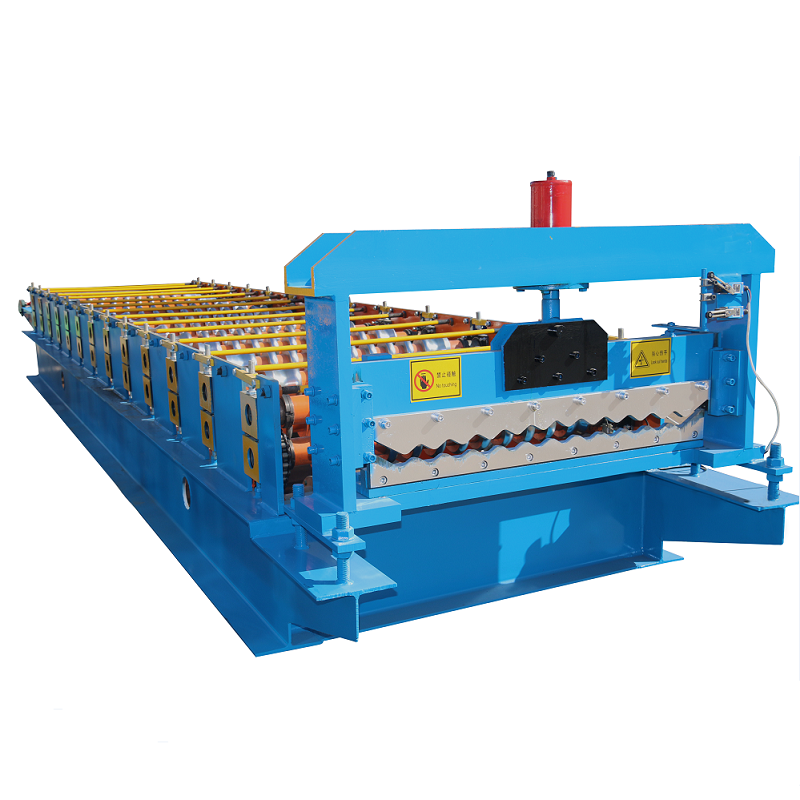

Affordable Metal Step Tile Forming Machine with Filming Technology Available Now

By:Admin

The roofing industry has seen a significant technological advancement with the introduction of the Metal Step Tile With Filming Forming Machine by {}. This innovative machine has revolutionized the way metal step tiles are manufactured, providing a more efficient and cost-effective solution for the construction and roofing industry.

The Metal Step Tile With Filming Forming Machine, developed by {}, is a state-of-the-art equipment designed to produce high-quality metal step tiles with precision and speed. The machine utilizes advanced technology and innovative features to create step tiles that meet the highest industry standards.

One of the key features of the Metal Step Tile With Filming Forming Machine is its ability to apply a protective film on the surface of the metal step tiles. This film not only enhances the aesthetic appeal of the tiles but also provides added protection against corrosion, weathering, and other environmental factors. This ensures that the metal step tiles are durable and long-lasting, making them an ideal choice for roofing applications.

Additionally, the Metal Step Tile With Filming Forming Machine is equipped with a high-speed forming system that allows for rapid production of metal step tiles. This ensures that manufacturers can meet the growing demand for these tiles without compromising on quality or efficiency. The machine also has a user-friendly interface, making it easy to operate and maintain, thus increasing productivity and reducing downtime.

With the introduction of this cutting-edge technology, the roofing industry has experienced a significant shift towards the use of metal step tiles for various construction projects. These tiles are known for their durability, versatility, and aesthetic appeal, making them a popular choice among architects, builders, and homeowners.

In addition to its technological advancements, {} is a leading company in the roofing industry with a strong commitment to quality, innovation, and customer satisfaction. With a team of highly skilled engineers and designers, the company has been at the forefront of developing advanced roofing solutions that meet the evolving needs of the industry.

The Metal Step Tile With Filming Forming Machine is just one of the many innovative products offered by {} that have cemented the company's reputation as a leader in the roofing industry. The company's dedication to research and development, as well as its investment in cutting-edge technology, have positioned it as a trusted partner for businesses looking to improve their roofing processes and capabilities.

