High-Quality Corrugated Metal Roof Panel Roll Forming Machine for Sale

By:Admin

A leading manufacturer in the construction machinery industry, has recently launched a new and innovative Corrugated Metal Roof Panel Roll Forming Machine. This machine is set to revolutionize the process of manufacturing corrugated metal roof panels, providing faster production times and higher precision.

The Corrugated Metal Roof Panel Roll Forming Machine is specifically designed to produce high-quality corrugated metal roof panels with efficiency and accuracy. With its advanced technology and state-of-the-art features, it offers a cost-effective solution for companies involved in the production of roofing materials.

The machine is equipped with a range of cutting-edge features, including a high-speed roll forming system, automatic control system, and precision alignment technology. These features enable the machine to produce corrugated metal roof panels with unparalleled accuracy and consistency, ensuring that each panel meets the highest industry standards.

In addition to its cutting-edge technology, the Corrugated Metal Roof Panel Roll Forming Machine also offers a high level of automation, reducing the need for manual labor and increasing overall production efficiency. This automation not only speeds up the production process but also reduces the risk of errors, resulting in a more reliable and consistent output.

Furthermore, the machine's ergonomic design and user-friendly interface make it easy to operate and maintain, ensuring that companies can maximize their productivity without the need for specialized training or expertise.

The launch of the Corrugated Metal Roof Panel Roll Forming Machine reflects the company's commitment to innovation and excellence in the construction machinery industry. With a strong focus on research and development, the company has continuously invested in cutting-edge technology to address the evolving needs of the market and provide solutions that offer significant value to its customers.

The company has also established a robust support system to accompany its products, including comprehensive training programs, technical support, and after-sales service. This ensures that customers can maximize the benefits of the Corrugated Metal Roof Panel Roll Forming Machine and continue to receive the highest level of performance and efficiency throughout its lifespan.

In addition to its commitment to technical excellence, the company also places a strong emphasis on environmental sustainability. The Corrugated Metal Roof Panel Roll Forming Machine is designed to minimize energy consumption and waste, contributing to a greener and more sustainable manufacturing process.

With its advanced technology, high efficiency, and commitment to excellence, the Corrugated Metal Roof Panel Roll Forming Machine is set to become a game-changer in the construction machinery industry. It provides a reliable and cost-effective solution for companies looking to enhance their production capabilities and meet the increasing demand for high-quality corrugated metal roof panels.

The launch of this innovative machine is a testament to the company's dedication to driving progress and innovation in the construction machinery industry. By continuously pushing the boundaries of technology and offering solutions that address the needs of its customers, the company is poised to maintain its position as a leader in the industry and set new standards for quality and performance.

