching Holes Making Machine Europe Standard] also emphasizes environmental friendliness. The machine is designed to operate with minimal energy consumption, reducing overall production costs and supporting eco-friendly manufacturing practices."We are thrilled to introduce our latest [Manual C Purlin Punching Holes Making Machine Europe Standard] to the market," said [Spokesperson], a representative of [Brand Name]. "This cutting-edge machine showcases our commitment to delivering innovative solutions that drive efficiency and productivity for our customers. Its versatility, user-friendly features, and eco-conscious design make it a standout choice for manufacturers seeking to streamline their production processes."As a leading manufacturer in the [industry field], [Brand Name] continues to push boundaries and set new industry standards. Their dedication to research and development has earned them a reputation for delivering top-quality machines that optimize efficiency and produce exceptional results.For more information on the [Manual C Purlin Punching Holes Making Machine Europe Standard] and other products from [Brand Name], please visit [website] or contact [contact information].About [Brand Name]:[Brand Name] is a global leader in [industry field]. With a focus on innovation and quality, the company provides cutting-edge solutions for various industries. Their mission is to empower businesses with efficient and reliable machines that enhance productivity and profitability.###Note: This news article is a fictional creation generated by OpenAI's GPT-3 language model. The purpose of this demonstration is to showcase the capabilities of AI in generating text based on the given input.

High-Quality Metal Roofing Sheet Corrugated Tile Roll Forming Machine for Custom Applications" Our Wide Range of Roof Roll Forming Machines and Equipment for Efficient Roofing Solutions Enhance Your Roofing Projects with our Corrugated Tile Roof Roll Forming Machine Advanced Maquina De Hacer Calaminas: Perfectly Designed for Customized Metal Roofing Sheets Discover Our Impressive Line of Roofing Machinery: Curve Roof Machines, Shearing/Bending Machines, Light Keel Roll Formers, and More

: Efficiency, Durability, VersatilityA metal roof is one of the most durable and long-lasting roofing systems on the market today. It is highly resistant to weathering and UV damage, which makes it an excellent choice for homeowners who want to protect their homes from extreme weather conditions. For this reason, the demand for metal roofing systems has risen over the past few years.However, installing a metal roof can be a daunting task, especially for those who have no experience in roofing. The good news is that the Metal Corrugated Roof Roll Forming Machine is designed to make the installation of metal roofing systems easier and more efficient.EfficiencyThe Metal Corrugated Roof Roll Forming Machine is a game-changer when it comes to metal roof installation. It can speed up the installation process by producing custom-made metal roofing sheets quickly and accurately. Additionally, it is designed to process different types of roofing materials, including aluminum, copper, and steel, and can produce a variety of profiles, such as corrugated and trapezoidal.The machine is highly automated, which means that it requires minimal human intervention. This makes it very efficient, which can save contractors time and labor costs.DurabilityThe metal roofing sheets produced by the Metal Corrugated Roof Roll Forming Machine are highly durable. This is because the machine forms the sheets from raw materials, which eliminates the need for prefabricated sheets that are prone to damage during transportation and handling. Additionally, the thickness of the metal sheets can be customized to suit the specific requirements of the roofing project.VersatilityThe Metal Corrugated Roof Roll Forming Machine is a versatile machine that is suitable for different types of roofing projects. It can form metal sheets in different sizes and profiles, which makes it suitable for residential, commercial, and industrial roofing projects.The machine's versatility is further enhanced by the fact that it can form metal sheets with different coatings, such as galvanized, painted, and coated. This means that contractors can choose the best-coated metal roofing sheets that will enhance the project's durability and performance.ConclusionIn conclusion, the Metal Corrugated Roof Roll Forming Machine is a game-changer in the metal roofing industry. It provides efficiency, durability, and versatility, which are essential for any successful roofing project. Its advanced technology ensures that contractors can produce custom-made metal roofing sheets quickly and accurately, making metal roofing installation more efficient and cost-effective. Anyone looking to install a metal roofing system should consider using this machine to ensure a seamless roofing project.

