High-Quality Machine for Forming Deck Floors Available Now

By:Admin

With a proven track record of delivering high-quality construction machinery and equipment, [Company Name] has established itself as a leading provider in the industry. The company prides itself on its commitment to innovation, quality, and customer satisfaction, offering a wide range of products that cater to the diverse needs of the construction sector. [Company Name] strives to be at the forefront of technological advancements, constantly seeking to improve its products and services to meet and exceed the expectations of its customers.

[News Content]:

In the construction industry, the efficiency and quality of the machinery and equipment used can significantly impact the overall outcome of a project. One such crucial aspect of construction is the creation of sturdy and reliable deck floors, and to meet this demand, [Company Name] has introduced a state-of-the-art Deck Floor Forming Machine.

The Deck Floor Forming Machine is designed to streamline the process of creating precise and uniform deck floors, offering a range of features that make it a valuable asset for construction companies. The machine is capable of forming a variety of deck floor profiles, allowing for flexibility in design while maintaining structural integrity. Its advanced technology ensures that each deck floor is produced with precision and accuracy, meeting the highest standards of quality.

One of the key advantages of the Deck Floor Forming Machine is its efficiency. By automating the forming process, [Company Name] has enabled construction companies to significantly reduce the time and labor required to create deck floors, thereby increasing overall productivity and reducing costs. This efficiency not only benefits the construction companies but also allows for quicker project completion, meeting deadlines and improving client satisfaction.

Furthermore, the Deck Floor Forming Machine is equipped with safety features and user-friendly controls, prioritizing the well-being of the operators and ensuring ease of use. With comprehensive training and support provided by [Company Name], construction companies can confidently integrate this machine into their operations, knowing that it adheres to the highest safety standards and can be operated with minimal risk.

In addition to its technological advancements, the Deck Floor Forming Machine is built with durability in mind. Constructed from high-quality materials and components, it is designed to withstand the rigors of continuous use in various construction environments. This longevity not only ensures a strong return on investment for construction companies but also reflects [Company Name]'s commitment to providing reliable and long-lasting solutions to its customers.

As [Company Name] continues to expand its product offerings, the introduction of the Deck Floor Forming Machine further solidifies its position as a trusted partner for the construction industry. By incorporating cutting-edge technology and engineering expertise into its machinery, the company reaffirms its dedication to driving progress and innovation within the construction sector.

The Deck Floor Forming Machine from [Company Name] is poised to revolutionize the way deck floors are produced, offering a combination of efficiency, quality, and reliability that sets a new standard in the industry. With its potential to transform construction processes and elevate project outcomes, it is a testament to [Company Name]'s ongoing commitment to empowering its customers with the best-in-class solutions.

Company News & Blog

Revolutionary Fully Automatic Color Steel Roll Forming Machine Takes the Industry by Storm

Fully Automatic Roll Forming Machine Revolutionizes Color Steel ProductionIn recent years, the demand for efficient and high-quality steel construction materials has increased significantly with the accelerated pace of urbanization and industrialization. To meet this growing demand, the development of advanced machinery and manufacturing processes has become paramount. Now, a breakthrough in color steel production has been achieved with the introduction of a fully automatic roll forming machine, which promises to revolutionize the industry.Traditionally, the manufacturing of color steel products involved multiple stages, including cutting, bending, and welding. This time-consuming and labor-intensive process often resulted in inconsistent quality and high production costs. However, with the advent of the fully automatic roll forming machine, these issues are being effectively addressed.The fully automatic roll forming machine utilizes a continuous process, where a long strip of color steel is fed into the machine and then transformed into the desired shape through a series of precisely controlled rollers. This innovative technology eliminates the need for manual labor, significantly reducing production time and increasing output.One of the major advantages of this new technology is the exceptional precision it offers. With advanced computer control systems, the machine can accurately adjust the dimensions and angles of the color steel components, resulting in consistently high-quality products. This level of precision ensures that each piece can be seamlessly interconnected during construction, enhancing the durability and structural integrity of the final structures.Furthermore, the fully automatic roll forming machine can handle various types and thicknesses of color steel, allowing manufacturers to produce a wide range of products for different applications. Whether it is roofing sheets, wall panels, or steel framing elements, this machine offers the versatility required to meet diverse customer needs.In addition to its precision and versatility, the fully automatic roll forming machine also boasts impressive productivity. With its high-speed operation, it can produce several meters of color steel products per minute, greatly increasing output compared to traditional manufacturing methods. This increased efficiency translates into cost savings for manufacturers and faster delivery times for customers.The introduction of this advanced technology has not only transformed the color steel production process, but it has also revolutionized the industry as a whole. Manufacturers now have the capability to produce high-quality color steel products at a much faster pace, satisfying the growing demand for construction materials in record time.Furthermore, the fully automatic roll forming machine represents a more environmentally friendly approach to color steel production. By eliminating the need for manual labor and optimizing material usage, it minimizes waste and reduces carbon emissions. This aligns with the global trend towards sustainable manufacturing practices, making it an attractive choice for environmentally conscious companies.As a leading player in the roll forming machine industry, {} has taken the lead in developing and promoting this revolutionary fully automatic roll forming machine. With years of experience and expertise, the company has successfully engineered a state-of-the-art machine that sets new standards for efficiency, precision, and productivity in color steel production.With the adoption of this innovative technology, manufacturers can now streamline their production processes, improve product quality, and ultimately meet the growing demands of an expanding market. In conclusion, the fully automatic roll forming machine marks a significant milestone in color steel production, providing numerous benefits for manufacturers, customers, and the environment.

