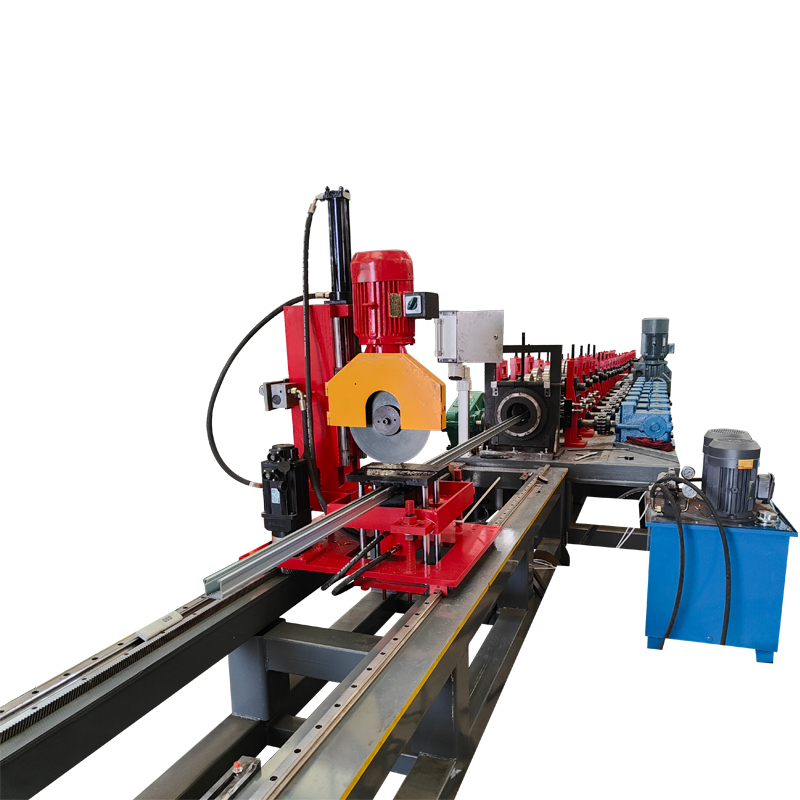

High-Quality Cable Tray Forming Machine for Efficient Cable Management

By:Admin

Cable tray forming machines are revolutionizing the way industrial manufacturing companies produce cable management systems. These machines are a crucial component in the production of cable trays, which are used to support insulated electrical cables for power distribution and communication. With the increasing demand for cable management systems in various industries, the need for efficient and high-quality cable tray forming machines has become paramount.

{Company Name}, a leading manufacturer of industrial machinery, has been at the forefront of producing state-of-the-art cable tray forming machines. With over 20 years of experience in the industry, {Company Name} has established itself as a reliable and innovative provider of machinery for the manufacturing sector.

The cable tray forming machine manufactured by {Company Name} boasts a range of advanced features that set it apart from the competition. Equipped with cutting-edge technology and precision engineering, this machine is capable of producing cable trays of various sizes and specifications with remarkable speed and accuracy. Furthermore, its user-friendly interface and automated controls make it easy to operate and maintain, reducing the need for extensive training and technical expertise.

In addition to its high-performance capabilities, the cable tray forming machine from {Company Name} is also designed with energy efficiency in mind. By minimizing energy consumption and optimizing production processes, this machine helps manufacturing companies reduce their carbon footprint and operational costs, contributing to a more sustainable and environmentally friendly industrial sector.

One of the key advantages of using {Company Name}'s cable tray forming machine is its versatility. Whether it's for the automotive, construction, telecommunications, or energy sectors, this machine can adapt to the specific requirements of different industries, making it an ideal solution for manufacturers with diverse production needs.

Moreover, {Company Name} provides comprehensive technical support and after-sales services to ensure that their customers can maximize the potential of the cable tray forming machine. With a team of skilled engineers and technicians, the company offers training programs, maintenance services, and troubleshooting assistance to help clients overcome any operational challenges and keep their production running smoothly.