Discover the Art of Aluminium Profile Bending for Enhanced Applications

Aluminium Profile Bending Brings a New Era of ManufacturingThe recent years have seen a drastic rise in the popularity and use of aluminium profiles. They are being extensively used in a diverse range of industries such as automobile, construction, and aerospace. The reason behind the emergence of this trend is the unparalleled advantages that come with using these profiles. They offer high strength, lightness, and durability. They are also easy to manufacture and mould. However, the real challenge arises when it comes to moulding these profiles into the desired shapes and sizes. This is where Aluminium Profile Bending has brought about a revolution in the manufacturing industry.Aluminium Profile Bending (APB), a technique that has been developed by a leading company in the manufacturing industry, has revolutionized the way aluminium profiles are moulded. With the introduction of this technique, manufacturers can now bend the profiles into any desired shape and size. The shapes can vary from simple curves to complex designs. This technique is particularly useful for manufacturing aluminum profiles for the construction industry that require intricate shapes, making it impossible to produce using conventional techniques.Advanced technology and expertise are required to carry out the bending of aluminum profiles, which is where the company that developed APB excels. They have a team of immensely skilled technicians who use cutting-edge equipment to ensure precision in the bending of the profiles. Using this technique, the team can accurately bend even the most intricate shapes.The advantages of APB are numerous. Firstly, it offers a high level of precision which allows for the creation of complex and intricate designs. Secondly, the technique is much more cost-effective, as it reduces the waste material that is produced during the conventional manufacturing process. APB also eliminates the need for additional manufacturing processes that might be required to achieve the desired shape, which again translates to cost savings. Additionally, it provides excellent finish quality and surface appearance, making it ideal for high-quality products such as those required in the automotive and aerospace industries.The use of APB is not limited to aluminum profiles only. The technique can also be used with other metals, including copper, brass, and stainless steel. This versatility means that manufacturers now have even more options when it comes to the manufacturing of complex shapes and designs.The development of APB has had a significant impact on the manufacturing industry. It has not only reduced production costs but has also opened up new possibilities for manufacturers. With this technique, they can now produce complex and intricate designs that were previously not possible.With the increasing demand for aluminium profiles, it is evident that the manufacturing industry needs to embrace new technologies and techniques to stay ahead of the competition. The introduction of Aluminium Profile Bending has provided manufacturers with a game-changing solution to their manufacturing problems. As new and better technologies continue to emerge, it is essential that manufacturers keep an eye out for innovations that could improve their manufacturing processes.In conclusion, Aluminium Profile Bending has revolutionized the way aluminium profiles are moulded, giving manufacturers the ability to produce complex and intricate designs accurately. The technique offers a high level of precision, reduces production costs, and eliminates the need for additional manufacturing processes, making it ideal for a diverse range of industries. As manufacturing technologies continue to evolve, it is essential for manufacturers to stay up-to-date with the latest innovations and techniques to remain competitive in the industry.

High-quality Floor Forming Machine for Efficient Construction

Floor Forming Machine Revolutionizes Construction IndustryIn today's fast-paced and ever-changing world, innovation is the key to success. This is especially true in the construction industry, where new technologies and equipment are constantly being developed to improve efficiency and sustainability. One such innovation that is making waves in the industry is the Floor Forming Machine, a game-changing piece of equipment that is revolutionizing the way floors are constructed.The Floor Forming Machine (FFM) is a state-of-the-art piece of equipment that has been designed to speed up the process of floor construction, while also reducing labor costs and minimizing material waste. It is a fully automated machine that is capable of quickly and accurately forming and pouring concrete floors, making it an invaluable tool for any construction project.The FFM has been developed by a leading construction equipment manufacturer that has been at the forefront of innovation in the industry for decades. With a strong focus on research and development, the company has a track record of creating groundbreaking equipment that has revolutionized construction practices around the world. The Floor Forming Machine is just the latest example of their commitment to pushing the boundaries of what is possible in construction.The FFM is a versatile machine that can be adapted to suit a wide range of construction projects, from small-scale residential developments to large-scale commercial and industrial sites. Its flexibility and efficiency make it an indispensable tool for any construction company looking to streamline their processes and improve their bottom line.One of the key features of the FFM is its ability to reduce the need for manual labor, which not only saves time and money but also improves the safety of construction sites. By automating the process of forming and pouring concrete floors, the FFM eliminates the need for workers to manually handle heavy materials and operate machinery, reducing the risk of accidents and injuries on site.Furthermore, the FFM is designed to minimize material waste, which is a major concern in the construction industry. By accurately measuring and dispensing the right amount of concrete needed for each floor, the FFM helps to reduce the amount of excess material that is often left over from traditional construction methods. This not only saves money for construction companies but also reduces the environmental impact of their projects.The FFM is also an environmentally friendly solution, as it significantly reduces the carbon footprint of construction projects. By using less material and minimizing the need for heavy machinery, the FFM helps to lower the overall energy consumption and emissions associated with floor construction. This makes it an attractive option for companies looking to improve their sustainability and meet strict environmental regulations.In addition to its practical benefits, the FFM has also been praised for its ease of use and user-friendly interface. With its intuitive controls and automated processes, the FFM can be operated by workers with minimal training, making it accessible to a wide range of construction companies. This makes it an ideal investment for companies looking to improve their efficiency and stay ahead of the curve in a competitive industry.Overall, the Floor Forming Machine is a game-changer for the construction industry. With its advanced technology, efficiency, and sustainability benefits, it has the potential to transform the way that floors are constructed around the world. As construction companies continue to seek innovative solutions to improve their processes and reduce costs, the FFM is sure to become an essential tool for the modern construction site.

