Ultimate Guide to Horizontal Corrugated Roof Panels: Everything You Need to Know

By:Admin

Introduction:

In the ever-evolving construction industry, constant innovation is paramount to meeting the needs and demands of customers. Introducing the cutting-edge Horizontal Corrugated Roof Panel, developed by a renowned construction solutions provider, this revolutionary roofing option is set to transform both commercial and residential construction projects. By combining durability, versatility, and aesthetic appeal, this innovative roof panel promises to set new industry standards.

Paragraph 1:

The (Company name) has unveiled its newest offering, the Horizontal Corrugated Roof Panel, designed to address the challenges faced by traditional roofing solutions. This state-of-the-art product combines advanced engineering with superior materials, providing a myriad of benefits for both architects and property owners. Unlike traditional roof panels, these horizontal corrugated roof panels prioritize durability without compromising on aesthetics or practicality.

Paragraph 2:

One of the key advantages of Horizontal Corrugated Roof Panels is their unmatched durability. Manufactured using high-quality materials, these panels are resistant to extreme weather conditions, including heavy rain, wind, snow, and hail. This weatherproof design ensures long-term protection for any structure, reducing the risk of leaks and associated damage.

Paragraph 3:

Furthermore, the Horizontal Corrugated Roof Panel offers unmatched versatility. Its ingenious design enables seamless integration with both traditional and contemporary architectural styles. This transformative roofing solution enhances the visual appeal of any building, offering more design options for architects and homeowners alike. With a wide range of colors, finishes, and panel thicknesses available, customers can customize their roofs to perfectly complement the overall aesthetic of their construction projects.

Paragraph 4:

Another notable advantage of this innovative roof panel is its ease of installation. The Horizontal Corrugated Roof Panel's unique design facilitates quick and hassle-free installation, reducing labor costs and construction time. This is especially beneficial for large-scale commercial projects where time and budget constraints are crucial factors.

Paragraph 5:

The Horizontal Corrugated Roof Panel is also eco-friendly, contributing to sustainable building practices. These panels are manufactured using recyclable materials, ensuring minimal environmental impact. By choosing this roofing solution, construction professionals and homeowners demonstrate their commitment to preserving the environment while simultaneously maximizing the durability and longevity of their structures.

Paragraph 6:

Moreover, the Horizontal Corrugated Roof Panel boasts exceptional energy efficiency. Its expertly engineered insulation properties help regulate internal temperature, reducing the need for excessive heating or cooling. Consequently, this leads to lower energy consumption, contributing to cost savings for building owners and reducing their carbon footprint.

Conclusion:

The introduction of the Horizontal Corrugated Roof Panel by (Company name) heralds a new era in the construction industry. Its unrivaled combination of durability, versatility, aesthetic appeal, ease of installation, sustainability, and energy efficiency makes it a game-changer for both new construction projects and renovations. Architects, construction professionals, and homeowners can embrace this innovative roof panel with confidence, knowing that their investment will offer long-term protection and excite with its unparalleled visual impact.

Company News & Blog

Efficient and Cost-Effective CFS Rollformer for Pods, Modular & Residential Construction

for Pods, Modular and Residential Construction.In the modern age of construction, technology is advancing at an incredible rate. As the demand for affordable and sustainable housing increases, the construction industry is turning to innovative solutions for faster, more efficient building practices. One such solution is the FRAMECAD P325iT CFS Rollformer for Pods, Modular, and Residential Construction, which offers a range of benefits for builders looking to streamline their workflows.One of the key advantages of the P325iT is its ability to produce wall frames and trusses at high speeds. Thanks to its automation and advanced technology, this rollformer is capable of producing frames at a much faster pace than traditional building methods, allowing for increased efficiency and throughput. This makes it a valuable tool for construction companies looking to quickly and economically produce high-quality building components.Another benefit of the P325iT is its versatility. This rollformer is designed to produce frames and trusses for a range of building types, including pods, modular structures, and residential homes. Its flexibility means it can be used across a variety of projects, making it a smart investment for any construction company.One of the standout features of the P325iT is its high level of precision. Thanks to its advanced technology, this rollformer can produce frames with incredibly high accuracy, ensuring a perfect fit every time. This precision is essential for modular construction, where components need to fit together seamlessly to create a fully functioning building.The P325iT is also designed with sustainability in mind. By using lightweight steel framing, this rollformer can help reduce the carbon footprint of construction projects. Steel is a highly recyclable material, making it an ideal choice for builders concerned about their environmental impact.In conclusion, the FRAMECAD P325iT CFS Rollformer for Pods, Modular, and Residential Construction is an incredibly versatile and efficient tool for modern builders. Its automation, precision, speed, and sustainability features make it a smart investment for any construction company looking to streamline their workflows and produce high-quality building components quickly and economically. With the use of this rollformer, builders can enjoy the efficiency of modern construction without sacrificing quality or precision.