Company News & Blog

Roll Forming Machine for Creating Corrugated Galvanized Steel Roofing

Title: Corrugated Metal Roll Forming Machine: Revolutionizing Modern Roofing SolutionsIntroduction:As the construction industry continues to evolve, it is essential to embrace cutting-edge technologies that enhance efficiency and productivity. One such innovation that has revolutionized the roofing industry is the Corrugated Metal Roll Forming Machine. Specifically designed for producing corrugated galvanized steel, this advanced machine has become indispensable for manufacturers, delivering top-quality metal roofing solutions. In this blog post, we will delve deeper into the benefits and significance of the Corrugated Metal Roll Forming Machine in the modern construction landscape.Exploring the Corrugated Metal Roll Forming Machine:1. Enhanced productivity and efficiency:The Corrugated Metal Roll Forming Machine offers unmatched precision and speed, eliminating wastage and reducing production time. With its automated processes and cutting-edge design, manufacturers can produce more roofing sheets in a shorter span of time, resulting in increased productivity.2. Superior quality products:Equipped with state-of-the-art technology, the Corrugated Metal Roll Forming Machine ensures impeccable finishes and consistent corrugation patterns. This reliability guarantees high-quality roofing solutions that meet and exceed industry standards. The machine's ability to roll galvanized, pre-painted, and galvalume steels into corrugated galvanized steel ensures durability and longevity for the roofs.3. Flexibility in design:Corrugated roofing comes in various shapes, sizes, and profiles. With a versatile Corrugated Metal Roll Forming Machine at their disposal, manufacturers have the freedom to create tailored roofing solutions to cater to diverse customer needs. This adaptability allows for unique designs, providing architects and homeowners with extensive choices for their projects.4. Cost-effective solution:The Corrugated Metal Roll Forming Machine optimizes material usage and minimizes wastage, resulting in cost-effective manufacturing. Its highly efficient processes drastically reduce labor costs and turnaround times, making it an ideal choice for both large-scale production facilities and smaller roofing businesses. The savings accumulated through the use of this machine can be passed on to customers, making metal roofing a more economical option.5. Environmentally friendly:In the era of sustainability, the Corrugated Metal Roll Forming Machine has become a vital player in eco-friendly construction practices. By minimizing the excess material generated during the manufacturing process, this machine contributes to reducing waste and conserving resources. Furthermore, the durability and recyclability of corrugated galvanized steel roofing make it an environmentally conscious choice for builders and homeowners.Keywords and SEO:To maximize the search engine optimization (SEO) of this blog, it is crucial to incorporate relevant keywords ensuring the content aligns with search engine algorithms. By including words such as "corrugated metal roll forming machine," "corrugated metal roofing," "galvanized steel," and "roll forming," we can enhance the visibility of this blog post to the target audience actively searching for information related to metal roofing machinery.Conclusion:The Corrugated Metal Roll Forming Machine has emerged as a game-changer in the roofing industry, providing remarkable benefits such as enhanced productivity, superior quality products, design flexibility, cost-effectiveness, and environmental sustainability. By harnessing the power of this advanced machinery, manufacturers can meet the growing demand for modern, durable, and visually appealing metal roofs. As the construction industry continues to advance, embracing cutting-edge technology like the Corrugated Metal Roll Forming Machine is essential for the success and growth of businesses in the industry.

Roll Forming Machine for Deck Floors: Enhancing Efficiency and Precision

[Company Introduction]With a strong reputation for excellence in the manufacturing industry, our company has been a leading provider of innovative machinery and equipment for the construction sector for over two decades. We are dedicated to continuously improving our products and services to meet the ever-evolving needs of our customers. Our commitment to quality and customer satisfaction has propelled us to the forefront of the industry.[News Content]In the realm of construction machinery, one particularly noteworthy addition to our product lineup is the highly efficient Deck Floor Roll Forming Machine. Designed to revolutionize the process of creating durable and reliable deck floors, this advanced equipment offers unprecedented precision and speed.The Deck Floor Roll Forming Machine effectively eliminates the traditional method of manually constructing deck floors, saving both time and labor costs. With its automated capabilities, it can swiftly and accurately produce high-quality deck floors that meet the stringent requirements of modern construction projects. The machine's cutting-edge technology ensures consistency and durability in every finished product.One of the key features of this machine is its versatility. It can produce a wide range of deck floor profiles, catering to the diverse needs of different construction projects. Whether it is a simple residential deck or a complex commercial structure, the machine can adapt to the specific requirements with ease. This flexibility makes it an ideal choice for construction companies of all sizes.Safety is paramount in any construction project, and the Deck Floor Roll Forming Machine prioritizes this aspect as well. The machine is equipped with the latest safety features, including emergency stop buttons, safety guards, and sensors to detect any potential malfunctions. This ensures a secure working environment for operators, minimizing the risk of accidents and injuries.To enhance productivity, the machine has been meticulously designed for ease of operation. Its user-friendly interface allows operators to quickly understand and control the various parameters of the roll forming process. Additionally, the machine's automated functions reduce the need for constant monitoring, allowing operators to focus on other essential aspects of the project.Moreover, the Deck Floor Roll Forming Machine is built to withstand the rigors of continuous operation. Its robust construction and high-grade materials ensure longevity and reliability, reducing downtime and maintenance costs. As a result, construction companies can seamlessly integrate this machine into their workflow, improving overall efficiency and profitability.As sustainability becomes an increasingly important consideration in the construction industry, the Deck Floor Roll Forming Machine aligns with eco-conscious practices. By significantly reducing material waste and minimizing energy consumption, the machine contributes to a more environmentally friendly approach to construction.With our extensive experience in the manufacturing industry, we provide comprehensive support and after-sales services for the Deck Floor Roll Forming Machine. Our team of skilled professionals is always on hand to offer technical assistance, training, and troubleshooting, ensuring that our customers receive uninterrupted productivity and optimum results.In summary, the Deck Floor Roll Forming Machine represents a significant advancement in the construction machinery sector. Its precision, versatility, safety features, ease of operation, and durability make it an invaluable asset for any construction company. Our company remains committed to delivering innovative solutions that meet the evolving needs of the industry, and we are confident that this machine will revolutionize deck floor production processes.