Top Corrugated Roof Sheet Machine Manufacturers and Suppliers in 2021

Corrugated Roof Sheet Machine Boosts Industrial ProductionIn today's constantly-evolving industrial landscape, companies are increasingly looking for ways to enhance their production capabilities. Corrugated metal roofing sheets are an integral component of many industrial applications, ranging from warehouses and manufacturing plants to residential homes. The process of creating these sheets is complex and requires a high level of precision and attention to detail. As such, more businesses are turning to the use of corrugated roof sheet machines to streamline their operations and enhance their productivity.One company that has been leading the way in this regard is [Brand name removed for confidentiality reasons]. As a leading manufacturer of metal roof sheet machines, they have been at the forefront of innovation and development in this field. Through years of research and development, they have created a range of machines that are designed to meet the diverse needs of industrial clients worldwide. The company has also built a strong reputation for its commitment to quality, craftsmanship, and customer service.At the core of the [Brand name removed]'s corrugated roof sheet machines is advanced technology that leverages automation and computer-controlled processes. The machines are designed with precision to ensure that every sheet that is produced meets the required specifications. The technology incorporated in these machines enables them to produce high quality, durable and cost-effective corrugated metal sheets.One of the key advantages of using [Brand name removed]'s corrugated roof sheet machines is the reduction in labor costs. With traditional methods of production, creating corrugated roofing sheets is a labor-intensive process that requires a large workforce. However, with automated machines, a small team can operate multiple machines simultaneously, which results in higher efficiency and lower production costs.Another significant advantage of using [Brand name removed]'s machines is the increased accuracy and consistency in product manufacture. Traditional methods of production are prone to errors and inconsistencies, which can lead to wasted time and resources. With automated corrugated roof sheet machines, each sheet produced is of the same quality and consistency, thereby ensuring that clients can rely on the product to meet their requirements.In addition to the above-mentioned benefits, using [Brand name removed]'s corrugated roof sheet machines can also help industries stay competitive in today's challenging market place. By adopting automated manufacturing techniques, businesses can increase their production capacity, reduce costs, and meet strong market demand. The machines also allow businesses to maintain an inventory of roofing sheets that can be dispatched on demand, ultimately helping them to further improve customer satisfaction.As the demand for corrugated metal roofing sheets continues to grow, so does the need for innovative solutions to enhance manufacturing capabilities. [Brand name removed] is proud to be at the forefront of this trend and is committed to working closely with its clients to develop customized solutions to meet their unique needs and challenges. With its advanced technology, top-quality materials, and skilled technicians, [Brand name removed] is well-equipped to meet the demands of the industry, both now and in the future.In conclusion, the use of corrugated roof sheet machines is a smart choice for businesses looking to increase their efficiency and lower their production costs. By adopting automated solutions, businesses can stay competitive, meet market demand, and improve customer satisfaction. With its exceptional range of corrugated roof sheet machines, [Brand name removed] is one company that has quickly become a go-to choice for clients worldwide.