The introduction of the Metal Step Tile With Filming Forming Machine has not only enhanced the production of metal step tiles but has also paved the way for a more sustainable and eco-friendly approach to roofing. These metal step tiles are recyclable and environmentally friendly, making them an attractive option for environmentally-conscious consumers.

The impact of the Metal Step Tile With Filming Forming Machine can already be seen across the industry, with manufacturers and contractors adopting this technology to improve their operations. By offering improved efficiency, higher quality, and enhanced durability, the machine has set a new standard for metal step tile production.

As the demand for metal step tiles continues to grow, {} is dedicated to further enhancing its Metal Step Tile With Filming Forming Machine and developing new technologies that will continue to shape the future of the roofing industry. With its commitment to innovation and excellence, the company is poised to remain a driving force in the industry for years to come.

In conclusion, the Metal Step Tile With Filming Forming Machine has transformed the roofing industry by offering a more efficient, cost-effective, and sustainable solution for metal step tile production. Its advanced features, combined with the expertise and dedication of {}, have set a new standard for the industry and have positioned the company as a leader in roofing technology. With the continued development of innovative solutions, {} is well-positioned to meet the evolving needs of the roofing industry and contribute to its continued growth and success.

Company News & Blog

High-Quality Rack Forming Machine for Efficient Production

Rack Forming Machine Revolutionizing the Manufacturing IndustryIn recent years, the manufacturing industry has witnessed significant advancements in technology, especially in the realm of machinery and equipment. One such innovative invention that has garnered attention and redefined the manufacturing process is the Rack Forming Machine. A Rack Forming Machine is a revolutionary piece of equipment that has the capability to form metal racks with precision and speed, bringing about a significant transformation in the manufacturing process.The Rack Forming Machine has been designed and developed by a leading manufacturing machinery company, which has carved a niche for itself in the industry through its cutting-edge solutions and state-of-the-art technology. The company, with its unwavering commitment to innovation and quality, has been at the forefront of delivering high-performance machinery that is tailored to meet the evolving needs of the manufacturing sector.The Rack Forming Machine is a testament to the company's expertise and dedication to engineering excellence. It boasts of a robust and high-precision design that enables it to form metal racks with utmost accuracy and efficiency. The machine is equipped with advanced features such as automatic feeding and cutting, adjustable settings for different rack sizes, and user-friendly controls, making it incredibly versatile and adaptable to various manufacturing requirements.One of the key advantages of the Rack Forming Machine is its ability to streamline the rack forming process, thereby significantly reducing production time and labor costs. The machine's automated functionalities and high-speed production capabilities enable manufacturers to enhance their operational efficiency and meet the demands of a competitive market. Furthermore, the precision and consistency in the rack forming process ensure that the end products meet stringent quality standards, thereby adding value to the manufacturing process.Moreover, the Rack Forming Machine is designed with a focus on safety and ergonomics, prioritizing the well-being of the operators and ensuring a conducive working environment. With its intuitive design and built-in safety features, the machine offers a reliable and secure operation, mitigating the risks associated with manual labor and traditional rack forming methods.In addition to its technological prowess, the Rack Forming Machine is also a sustainable solution for the manufacturing industry. By optimizing the use of resources, minimizing material wastage, and reducing energy consumption, the machine aligns with the growing emphasis on sustainability and eco-friendly practices in manufacturing.The introduction of the Rack Forming Machine has been met with widespread enthusiasm and anticipation within the manufacturing sector. Manufacturers across various industries, including automotive, logistics, and warehouse storage, have recognized the potential of this innovative equipment in enhancing their production capabilities and driving business growth.As the demand for efficient and reliable rack forming solutions continues to rise, the company remains committed to supporting manufacturers with cutting-edge technology and unparalleled service. With a global presence and a strong network of partners and distributors, the company is well-positioned to cater to the needs of manufacturers worldwide, offering comprehensive support and expertise in the integration and utilization of the Rack Forming Machine.In conclusion, the Rack Forming Machine represents a significant leap forward in the manufacturing industry, signaling a new era of efficiency, precision, and sustainability. With its advanced capabilities and the backing of a reputable and innovative company, the machine is poised to set new standards in rack forming and reshape the manufacturing landscape for years to come.