Purline Machine for C and C Z Purline: A Guide to Stacker Functions

[Company Introduction]With years of experience and a strong reputation in the industry, {Company} has become a leading manufacturer in the field of steel structure machinery. The company specializes in the production of high-quality machines for the manufacturing of steel purline, including the C purline machine and C Z purline machine. Their dedication to innovative technology and superior quality has earned them the trust of customers worldwide.[News Content]As the demand for steel structures continues to rise, {Company} has remained at the forefront of the industry by continuously improving and expanding its product line. One of their latest innovations is the Stacker for the C Purline Machine and C Z Purline Machine. This new addition to their machinery lineup is set to revolutionize the steel purline manufacturing process with its advanced features and capabilities.The Stacker is designed to efficiently and accurately stack the finished purline products, providing a seamless and automated solution for production line efficiency. This innovative system eliminates the need for manual handling, reducing the risk of product damage and increasing overall productivity. With its adjustable stacking parameters, the Stacker can accommodate a variety of purline dimensions, making it a versatile and adaptable addition to any steel manufacturing operation.{Company} has always been committed to delivering cutting-edge technology and reliable machinery to their customers, and the Stacker is no exception. With its precision engineering and high-performance capabilities, this new addition to their product line is a testament to the company's dedication to meeting the evolving needs of the steel structure industry.In addition to the Stacker, {Company} continues to offer a comprehensive range of machinery for steel purline manufacturing, including roll forming machines, punching machines, and cutting machines. Their commitment to providing end-to-end solutions for steel structure production makes them a preferred partner for manufacturers around the world.The quality and reliability of {Company}'s machines are further exemplified by their strict adherence to international manufacturing standards and certifications. This ensures that their products meet the highest levels of safety, efficiency, and overall quality, giving customers peace of mind in their investment.In line with their customer-centric approach, {Company} also provides comprehensive after-sales support and service, ensuring that their clients can maximize the performance and longevity of their machinery. Their team of experienced technicians and engineers are readily available to provide assistance and maintenance services, further solidifying their reputation as a trusted partner in the industry.In conclusion, {Company}'s introduction of the Stacker for the C Purline Machine and C Z Purline Machine is a testament to their ongoing commitment to innovation and excellence in the steel structure machinery industry. With their dedication to quality, reliability, and customer satisfaction, they continue to set the standard for advanced and efficient manufacturing solutions. As the demand for steel structures continues to grow, {Company} stands ready to meet the evolving needs of their customers with their state-of-the-art machinery and unwavering dedication to excellence.

Highway Guardrail Forming Machine: Streamline Production for Guardrail Manufacturing