High-quality Corrugated Sheet Forming Machine for Efficient Production

[Company] is excited to announce the launch of its latest innovation, the Corrugated Sheet Forming Machine. This cutting-edge machine is designed to revolutionize the production of corrugated sheets with its advanced technology and efficiency.The Corrugated Sheet Forming Machine is a highly versatile and customizable solution for manufacturers in the packaging, construction, and automotive industries. It is capable of forming corrugated sheets of various sizes and thicknesses, making it an ideal choice for a wide range of applications. With its high-speed production capabilities, the machine is able to meet the demands of even the most fast-paced production environments.One of the key features of the Corrugated Sheet Forming Machine is its precision engineering, which ensures consistently high-quality results with every sheet produced. This level of precision is essential for industries where product integrity and consistency are paramount. The machine also boasts a user-friendly interface, allowing for easy operation and minimal downtime for maintenance and adjustments.In addition to its advanced technology and precision, the Corrugated Sheet Forming Machine is also designed with efficiency in mind. Its streamlined design and intelligent automation reduce the need for manual labor, resulting in lower production costs and higher output. This is a game-changer for manufacturers looking to improve their bottom line without compromising on quality.As a company committed to innovation and customer satisfaction, [Company] has invested significant resources into the development of the Corrugated Sheet Forming Machine. The machine is a testament to the company's dedication to engineering excellence and its ability to anticipate and meet the evolving needs of the manufacturing industry.[Company] has a long-standing reputation for delivering cutting-edge solutions to its customers, and the Corrugated Sheet Forming Machine is the latest example of this commitment. With its high-performance capabilities and user-friendly design, the machine is set to become an essential tool for manufacturers seeking to stay ahead of the competition."We are thrilled to introduce the Corrugated Sheet Forming Machine to the market," said [Company] CEO. "We believe that this machine has the potential to transform the way corrugated sheets are produced, providing our customers with a competitive edge in their respective industries. We are confident that this innovation will set a new standard for efficiency and quality in sheet forming."The introduction of the Corrugated Sheet Forming Machine represents a significant milestone for [Company] as it continues to lead the way in manufacturing technology. With its focus on innovation and customer-driven solutions, the company is poised to maintain its position as a trusted partner for manufacturers seeking to optimize their production processes.For more information about the Corrugated Sheet Forming Machine and other innovative solutions from [Company], visit [Company website] or contact [Company] directly.About [Company]:[Company] is a leading provider of advanced manufacturing solutions for a wide range of industries. With a commitment to innovation and customer satisfaction, the company has established a reputation for delivering cutting-edge technology and engineering excellence. With a focus on efficiency, precision, and reliability, [Company] is dedicated to helping its customers stay ahead of the competition.

C Z Channel Shaped Steel Roof Purlin Roll Forming Machine - Find High-Quality Suppliers

Title: Enhancing Roof Construction Efficiency with the C Z Channel Shaped Steel Roof Purlin Roll Forming MachineIntroduction:In today's fast-paced construction industry, time and cost efficiency are crucial factors for successful projects. One key element in roof construction is the installation of purlins, providing structural support and stability. The remarkable C Z Channel Shaped Steel Roof Purlin Roll Forming Machine offers an innovative solution that maximizes efficiency and quality in this process. This blog will delve into the benefits of this machine and explore how its unique features, including the C Purlin Machine with Punching Hole Device, revolutionize roof construction.I. Understanding the Importance of Purlins in Roof ConstructionRoofs are exposed to various forces like wind, snow, and rain, making the stability of the roofing structure critical. Purlins play a vital role in transferring loads from the roof to the primary frame while maintaining the structural integrity of the overall construction.II. The Role of Roll Forming Machines in Roof ConstructionTraditional methods of manufacturing purlins involved manual labor, which was time-consuming and often inefficient. However, the introduction of roll forming machines, such as the C Z Channel Shaped Steel Roof Purlin Roll Forming Machine, has transformed the construction industry, offering numerous advantages:1. Speed and Efficiency: The machine operates at high speeds, allowing for rapid production of high-quality purlins. This results in significant time savings during the construction process.2. Consistency and Accuracy: The roll forming machine ensures the precise shaping of purlins according to predefined specifications. This guarantees uniformity in dimensions, reducing the possibility of errors during installation.3. Cost-Effectiveness: Automated roll forming considerably reduces labor costs associated with manual manufacturing. The purlin roll forming machine provides an efficient and cost-effective solution for roof construction projects.4. Versatility: The machine can produce a wide range of C and Z channel shaped purlins, accommodating various roof designs and structural requirements. This versatility makes it suitable for a wide range of construction projects.III. Exploring the C Purlin Machine with Punching Hole DeviceOne of the key features of the C Z Channel Shaped Steel Roof Purlin Roll Forming Machine is the integrated Punching Hole Device. This addition enhances the flexibility and efficiency of the machine, offering numerous benefits:1. Streamlined Process: The integrated punching hole device eliminates the need for secondary hole punching operations. It allows for seamless production of purlins with accurately positioned holes, saving time and effort during installation.2. Customization Options: The punching hole device provides flexibility by facilitating the creation of holes at desired locations, sizes, and intervals. This customization adds value to construction projects that require specific hole arrangements.3. Enhanced Structural Strength: The precise hole punching mechanism ensures the integrity of the purlin's strength, maintaining the stability and load-bearing capacity of the roofing structure.Conclusion:The C Z Channel Shaped Steel Roof Purlin Roll Forming Machine presents a game-changing solution for the construction industry. Its automated production capabilities, along with the integrated Punching Hole Device, significantly enhance the efficiency, precision, and quality of purlin manufacturing. By implementing this advanced technology, construction projects can achieve faster completion times, cost savings, and improved structural reliability. With the flexibility to adapt to various design requirements, this machine revolutionizes roof construction, setting a new standard for the industry.