High Precision Cut To Length Line Metal Sheet Cutting Machine for Efficient Sheet Metal Slitting

and Sheet Metal Slitter Machine.When it comes to cutting metal sheets, it is imperative to have a reliable and precise Cut-To-Length Machine and Sheet Metal Slitter Machine. These machines are designed to offer efficient precision cutting of metal sheets, which is essential in most metal fabrication industries. The High Precision Cut-To-Length Line Metal Sheet Cutting Machine/Sheet Metal Slitter Machine is among the most sought after machines in the market today.This machine is made using high-quality materials that guarantee its durability and efficiency. The machine is specifically designed to cut metal sheets into specific sizes, lengths, and widths, making it ideal for various metal fabrication projects. It utilizes high precision sensors that measure and cut metal sheets according to the desired lengths.One of the benefits of this machine is its ability to deliver high precision cutting. The machine is designed to deliver accurate and consistent cuts that meet your specifications. This is essential in ensuring that the finished products meet the required standards, and there is no wastage of materials.The High Precision Cut-To-Length Line Metal Sheet Cutting Machine/Sheet Metal Slitter Machine is also versatile. It can be used to cut different types of metal sheets, including aluminum, galvanized, cold-rolled, and stainless steel. This makes it ideal for use in different industries such as construction, automotive, and aerospace.Another advantage of this machine is its efficiency. The machine is designed to operate at high speeds, enabling it to cut several metal sheets within a short period. This not only saves time but also increases production capacity, which is essential in meeting high demand in the market.In conclusion, the High Precision Cut-To-Length Line Metal Sheet Cutting Machine/Sheet Metal Slitter Machine is a vital investment for any metal fabricator. It offers high precision cutting, versatility, and efficiency, which are essential in meeting the demands of the market. If you are looking to enhance your metal fabrication business's productivity, then this machine is a must-have.

High-Quality Corrugated Metal Roofing Machine for Sale

Corrugated Metal Roofing Machine Revolutionizes Roofing Industry{Company Name} has recently announced the launch of their newest innovation in the roofing industry - the Corrugated Metal Roofing Machine. This state-of-the-art machine is set to revolutionize the way metal roofing is manufactured, offering advanced technology and unparalleled efficiency.The Corrugated Metal Roofing Machine is designed to produce high-quality, corrugated metal roofing panels with speed and precision. The innovative technology used in the machine ensures that the panels are uniform in shape and size, with smooth, accurate corrugations. This not only enhances the aesthetic appeal of the roofing panels but also improves their functionality and durability.The company has invested extensive research and development into the Corrugated Metal Roofing Machine, ensuring that it meets the highest standards of quality and performance. The machine is equipped with cutting-edge automation and control systems, allowing for seamless operation and minimal human intervention. This not only increases productivity but also reduces the margin of error, resulting in consistently superior roofing panels.Additionally, the Corrugated Metal Roofing Machine is designed to be versatile and adaptable, capable of producing a wide range of corrugated metal roofing panels to meet the diverse needs of the market. From different shapes and profiles to varying thicknesses and coatings, the machine can be customized to manufacture roofing panels to exact specifications, catering to the specific requirements of each project.{Company Name} has a long-standing reputation for excellence in the roofing industry, with a commitment to innovation and customer satisfaction. The launch of the Corrugated Metal Roofing Machine is a testament to the company's dedication to pushing the boundaries of technology and delivering cutting-edge solutions to its customers."We are thrilled to introduce the Corrugated Metal Roofing Machine to the market," said {Spokesperson}. "This is a game-changer for the roofing industry, and we believe it will set a new standard for efficiency, quality, and innovation in metal roofing manufacturing. We are confident that this machine will benefit our customers by offering them unmatched precision and productivity, ultimately helping them to achieve superior results with their roofing projects."In addition to its technological advancements, the Corrugated Metal Roofing Machine is also designed with sustainability in mind. By optimizing material usage and reducing waste, the machine minimizes the environmental impact of metal roofing production. Furthermore, the high efficiency of the machine results in lower energy consumption, contributing to overall energy conservation.The launch of the Corrugated Metal Roofing Machine demonstrates {Company Name}'s commitment to driving progress and excellence in the roofing industry. With its cutting-edge technology, superior quality, and sustainable design, the machine is poised to revolutionize the way metal roofing panels are manufactured, setting a new standard for the industry.As the demand for metal roofing continues to grow, driven by its durability, longevity, and aesthetic appeal, the Corrugated Metal Roofing Machine is set to play a pivotal role in meeting this demand. By offering a technologically advanced and efficient solution for metal roofing manufacturing, {Company Name} is poised to strengthen its position as a leader in the roofing industry and capture new opportunities in the market.For more information about the Corrugated Metal Roofing Machine and {Company Name}'s other innovative solutions, visit their website {website}.