Discover the Latest Advancements in Forming Machines for Enhanced Efficiency

Forming Machines, Revolutionizing Manufacturing ProcessesIn recent years, the manufacturing industry has witnessed numerous advancements that have transformed the way products are made. Among these revolutionary innovations, the introduction of state-of-the-art forming machines has played a significant role in enhancing production efficiency and product quality across various sectors.Forming machines, known for their precision and speed, have become an indispensable tool for manufacturers worldwide. These machines, designed to shape metal or other materials into custom forms or parts, offer numerous advantages over traditional manufacturing methods. With their high degree of automation and computer-aided design capabilities, forming machines have streamlined production processes, resulting in increased productivity and cost-effectiveness.One prominent player in the field of forming machines is {}, a leading global manufacturing solutions provider. With years of experience and expertise, they have established themselves as an industry leader, delivering cutting-edge technology and innovative solutions to a wide range of industries.{} offers a diverse range of forming machines that cater to the evolving needs of the manufacturing sector. From hydraulic and mechanical presses to automated stamping systems, their product portfolio covers a broad spectrum of applications. These machines are built to deliver optimal performance, ensuring accuracy, repeatability, and the ability to handle high volumes of production.One of the key features that set {} forming machines apart from the competition is their advanced control systems. These machines are equipped with state-of-the-art software and sensors that enable precise control over the forming process. Manufacturers can easily program and adjust various parameters, such as speed, force, and position, ensuring precise and consistent results. With such control, they can not only meet the strict quality requirements but also minimize wastage and material costs.Moreover, {} forming machines incorporate intelligent monitoring systems that provide real-time feedback and diagnostics. This allows operators to identify and resolve issues promptly, minimizing downtime and increasing overall equipment effectiveness. With the ability to analyze data and generate reports, manufacturers can also gain valuable insights into their production efficiency, facilitating continuous improvement efforts.In addition to their impeccable performance, {} forming machines prioritize the safety of both operators and machinery. These machines are equipped with advanced safety features, including safety guards, emergency stop buttons, and interlocking systems. Additionally, they adhere to international safety standards and regulations, ensuring the well-being of personnel and compliance with industry guidelines.The versatility of {} forming machines is another key aspect that has contributed to their popularity. With their customizable tooling options, manufacturers can easily adapt the machines to suit various production requirements. Whether it is bending, stamping, or deep drawing, {} machines offer flexible solutions that can handle a wide range of materials, from metals to plastics.Beyond their impressive technical capabilities, {} excels in their commitment to customer satisfaction. Their dedicated team of experts provides comprehensive support, from machine installation and training to ongoing maintenance and troubleshooting. By closely collaborating with clients, they strive to understand their specific needs and challenges, ensuring the delivery of tailored solutions that meet and exceed expectations.As the manufacturing industry continues to evolve and demand for efficient, reliable production processes rises, the role of forming machines becomes ever more crucial. Companies like {} are at the forefront of innovation, driving industry growth and enabling manufacturers to achieve new levels of efficiency and competitiveness.In conclusion, forming machines have revolutionized the manufacturing landscape, enabling efficient and precise production processes across various industries. With their advanced control systems, safety features, and versatility, {} forming machines have proven to be a game-changer. As manufacturers strive to meet increasing demands and stay ahead in a competitive market, these machines provide the technological edge needed to succeed.