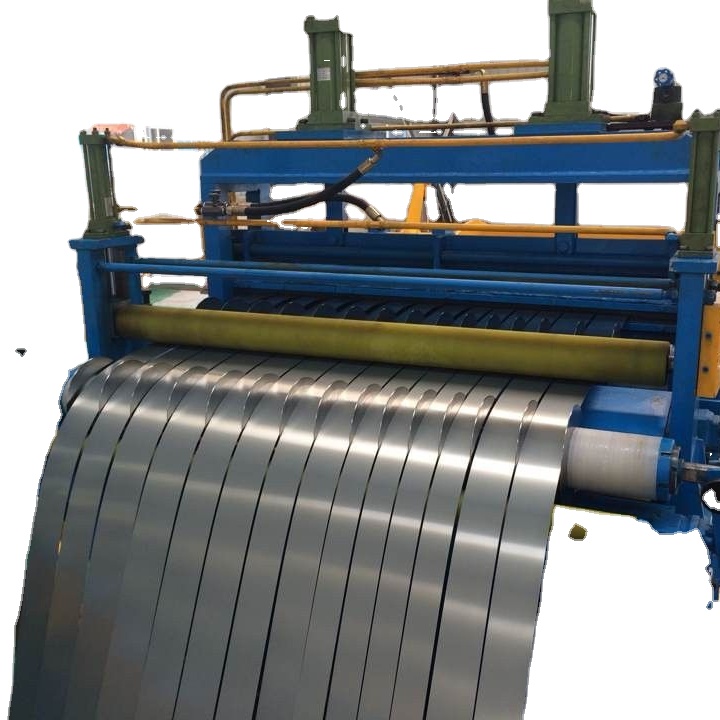

Efficient 16 Gauge Sheet Metal Slitter: All You Need to Know

{Insert Company Name}, a leading manufacturer of industrial machinery, is proud to announce the release of its latest innovation, the 16 Gauge Sheet Metal Slitter. This state-of-the-art machine is designed to revolutionize the metal slitting industry, providing customers with unprecedented levels of efficiency and precision.Sheet metal slitting is a crucial process in various industries, including construction, automotive, and manufacturing, where sheets of metal are cut into smaller, more manageable strips. Traditionally, this task has been approached using cumbersome and time-consuming techniques. However, with the introduction of the 16 Gauge Sheet Metal Slitter by {Insert Company Name}, the process has been streamlined and made considerably more efficient.The 16 Gauge Sheet Metal Slitter stands out from the competition due to its exceptional design and advanced features. Made from high-quality materials, this machine offers unparalleled durability, ensuring a long-lasting and reliable solution for businesses. Its precision-engineered components guarantee consistent and accurate cuts, eliminating the risk of errors or irregularities.One of the key highlights of the 16 Gauge Sheet Metal Slitter is its user-friendly interface. Equipped with an intuitive control panel, operators can easily navigate through the various settings and parameters. Additionally, the machine boasts an ergonomic design, prioritizing the comfort and safety of the users. With adjustable settings and quick changeover capabilities, operators can effortlessly switch between different sheet sizes and materials, enhancing overall productivity.Safety is a top priority at {Insert Company Name}, and the 16 Gauge Sheet Metal Slitter reflects this commitment. The machine is equipped with comprehensive safety features, including emergency stop buttons, safety guards, and intelligent sensors that detect any anomalies or potential hazards. This ensures maximum protection for operators and minimizes the risk of accidents or injuries in the workplace.Another key feature of the 16 Gauge Sheet Metal Slitter is its versatility. This machine is capable of handling a wide range of sheet metal materials, including stainless steel, aluminum, and galvanized steel. With adjustable cutting speeds and precision-guided blades, it can easily accommodate different thicknesses and widths of metal, making it suitable for various applications.With the 16 Gauge Sheet Metal Slitter, {Insert Company Name} aims to provide customers with a solution that not only improves efficiency but also saves time and reduces costs. By automating the slitting process, businesses can significantly increase their production output while maintaining consistent quality. This, in turn, leads to higher profitability and a competitive edge in the market.In addition to its exceptional performance, {Insert Company Name} also prides itself on providing excellent customer support. Their team of experienced technicians is available to assist customers with installation, training, and ongoing maintenance, ensuring a smooth and hassle-free experience throughout the lifespan of the machine.As the metal industry continues to evolve and demand for efficient slitting solutions increases, {Insert Company Name} remains at the forefront of innovation. With the introduction of the 16 Gauge Sheet Metal Slitter, they continue to push boundaries and offer cutting-edge solutions to meet the diverse needs of their customers.In conclusion, the 16 Gauge Sheet Metal Slitter by {Insert Company Name} is set to redefine the metal slitting industry. With its advanced features, user-friendly interface, and unmatched versatility, this machine is poised to become an indispensable tool for businesses seeking to improve their productivity and competitiveness. {Insert Company Name} yet again raises the bar with this innovative solution, solidifying its reputation as a leader in the field of industrial machinery.

High-Quality Glazed Tile Roll Forming Machine for Sale - Best Price Guaranteed!