Highway Guardrail Forming Machine: Revolutionizing Road SafetyIn an age where road safety is of crucial importance, the demand for efficient and effective highway guardrail forming machines has never been greater. With the goal of revolutionizing road safety, the innovative team at [Company Name] has developed a cutting-edge highway guardrail forming machine that is set to redefine the construction and maintenance of highway guardrails. This state-of-the-art machine is designed to provide high-quality and precision-engineered guardrails, ensuring the utmost safety for all road users.The [Company Name] highway guardrail forming machine is the result of years of research and development, coupled with a deep understanding of the unique challenges and requirements of the road construction industry. Incorporating the latest technological advancements, this machine is capable of producing guardrails of various specifications and sizes, catering to the diverse needs of different road projects. Whether it is for a busy urban highway or a remote rural road, the versatility of this machine makes it a valuable asset for road construction companies and government authorities alike.One of the key features of the [Company Name] highway guardrail forming machine is its ability to produce guardrails with exceptional precision and accuracy. This is achieved through advanced automated systems that ensure consistent quality and uniformity in every guardrail produced. As a result, road safety is greatly enhanced, as drivers can have full confidence in the reliability and durability of the guardrails protecting them on the road.Furthermore, the efficiency of the [Company Name] highway guardrail forming machine is unmatched, thanks to its high production capacity and rapid output. This not only saves time and labor costs for road construction companies but also allows for the timely completion of road projects, minimizing disruptions and inconveniences for the public. In addition, the machine is designed for easy setup and operation, ensuring that even novice users can quickly master its functions and produce high-quality guardrails with minimal training.In line with [Company Name]'s commitment to sustainability and environmental responsibility, the highway guardrail forming machine is designed to minimize material wastage and energy consumption. This is accomplished through optimized production processes and efficient use of resources, making it a cost-effective and eco-friendly solution for road construction projects. By reducing the environmental impact of guardrail production, [Company Name] is contributing to the global effort to create greener and more sustainable infrastructure.The [Company Name] highway guardrail forming machine is also built to withstand the rigors of the road construction industry, with durable construction and reliable performance. This ensures a long and trouble-free service life, allowing road construction companies to maximize their investment and minimize downtime. Additionally, the machine is backed by [Company Name]'s comprehensive aftersales support and maintenance services, providing customers with peace of mind and assurance of continued operational excellence.With its groundbreaking capabilities and practical benefits, the [Company Name] highway guardrail forming machine is set to become an indispensable tool for the road construction industry. By streamlining the production of high-quality guardrails and improving road safety standards, this machine is driving positive change and making a lasting impact on infrastructure development. As road networks continue to expand and evolve, the [Company Name] highway guardrail forming machine will play a crucial role in shaping the future of road safety and ensuring safe and reliable journeys for all.