High Speed Steel Roof Truss C Z Purline Making Machinery

High Speed Steel Roof Truss C Z Purline Making Machinery Unveiled by Renowned CompanyThe construction industry is constantly evolving, and with the advancement of technology, new and innovative machinery is constantly being introduced to make the process more efficient and effective. [Company Name], a leading manufacturer of construction machinery, has unveiled its latest offering – the High Speed Steel Roof Truss C Z Purline Making Machinery. This cutting-edge equipment is set to revolutionize the production of roof trusses and purlins, making the process faster, more precise, and more cost-effective.The High Speed Steel Roof Truss C Z Purline Making Machinery is the result of years of research and development by [Company Name]. The company has a strong track record of delivering high-quality construction machinery, and this latest offering is no exception. With its advanced technology and innovative design, this machinery is expected to set a new standard in the industry.One of the key features of the High Speed Steel Roof Truss C Z Purline Making Machinery is its high speed production capability. Equipped with state-of-the-art components and a powerful motor, this machinery is able to produce roof trusses and purlins at a significantly faster rate than traditional methods. This not only increases productivity but also allows for shorter lead times on construction projects, ultimately saving time and money for builders and contractors.In addition to its speed, the High Speed Steel Roof Truss C Z Purline Making Machinery also boasts a high level of precision. The machinery is designed to create trusses and purlins with exact measurements, ensuring a perfect fit and optimal structural integrity. This level of precision is crucial in construction, where even the smallest deviation can lead to significant issues down the line. With this machinery, builders can have confidence in the quality and accuracy of the roof trusses and purlins produced.Furthermore, the High Speed Steel Roof Truss C Z Purline Making Machinery is designed with user-friendliness in mind. It is equipped with intuitive controls and a user-friendly interface, making it easy for operators to set up and operate the machinery. This not only reduces the learning curve for new operators but also minimizes the risk of errors during production.[Company Name] is known for its commitment to quality and reliability, and the High Speed Steel Roof Truss C Z Purline Making Machinery is no exception. The machinery is built to last, with durable materials and robust construction that can withstand the rigors of the construction industry. This ensures that builders and contractors can rely on the machinery for consistent performance and longevity.With the unveiling of the High Speed Steel Roof Truss C Z Purline Making Machinery, [Company Name] is once again demonstrating its leadership in the construction machinery industry. The company is dedicated to continuously pushing the boundaries of innovation, and this latest offering is a testament to that commitment. Builders and contractors can now look forward to a more efficient and effective production process for roof trusses and purlins, thanks to this advanced machinery.In conclusion, the High Speed Steel Roof Truss C Z Purline Making Machinery by [Company Name] is a game-changer for the construction industry. With its high speed production, precision, user-friendliness, and durability, this machinery is set to redefine the production of roof trusses and purlins. Builders and contractors can expect a more efficient and cost-effective production process, ultimately leading to enhanced productivity and quality in construction projects. [Company Name] continues to lead the way in construction machinery, and this latest offering is a clear example of their commitment to innovation and excellence.