As the demand for cable management systems continues to grow across various industries, the role of cable tray forming machines in the manufacturing process has become increasingly vital. By partnering with {Company Name} and investing in their cutting-edge machinery, industrial manufacturers can enhance their production capabilities, increase efficiency, and stay competitive in the ever-evolving market.

In conclusion, the cable tray forming machine from {Company Name} exemplifies the innovative spirit and commitment to excellence that has made the company a trusted name in the industrial machinery sector. With its advanced technology, energy-efficient design, and exceptional versatility, this machine is poised to play a crucial role in shaping the future of industrial manufacturing. As more companies recognize the benefits of using this state-of-the-art equipment, the industry can look forward to a more efficient, sustainable, and productive future powered by the cable tray forming machine from {Company Name}.

Company News & Blog

Revolutionary Aluminum Profile Bending Machine Unveiled in Latest News

Title: Revolutionary CNC Aluminum Profile Bending Machine Transforming the Manufacturing IndustryIntroduction:In a rapidly evolving manufacturing industry, technological advancements have always played a crucial role in enhancing efficiency and precision. A groundbreaking solution has emerged in the form of a CNC Aluminum Profile Bending Machine, which is revolutionizing the way aluminum profiles are bent and shaped. By seamlessly merging technology and precision engineering, this innovative machine promises to deliver unprecedented results in terms of accuracy, speed, and versatility.Technological Features:The CNC Aluminum Profile Bending Machine is equipped with state-of-the-art computer numerical control (CNC) technology, allowing for precise control and automation of the bending process. It utilizes advanced algorithms to calculate the required bending angles, eliminating human errors and ensuring consistent quality.The machine is designed to accommodate a wide range of aluminum profiles, from simple extrusions to complex designs, catering to the diverse needs of industries such as architecture, construction, automotive, and aerospace. Its adjustable mandrel enables the bending of profiles in various sizes and shapes, offering infinite possibilities for customization.Furthermore, the CNC Aluminum Profile Bending Machine boasts a user-friendly interface, making it accessible to operators with varying levels of expertise. The intuitive controls allow for easy programming and quick set-up, reducing downtime and enhancing overall productivity.Benefits and Advantages:The introduction of this cutting-edge machine brings several benefits to the manufacturing industry, including:1. Enhanced Precision: The CNC technology ensures consistent results, minimizing deviations and errors. The machine's ability to bend aluminum profiles with exceptional accuracy and repeatability guarantees a high-quality end product.2. Improved Efficiency: By automating the bending process, the machine significantly reduces production time. Its high-speed operation enables rapid bending without compromising precision, making it ideal for large-scale manufacturing.3. Cost Savings: The CNC Aluminum Profile Bending Machine optimizes material usage, reducing waste. Its efficiency also translates into lower labor costs and increased production capacity, ultimately contributing to enhanced profitability.4. Versatility: The machine accommodates various aluminum profiles, allowing manufacturers to explore new design possibilities. It empowers engineers and designers to create complex and intricate shapes with ease, thus expanding the scope of their creative capabilities.5. Safety and Reliability: With advanced safety features and robust construction, the CNC Aluminum Profile Bending Machine prioritizes operator well-being. Its reliability ensures minimal maintenance requirements, leading to minimal downtime.Company's Commitment to Innovation:In keeping with its commitment to innovation and customer satisfaction, the company responsible for the CNC Aluminum Profile Bending Machine continually invests in research and development. It employs a team of highly skilled engineers and technicians dedicated to enhancing the machine's capabilities and exploring new possibilities for aluminum profile bending.The company possesses a solid track record, having successfully introduced several revolutionary machines to the manufacturing industry. Its relentless pursuit of excellence and customer-centric approach have earned it a reputation as a leading innovator in the field.Conclusion:The introduction of the CNC Aluminum Profile Bending Machine marks a significant technological breakthrough in the manufacturing industry. Its advanced CNC technology, precision engineering, and versatility empower manufacturers to achieve unprecedented precision, efficiency, and design possibilities. With its numerous benefits and the company's commitment to innovation, this machine is set to redefine the aluminum profile bending process and contribute to the advancement of the manufacturing sector as a whole.