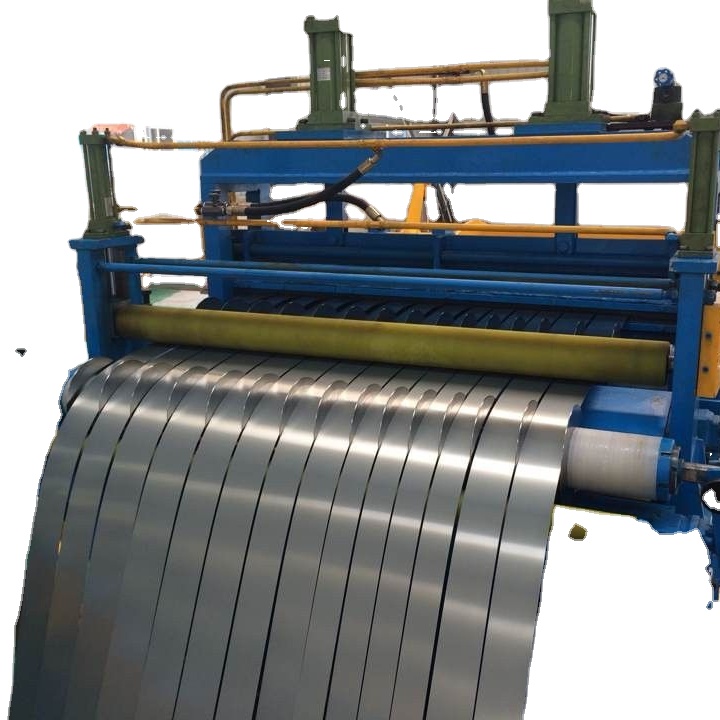

High-Quality Heavy Gauge Slitting Line for Efficient Production

Heavy Gauge Slitting Line plays a crucial role in the metal processing industry. It is a highly efficient and versatile machine that is used to cut large coils of metal into narrower strips, which are then used for various purposes in different industries. With its high precision and speed, Heavy Gauge Slitting Line has become an essential tool for metal processing companies around the world.One of the leading manufacturers of Heavy Gauge Slitting Line, is known for producing high-quality and reliable machines that meet the needs of its customers. The company has a strong commitment to research and development, and it continuously strives to improve its products and services to meet the evolving needs of the market. With a focus on innovation and technology, the company has established itself as a trusted name in the metal processing industry.The Heavy Gauge Slitting Line produced by the company is designed to meet the demands of heavy-duty metal processing. It is capable of handling large coils of metal with precision and efficiency, making it an ideal choice for companies that require high-volume production. The machine is equipped with advanced control systems and cutting-edge technology to ensure consistent and accurate slitting of metal coils, resulting in high-quality strips that meet the industry standards.The Heavy Gauge Slitting Line is also known for its versatility and flexibility. It can be customized to meet the specific requirements of different types of metal and can handle a wide range of thickness and width, making it suitable for various applications in the metal processing industry. Whether it is stainless steel, aluminum, or other metals, the Heavy Gauge Slitting Line can deliver superior performance and precision cutting, making it a valuable asset for companies across different sectors.In addition to its technical capabilities, the company also provides excellent after-sales support and services to ensure the smooth operation of its Heavy Gauge Slitting Line. Its team of skilled engineers and technicians are committed to providing prompt and efficient assistance to its customers, offering training, maintenance, and troubleshooting services to maximize the performance and lifespan of the machine.The company’s commitment to quality, innovation, and customer satisfaction has earned it a strong reputation in the metal processing industry. Its Heavy Gauge Slitting Line is trusted by companies around the world for its reliability, efficiency, and precision, making it a preferred choice for businesses looking to enhance their metal processing capabilities.With its dedication to excellence and a strong track record in delivering high-quality machines, the company continues to be a leading player in the metal processing industry. As it continues to innovate and evolve, it remains committed to providing the best solutions for its customers and driving the industry forward with its cutting-edge Heavy Gauge Slitting Line.

Discover the Innovation of Colored Metal Trapezoidal Sheet Roll Forming Machine

Colored Metal Trapezoidal Sheet Roll Forming Machine Brings Efficiency and Quality to Roofing IndustryThe roofing industry is set to witness a significant boost in efficiency and quality with the introduction of the advanced Colored Metal Trapezoidal Sheet Roll Forming Machine. This innovative machinery, manufactured by a leading company in the industry, aims to revolutionize the way metal roofing sheets are produced.Metal roofing has gained popularity in recent years due to its durability, energy efficiency, and aesthetic appeal. However, the process of manufacturing metal roofing sheets has often been time-consuming, labor-intensive, and prone to errors. The introduction of the Colored Metal Trapezoidal Sheet Roll Forming Machine seeks to address these challenges, ultimately leading to improved productivity and customer satisfaction.The key feature of this roll forming machine is its ability to efficiently produce trapezoidal-shaped metal sheets. This shape is commonly used in roofing applications due to its excellent water drainage capabilities, structural strength, and ease of installation. The machine's precision engineering ensures accurate dimensions, uniformity, and high-quality finishes, meeting the stringent requirements of the roofing industry.Furthermore, the Colored Metal Trapezoidal Sheet Roll Forming Machine can process various types of colored metal sheets, catering to the diverse needs and preferences of customers. It allows for the production of a wide range of colors and coatings, including but not limited to, galvanized steel, galvalume steel, and pre-painted steel sheets. This versatility empowers roofing contractors and manufacturers to meet the specific demands of different projects, further enhancing their competitiveness in the market.The use of this advanced machinery also significantly reduces manual labor and associated costs. The integration of automated procedures and computerized controls ensures precise and consistent results, eliminating the likelihood of human errors. Moreover, the machine's speed and efficiency enable manufacturers to meet tight project deadlines and handle large-scale orders efficiently.The company behind the Colored Metal Trapezoidal Sheet Roll Forming Machine has established itself as a leader in the metal processing industry. With a strong commitment to research and development, their team of experts continually innovate to provide cutting-edge solutions that deliver superior performance and durability. By collaborating with roofing industry professionals, they ensure that their machines meet the specific requirements of the market, ultimately driving the growth and progress of the entire sector.In addition to manufacturing state-of-the-art machinery, the company also offers comprehensive training programs and technical support to its customers. Recognizing the importance of knowledge transfer and skill development, they equip their clients with the necessary expertise to operate the Colored Metal Trapezoidal Sheet Roll Forming Machine optimally. This commitment to customer service further solidifies the company's reputation as a reliable and trusted provider in the industry.The introduction of the Colored Metal Trapezoidal Sheet Roll Forming Machine marks a significant milestone in the roofing industry. By leveraging the capabilities of this efficient and versatile machinery, contractors and manufacturers can enhance productivity, improve product quality, and boost customer satisfaction. This innovative solution showcases the company's dedication to driving progress and innovation in the metal roofing sector, solidifying their position as a leader in the market.