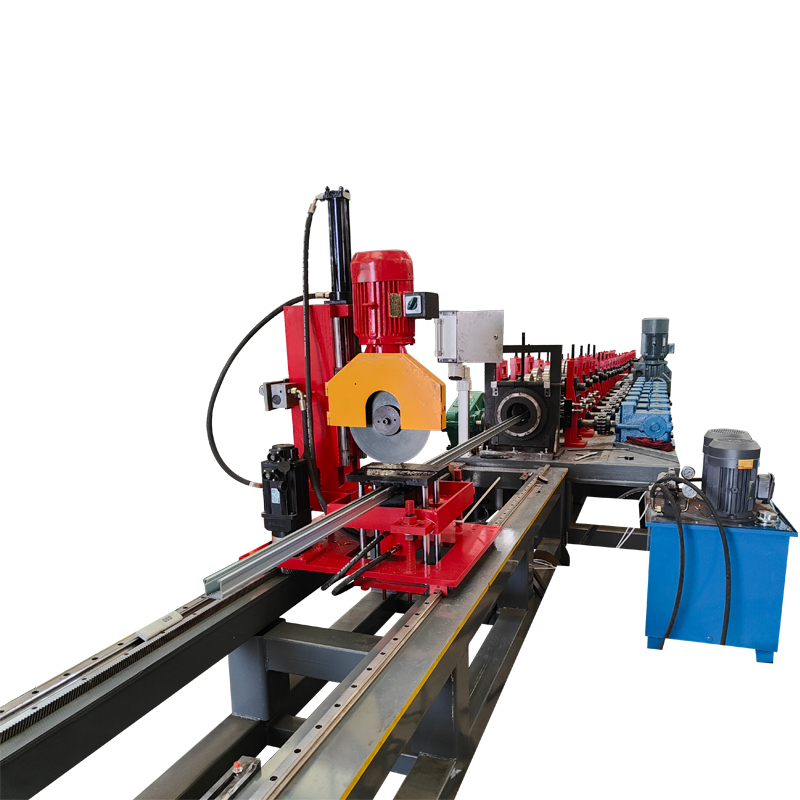

C Shape Purlin Forming Machine: Transforming the Construction Industry

article.C Shape Purlin Forming Machine: The Ultimate Solution for Construction IndustryIn recent years, the global construction industry has undergone massive creativity and innovation, giving rise to new designs and architectures. One of the critical components of these new designs is the C-shaped purlin, which provides structural support and stability to the buildings. However, the traditional manual production of C-shaped purlin is cumbersome, time-consuming, and sometimes inaccurate.To address this challenge, many construction companies are turning to C Shape Purlin Forming Machine. This advanced machine offers a fast, efficient, and accurate way to manufacture C-shaped purlins, thus improving the quality of the final product.One of the leading manufacturers of C shape purlin forming machines in the global market is a reputable manufacturing company (). The company has been in the industry for several years and has built a reputation for producing high-quality and durable machinery to cater to various industrial needs.The C shape purlin forming machine from the company has a unique design and features that make it ideal for any construction project. It is made of high-grade materials, ensuring durability, longevity, and reliability. Additionally, it has an advanced electronic control system that enables automatic production, further enhancing efficiency.The machine's versatility allows it to produce different sizes and shapes of purlins, making it an ideal choice for any construction project. Whether you are working on a commercial, residential, or industrial structure, the C shape purlin forming machine will deliver quality and efficiency.Another critical aspect of the machine is its user-friendly nature. Operators can easily control and adjust the forming parameters, ensuring that the final product meets the required standards. Additionally, the machine has a low maintenance cost, thus allowing business owners to save on expenses.The C Shape Purlin Forming Machine has revolutionized the construction industry by providing an efficient, cost-effective, and accurate method of producing C-shaped purlins. The machine has been a game-changer, enabling business owners to meet the increasing demand for high-quality and reliable purlins.Furthermore, the machine's electronic controls and advanced features enable it to produce purlins with high precision and accuracy, further improving the final product's quality. This has led to increased customer satisfaction and repeat business, further boosting profitability.In conclusion, the C Shape Purlin Forming Machine is the ultimate solution for the construction industry. Its advanced features, durability, and versatility make it an ideal choice for any construction project. Additionally, its user-friendly nature and low maintenance cost make it an excellent investment for business owners. With the increasing demand for high-quality and reliable purlins, investing in this machine is a wise decision for any construction company. Contact reputable manufacturing company () today and take your construction business to the next level.