High-quality Glazed Tile Roof Panel Roll Former for Color Steel Roofing

Color Steel Glazed Tile Roof Panel Roll Former Revolutionizes Roofing IndustryThe roofing industry has experienced a revolutionary change with the introduction of the Color Steel Glazed Tile Roof Panel Roll Former, a state-of-the-art machine that has quickly gained attention for its advanced technology and innovative approach to roof panel production. This cutting-edge equipment is setting new industry standards and has been well received by clients and professionals in the construction and architectural sectors.The Color Steel Glazed Tile Roof Panel Roll Former is the product of extensive research and development by a leading machinery manufacturer, {company introduction}. With a commitment to excellence and a focus on meeting the evolving needs of the market, {company introduction} has positioned itself as a pioneer in the development of advanced machinery for the construction industry.The Color Steel Glazed Tile Roof Panel Roll Former offers a range of features that set it apart from traditional roof panel roll forming machines. One of the most notable aspects of this equipment is its ability to produce glazed tile roof panels with exceptional precision and efficiency. This is made possible by the machine's advanced technology, which allows for seamless and consistent production of high-quality roof panels.In addition to its superior performance, the Color Steel Glazed Tile Roof Panel Roll Former is also designed with user-friendly features that enhance its practicality and ease of use. The machine is equipped with intuitive controls and a streamlined interface, making it accessible to operators with varying levels of experience. This has been a significant factor in its widespread adoption across different construction and roofing companies.Furthermore, the Color Steel Glazed Tile Roof Panel Roll Former is engineered with a focus on durability and reliability. Its robust construction and high-quality materials ensure that it can withstand the demands of heavy-duty usage, making it a long-term investment for businesses in the construction industry. This has resonated with companies looking for machinery that can deliver consistent performance and minimize downtime.The introduction of the Color Steel Glazed Tile Roof Panel Roll Former has had a profound impact on the roofing industry. Not only has it streamlined the production process for roof panels, but it has also raised the bar for the quality and efficiency of these essential building components. As a result, construction projects can benefit from the enhanced performance and durability of glazed tile roof panels, contributing to the overall integrity of structures.{company introduction} has played a pivotal role in spearheading this transformation in the roofing industry. With a commitment to innovation and a deep understanding of the market, the company has been able to develop machinery that meets the evolving needs of construction and architectural professionals. This dedication to delivering cutting-edge solutions has solidified {company introduction}'s position as a leader in the development of advanced machinery for the construction industry.The reception of the Color Steel Glazed Tile Roof Panel Roll Former has been overwhelmingly positive, with clients and industry professionals praising its performance, reliability, and user-friendly design. As more companies recognize the benefits of this state-of-the-art equipment, its influence on the roofing industry is expected to continue growing, setting new standards for the production of roof panels and contributing to the overall advancement of construction practices.

Discover the Benefits of Standing Seam Metal Roofing for Your Home

Looking for a roofing solution that will stand the test of time and provide exceptional protection against the elements? Look no further than standing seam metal roofing. This type of roofing has gained immense popularity in recent years due to its outstanding performance and long-lasting durability.At our company, we are proud to be one of the leading standing seam metal roof suppliers in the market. Our standing seam metal roofs are made using the finest quality materials and state-of-the-art manufacturing techniques to ensure that they provide the best possible protection for your home.One of the most significant advantages of standing seam metal roofing is its excellent weather-tightness. These roofs have interlocking seams that are raised above the surface of the roof, providing an impenetrable barrier against rain, snow, and wind. This means that you won't have to worry about leaks or water damage, even during the most extreme weather conditions.Another key benefit of standing seam metal roofing is its fire-resistant properties. Metal is one of the most non-combustible roofing materials available, making it an ideal choice for homes located in fire-prone areas. In addition, standing seam metal roofs are typically coated with a protective layer that further enhances their fire-resistant properties.One of the most attractive features of standing seam metal roofing is its stylish design. These roofs are available in a wide range of colors and finishes, allowing you to choose the perfect look to complement your home's architecture and style. Whether you prefer a sleek and modern look or a more traditional appearance, our standing seam metal roof suppliers can help you find the perfect match for your home.To achieve the best results with your standing seam metal roofing, it's essential to choose a reputable supplier who has the expertise and experience to install your roof properly. Our company has been in the business of providing top-quality roofing solutions for many years, and we pride ourselves on our commitment to customer satisfaction.Our standing seam metal roof suppliers are equipped with all the latest tools and equipment to ensure that your roof is installed with precision and care. We work closely with our customers to understand their specific needs and preferences, and we always strive to exceed their expectations.In conclusion, if you are looking for a roofing solution that will provide outstanding protection, durability, and style for your home, standing seam metal roofing is an excellent option. At our company, we are dedicated to providing you with the best possible products and services to ensure that your roof performs exceptionally for many years to come. Contact our standing seam metal roof suppliers today to learn more about our products and services and get started on your next roofing project!