Roll Forming Machine for Creating Corrugated Galvanized Steel Roofing

Title: Corrugated Metal Roll Forming Machine: Revolutionizing Modern Roofing SolutionsIntroduction:As the construction industry continues to evolve, it is essential to embrace cutting-edge technologies that enhance efficiency and productivity. One such innovation that has revolutionized the roofing industry is the Corrugated Metal Roll Forming Machine. Specifically designed for producing corrugated galvanized steel, this advanced machine has become indispensable for manufacturers, delivering top-quality metal roofing solutions. In this blog post, we will delve deeper into the benefits and significance of the Corrugated Metal Roll Forming Machine in the modern construction landscape.Exploring the Corrugated Metal Roll Forming Machine:1. Enhanced productivity and efficiency:The Corrugated Metal Roll Forming Machine offers unmatched precision and speed, eliminating wastage and reducing production time. With its automated processes and cutting-edge design, manufacturers can produce more roofing sheets in a shorter span of time, resulting in increased productivity.2. Superior quality products:Equipped with state-of-the-art technology, the Corrugated Metal Roll Forming Machine ensures impeccable finishes and consistent corrugation patterns. This reliability guarantees high-quality roofing solutions that meet and exceed industry standards. The machine's ability to roll galvanized, pre-painted, and galvalume steels into corrugated galvanized steel ensures durability and longevity for the roofs.3. Flexibility in design:Corrugated roofing comes in various shapes, sizes, and profiles. With a versatile Corrugated Metal Roll Forming Machine at their disposal, manufacturers have the freedom to create tailored roofing solutions to cater to diverse customer needs. This adaptability allows for unique designs, providing architects and homeowners with extensive choices for their projects.4. Cost-effective solution:The Corrugated Metal Roll Forming Machine optimizes material usage and minimizes wastage, resulting in cost-effective manufacturing. Its highly efficient processes drastically reduce labor costs and turnaround times, making it an ideal choice for both large-scale production facilities and smaller roofing businesses. The savings accumulated through the use of this machine can be passed on to customers, making metal roofing a more economical option.5. Environmentally friendly:In the era of sustainability, the Corrugated Metal Roll Forming Machine has become a vital player in eco-friendly construction practices. By minimizing the excess material generated during the manufacturing process, this machine contributes to reducing waste and conserving resources. Furthermore, the durability and recyclability of corrugated galvanized steel roofing make it an environmentally conscious choice for builders and homeowners.Keywords and SEO:To maximize the search engine optimization (SEO) of this blog, it is crucial to incorporate relevant keywords ensuring the content aligns with search engine algorithms. By including words such as "corrugated metal roll forming machine," "corrugated metal roofing," "galvanized steel," and "roll forming," we can enhance the visibility of this blog post to the target audience actively searching for information related to metal roofing machinery.Conclusion:The Corrugated Metal Roll Forming Machine has emerged as a game-changer in the roofing industry, providing remarkable benefits such as enhanced productivity, superior quality products, design flexibility, cost-effectiveness, and environmental sustainability. By harnessing the power of this advanced machinery, manufacturers can meet the growing demand for modern, durable, and visually appealing metal roofs. As the construction industry continues to advance, embracing cutting-edge technology like the Corrugated Metal Roll Forming Machine is essential for the success and growth of businesses in the industry.

Photos of Cold Rolling Forming Production Line for Stud Profile C Purlin & U Purlin Roll Forming Machine

Zhiye Cold Forming Machinery Co., Ltd. has launched a new product for the construction industry – the Stud Profile C Purlin Cold Rolling Forming Production Line or more commonly known as the stud U purlin roll forming machine.This machine is designed to produce C purlins and U purlins that are commonly used as framing elements in the construction of roofs, walls, and ceilings. The purlins produced by this machine are known for their high strength, versatility, and cost-effectiveness, making them a popular choice for most building projects.The Stud Profile C Purlin Cold Rolling Forming Production Line operates using advanced technology that ensures the production of high-quality purlins with precise dimensions. Its production process involves feeding raw material into the machine where it is pre-cut and fed into the main roll forming machine. The machine then goes through a series of operations such as leveling, punching, cutting, and stacking, before the final product is produced.The C Purlin Profiles Cold Roll Forming Lines produced by Zhiye Cold Forming Machinery Co., Ltd. are all equipped with state-of-the-art control systems that ensure easy operation, smooth production, and high productivity. The machine can produce purlins of different shapes and sizes, ranging from 100mm to 300mm. It can run at speeds of up to 25 meters per minute, making it possible to produce a large volume of purlins in a short period.The Stud Profile C Purlin Cold Rolling Forming Production Line is made using high-quality components and materials, ensuring its durability and long lifespan. The machine is also flexible and can be easily customized to suit specific customer needs. It is designed for ease of maintenance, with minimal downtime required for repairs and servicing.The launch of this new product by Zhiye Cold Forming Machinery Co., Ltd. is expected to have a significant impact on the construction industry, particularly in the roofing and framing sectors. The machine's ability to produce high-quality purlins quickly and efficiently means that construction companies can save time and money on their projects without compromising the quality of the final product. This is essential, given the increasing demand for construction works globally, where cost and time efficiency are critical.In conclusion, the Stud Profile C Purlin Cold Rolling Forming Production Line/stud U purlin roll forming machine from Zhiye Cold Forming Machinery Co., Ltd. is a significant innovation that will revolutionize the construction industry. The machine's advanced technology, coupled with its efficiency and precision, will ensure that construction companies can produce high-quality purlins quickly and cost-effectively. This will ultimately lead to faster project completion times and reduced costs, making it a popular choice in the industry.