High-Quality Automatic Corrugated Tile Roll Forming Machine for Metal Roofing and Colored Steel Sheets

Title: Enhancing Efficiency and Quality with the Colored Metal Corrugated Sheet Roll Forming MachineIntroduction:In the rapidly evolving construction industry, keeping up with the latest technological advancements is crucial. When it comes to roofing materials, the demand for colored metal corrugated sheets has significantly increased due to their durability and aesthetic appeal. To meet the rising need for these sheets, the Automatic Metal Roofing Corrugated Tile Roll Forming Machine, also known as the Colored Steel Sheet Roll Forming Machine, has emerged as a game-changer. This blog post will delve into the key features, benefits, and applications of this advanced machine that has revolutionized the manufacturing process.1. Features of the Automatic Metal Roofing Corrugated Tile Roll Forming Machine:The Automatic Metal Roofing Corrugated Tile Roll Forming Machine is designed with cutting-edge technology to ensure seamless production of colored metal corrugated sheets. Some notable features include:a) High-Speed Performance: This machine boasts an exceptional production speed that enables efficient manufacturing without compromising the product's quality. Its advanced automation capabilities contribute to enhanced productivity and a significant reduction in labor costs.b) Precision and Accuracy: Equipped with advanced PLC control systems and digital displays, the machine guarantees precise and accurate sheet dimensions, angles, and curves. This ensures that the final product meets the required specifications, resulting in superior quality roofing sheets.c) Versatile Design: The machine's versatility allows it to handle various raw materials such as galvanized steel, aluminum, and stainless steel. This flexibility enables manufacturers to cater to a wide range of customer preferences, expanding their market reach.d) Durability and Longevity: The machine is built with robust materials, ensuring its durability and longevity. Its reliable performance minimizes downtime and maintenance, contributing to uninterrupted manufacturing operations.2. Benefits of the Colored Metal Corrugated Sheet Roll Forming Machine:a) Enhanced Efficiency: The high-speed performance of the machine significantly reduces the manufacturing time, enabling manufacturers to meet customer demands promptly. Its precision and accuracy eliminate the need for manual adjustments, resulting in increased productivity.b) Cost-Effectiveness: With its automation capabilities, the machine reduces labor costs and minimizes errors caused by human intervention. Its durable construction ensures longevity, reducing maintenance expenses and enhancing the return on investment.c) Customization and Design Flexibility: The machine's versatility allows manufacturers to produce colored metal corrugated sheets in various sizes, shapes, and colors. This flexibility enables them to cater to the unique design preferences and requirements of their customers.d) Superior Quality: The machine's advanced technology ensures the production of high-quality roofing sheets with accurate dimensions and excellent finishes. This quality assurance leads to satisfied customers and increased brand reputation.3. Applications of the Colored Metal Corrugated Sheet Roll Forming Machine:The Colored Metal Corrugated Sheet Roll Forming Machine finds extensive applications in the construction industry. Some notable uses include:a) Residential Roofing: The machine is used to manufacture corrugated metal roofing sheets for residential buildings. These sheets provide durability, weather resistance, and aesthetically pleasing options for homeowners.b) Commercial and Industrial Roofs: Manufacturing large quantities of colored metal corrugated sheets using this machine is ideal for commercial and industrial roofing projects. The sheets' strength, longevity, and low maintenance make them a cost-effective solution.c) Agricultural Structures: The machine caters to the specific requirements of the agricultural sector, enabling the production of corrugated metal sheets for barns, sheds, and other farm structures. These sheets provide a durable and weather-resistant solution for protecting livestock and equipment.Conclusion:The Automatic Metal Roofing Corrugated Tile Roll Forming Machine, also known as the Colored Metal Corrugated Sheet Roll Forming Machine, is a game-changer in the manufacturing of roofing sheets. Its high-speed performance, precision, versatility, and durability have significantly enhanced the efficiency and quality of production. By investing in this advanced machine, manufacturers can cater to customer demands promptly, reduce costs, and produce high-quality colored metal corrugated sheets for various applications in the construction industry.