Revolutionary Fully Automatic Color Steel Roll Forming Machine Takes the Industry by Storm

Fully Automatic Roll Forming Machine Revolutionizes Color Steel ProductionIn recent years, the demand for efficient and high-quality steel construction materials has increased significantly with the accelerated pace of urbanization and industrialization. To meet this growing demand, the development of advanced machinery and manufacturing processes has become paramount. Now, a breakthrough in color steel production has been achieved with the introduction of a fully automatic roll forming machine, which promises to revolutionize the industry.Traditionally, the manufacturing of color steel products involved multiple stages, including cutting, bending, and welding. This time-consuming and labor-intensive process often resulted in inconsistent quality and high production costs. However, with the advent of the fully automatic roll forming machine, these issues are being effectively addressed.The fully automatic roll forming machine utilizes a continuous process, where a long strip of color steel is fed into the machine and then transformed into the desired shape through a series of precisely controlled rollers. This innovative technology eliminates the need for manual labor, significantly reducing production time and increasing output.One of the major advantages of this new technology is the exceptional precision it offers. With advanced computer control systems, the machine can accurately adjust the dimensions and angles of the color steel components, resulting in consistently high-quality products. This level of precision ensures that each piece can be seamlessly interconnected during construction, enhancing the durability and structural integrity of the final structures.Furthermore, the fully automatic roll forming machine can handle various types and thicknesses of color steel, allowing manufacturers to produce a wide range of products for different applications. Whether it is roofing sheets, wall panels, or steel framing elements, this machine offers the versatility required to meet diverse customer needs.In addition to its precision and versatility, the fully automatic roll forming machine also boasts impressive productivity. With its high-speed operation, it can produce several meters of color steel products per minute, greatly increasing output compared to traditional manufacturing methods. This increased efficiency translates into cost savings for manufacturers and faster delivery times for customers.The introduction of this advanced technology has not only transformed the color steel production process, but it has also revolutionized the industry as a whole. Manufacturers now have the capability to produce high-quality color steel products at a much faster pace, satisfying the growing demand for construction materials in record time.Furthermore, the fully automatic roll forming machine represents a more environmentally friendly approach to color steel production. By eliminating the need for manual labor and optimizing material usage, it minimizes waste and reduces carbon emissions. This aligns with the global trend towards sustainable manufacturing practices, making it an attractive choice for environmentally conscious companies.As a leading player in the roll forming machine industry, {} has taken the lead in developing and promoting this revolutionary fully automatic roll forming machine. With years of experience and expertise, the company has successfully engineered a state-of-the-art machine that sets new standards for efficiency, precision, and productivity in color steel production.With the adoption of this innovative technology, manufacturers can now streamline their production processes, improve product quality, and ultimately meet the growing demands of an expanding market. In conclusion, the fully automatic roll forming machine marks a significant milestone in color steel production, providing numerous benefits for manufacturers, customers, and the environment.