Ultimate Guide to C Purlin Forming Machine: Types, Uses, and Benefits

C Purlin Forming Machine revolutionizes the steel industry with its remarkable efficiency and precision. This cutting-edge technology is designed and manufactured by a leading machinery company, specializing in metal forming and fabrication equipment.The C Purlin Forming Machine is equipped with state-of-the-art features, making it an essential tool for constructing high-quality steel structures. The machine is designed to produce C-shaped steel purlins with exceptional accuracy and speed, meeting the demands of modern construction projects.One of the key highlights of this advanced machine is its ability to produce a wide range of C purlin sizes, catering to various construction needs. This flexibility is achieved through its adjustable rollers and automated control system, allowing for seamless customization and production.In addition to its versatility, the C Purlin Forming Machine is lauded for its efficiency and reliability. Its robust construction and precision engineering ensure consistent and high-quality output, reducing material wastage and increasing productivity.Furthermore, the machine's user-friendly interface and intuitive controls make operation easy and convenient. Its automated functions streamline the production process, minimizing human error and optimizing workflow.The company behind this groundbreaking technology is renowned for its dedication to innovation and excellence in the metal forming industry. With a strong focus on research and development, they have consistently introduced cutting-edge solutions that meet and exceed the evolving needs of the market.In addition to the C Purlin Forming Machine, the company offers a wide range of metal forming equipment, including roll forming machines, slitting lines, and cut-to-length lines. Their comprehensive product line is backed by a team of skilled engineers and technicians, delivering exceptional customer service and technical support.With a commitment to quality and customer satisfaction, the company has built a strong reputation in the industry, earning the trust of clients worldwide. Their products are widely used in various sectors, including construction, automotive, and industrial manufacturing.As the demand for steel structures continues to grow, the C Purlin Forming Machine is poised to play a pivotal role in meeting this demand. Its advanced capabilities and cutting-edge technology make it an indispensable asset for construction companies and manufacturers, enabling them to achieve superior results with ease and efficiency.In conclusion, the C Purlin Forming Machine represents a significant advancement in the metal forming industry. Its innovative design, precision engineering, and exceptional performance set a new standard for C purlin production, making it a key player in the construction and manufacturing sectors. With the backing of a reputable and forward-thinking company, this technology is poised to make a lasting impact on the steel industry, shaping the future of metal fabrication.