Metal Roll Forming Machines for Producing Trapezoidal Roof and Wall Cladding Panels

Are you looking to enhance the quality and durability of your roofs and wall claddings? Look no further, as we have the perfect solution for all your needs! Our trapezoidal panel roll forming machines are designed exclusively for the production of Roof & Siding Panels, Steel Ribbed Roofing Panels, and Steel Roof & Wall Claddings. With our cutting-edge technology and expertise, we ensure the highest level of precision and efficiency in the production of metal roofing and cladding sheets.Before we delve into the details of our trapezoidal panel roll forming machines, let's understand the significance of metal roofing sheets and trapezoid profiles. Metal roofing sheets are widely recognized for their exceptional strength, longevity, and aesthetic appeal. They offer unparalleled protection against weather elements such as rain, wind, and snow, ensuring the safety and security of your establishments. Moreover, metal roofing sheets are also eco-friendly, as they are made from recyclable materials and contribute to energy conservation.Now, let's discuss the trapezoid profile and its importance in the realm of metal roofing sheets. The trapezoid profile is a unique structural shape that plays a key role in enhancing the efficiency and functionality of metal roofing sheets. This specific profile is designed in a trapezoidal shape, which enables easy installation, excellent water drainage, and superior load-bearing capacity. With our trapezoidal panel roll forming machines, you can effortlessly produce metal roofing sheets with trapezoid profiles, providing your customers with an exemplary roofing solution.At our state-of-the-art manufacturing facility, we have engineered trapezoidal panel roll forming machines that are unrivaled in terms of their performance and quality. These machines are equipped with advanced features and technologies that ensure seamless and error-free production. By automating the roll forming process, our machines guarantee consistent quality, precise dimensions, and tight tolerances, resulting in flawless metal roofing sheets every time.One of the key advantages of our trapezoidal panel roll forming machines is their versatility. They can produce a wide range of roofing and cladding profiles, catering to different design preferences and architectural requirements. Whether you need corrugated sheets, standing seam panels, or any other trapezoidal profiles, our machines can accommodate your diverse production needs, ensuring utmost customer satisfaction.Furthermore, our trapezoidal panel roll forming machines are designed with utmost safety considerations. They are equipped with safety features such as emergency stop buttons, safety guards, and sensors to prevent accidents and ensure the well-being of your operators. Additionally, our machines are operator-friendly, with user-friendly interfaces and easy-to-understand controls, making the production process efficient and hassle-free.In conclusion, if you are in the market for a reliable and efficient trapezoidal panel roll forming machine, look no further than our product range. With our cutting-edge technology, versatile production capabilities, and commitment to excellence, we provide you with the best solution for your metal roofing and cladding needs. Our machines ensure consistent quality, precise dimensions, and exceptional performance, delivering outstanding results every time. Invest in our trapezoidal panel roll forming machines, and elevate the standards of your roofing and cladding projects.