High Speed Metal Roof Panel Roll Forming Machine with Hydraulic Control System: Quality Supplier from China

Jiangyin Dingbo Technology CO., Ltd., a leading provider of roofing panel roll forming machines, has recently introduced their latest innovation - a high speed metal roof panel roll forming machine with hydraulic control system. This advanced machine is designed to efficiently produce metal roof panels with precision and speed, offering superior quality and performance.The 380V 50Hz high speed metal roof panel roll forming machine is equipped with a hydraulic control system, which ensures smooth and accurate operation. The hydraulic control system not only enhances the efficiency of the roll forming process but also enables precise control over the shaping and cutting of the metal sheets. This results in high-quality roof panel production that meets the stringent industry standards.One of the key features of this machine is its ability to produce metal roof panels in various sizes and profiles. The roll forming process involves feeding the metal sheets into the machine, where they are gradually shaped and cut into the desired profile. With the hydraulic control system, the machine can easily adjust its settings to accommodate different panel sizes and profiles, making it highly versatile and adaptable to the specific needs of the customers.Another notable feature of this machine is its high-speed production capability. With its efficient hydraulic control system and advanced technology, the roll forming process is significantly accelerated, allowing for faster production rates. This is especially beneficial for large-scale roofing projects where time is of the essence. The high-speed production not only increases efficiency but also reduces labor costs and enhances overall productivity.In addition to its impressive speed, this metal roof panel roll forming machine also ensures uncompromised quality. The advanced hydraulic control system ensures precise shaping and cutting, resulting in panels with smooth edges, consistent dimensions, and superior finish. The machine is designed to operate with utmost precision and accuracy, eliminating any potential errors or imperfections in the production process. This ensures that the produced roof panels meet the highest quality standards, providing customers with durable and aesthetically pleasing roofing solutions.Furthermore, Jiangyin Dingbo Technology CO., Ltd. emphasizes their commitment to customer satisfaction and reliability. As a reputable supplier of roof panel roll forming machines, the company strives to deliver top-notch products that meet and exceed customer expectations. They offer full support and assistance throughout the entire purchasing process, from consultation and customization to installation and after-sales service.Jiangyin Dingbo Technology CO., Ltd. continues to innovate and enhance their products to meet the evolving needs of the roofing industry. Their high-speed metal roof panel roll forming machine with hydraulic control system is a testament to their dedication to providing cutting-edge solutions that optimize efficiency, productivity, and quality. With this advanced machine, customers can benefit from faster production rates, superior panel quality, and enhanced overall performance.In conclusion, the introduction of the 380V 50Hz high speed metal roof panel roll forming machine with hydraulic control system by Jiangyin Dingbo Technology CO., Ltd. showcases their commitment to technological innovation and customer satisfaction. This advanced machine offers versatility, speed, and unmatched quality in the production of metal roof panels. As a trusted supplier, this company continues to revolutionize the roofing industry with their state-of-the-art solutions that enhance productivity and deliver excellence.

High-Quality Aluminum Extrusion Milling Machine for Sale - Find Out More!