Title: Enhance Efficiency and Precision with the Glazed Tile Roll Forming MachineIntroduction:In the fast-paced construction industry, time and precision are paramount. The Glazed Tile Roll Forming Machine offers an efficient and reliable solution for producing high-quality glazed tiles quickly and accurately. As a leading manufacturer and supplier of glazed tile forming machines in China, we strive to provide state-of-the-art equipment that meets our clients' needs. In this blog, we will explore the benefits of using a Glazed Tile Roll Forming Machine and why it is crucial to contact us for your machinery requirements.1. What is a Glazed Tile Roll Forming Machine?A Glazed Tile Roll Forming Machine is a specialized piece of equipment designed to transform raw materials into elegantly-designed glazed tiles. It encompasses a series of forming rollers, cutters, and other components that shape the metal sheets into the desired tile profile. This automated process ensures consistency, precision, and a high production rate, eliminating the need for labor-intensive and time-consuming manual fabrication.2. Unraveling the Advantages:2.1 Impeccable Precision:The Glazed Tile Roll Forming Machine allows for precise control over the dimensions and specifications of each tile produced. With computer-aided design (CAD) software, it provides detailed and accurate customization, ensuring a seamless fit when installing the tiles. This level of precision translates into reduced wastage and increased customer satisfaction.2.2 High Production Rate:By automating the tile production process, the Glazed Tile Roll Forming Machine significantly enhances productivity. It can roll out a large number of tiles in a short period while maintaining consistency in shape, size, and quality. This enables contractors and manufacturers to meet deadlines efficiently and fulfill large-scale projects with ease.2.3 Versatility in Design and Dimensions:Our Glazed Tile Roll Forming Machine can create a wide range of tile profiles, including step tiles, corrugated tiles, and much more. Its flexibility allows customization to suit specific project requirements, providing architects and designers with endless possibilities for creative expression. Whether it's a traditional or contemporary architectural style, this machine can accommodate various designs flawlessly.2.4 Durability and Longevity:Utilizing high-quality materials and advanced manufacturing techniques, our Glazed Tile Roll Forming Machine ensures robustness and longevity. The sturdy construction guarantees reliable performance even in demanding working conditions, reducing maintenance costs and maximizing profitability.3. Why Choose Us?As a distinguished manufacturer and supplier, we provide a comprehensive range of Glazed Tile Roll Forming Machines to meet diverse industry needs. Here are a few reasons why you should consider partnering with us:3.1 Experience and Expertise:With years of experience in the industry, we have honed our manufacturing process to produce top-notch machinery. Our team of skilled engineers and technicians undergo continuous training to stay updated with the latest advancements, ensuring that our clients receive cutting-edge products.3.2 Tailored Solutions:We understand that every project has unique requirements, which is why our Glazed Tile Roll Forming Machines can be tailored to suit specific specifications. Whether it's dimensions, tile profiles, or any other customization, we work closely with our clients to deliver machines that align perfectly with their needs.3.3 Excellent Customer Support:Customer satisfaction is of utmost importance to us, and we strive to provide exceptional support at every stage – from product selection to after-sales services. Our dedicated team is always ready to assist you, ensuring a seamless and hassle-free experience.Contact Us:A Glazed Tile Roll Forming Machine is a valuable investment that can accelerate your business growth and elevate the quality of your tile production. If you are searching for a reliable and top-quality supplier, look no further. Contact us today to discuss your requirements and revolutionize your tile manufacturing process.