High-Quality Metal Roof Forming Machine for Sale - Get a Quote Now

Metal Roof Forming Machine IndustryMetal Roof Forming Machine Market is forecast to reach $49.29 million by 2026, after growing at a CAGR of 3.4% during 2021-2026. Metal roof forming machines are used in the construction industry to produce metal roofing materials. These machines are designed to create different types of metal roofing panels, such as standing seam, corrugated, and ribbed panels, with varying widths, lengths, and depths.The growing demand for metal roofing in residential and commercial construction projects is a key factor driving the growth of the metal roof forming machine market. Metal roofs are gaining popularity due to their durability, energy efficiency, and low maintenance requirements. In addition, metal roofing materials are available in a wide range of colors and designs, making them a versatile choice for architectural applications.The construction industry's increasing focus on sustainable building materials is also contributing to the growing adoption of metal roofing. Metal roofs are recyclable and have a longer lifespan compared to traditional asphalt shingles, making them an environmentally friendly choice for building owners. As a result, contractors and builders are investing in metal roof forming machines to meet the demand for high-quality metal roofing materials.The metal roof forming machine market is highly competitive, with several key players competing for market share. These companies are investing in research and development activities to introduce advanced metal roof forming machines that offer enhanced efficiency and productivity. The market is also witnessing a trend toward the integration of automation and digital technologies in metal roof forming machines, enabling manufacturers to optimize production processes and reduce operational costs.One of the leading players in the metal roof forming machine market is {Company Name}. Established in 1998, {Company Name} is a renowned manufacturer of metal forming machinery, specializing in the design and production of advanced metal roof forming machines. The company's product portfolio includes a wide range of metal roof forming machines, such as standing seam roll formers, corrugated panel roll formers, and ribbed panel roll formers, designed to meet the diverse requirements of the construction industry.{Company Name} is known for its commitment to quality and innovation, offering metal roof forming machines that are built to high precision and performance standards. The company's engineering team continuously strives to incorporate the latest technological advancements in its machines, ensuring maximum productivity and reliability for its customers. With a strong focus on customer satisfaction, {Company Name} provides comprehensive after-sales support and technical assistance to help customers optimize the performance of their metal roof forming machines.In addition to its commitment to excellence in product design and manufacturing, {Company Name} is dedicated to sustainability and environmental responsibility. The company's metal roof forming machines are designed to minimize waste and energy consumption, aligning with the industry's emphasis on sustainable construction practices. {Company Name} also emphasizes the importance of safety in its machine designs, implementing robust safety features to protect operators and workers in the production environment.As a market leader in the metal roof forming machine industry, {Company Name} is well-positioned to capitalize on the growing demand for metal roofing materials. The company's focus on continuous innovation and customer-centric approach has enabled it to establish a strong presence in the global market, serving a diverse customer base across various regions. With a proven track record of delivering high-quality and reliable metal roof forming machines, {Company Name} is poised for continued growth and success in the construction industry.In conclusion, the metal roof forming machine market is witnessing steady growth, driven by the increasing demand for metal roofing materials in residential and commercial construction projects. {Company Name} stands out as a leading manufacturer of metal roof forming machines, offering innovative and high-quality solutions to meet the evolving needs of the industry. With a strong commitment to quality, innovation, and sustainability, {Company Name} is well-positioned to maintain its position as a key player in the global metal roof forming machine market.

CZ Interchange Purlin Roll Forming Machine - Quality and Affordable Solution for Steel Processing Equipment