Complete Roll Forming Solution for Various Applications in China

Roll forming machines have become increasingly popular in the manufacturing industry, thanks to their ability to produce high-quality and consistent products. There are various roll forming machine manufacturers across the globe, but one that stands out is MTC, a leading Cold Roll Former Manufacturer in China. The company provides one-stop roll forming solutions, from consultation to final training for many different applications where roll forming machines can do their best.MTC has been in the roll forming machine industry for over 15 years and has grown to become a highly respected manufacturer. The company specializes in producing a wide range of roll forming machines, including roof panel forming machines, floor decking roll forming machines, C/Z purlin roll forming machines, door frame forming machines, and more. The team at MTC is dedicated to providing innovative solutions that meet the unique needs of their clients.MTC provides clients with an end-to-end service, starting with a consultation. During this stage, MTC experts work together with clients to identify their requirements and recommend the most appropriate roll forming machine for their needs. The company takes into consideration factors such as the application, material used, cost, and desired results, among others. This ensures that clients get the best possible solution that meets their unique requirements.Once the consultation stage is complete and the ideal roll forming machine has been selected, the manufacturing process begins. MTC uses state-of-the-art equipment and technology to produce high-quality roll forming machines that meet international standards. The machines are built using top-grade materials to ensure their durability, and the company guarantees their quality.After the machine has been manufactured, MTC provides installation, testing, and training services. The company has a team of experienced engineers who work with clients to ensure that the machine is installed and tested correctly. The team also provides training services to clients to ensure that they can operate the machine safely and effectively. This ensures that clients get the most out of their investment and can produce high-quality products consistently.One of the popular products produced by MTC is the Roofing Sheet Forming Machine. This machine is designed to produce a variety of roofing sheets, including corrugated sheets. The Roofing Sheet Forming Machine is highly efficient, producing high-quality sheets at a remarkable speed. The machine is versatile and can be customized to meet the specific needs of clients. The machine is also easy to operate, making it ideal for both seasoned and beginner manufacturers.The Roofing Sheet Forming Machine is made using high-quality materials, ensuring its durability. The machine is also low maintenance, making it cost-effective in the long run. Clients who choose this machine can enjoy increased productivity, reduced production time, and a superior quality end-product. The machine is ideal for manufacturing roofing sheets for industrial, commercial, and even residential applications.In conclusion, MTC is a leading Cold Roll Former Manufacturer in China, providing one-stop roll forming solutions to clients worldwide. The company's commitment to delivering innovative solutions, coupled with its dedication to producing high-quality roll forming machines, sets it apart from the competition. The Roofing Sheet Forming Machine is one of the many products produced by MTC that demonstrates the company's commitment to excellence. Clients who choose MTC can enjoy a range of benefits, including increased productivity, reduced production time, and a superior quality end-product.

High Speed Light Steel Keel Roll Forming Machine: Efficient Building Material Solution

, Stud Truss Roll Forming Machine, High Speed Roll Forming Machine, Metal Stud Roll Forming Machine.With the advancement in technology, the construction industry also has advanced equipment and machines to produce high-quality materials. One such essential machine is the stud truss high speed light steel keel roll forming machine. This machine is used to make light keel studs and trusses that are used for constructing the roof and walls of a building. It is known for its efficiency, reliability, and high speed.The light steel keel machine is designed differently based on the model and the customer's specifications. The metal stud roll-forming machine produces rolls of metal that are used as roofing or wall material in places such as factories, warehouses, garages, gymnasiums, and exhibition centers. These products are popular because of their lightweight, high strength, and easy installation.One of the many advantages of using a stud truss high speed light steel keel roll forming machine is its speed. The machine is designed to produce large quantities of metal strips rapidly, therefore, allowing for mass production, this significantly reduces the time taken to construct a building. The machine is also straightforward to operate, reducing the need for large labor forces on construction sites.Another benefit of using the light steel keel machine is the quality of the material produced; the metal strips produced are of a consistent thickness, length, and size, eliminating the possibility of defects that could lead to the loss of material. The machines are also low-maintenance as they are designed to be robust and long-lasting, thus reducing the operators' servicing costs.In conclusion, the stud truss high speed light steel keel roll forming machine is a must-have piece of equipment in the construction industry. It's easy operation, and high-speed production makes it a favorite among operators globally. The machine's accuracy and quality of the material produced make it an indispensable tool in the construction of buildings. For cost-effective construction materials, the light steel keel machine is the way to go. So if you are in the construction industry, it's essential to invest in a high-quality stud truss roll forming machine that will provide the best results.