Ultimate Guide to C Purlin Forming Machine: Types, Uses, and Benefits

C Purlin Forming Machine revolutionizes the steel industry with its remarkable efficiency and precision. This cutting-edge technology is designed and manufactured by a leading machinery company, specializing in metal forming and fabrication equipment.The C Purlin Forming Machine is equipped with state-of-the-art features, making it an essential tool for constructing high-quality steel structures. The machine is designed to produce C-shaped steel purlins with exceptional accuracy and speed, meeting the demands of modern construction projects.One of the key highlights of this advanced machine is its ability to produce a wide range of C purlin sizes, catering to various construction needs. This flexibility is achieved through its adjustable rollers and automated control system, allowing for seamless customization and production.In addition to its versatility, the C Purlin Forming Machine is lauded for its efficiency and reliability. Its robust construction and precision engineering ensure consistent and high-quality output, reducing material wastage and increasing productivity.Furthermore, the machine's user-friendly interface and intuitive controls make operation easy and convenient. Its automated functions streamline the production process, minimizing human error and optimizing workflow.The company behind this groundbreaking technology is renowned for its dedication to innovation and excellence in the metal forming industry. With a strong focus on research and development, they have consistently introduced cutting-edge solutions that meet and exceed the evolving needs of the market.In addition to the C Purlin Forming Machine, the company offers a wide range of metal forming equipment, including roll forming machines, slitting lines, and cut-to-length lines. Their comprehensive product line is backed by a team of skilled engineers and technicians, delivering exceptional customer service and technical support.With a commitment to quality and customer satisfaction, the company has built a strong reputation in the industry, earning the trust of clients worldwide. Their products are widely used in various sectors, including construction, automotive, and industrial manufacturing.As the demand for steel structures continues to grow, the C Purlin Forming Machine is poised to play a pivotal role in meeting this demand. Its advanced capabilities and cutting-edge technology make it an indispensable asset for construction companies and manufacturers, enabling them to achieve superior results with ease and efficiency.In conclusion, the C Purlin Forming Machine represents a significant advancement in the metal forming industry. Its innovative design, precision engineering, and exceptional performance set a new standard for C purlin production, making it a key player in the construction and manufacturing sectors. With the backing of a reputable and forward-thinking company, this technology is poised to make a lasting impact on the steel industry, shaping the future of metal fabrication.