Roll Forming Machine for Deck Floors: Enhancing Efficiency and Precision

[Company Introduction]With a strong reputation for excellence in the manufacturing industry, our company has been a leading provider of innovative machinery and equipment for the construction sector for over two decades. We are dedicated to continuously improving our products and services to meet the ever-evolving needs of our customers. Our commitment to quality and customer satisfaction has propelled us to the forefront of the industry.[News Content]In the realm of construction machinery, one particularly noteworthy addition to our product lineup is the highly efficient Deck Floor Roll Forming Machine. Designed to revolutionize the process of creating durable and reliable deck floors, this advanced equipment offers unprecedented precision and speed.The Deck Floor Roll Forming Machine effectively eliminates the traditional method of manually constructing deck floors, saving both time and labor costs. With its automated capabilities, it can swiftly and accurately produce high-quality deck floors that meet the stringent requirements of modern construction projects. The machine's cutting-edge technology ensures consistency and durability in every finished product.One of the key features of this machine is its versatility. It can produce a wide range of deck floor profiles, catering to the diverse needs of different construction projects. Whether it is a simple residential deck or a complex commercial structure, the machine can adapt to the specific requirements with ease. This flexibility makes it an ideal choice for construction companies of all sizes.Safety is paramount in any construction project, and the Deck Floor Roll Forming Machine prioritizes this aspect as well. The machine is equipped with the latest safety features, including emergency stop buttons, safety guards, and sensors to detect any potential malfunctions. This ensures a secure working environment for operators, minimizing the risk of accidents and injuries.To enhance productivity, the machine has been meticulously designed for ease of operation. Its user-friendly interface allows operators to quickly understand and control the various parameters of the roll forming process. Additionally, the machine's automated functions reduce the need for constant monitoring, allowing operators to focus on other essential aspects of the project.Moreover, the Deck Floor Roll Forming Machine is built to withstand the rigors of continuous operation. Its robust construction and high-grade materials ensure longevity and reliability, reducing downtime and maintenance costs. As a result, construction companies can seamlessly integrate this machine into their workflow, improving overall efficiency and profitability.As sustainability becomes an increasingly important consideration in the construction industry, the Deck Floor Roll Forming Machine aligns with eco-conscious practices. By significantly reducing material waste and minimizing energy consumption, the machine contributes to a more environmentally friendly approach to construction.With our extensive experience in the manufacturing industry, we provide comprehensive support and after-sales services for the Deck Floor Roll Forming Machine. Our team of skilled professionals is always on hand to offer technical assistance, training, and troubleshooting, ensuring that our customers receive uninterrupted productivity and optimum results.In summary, the Deck Floor Roll Forming Machine represents a significant advancement in the construction machinery sector. Its precision, versatility, safety features, ease of operation, and durability make it an invaluable asset for any construction company. Our company remains committed to delivering innovative solutions that meet the evolving needs of the industry, and we are confident that this machine will revolutionize deck floor production processes.

Revolutionary Color Steel Glazed Tile Corrugation Machine Promises Unmatched Performance

[Title]: Innovative Color Steel Glazed Tile Corrugation Machine Revolutionizes Roofing Industry[Subtitle]: {Company Name}'s Cutting-edge Solution Takes Roofing Efficiency to New Heights[Date][City], [State] - {Company Name}, a renowned pioneer in the manufacturing industry, has recently unveiled its revolutionary Color Steel Glazed Tile Corrugation Machine, poised to transform the roofing industry worldwide. This cutting-edge technology promises exceptional efficiency and durability, empowering construction companies and homeowners alike with a game-changing roofing solution.With years of industry experience and a commitment to innovative designs, {Company Name} has overcome previous limitations seen in traditional glazed tile corrugation machines. By leveraging advanced engineering techniques, this new machine raises the bar in terms of speed, precision, and quality of output.The Color Steel Glazed Tile Corrugation Machine boasts an impressive range of features specifically designed to address the demands of modern roofing projects. Equipped with an intelligent control system, it offers heightened automation and precision, ensuring a seamless production process. Operators can effortlessly set parameters such as tile size, thickness, and curvature, thus greatly reducing human errors and increasing overall productivity.One of the key benefits of this state-of-the-art machine is its exceptional speed. With a production capacity of up to [X] tiles per minute, it significantly reduces manufacturing time, leading to shorter project timelines and improved customer satisfaction. This increased efficiency is complemented by the machine's ability to produce tiles of varying shapes and colors, allowing for greater customization to suit clients' specific aesthetic requirements.Moreover, the Color Steel Glazed Tile Corrugation Machine prioritizes durability and longevity. By utilizing high-quality materials such as reinforced steel and wear-resistant components, {Company Name} ensures that the machine can withstand continuous use over extended periods. This durability translates into cost savings for roofing companies, as maintenance costs and the frequency of machine replacement are drastically reduced.{Company Name}, an industry leader known for its commitment to environmental sustainability, has also incorporated eco-friendly elements into the design of their Color Steel Glazed Tile Corrugation Machine. By optimizing energy consumption and reducing waste materials during production, the machine aligns with global efforts to encourage sustainable development practices. This commitment not only benefits the environment but also enhances {Company Name}'s reputation as a socially responsible organization.In addition to its technical superiority, {Company Name} provides exceptional customer support and after-sales service. Their team of qualified technicians is readily available to assist clients with installation, training, and troubleshooting, ensuring a seamless transition to the new technology. Continuous software updates and technological advancements further guarantee that {Company Name} remains at the forefront of the roofing industry, offering the latest innovations to their customers.Looking ahead, {Company Name} is excited about the potential of their Color Steel Glazed Tile Corrugation Machine to disrupt the roofing industry on a global scale. With its streamlined production, exceptional durability, and eco-friendly features, this groundbreaking technology sets a new standard in efficiency, quality, and sustainability. Construction companies and homeowners can now benefit from a roofing solution that combines aesthetics with functionality, providing long-lasting protection for years to come.About {Company Name}:{Company Name} is a leading manufacturer and supplier of industrial machinery, renowned for its commitment to innovation and quality. With a rich history spanning over [X] years, they have earned a stellar reputation for providing cutting-edge solutions that empower businesses across various sectors. Committed to sustainable development, {Company Name} constantly strives to deliver eco-friendly and efficient products that meet the evolving needs of their customers.For more information, please visit: [Website URL]Press Contact:[Contact Name][Title][Company Name][Phone Number][Email Address]