Discover High-Quality Roll Forming Machines from China's Top Supplier

As much as architecture has evolved over the years, the use of different materials has remained constant, one of which being steel. The durability, strength, and versatility of steel make it a go-to material for various structural applications, from high-rise buildings to residential homes. Therefore, to meet the demands of this ever-growing market, the roll forming industry has evolved and continues to extend its limits by offering innovative and modernized products. Today, we will discuss everything about the Color Steel Roll Forming Machine Factory.What is a Roll Forming Machine?A Roll Forming Machine refers to a piece of equipment that produces shapes of different sizes and profiles from metallic coils or sheets. The machine achieves this by passing these sheets through a series of rollers that gradually bend and form them into the desired shape. This process is known as roll forming, and the entire unit consists of a de-coiler, a roller system, a cutting system, and a control system. These machines offer several advantages over other manufacturing techniques, such as reduced material wastage, faster production speeds, and increased precision.What is a Color Steel Roll Forming Machine Factory?A Color Steel Roll Forming Machine Factory refers to a production facility that is specifically designed for manufacturing various types of color coated steel products. These machines provide a convenient solution for meeting the demand of the modern construction industry. The color steel material produced is attractive and durable, making it an ideal choice for the roofing, walling, and cladding systems.The Color Steel Roll Forming Machine Factory is highly flexible, which means it can produce a wide range of profiles and shapes with high precision and consistently. This flexibility, combined with the ability to customize profiles and shapes, makes it the ideal choice for architects, contractors, and manufacturers, who need to create unique products suited to their specific requirements.Features of the Color Steel Roll Forming Machine FactoryThe Color Steel Roll Forming Machine Factory is a versatile piece of equipment that can handle multiple projects. Some of the features that make it stand out include;1. High Precision and ConsistencyThe high precision and consistency of the roll forming process means that all the products produced are uniform in quality, size, and shape.2. VersatilityA color steel roll forming machine factory can create different profiles and shapes. The factory can produce panels of different profiles, including corrugated or ribbed, standing seams, box profiles, and curved products.3. Reduced Material WastageBy eliminating the need for manual cutting and forming, roll forming machines reduce the amount of wastage generated during the manufacturing process.4. High-Speed ProductionOne of the primary advantages of using a color steel roll forming machine factory is the high-speed production cycle that reduces lead times while maintaining the quality of the products.ConclusionIn conclusion, the Color Steel Roll Forming Machine Factory is an integral part of the steel industry, providing a modern and innovative alternative to traditional steel products. With a wide range of features designed to cater to the needs of the modern construction industry, the possibilities for color steel roll forming machines are endless. As a leading manufacturer of Roll Forming Machines, (brand name removed) offers high-quality machines, unmatched customer service, and competitive prices. Contact us today for further inquiries or visit our website for more information about our products and services.

Coil-fed Cutting Machine for Metal and Sheet Metal - Efficient and Precise Solution

Sheet metal coil cutting machines have revolutionized the way sheet metal fabrication was done earlier. These machines use highly advanced laser cutting technology to cut sheet metal coils of various thicknesses with ease. A staunch player in this industry is the DANOBAT LB coil-fed cutting machine, offered by the renowned DANOBATGROUP.The DANOBAT LB coil-fed cutting machine is an efficient and high-quality equipment specially designed for the sheet metal cutting industry. It offers advanced precision in cutting operations, enabling the production of high-quality products with elevated efficiency. The machine can cut coil sheets of various materials such as steel, aluminum, brass, copper, and other alloys.The machine has a cutting speed of up to 150 meters per minute and can handle sheets of thickness ranging from 0.4mm to 16 mm. This coil-fed cutting machine features a robust structure that can withstand intense workload for years, making it one of the most reliable sheet metal cutting machines on the market.Equipped with a fiber laser, the DANOBAT LB coil-fed cutting machine is an extremely precise machine that delivers remarkable cuts on various materials. The laser facilitates high cutting speeds with a minimal kerf width, thus reducing the amount of scrap and maximizing the yield.Moreover, DANOBATGROUP's coil-fed cutting machine is incredibly easy to operate and maintain. The machine's user-friendly interface makes it possible to control the cutting processes and communicate with the machine directly. The intuitive software technology integrated into the machine enables operators to modify cutting parameters and prepare the cutting process quickly and efficiently.The DANOBAT LB coil-fed cutting machine is ideal for the production of various products, including automotive components, industrial equipment, and construction materials, among others. The machine ensures efficient production, improved automation, and enhanced product quality.DANOBATGROUP is not only known for its cutting-edge sheet metal coil cutting machines but also for providing excellent customer service. The company has a team of professionals who are always ready to offer technical support and assistance. With a worldwide presence, DANOBATGROUP ensures that its customers receive timely assistance and a reliable after-sales service.In summary, the DANOBAT LB coil-fed cutting machine is a top-of-the-line equipment that offers high-precision, efficiency, and reliability to the sheet metal cutting industry. Its excellent cutting speed, user-friendly interface, and optimal usage of materials result in minimized production costs and high-quality products. To learn more about this cutting-edge technology and to request a quote, contact DANOBATGROUP, a reputed provider of sheet metal processing solutions.