Top-rated Roof Panel Machine: A Game-Changer in Construction Industry

Roof Panel Machine Revolutionizes the Manufacturing IndustryThe manufacturing industry has seen a significant breakthrough with the introduction of the state-of-the-art Roof Panel Machine by a leading company. This innovative machine has redefined the process of manufacturing roof panels, making it faster, more efficient, and cost-effective.The Roof Panel Machine is designed to streamline the production of roof panels, providing manufacturers with a high-quality and reliable solution for their production needs. With advanced technology and precision engineering, this machine has the capability to produce a wide range of roof panels with varying thickness, length, and design specifications. This level of flexibility allows manufacturers to meet the diverse needs of their customers, while maintaining a high standard of quality and consistency.One of the key features of the Roof Panel Machine is its automated operation, which minimizes the need for manual labor and reduces the risk of errors in the production process. This automated system is equipped with intelligent controls and sensors that ensure the accurate and precise fabrication of roof panels, resulting in a higher level of efficiency and productivity. As a result, manufacturers can increase their output and meet tight production deadlines without compromising on the quality of their products.In addition, the Roof Panel Machine is designed for ease of use, with a user-friendly interface and intuitive controls that make it accessible to operators of varying skill levels. This allows manufacturers to train their staff quickly and efficiently, reducing the time and resources required for onboarding new employees. The simplified operation of the machine also minimizes the risk of human error, resulting in a more consistent and reliable production process.Furthermore, the Roof Panel Machine is engineered for durability and longevity, ensuring a reliable and long-lasting solution for manufacturers. With robust construction and high-quality components, this machine is designed to withstand the rigors of continuous use in a manufacturing environment, providing a dependable and low-maintenance option for production facilities.The introduction of the Roof Panel Machine has significantly impacted the manufacturing industry, offering a transformative solution for the production of roof panels. With its advanced technology, automated operation, ease of use, and durability, this machine has redefined the standards of manufacturing, setting new benchmarks for efficiency, productivity, and quality.Company Introduction:The company behind the Roof Panel Machine is a leading innovator in the field of manufacturing technology. With a strong focus on research and development, this company has consistently introduced cutting-edge solutions that address the evolving needs of the industry. The Roof Panel Machine is the latest addition to their portfolio of advanced machinery, and it reflects their commitment to driving innovation and excellence in manufacturing.In addition to their dedication to technological advancement, the company is also known for their comprehensive support and service network. They offer a range of services, including installation, training, maintenance, and technical support, to ensure that their customers can fully maximize the benefits of their machinery. This level of support reinforces the company's dedication to customer satisfaction and their commitment to delivering value beyond the sale of their products.With a strong track record of success and a reputation for delivering superior technology, the company is poised to continue leading the way in the manufacturing industry. The Roof Panel Machine is just one example of their innovative solutions, and it serves as a testament to their vision of shaping the future of manufacturing with cutting-edge technology and unmatched expertise.In conclusion, the Roof Panel Machine has ushered in a new era of manufacturing, offering a game-changing solution for the production of roof panels. With its advanced technology, automated operation, ease of use, and durability, this machine has set a new standard for efficiency, productivity, and quality in the industry. As a testament to the company's commitment to innovation and excellence, the Roof Panel Machine stands as a pioneering achievement that is revolutionizing the manufacturing landscape.

High-quality Glazed Tile Roof Panel Roll Former for Color Steel Roofing

Color Steel Glazed Tile Roof Panel Roll Former Revolutionizes Roofing IndustryThe roofing industry has experienced a revolutionary change with the introduction of the Color Steel Glazed Tile Roof Panel Roll Former, a state-of-the-art machine that has quickly gained attention for its advanced technology and innovative approach to roof panel production. This cutting-edge equipment is setting new industry standards and has been well received by clients and professionals in the construction and architectural sectors.The Color Steel Glazed Tile Roof Panel Roll Former is the product of extensive research and development by a leading machinery manufacturer, {company introduction}. With a commitment to excellence and a focus on meeting the evolving needs of the market, {company introduction} has positioned itself as a pioneer in the development of advanced machinery for the construction industry.The Color Steel Glazed Tile Roof Panel Roll Former offers a range of features that set it apart from traditional roof panel roll forming machines. One of the most notable aspects of this equipment is its ability to produce glazed tile roof panels with exceptional precision and efficiency. This is made possible by the machine's advanced technology, which allows for seamless and consistent production of high-quality roof panels.In addition to its superior performance, the Color Steel Glazed Tile Roof Panel Roll Former is also designed with user-friendly features that enhance its practicality and ease of use. The machine is equipped with intuitive controls and a streamlined interface, making it accessible to operators with varying levels of experience. This has been a significant factor in its widespread adoption across different construction and roofing companies.Furthermore, the Color Steel Glazed Tile Roof Panel Roll Former is engineered with a focus on durability and reliability. Its robust construction and high-quality materials ensure that it can withstand the demands of heavy-duty usage, making it a long-term investment for businesses in the construction industry. This has resonated with companies looking for machinery that can deliver consistent performance and minimize downtime.The introduction of the Color Steel Glazed Tile Roof Panel Roll Former has had a profound impact on the roofing industry. Not only has it streamlined the production process for roof panels, but it has also raised the bar for the quality and efficiency of these essential building components. As a result, construction projects can benefit from the enhanced performance and durability of glazed tile roof panels, contributing to the overall integrity of structures.{company introduction} has played a pivotal role in spearheading this transformation in the roofing industry. With a commitment to innovation and a deep understanding of the market, the company has been able to develop machinery that meets the evolving needs of construction and architectural professionals. This dedication to delivering cutting-edge solutions has solidified {company introduction}'s position as a leader in the development of advanced machinery for the construction industry.The reception of the Color Steel Glazed Tile Roof Panel Roll Former has been overwhelmingly positive, with clients and industry professionals praising its performance, reliability, and user-friendly design. As more companies recognize the benefits of this state-of-the-art equipment, its influence on the roofing industry is expected to continue growing, setting new standards for the production of roof panels and contributing to the overall advancement of construction practices.