High Speed Metal Roof Panel Roll Forming Machine with Hydraulic Control System: Quality Supplier from China

Jiangyin Dingbo Technology CO., Ltd., a leading provider of roofing panel roll forming machines, has recently introduced their latest innovation - a high speed metal roof panel roll forming machine with hydraulic control system. This advanced machine is designed to efficiently produce metal roof panels with precision and speed, offering superior quality and performance.The 380V 50Hz high speed metal roof panel roll forming machine is equipped with a hydraulic control system, which ensures smooth and accurate operation. The hydraulic control system not only enhances the efficiency of the roll forming process but also enables precise control over the shaping and cutting of the metal sheets. This results in high-quality roof panel production that meets the stringent industry standards.One of the key features of this machine is its ability to produce metal roof panels in various sizes and profiles. The roll forming process involves feeding the metal sheets into the machine, where they are gradually shaped and cut into the desired profile. With the hydraulic control system, the machine can easily adjust its settings to accommodate different panel sizes and profiles, making it highly versatile and adaptable to the specific needs of the customers.Another notable feature of this machine is its high-speed production capability. With its efficient hydraulic control system and advanced technology, the roll forming process is significantly accelerated, allowing for faster production rates. This is especially beneficial for large-scale roofing projects where time is of the essence. The high-speed production not only increases efficiency but also reduces labor costs and enhances overall productivity.In addition to its impressive speed, this metal roof panel roll forming machine also ensures uncompromised quality. The advanced hydraulic control system ensures precise shaping and cutting, resulting in panels with smooth edges, consistent dimensions, and superior finish. The machine is designed to operate with utmost precision and accuracy, eliminating any potential errors or imperfections in the production process. This ensures that the produced roof panels meet the highest quality standards, providing customers with durable and aesthetically pleasing roofing solutions.Furthermore, Jiangyin Dingbo Technology CO., Ltd. emphasizes their commitment to customer satisfaction and reliability. As a reputable supplier of roof panel roll forming machines, the company strives to deliver top-notch products that meet and exceed customer expectations. They offer full support and assistance throughout the entire purchasing process, from consultation and customization to installation and after-sales service.Jiangyin Dingbo Technology CO., Ltd. continues to innovate and enhance their products to meet the evolving needs of the roofing industry. Their high-speed metal roof panel roll forming machine with hydraulic control system is a testament to their dedication to providing cutting-edge solutions that optimize efficiency, productivity, and quality. With this advanced machine, customers can benefit from faster production rates, superior panel quality, and enhanced overall performance.In conclusion, the introduction of the 380V 50Hz high speed metal roof panel roll forming machine with hydraulic control system by Jiangyin Dingbo Technology CO., Ltd. showcases their commitment to technological innovation and customer satisfaction. This advanced machine offers versatility, speed, and unmatched quality in the production of metal roof panels. As a trusted supplier, this company continues to revolutionize the roofing industry with their state-of-the-art solutions that enhance productivity and deliver excellence.

Top Quality HR CR SS GI Steel Coil Slitting Machines: High-Quality Manufacturer & Suppliers in China