Aluminum Extrusion Milling Machine Revolutionizes Manufacturing IndustryIn an era characterized by technological advancements and innovations, the manufacturing industry is constantly seeking new, efficient, and cost-effective solutions to improve production processes. The introduction of the groundbreaking Aluminum Extrusion Milling Machine by {Company Name} has taken the industry by storm, offering a cutting-edge solution to aluminum extrusion milling with unparalleled precision and efficiency.{Company Name} is a renowned leader in the manufacturing and distribution of industrial machinery, offering a wide range of high-quality equipment designed to meet the diverse needs of the industry. With a strong emphasis on research and development, {Company Name} has consistently delivered state-of-the-art solutions that have garnered widespread recognition and acclaim.The Aluminum Extrusion Milling Machine is the latest addition to {Company Name}'s impressive portfolio, and it represents a significant advancement in the field of aluminum extrusion processing. The machine is equipped with advanced technologies and features that enable it to perform milling operations on aluminum extrusions with unmatched accuracy and speed, making it a game-changer for manufacturers in various sectors.One of the key highlights of the Aluminum Extrusion Milling Machine is its precision engineering, which allows for the seamless milling of complex shapes, profiles, and structures with minimal margin for error. This level of precision is critical in industries such as aerospace, automotive, and construction, where the quality and accuracy of aluminum components are paramount.Furthermore, the machine's high-speed milling capabilities significantly reduce production times, leading to greater efficiency and cost savings for manufacturers. By streamlining the milling process, {Company Name}'s Aluminum Extrusion Milling Machine enables companies to meet tight deadlines and production targets without compromising on quality.Another noteworthy feature of the Aluminum Extrusion Milling Machine is its versatility, as it can accommodate a wide range of aluminum extrusion profiles, sizes, and geometries. This versatility makes the machine an ideal solution for manufacturers with diverse milling requirements, allowing them to handle a variety of projects with ease and flexibility.In addition to its technical capabilities, the Aluminum Extrusion Milling Machine is also designed with user-friendly features that enhance ease of operation and maintenance. This attention to ergonomic design ensures that operators can maximize productivity while minimizing downtime and maintenance costs.The introduction of {Company Name}'s Aluminum Extrusion Milling Machine has generated significant interest and excitement within the manufacturing industry, with many companies expressing keen interest in adopting this cutting-edge technology. As the demand for high-quality, precision-milled aluminum components continues to grow, the machine is poised to play a pivotal role in meeting the evolving needs of the industry.In response to the overwhelming interest in the Aluminum Extrusion Milling Machine, {Company Name} has announced plans to offer comprehensive training and support services to help manufacturers integrate the technology seamlessly into their operations. This commitment to customer satisfaction underscores {Company Name}'s dedication to delivering not only advanced machinery but also value-added services that empower manufacturers to excel in a competitive market.With its unwavering commitment to innovation, quality, and customer satisfaction, {Company Name} has once again raised the bar for excellence in the manufacturing industry with the launch of the Aluminum Extrusion Milling Machine. As manufacturers continue to seek modern solutions that enhance productivity and precision, this groundbreaking technology is poised to usher in a new era of efficiency and performance in aluminum extrusion milling.