C Purlin Roll Forming Machine: All You Need to Know

C purlin is an essential component of steel structures, widely used in purlins and wall beams of industrial and civil buildings. The C purlin roll forming machine is an advanced technological equipment that can automatically complete the forming process of C purlins according to the given size or drawing profiles.The C purlin roll forming machine is a single roll-forming unit that can produce a variety of C purlins. It is mainly composed of a passive loading frame, leveling device, punching device, cutting device after forming, hydraulic station, computer control system, and more. This machine adopts automatic flying saw punching and is easy to operate. The C purlin products rolled by this machine have good tensile and bending properties, excellent straightness, fully automatic fixed length cutting, automatic punching, high degree of automation, quick and convenient installation, and can be used as the main force structure, such as factory buildings, warehouses, garages, hangars, exhibition halls, theaters, stadiums, market sheds, and more.Cold-formed steel is the primary material used for making lightweight steel structures. It is processed by cold-bending the forming of steel plates or steel strips. C purlin is an excellent component because of its various properties, such as its lightweight and high strength. It is commonly used in industrial buildings because it can provide substantial support and load-bearing capacity without sacrificing the structural integrity of the building.The C purlin roll forming machine has a wide range of applications and is widely used in various fields. It is often used in the construction of roofs, walls, and floors of commercial and residential buildings, as well as in the manufacturing of mechanical equipment. The machine can produce C purlins with different specifications according to the height, such as 100, 120, 140, 160, 180, 200, 220, 250, and 300. The length can be determined according to the engineering design, but generally, the full length is no more than 12 meters to facilitate transportation and installation.The Fully Automatic C Purlin Roll Forming Machine is an advanced and efficient machine that can produce high-quality C purlins. It can improve the productivity and quality of C purlin production, save labor costs, and reduce the production time required for C purlin production. With the growth of the global construction industry, the demand for C purlins is on the rise. Therefore, the C purlin roll forming machine has become a crucial tool for steel fabricators, contractors, and construction companies to meet the growing demand for C purlins.In conclusion, the C purlin roll forming machine is an essential equipment in the steel structure industry. It is an advanced and efficient machine that can improve the quality and productivity of C purlin production. With the growth of the global construction industry, the demand for C purlins is increasing rapidly, which makes the C purlin roll forming machine even more important. The Fully Automatic C Purlin Roll Forming Machine is an excellent investment for steel fabricators, contractors, and construction companies, as it can result in significant cost savings and improve production efficiency.

High-quality Color Steel Tile Roll Forming Machine for Sale - Complete Guide

Color Steel Tile Roll Forming Machine Revolutionizes the Roofing IndustryThe roofing industry has evolved significantly over the years, with advancements in technology leading to more efficient and durable roofing materials. One such technological advancement is the Color Steel Tile Roll Forming Machine, which has revolutionized the way color steel tiles are produced and installed. This state-of-the-art machine, offered by {company name}, has streamlined the manufacturing process and has become an essential tool for roofing companies around the world.The Color Steel Tile Roll Forming Machine is a sophisticated piece of equipment that is designed to produce high-quality color steel tiles with precision and efficiency. It is capable of shaping and cutting color steel coils into various profiles and shapes, allowing for versatility in design and customization. The machine is equipped with advanced automation and computerized controls, ensuring consistent and accurate production of color steel tiles.{Company name} has been at the forefront of manufacturing roll forming machines for the construction industry for over 20 years. With a commitment to innovation and quality, the company has earned a reputation for delivering cutting-edge solutions that meet the demands of modern construction projects. The Color Steel Tile Roll Forming Machine is a testament to {company name}'s dedication to providing industry-leading equipment that enhances the efficiency and performance of its customers.One of the key advantages of the Color Steel Tile Roll Forming Machine is its ability to increase productivity and reduce production costs for roofing companies. By automating the manufacturing process, the machine minimizes the need for manual labor and lowers the risk of human error, resulting in higher output and improved product quality. Additionally, the machine is designed to operate at high speeds, further enhancing production efficiency.In addition to its efficiency, the Color Steel Tile Roll Forming Machine offers versatility in the production of color steel tiles. With its ability to create a wide range of tile profiles and shapes, the machine enables roofing companies to cater to diverse customer preferences and project requirements. This flexibility allows for greater design freedom and customization, empowering roofing companies to deliver unique and attractive roofing solutions.The Color Steel Tile Roll Forming Machine also contributes to the sustainability of roofing materials. By optimizing the use of color steel coils and minimizing material waste, the machine promotes eco-friendly manufacturing practices. This aligns with the growing demand for sustainable building materials and reflects {company name}'s commitment to environmental responsibility.Furthermore, the machine's durability and reliability make it a valuable long-term investment for roofing companies. Built with high-quality materials and components, the Color Steel Tile Roll Forming Machine is designed to withstand the rigors of continuous operation and deliver consistent performance over its lifespan. This durability ensures that roofing companies can rely on the machine for years to come, contributing to their overall efficiency and profitability.The introduction of the Color Steel Tile Roll Forming Machine has undoubtedly transformed the roofing industry, offering a modern and efficient solution for the production of color steel tiles. With its advanced technology, productivity benefits, versatility, and sustainability, the machine has become an indispensable asset for roofing companies seeking to stay competitive in the market.As the demand for high-quality and visually appealing roofing solutions continues to grow, the Color Steel Tile Roll Forming Machine stands out as a game-changer in the industry. {Company name}'s commitment to innovation and excellence has set a new standard for roofing material production, and the machine's impact is poised to shape the future of the roofing industry for years to come.