Implementation of Mid-Day Meal Programme in India: A Public-Private Partnership Model

Title: Enhancing the Mid-Day Meal Programme with Akshaya Patra's Steel Patra Making MachineIntroduction:The Mid-Day Meal Programme in India has been a significant initiative implemented by the government to combat hunger and promote education. The Akshaya Patra Foundation, an NGO in India, plays a crucial role as an implementing partner of the Mid-Day Meal Scheme. With steadfast support from various stakeholders, including corporate donors, Akshaya Patra is revolutionizing the meal preparation process through the introduction of cutting-edge technology such as the Steel Patra Making Machine. In this blog post, we will delve into the Akshaya Patra Foundation's journey in implementing the Mid-Day Meal Programme and explore the remarkable impact of the Steel Patra Making Machine.Akshaya Patra's Role in the Mid-Day Meal Programme:The Akshaya Patra Foundation, founded in 2000, operates with a robust public-private partnership (PPP) model. It endeavors to provide wholesome meals to millions of underprivileged children across India, thereby encouraging regular school attendance and enhancing their overall well-being. As an implementing partner of the Mid-Day Meal Scheme, Akshaya Patra plays a critical role in ensuring the successful execution of this ambitious program.Steel Patra Making Machine: Revolutionizing Meal PreparationOne of the key challenges faced by Akshaya Patra during the early stages of the programme was the need for efficient, time-saving, and hygienic meal preparation methods. Traditional cooking methods, involving large vessels and wood-fired stoves, were not conducive to serving nutritious meals to millions of children every day. Recognizing this obstacle, the foundation collaborated with corporate donors to develop the Steel Patra Making Machine.This innovative piece of equipment has significantly transformed the meal preparation process, making it more streamlined and efficient. The machine applies advanced technology to automate the production of stainless steel cooking pots (or Patras) used for cooking the Mid-Day Meals. These standardized Patras ensure consistency in cooking, diminish the risk of contamination, and enhance the overall hygiene quotient of the meals provided.Impressive Features and Benefits of the Steel Patra Making Machine:1. Time-Saving: The automated process of the Steel Patra Making Machine expedites the production of cooking pots. This saves valuable time for the Akshaya Patra team, enabling them to serve meals to more children within the stipulated time.2. Standardization: The machine ensures uniformity in the size and quality of the Patras, eliminating variations in the cooking process. This not only enhances the taste of the meals but also optimizes the resource utilization, resulting in cost efficiency.3. Hygiene and Safety Measures: Stainless steel Patras are not only durable but also offer superior hygiene due to their non-reactive nature. The Steel Patra Making Machine produces stainless steel Patras that are easy to clean and maintain, thereby minimizing the risk of cross-contamination and ensuring safe meals for children.4. Scalability: The machine's capability to produce a large number of standardized Patras enables the Akshaya Patra Foundation to seamlessly expand its operations and reach out to more schools and children. This scalability is crucial for effectively tackling malnutrition and maximizing the impact of the Mid-Day Meal Programme.Conclusion:The Akshaya Patra Foundation's implementation of the Mid-Day Meal Programme has been significantly reinforced by the introduction of the Steel Patra Making Machine. Through this innovative technology, the foundation has overcome numerous logistical challenges and enhanced the overall efficiency, hygiene, and safety of the meal preparation process. As a result, Akshaya Patra continues to make an invaluable contribution to the lives of millions of children in need across India.When organizations and individuals collaborate to develop sustainable solutions, like the Steel Patra Making Machine, we can create a positive ripple effect that benefits society as a whole. Akshaya Patra's journey stands as a testament to the immense potential of public-private partnerships in transforming lives and fostering a better future for generations to come.Keywords: Akshaya Patra Foundation, Mid-Day Meal Programme, public-private partnership, Steel Patra Making Machine, meal preparation, hygiene, automation, efficiency, scalability, nutrition.