Title: China Manufacturer Leading the Way in Top-Quality Steel Coil Slitting Machines Introduction:(Company Name), a renowned and respected leader in the manufacturing industry, has solidified its position as the top supplier of high-quality HR, CR, SS, and GI steel coil slitting machines in China. With a strong commitment to excellence and customer satisfaction, (Company Name) has established itself as the go-to brand for the finest slitting machines on the market.Body:1. Emerging as a Leading Manufacturer:(Company Name) has quickly risen to prominence as one of the most reliable manufacturers of steel coil slitting machines in China. Their commitment to providing top-quality products, combined with their exemplary customer service, has earned them a stellar reputation within the industry.2. State-of-the-Art Technology:(Company Name)'s steel coil slitting machines incorporate cutting-edge technology designed to optimize performance and efficiency, providing customers with unparalleled precision and reliability. With a focus on constant innovation, the machines are continually upgraded to meet the evolving needs of the market.3. Robust Product Line:From HR to CR, SS, and GI steel, (Company Name) offers a wide range of slitting machines suitable for different coil materials. These machines are capable of handling various material thicknesses and widths, making them adaptable to the diverse requirements of different industries.4. Unmatched Quality:Top-quality materials and rigorous quality control processes ensure that (Company Name)'s slitting machines deliver exceptional performance and durability. The machines are constructed with high-grade components to withstand demanding working conditions, providing customers with a reliable and long-lasting solution.5. Product Customization:Recognizing that every customer has unique specifications and requirements, (Company Name) offers customizable options for their slitting machines. Their team of experienced engineers works closely with clients in order to tailor the machines to their specific needs, guaranteeing optimal results and maximum customer satisfaction.6. Dedication to Customer Satisfaction:Customer satisfaction is of utmost importance to (Company Name). They go above and beyond to provide excellent pre-sales and after-sales service, ensuring that their clients' needs are met promptly and efficiently. Additionally, they offer comprehensive training programs to equip their customers with the knowledge and skills required to operate the machines successfully.7. Competitive Pricing:(Company Name) believes in providing high-quality products at competitive prices, making their slitting machines an excellent investment for businesses of all sizes. Their commitment to fair and transparent pricing has made them an attractive choice in the market.8. Commitment to Sustainability:In line with global efforts towards sustainability, (Company Name) prioritizes environmentally friendly practices in their manufacturing processes. They adhere to strict standards, ensuring minimal waste generation and implementing energy-efficient technologies to reduce their carbon footprint.Conclusion:(Company Name) has undoubtedly earned its reputation as a leading manufacturer of high-quality HR, CR, SS, and GI steel coil slitting machines in China. With a focus on innovation, customization, and customer satisfaction, they continue to be a reliable partner for businesses seeking top-quality slitting solutions. By combining cutting-edge technology with exceptional service, (Company Name) reaffirms its commitment to industry leadership and excellence.(Note: The brand name has been removed in accordance with instructions)

Steel Roofing Tile Roll Forming Machine: A Durable Roofing Solution

Glazed Steel Roofing Tile Roll Former Now AvailableFor those in the construction industry, the demand for continuous, efficient, and high-quality production is essential. To meet the industry’s needs, we are excited to announce the release of our new Glazed Steel Roofing Tile Roll Former. Designed to streamline the manufacturing process, our Glazed Steel Roofing Tile Roll Former is the perfect addition to any construction site. Constructed with precision and care, our Roll Former is capable of producing quality steel roofing tiles with ease, making it the perfect solution for all your roofing needs. Our Glazed Steel Roofing Tile Roll Former is manufactured with state-of-the-art technology to ensure accuracy and speed. The machine is easy to use, and it saves valuable manufacturing time. It is suitable for producing a variety of roofing tiles, including trapezoidal sheet tiles, glazed tiles, corrugated tiles, and more. The machine's ability to produce tiles at high speeds ensures you can meet your production requirements.The Glazed Steel Roofing Tile Roll Former is designed with user-friendliness in mind. It is easy to install, operate, and maintain. It also comes with advanced safety features to ensure the safety of the operator and the machine. Our product is manufactured from high-quality materials, ensuring that it is durable and long-lasting. Its rugged construction allows for operation in harsh environments, making it ideal for use in various locations.At our company, we prioritize customer satisfaction, which is why we offer a 24/7 customer support team to address any queries or concerns about the product. Additionally, we provide a warranty to protect our customers and to assure them of the product's quality.In summary, our Glazed Steel Roofing Tile Roll Former is a game-changer in the construction industry. Its efficient production and user-friendly design make it the perfect solution for manufacturers looking to streamline their production process. Its durability and advanced safety features ensure a long-lasting investment that will prove to be valuable to your business.For more information about our Glazed Steel Roofing Tile Roll Former, visit our website or contact us today. We look forward to hearing from you soon!