High-Quality Glazed Tile Roll Forming Machine for Sale - Best Price Guaranteed!

Title: Enhance Efficiency and Precision with the Glazed Tile Roll Forming MachineIntroduction:In the fast-paced construction industry, time and precision are paramount. The Glazed Tile Roll Forming Machine offers an efficient and reliable solution for producing high-quality glazed tiles quickly and accurately. As a leading manufacturer and supplier of glazed tile forming machines in China, we strive to provide state-of-the-art equipment that meets our clients' needs. In this blog, we will explore the benefits of using a Glazed Tile Roll Forming Machine and why it is crucial to contact us for your machinery requirements.1. What is a Glazed Tile Roll Forming Machine?A Glazed Tile Roll Forming Machine is a specialized piece of equipment designed to transform raw materials into elegantly-designed glazed tiles. It encompasses a series of forming rollers, cutters, and other components that shape the metal sheets into the desired tile profile. This automated process ensures consistency, precision, and a high production rate, eliminating the need for labor-intensive and time-consuming manual fabrication.2. Unraveling the Advantages:2.1 Impeccable Precision:The Glazed Tile Roll Forming Machine allows for precise control over the dimensions and specifications of each tile produced. With computer-aided design (CAD) software, it provides detailed and accurate customization, ensuring a seamless fit when installing the tiles. This level of precision translates into reduced wastage and increased customer satisfaction.2.2 High Production Rate:By automating the tile production process, the Glazed Tile Roll Forming Machine significantly enhances productivity. It can roll out a large number of tiles in a short period while maintaining consistency in shape, size, and quality. This enables contractors and manufacturers to meet deadlines efficiently and fulfill large-scale projects with ease.2.3 Versatility in Design and Dimensions:Our Glazed Tile Roll Forming Machine can create a wide range of tile profiles, including step tiles, corrugated tiles, and much more. Its flexibility allows customization to suit specific project requirements, providing architects and designers with endless possibilities for creative expression. Whether it's a traditional or contemporary architectural style, this machine can accommodate various designs flawlessly.2.4 Durability and Longevity:Utilizing high-quality materials and advanced manufacturing techniques, our Glazed Tile Roll Forming Machine ensures robustness and longevity. The sturdy construction guarantees reliable performance even in demanding working conditions, reducing maintenance costs and maximizing profitability.3. Why Choose Us?As a distinguished manufacturer and supplier, we provide a comprehensive range of Glazed Tile Roll Forming Machines to meet diverse industry needs. Here are a few reasons why you should consider partnering with us:3.1 Experience and Expertise:With years of experience in the industry, we have honed our manufacturing process to produce top-notch machinery. Our team of skilled engineers and technicians undergo continuous training to stay updated with the latest advancements, ensuring that our clients receive cutting-edge products.3.2 Tailored Solutions:We understand that every project has unique requirements, which is why our Glazed Tile Roll Forming Machines can be tailored to suit specific specifications. Whether it's dimensions, tile profiles, or any other customization, we work closely with our clients to deliver machines that align perfectly with their needs.3.3 Excellent Customer Support:Customer satisfaction is of utmost importance to us, and we strive to provide exceptional support at every stage – from product selection to after-sales services. Our dedicated team is always ready to assist you, ensuring a seamless and hassle-free experience.Contact Us:A Glazed Tile Roll Forming Machine is a valuable investment that can accelerate your business growth and elevate the quality of your tile production. If you are searching for a reliable and top-quality supplier, look no further. Contact us today to discuss your requirements and revolutionize your tile manufacturing process.