6MM Thickness C Purlin Roll Forming Machine for Sigma Shape Steel Purlin - High Quality and Durable

Are you in need of a high-quality C Purlin Roll Forming Machine for Sigma Shape Steel Purlin? Look no further! China has got you covered. With their state-of-the-art manufacturing capabilities, Chinese companies offer top-notch machinery that meets your production needs. This blog post aims to provide you with all the information you need about the Q195 - Q235 6MM Thickness C Purlin Roll Forming Machine.When it comes to roll forming machines, it's crucial to choose a reliable and efficient one that can deliver the desired results. The Q195 - Q235 6MM Thickness C Purlin Roll Forming Machine fits the bill perfectly. This machine is specifically designed to ensure high-quality production of Sigma Shape Steel Purlin.One of the key features of this machine is its capability to handle a thickness range of 6mm. This ensures that the desired C Purlin shape is accurately formed with precision. The machine's precision plays a vital role in achieving consistent and reliable results, allowing for smooth production processes.The Q195 - Q235 6MM Thickness C Purlin Roll Forming Machine is manufactured adhering to the strictest quality standards. Chinese manufacturers are known for their commitment to offering top-quality products, and this machine is no exception. When it comes to C Z Purlin Roll Forming Machines, it's reassuring to know that this particular machine undergoes rigorous quality control measures.By investing in this machine, you can expect high-quality production of Sigma Shape Steel Purlins. The resulting products are guaranteed to meet industry standards and exceed your expectations. Chinese manufacturers take pride in their ability to deliver reliable and durable machinery that stands the test of time.In addition to its exceptional quality, the Q195 - Q235 6MM Thickness C Purlin Roll Forming Machine also offers excellent efficiency. This allows for higher productivity, ultimately resulting in reduced manufacturing costs. With this machine, you can streamline your production processes and meet deadlines without compromising on quality.It's worth mentioning that the Q195 - Q235 6MM Thickness C Purlin Roll Forming Machine is ideal for a wide range of manufacturing applications. Whether you're producing purlins for industrial buildings, residential structures, or any other projects in need of Sigma Shape Steel Purlins, this machine will cater to your needs.When it comes to search engine optimization (SEO), including relevant keywords is crucial. By including terms such as "manual shape C Purlin Roll Forming Machine" in this blog, we can attract the attention of potential customers who are specifically looking for machines that require manual operation. This allows us to provide valuable information to those in the market for such equipment.In conclusion, the Q195 - Q235 6MM Thickness C Purlin Roll Forming Machine is an excellent choice for achieving high-quality Sigma Shape Steel Purlin production. Its exceptional precision, efficiency, and reliability make it a top contender in the market. Chinese manufacturers are renowned for their commitment to quality, and this machine is a prime example of their dedication to delivering superior machinery.If you're in the market for a manual shape C Purlin Roll Forming Machine, look no further. China's top-notch manufacturing capabilities ensure that you will find the perfect machine to meet your needs. Don't compromise on quality - choose the Q195 - Q235 6MM Thickness C Purlin Roll Forming Machine for all your Sigma Shape Steel Purlin production requirements.