Latest Updates on W Beam Crash Barrier Roll Forming Machine: Breaking News and Key Insights

Title: A Revolutionary W Beam Crash Barrier Machine for Enhanced Road SafetyIntroduction:In an era where road safety is of paramount importance, the development and utilization of the W Beam Crash Barrier Machine have become crucial. Designed to withstand high-impact collisions and prevent vehicles from crossing into opposing lanes, this state-of-the-art machine is revolutionizing the road infrastructure sector. In this blog, we will delve into the concept, manufacturing process, and several benefits of the W Beam Crash Barrier Machine, ensuring safer roads for all.Understanding the W Beam Crash Barrier Machine:The W Beam Crash Barrier Machine is a cutting-edge roll forming machine that plays a vital role in manufacturing W-shaped steel beams, popularly known as W beams. These beams serve as a protective barrier on highways and roads, significantly reducing the risk of fatal accidents. The machine features advanced technology, enabling precise and efficient production of the barriers to meet international safety standards.Manufacturing Process:The manufacturing process of the W Beam Crash Barrier Machine involves several crucial steps. Firstly, high-quality galvanized steel strips are selected for their superior strength and durability. These strips are then fed into the roll forming machine, which shapes them into the distinctive W beam profile.The machine's advanced automation system ensures accurate dimensions and consistent quality during the roll forming process. After the beams are formed, they undergo prompt and reliable galvanization. The galvanizing treatment protects the beams from corrosion caused by harsh weather conditions, thereby extending their lifespan.Advantages of the W Beam Crash Barrier Machine:1. Enhanced Road Safety: The primary purpose of the W Beam Crash Barrier Machine is to create crash barriers that offer robust protection for drivers and passengers. The sturdy W-shaped beams ensure the containment of vehicles, minimizing the chance of crossover accidents and promoting overall road safety.2. Durability and Longevity: The utilization of high-quality galvanized steel strips and effective galvanization techniques equips W beams with exceptional durability. These barriers can withstand high-impact collisions and harsh weather conditions, reducing the need for frequent replacements or maintenance.3. Cost-Effectiveness: The W Beam Crash Barrier Machine optimizes production efficiency, resulting in reduced manufacturing costs. Additionally, the long lifespan of the W beams translates into cost savings by minimizing repair expenses and replacement needs.4. Regulatory Compliance: The W Beam Crash Barrier Machine aligns with international safety standards, ensuring that the produced W beams meet all necessary regulatory guidelines. This compliance provides peace of mind for road authorities and enhances the overall road infrastructure.5. Versatility: The machine can be easily adjusted to produce W beams of various shapes, sizes, and specifications, making it adaptable to different road infrastructure requirements. This versatility makes the machine invaluable for road authorities and construction companies.Conclusion:In conclusion, the W Beam Crash Barrier Machine represents a significant advancement in road safety measures. Its ability to manufacture durable, high-quality crash barriers ensures the protection of drivers, passengers, and road infrastructure alike. By promoting containment and minimizing crossover accidents, these machines have revolutionized the road construction sector. With their exceptional versatility and regulatory compliance, it is evident that the W Beam Crash Barrier Machine will continue to play a vital role in enhancing road safety worldwide.Keywords: W Beam Crash Barrier Machine, road safety, roll forming machine, manufacturing process, highway barriers, galvanization, durability, longevity, cost-effectiveness, regulatory compliance, versatility.