High-Quality Corrugated Roof Tile Making Machine for Efficient Production

Corrugated Roof Tile Making Machine brings innovation in the roofing industryThe roofing industry has seen a significant shift in recent years, with a growing demand for durable, cost-effective, and eco-friendly roofing solutions. In response to this demand, a leading manufacturer, {company name removed}, has introduced an advanced Corrugated Roof Tile Making Machine that is set to revolutionize the roofing industry.The Corrugated Roof Tile Making Machine is a state-of-the-art equipment that is designed to produce high-quality roofing tiles with precision and efficiency. It is equipped with advanced technology and features that allow for the seamless production of corrugated roof tiles, which are known for their strength, durability, and aesthetic appeal.The machine is capable of producing a wide range of corrugated roof tiles, including various sizes, shapes, and colors, thereby catering to the diverse needs and preferences of customers. Whether it's for residential, commercial, or industrial applications, the machine has the capability to meet the demands of the market.One of the key features of the Corrugated Roof Tile Making Machine is its high production capacity, which enables manufacturers to meet large-scale orders and deadlines. This is particularly beneficial for roofing companies and contractors who require a reliable and efficient production system to fulfill their projects in a timely manner.Furthermore, the machine is designed with user-friendly controls and automation, which not only simplifies the production process but also minimizes the risk of errors and defects. This results in consistent quality and uniformity in the produced tiles, thereby enhancing the overall satisfaction of customers.In addition to its efficiency and productivity, the Corrugated Roof Tile Making Machine is also environmentally friendly. It is designed to minimize waste and energy consumption, thereby aligning with the growing emphasis on sustainable and eco-friendly manufacturing practices.The introduction of this advanced machine signifies a significant advancement in the roofing industry, offering manufacturers and customers alike a reliable and cutting-edge solution for their roofing needs. With its ability to produce high-quality, long-lasting, and visually appealing corrugated roof tiles, the machine is set to significantly impact the market and set new standards for roofing materials.In line with {company name removed}'s commitment to innovation and excellence, the Corrugated Roof Tile Making Machine reflects the company's dedication to providing advanced solutions that meet the evolving needs of the industry. With its extensive experience and expertise in manufacturing equipment for the construction and building materials sector, the company has once again demonstrated its leadership in driving innovation and progress in the market.The introduction of the Corrugated Roof Tile Making Machine is poised to bring about a positive change in the roofing industry, offering a cost-effective, efficient, and sustainable solution for both manufacturers and consumers. As the demand for high-quality and durable roofing materials continues to rise, this innovative machine is expected to play a pivotal role in shaping the future of the industry.In conclusion, the Corrugated Roof Tile Making Machine represents a significant leap forward in the roofing industry, offering a modern, efficient, and sustainable solution for the production of high-quality corrugated roof tiles. With its advanced technology, user-friendly features, and eco-friendly design, the machine is set to transform the way roofing materials are manufactured and used, setting new benchmarks for quality and performance in the market.

High-Quality Heavy Gauge Slitting Line for Efficient Production

Heavy Gauge Slitting Line plays a crucial role in the metal processing industry. It is a highly efficient and versatile machine that is used to cut large coils of metal into narrower strips, which are then used for various purposes in different industries. With its high precision and speed, Heavy Gauge Slitting Line has become an essential tool for metal processing companies around the world.One of the leading manufacturers of Heavy Gauge Slitting Line, is known for producing high-quality and reliable machines that meet the needs of its customers. The company has a strong commitment to research and development, and it continuously strives to improve its products and services to meet the evolving needs of the market. With a focus on innovation and technology, the company has established itself as a trusted name in the metal processing industry.The Heavy Gauge Slitting Line produced by the company is designed to meet the demands of heavy-duty metal processing. It is capable of handling large coils of metal with precision and efficiency, making it an ideal choice for companies that require high-volume production. The machine is equipped with advanced control systems and cutting-edge technology to ensure consistent and accurate slitting of metal coils, resulting in high-quality strips that meet the industry standards.The Heavy Gauge Slitting Line is also known for its versatility and flexibility. It can be customized to meet the specific requirements of different types of metal and can handle a wide range of thickness and width, making it suitable for various applications in the metal processing industry. Whether it is stainless steel, aluminum, or other metals, the Heavy Gauge Slitting Line can deliver superior performance and precision cutting, making it a valuable asset for companies across different sectors.In addition to its technical capabilities, the company also provides excellent after-sales support and services to ensure the smooth operation of its Heavy Gauge Slitting Line. Its team of skilled engineers and technicians are committed to providing prompt and efficient assistance to its customers, offering training, maintenance, and troubleshooting services to maximize the performance and lifespan of the machine.The company’s commitment to quality, innovation, and customer satisfaction has earned it a strong reputation in the metal processing industry. Its Heavy Gauge Slitting Line is trusted by companies around the world for its reliability, efficiency, and precision, making it a preferred choice for businesses looking to enhance their metal processing capabilities.With its dedication to excellence and a strong track record in delivering high-quality machines, the company continues to be a leading player in the metal processing industry. As it continues to innovate and evolve, it remains committed to providing the best solutions for its customers and driving the industry forward with its cutting-edge Heavy Gauge Slitting Line.