Reliable Sheet Metal Fabrication Services: Stainless Steel, Aluminum & Custom Metal

Title: Streamlining Your Business with Steel Sheet Making Machines: Unleashing the Power of Custom Metal FabricationIntroduction:In today's competitive market, businesses across various industries are increasingly turning to custom metal fabrication services to meet their unique manufacturing requirements. Among the many processes involved in metal fabrication, Steel Sheet Making Machines play a critical role in ensuring high-quality stainless steel and aluminum sheet production. This article aims to explore the significance of Steel Sheet Making Machines in the realm of custom metal fabrication and how they contribute to the manufacturing success of businesses across the globe.1. The Essence of Steel Sheet Making Machines:Steel Sheet Making Machines are advanced manufacturing tools designed to accurately shape and cut steel sheets into desired forms. These machines incorporate various components and mechanisms, including hydraulic systems, feeders, rollers, shears, and cutting devices. By utilizing cutting-edge technologies, these machines streamline the metal fabrication process, enhancing efficiency, precision, and overall productivity.2. Precision and Consistency:One significant advantage of Steel Sheet Making Machines is their ability to consistently produce high-quality steel sheets with utmost precision. The intricate mechanisms and cutting-edge technologies integrated into these machines ensure consistent sheet thickness, tight tolerances, smooth edges, and well-defined shapes. Custom metal fabrication companies can deliver products that meet or even exceed the expectations of their clients, reinforcing their reputation in the market.3. Increased Efficiency and Productivity:Steel Sheet Making Machines revolutionize the manufacturing process, significantly reducing production time and increasing efficiency. These machines can perform multiple operations, such as cutting, bending, and shaping, in a single run, eliminating the need for separate machinery or manual labor. The automated processes of these machines enable businesses to produce larger volumes of steel sheets with minimal human intervention, thereby increasing productivity and reducing labor costs.4. Versatility and Customization:Custom metal fabricators often deal with diverse client requirements, necessitating the ability to produce steel sheets in various shapes, sizes, and thicknesses. Steel Sheet Making Machines offer extensive flexibility and adaptability, allowing businesses to cater to these diverse demands. With adjustable settings and versatile tooling options, these machines can fabricate customized steel sheets to match unique specifications, enabling businesses to deliver tailored solutions to their customers.5. Cost and Resource Optimization:By investing in Steel Sheet Making Machines, businesses can optimize their use of resources and reduce costs in the long run. These machines minimize material wastage through precise cutting and shaping capabilities, ensuring minimal scrap and maximizing yield. Additionally, the automated nature of these machines reduces the reliance on manual labor, saving on labor expenses.Conclusion:In conclusion, Steel Sheet Making Machines have emerged as indispensable tools in the realm of custom metal fabrication. Their ability to deliver precision, consistency, efficiency, and customization has revolutionized the manufacturing industry. By investing in these advanced machines, businesses can streamline their metal fabrication processes, cater to diverse client requirements, minimize costs, and stay ahead in the competitive market. Whether it is stainless steel sheet metal fabrication, aluminum sheet metal fabrication, or any other custom metal fabrication needs, the utilization of Steel Sheet Making Machines ensures successful outcomes and drives the growth of businesses across the globe.Keywords: Steel Sheet Making Machine, custom metal fabrication, stainless steel sheet metal fabrication, aluminum sheet metal fabrication, metal fabrication services, precision manufacturing, increased productivity, cost optimization, versatile tooling options.