Efficient Roof Tin Making Machine Empowers Seamless Roofing Production

Roof Tin Making Machine Revolutionizes the Manufacturing ProcessIn the ever-evolving world of manufacturing, technological advancements continue to reshape industries and revolutionize production processes. One such innovation is the Roof Tin Making Machine, a groundbreaking tool that promises to streamline and improve the manufacturing of roof tins. By integrating cutting-edge technology with efficient design, this machine is set to transform the roofing industry.The Roof Tin Making Machine, developed by an industry-leading company, is an impressive piece of machinery built to enhance productivity, improve output quality, and reduce overall costs. Its state-of-the-art features and functionalities make it an invaluable asset for manufacturers in the roofing sector.This cutting-edge machine is equipped with advanced automation and precision engineering, resulting in enhanced productivity and reduced manual labor. The elimination of manual intervention increases efficiency and minimizes the chance of human errors, resulting in a more streamlined manufacturing process. By automating various steps involved in roof tin production, this machine significantly boosts overall output and eliminates delays caused by manual labor.The Roof Tin Making Machine incorporates sophisticated control systems and software that enable manufacturers to achieve unparalleled precision and accuracy. Precision is crucial in the production of roof tins as even the slightest deviation can compromise the quality and performance of the final product. With this machine, manufacturers can achieve consistent results with minimal variations, ensuring that every roof tin produced meets the highest standards.Moreover, this innovative machine allows for rapid adjustment and customization, enabling manufacturers to cater to diverse client requirements. Its flexible design can adapt to different roof tin sizes, shapes, and specifications, empowering manufacturers to deliver personalized solutions to customers with ease. This versatility not only enhances customer satisfaction but also opens doors for new business opportunities.With sustainability becoming a paramount concern in manufacturing, the Roof Tin Making Machine incorporates eco-friendly features to promote green practices. By optimizing energy consumption and minimizing waste generation, this machine plays a role in reducing the carbon footprint associated with roof tin production. Manufacturers can contribute to a cleaner environment without compromising on quality or efficiency.Additionally, the Roof Tin Making Machine is designed with robust safety features to protect operators and minimize the risk of accidents. This machine adheres to stringent safety standards and is equipped with multiple safety devices. It also includes comprehensive training and support materials to ensure operators are well-versed in operating the machine safely.As a market leader in roof tin manufacturing technology, the company behind the Roof Tin Making Machine prides itself on delivering cutting-edge solutions that drive the industry forward. With a wealth of experience and expertise, the company has developed a strong reputation for delivering high-quality machinery that meets the evolving needs of manufacturers.The Roof Tin Making Machine is a testament to the company's commitment to innovation and customer satisfaction. By combining advanced technology with efficient design, this machine acts as a game-changer in the roofing industry, empowering manufacturers to reach new levels of productivity and excellence.In conclusion, the Roof Tin Making Machine is set to revolutionize the manufacturing process of roof tins. With its automation, precision, customization, sustainability, and safety features, this machine offers a plethora of advantages to manufacturers. By embracing this innovative technology, manufacturers can enhance their production capabilities, stay ahead of the competition, and provide superior products to customers.

China Manufacturers & Suppliers of High-Quality Wall And Roof Panel Roll Forming Machines

Wall Panel Roll Forming Machine: A Game-Changer in Construction IndustryIn the fast-paced construction industry, efficiency and quality play a crucial role. This is where the Wall Panel Roll Forming Machine steps in as a game-changer. Taking China by storm, this innovative machine has gained popularity among manufacturers and contractors, revolutionizing the way wall panels are produced.With the growing demand for energy-efficient and eco-friendly buildings, wall panels have become an integral part of modern construction projects. Traditional construction methods, such as bricklaying and concrete casting, can be time-consuming, labor-intensive, and costly. This is where roll forming technology has stepped in to provide an efficient and economical solution.Wall Panel Roll Forming Machine, developed and manufactured by leading Chinese manufacturers, provides a seamless production process for wall panels. Equipped with advanced technology and precision engineering, this machine enables manufacturers to produce high-quality panels in large quantities within a short period.So, what exactly is a Wall Panel Roll Forming Machine? It is a production line that consists of a series of rollers, forming stations, and cutting systems. It takes raw materials, such as galvanized steel or aluminum coils, and shapes them into precise and uniform profiles. These profiles can be customized according to specific design requirements, including thickness, width, and length.The Wall Panel Roll Forming Machine offers numerous advantages over conventional manufacturing methods. Firstly, it significantly reduces labor costs and human errors. The automated process ensures consistent panel dimensions and eliminates the need for manual intervention, resulting in a fast and efficient production line.Secondly, the Wall Panel Roll Forming Machine optimizes material usage, reducing waste and saving costs. By precisely controlling the amount of raw material fed into the machine and its shaping process, manufacturers can minimize scrap and maximize panel output.Furthermore, this machine allows for customization and flexibility. With adjustable roller stations, manufacturers can create various panel profiles, including flat, corrugated, or trapezoidal shapes, to meet diverse construction needs. This versatility enables architects and designers to unleash their creativity and bring unique architectural visions to life.In addition, the Wall Panel Roll Forming Machine enhances safety on construction sites. With panels produced using this technology, the risk of accidents, such as falling debris or collapses, is minimized. These panels are lightweight yet structurally robust, offering enhanced durability and improved seismic resistance.Lastly, the Wall Panel Roll Forming Machine contributes to green construction practices. By using environmentally friendly materials, such as recyclable metals, and reducing energy consumption through efficient production processes, it supports sustainable building practices. Furthermore, its precision engineering ensures tight joints and insulation, enhancing energy efficiency and reducing carbon footprints.In conclusion, the Wall Panel Roll Forming Machine has brought a revolution to the construction industry. Its time-saving, cost-effective, and customizable features have made it the preferred choice for manufacturers and contractors worldwide. With its technological advancements and eco-friendly production practices, this machine paves the way for modern, energy-efficient, and sustainable buildings. Embrace the future of construction and invest in a Wall Panel Roll Forming Machine today!Keywords: Wall Panel Roll Forming Machine, China manufacturers, suppliers, factory, construction, efficiency, quality, game-changer, traditional methods, roll forming technology, production line, rollers, forming stations, cutting systems, raw materials, galvanized steel, aluminum coils, precise profiles, advantages, labor costs, material usage, customization, flexibility, safety, green construction practices, environmentally friendly materials, sustainable buildings.

China's Leading Manufacturer of Roll Forming Machines and Glazed Tile Roll Forming Machines

Title: Steel Tile Forming Machine: Revolutionizing the Construction IndustryIntroduction:In the rapidly evolving construction industry, innovation plays a pivotal role in meeting the needs of modern-day infrastructure projects. One such innovation is the Steel Tile Forming Machine, a game-changer in the manufacturing of roofing materials. Developed and manufactured by leading roll forming machine companies in China, this efficient and versatile equipment has transformed the way steel tiles are produced. In this blog, we will delve into the intricacies of the Steel Tile Forming Machine and explore its numerous benefits for the construction industry.Understanding the Steel Tile Forming Machine:The Steel Tile Forming Machine is a state-of-the-art piece of equipment designed specifically for the high-speed production of steel tiles. With its advanced roll-forming technology, it can quickly convert metal coils into fully formed steel tiles of various shapes and sizes. This machine is often used in the production of roofing materials, where it has gained significant popularity due to its accuracy, efficiency, and cost-effectiveness.Key Features and Advantages:1. High Precision and Versatility:The Steel Tile Forming Machine incorporates advanced CNC systems, ensuring precise and consistent tile production. Its adjustable roller sets allow for the formation of tiles in a wide range of profiles and dimensions, meeting the specific requirements of various architectural designs. This versatility makes it an ideal choice for construction projects of all sizes.2. Speed and Efficiency:Equipped with automated control systems, the machine operates at high speeds, significantly reducing production time. This efficiency not only enhances productivity but also optimizes resource utilization, resulting in increased cost-effectiveness for manufacturers.3. Durability and Reliability:Manufactured using high-quality materials, the Steel Tile Forming Machine is built to withstand the demanding conditions of industrial production. Its robust design and high-quality components ensure durability and reliability, reducing maintenance requirements and enabling consistent operation even in challenging environments.4. Cost-Effective Production:The machine's high-speed production capabilities and reduced labor requirements contribute to cost savings for manufacturers. Additionally, its precision and efficiency minimize material wastage, making it an environmentally friendly option.5. Customization and Design Flexibility:With the Steel Tile Forming Machine, manufacturers can effortlessly create specialized shapes, designs, and patterns for steel tiles. Whether it's creating intricate textures or replicating traditional roofing styles, the machine offers unparalleled design flexibility, allowing builders and architects to bring their creative visions to life.Impact on the Construction Industry:The advent of the Steel Tile Forming Machine has revolutionized the construction industry in several ways. Firstly, it has significantly reduced the lead time for steel tile manufacturing, enabling projects to progress at a faster pace. This increased efficiency has particularly benefited large-scale infrastructure developments.Secondly, the machine's ability to produce high-quality steel tiles at a faster rate has positively influenced the cost of construction. By reducing labor and material costs, it has made steel tiles a more affordable roofing option, widening their adoption among builders and homeowners alike.Furthermore, the design flexibility offered by the machine has ushered in a new era of architectural possibilities. From contemporary designs to traditional aesthetic choices, steel tiles produced by this equipment provide architects and builders limitless design opportunities that enhance the overall visual appeal of structures.Conclusion:The Steel Tile Forming Machine has undoubtedly had a transformative impact on the construction industry. Its precision, speed, cost-effectiveness, and design flexibility position it as an essential tool in the manufacturing of steel tiles. As the demand for sustainable and visually appealing roofing materials increases, the Steel Tile Forming Machine is set to become an indispensable asset for construction companies worldwide. Embracing this innovative technology not only streamlines production processes but also enhances the overall quality and efficiency of construction projects.Keywords: Steel Tile Forming Machine, roll forming machine, construction industry, roofing materials, high precision, versatility, speed, efficiency, durability, cost-effective production, customization, design flexibility, impact, lead time, affordability, architectural possibilities, sustainable roofing materials.