High-Quality Corrugated Roofing Sheet Making Machine for Sale

By:Admin

In today's fast-paced world, the demand for high-quality and innovative building materials is on the rise. As the construction industry continues to grow, there is an increasing need for durable, cost-effective, and environmentally friendly materials. This is where the Corrugated Roofing Sheet Making Machine from [Company Name] comes in.

The Corrugated Roofing Sheet Making Machine is a state-of-the-art piece of equipment that is revolutionizing the way roofing materials are manufactured. This machine is capable of producing high-quality, corrugated roofing sheets that are not only aesthetically pleasing but also incredibly durable and long-lasting. With its innovative design and advanced technology, this machine has quickly become a must-have for any roofing materials manufacturer.

One of the key features of the Corrugated Roofing Sheet Making Machine is its ability to produce a wide range of roofing sheet designs and sizes. Whether it's for a residential, commercial, or industrial project, this machine can effectively meet the diverse needs of the market. This level of flexibility and versatility is a game-changer for the industry, as it allows manufacturers to cater to a wide range of customer demands.

Furthermore, the machine is designed with efficiency and productivity in mind. Its automated processes and high-speed production capabilities allow for increased output, significantly reducing production time and labor costs. This not only benefits manufacturers in terms of cost savings but also ensures timely delivery of materials to customers.

The Corrugated Roofing Sheet Making Machine from [Company Name] also prioritizes sustainability and eco-friendliness. It is equipped with advanced technology that optimizes the use of raw materials, minimizing waste and promoting a more sustainable manufacturing process. In a world where environmental consciousness is becoming increasingly important, this approach sets the machine apart as a leader in the industry.

In addition to its impressive technical capabilities, the machine is also backed by the expertise and support of [Company Name]. With a strong reputation for producing high-quality machinery for the construction industry, the company has a wealth of experience and knowledge in the field. This means that customers can trust in the reliability and performance of their Corrugated Roofing Sheet Making Machine.

The Corrugated Roofing Sheet Making Machine is a reflection of [Company Name]'s commitment to innovation and excellence. With a focus on continuous improvement and staying ahead of market trends, the company has set a new standard for roofing sheet manufacturing. By investing in this machine, manufacturers can not only enhance their production capabilities but also gain a competitive edge in the market.

In conclusion, the Corrugated Roofing Sheet Making Machine from [Company Name] is not just a piece of equipment; it's a game-changer for the roofing materials industry. With its advanced technology, efficiency, versatility, and sustainability, this machine is setting a new benchmark for manufacturing processes. As the construction industry continues to evolve, this machine is poised to play a pivotal role in shaping the future of roofing materials production.

Company News & Blog

Discover the Art of Aluminium Profile Bending for Enhanced Applications

Aluminium Profile Bending Brings a New Era of ManufacturingThe recent years have seen a drastic rise in the popularity and use of aluminium profiles. They are being extensively used in a diverse range of industries such as automobile, construction, and aerospace. The reason behind the emergence of this trend is the unparalleled advantages that come with using these profiles. They offer high strength, lightness, and durability. They are also easy to manufacture and mould. However, the real challenge arises when it comes to moulding these profiles into the desired shapes and sizes. This is where Aluminium Profile Bending has brought about a revolution in the manufacturing industry.Aluminium Profile Bending (APB), a technique that has been developed by a leading company in the manufacturing industry, has revolutionized the way aluminium profiles are moulded. With the introduction of this technique, manufacturers can now bend the profiles into any desired shape and size. The shapes can vary from simple curves to complex designs. This technique is particularly useful for manufacturing aluminum profiles for the construction industry that require intricate shapes, making it impossible to produce using conventional techniques.Advanced technology and expertise are required to carry out the bending of aluminum profiles, which is where the company that developed APB excels. They have a team of immensely skilled technicians who use cutting-edge equipment to ensure precision in the bending of the profiles. Using this technique, the team can accurately bend even the most intricate shapes.The advantages of APB are numerous. Firstly, it offers a high level of precision which allows for the creation of complex and intricate designs. Secondly, the technique is much more cost-effective, as it reduces the waste material that is produced during the conventional manufacturing process. APB also eliminates the need for additional manufacturing processes that might be required to achieve the desired shape, which again translates to cost savings. Additionally, it provides excellent finish quality and surface appearance, making it ideal for high-quality products such as those required in the automotive and aerospace industries.The use of APB is not limited to aluminum profiles only. The technique can also be used with other metals, including copper, brass, and stainless steel. This versatility means that manufacturers now have even more options when it comes to the manufacturing of complex shapes and designs.The development of APB has had a significant impact on the manufacturing industry. It has not only reduced production costs but has also opened up new possibilities for manufacturers. With this technique, they can now produce complex and intricate designs that were previously not possible.With the increasing demand for aluminium profiles, it is evident that the manufacturing industry needs to embrace new technologies and techniques to stay ahead of the competition. The introduction of Aluminium Profile Bending has provided manufacturers with a game-changing solution to their manufacturing problems. As new and better technologies continue to emerge, it is essential that manufacturers keep an eye out for innovations that could improve their manufacturing processes.In conclusion, Aluminium Profile Bending has revolutionized the way aluminium profiles are moulded, giving manufacturers the ability to produce complex and intricate designs accurately. The technique offers a high level of precision, reduces production costs, and eliminates the need for additional manufacturing processes, making it ideal for a diverse range of industries. As manufacturing technologies continue to evolve, it is essential for manufacturers to stay up-to-date with the latest innovations and techniques to remain competitive in the industry.

How to Choose a Standing Seam Roof Panel Machine for Your Business

Title: Advanced Standing Seam Roof Panel Machine Revolutionizing Roofing IndustryIntroduction:With the constant need for efficient and innovative solutions in the roofing industry, the introduction of an advanced Standing Seam Roof Panel Machine (name omitted) is set to revolutionize the way roofs are manufactured and installed. Developed by a reputable company known for their dedication to quality and precision engineering, this state-of-the-art machine promises to streamline the roofing process while offering enhanced durability and sustainability. Let's delve into the features and benefits of this cutting-edge technology.1. Efficiency and Precision:The Standing Seam Roof Panel Machine combines years of experience with advanced engineering to deliver a machine that is highly efficient and accurate in its operations. The machine is equipped with an automated control system, allowing for precise and consistent panel measurements, ensuring a perfect fit with minimal waste. With the ability to produce up to 60 feet of roof panel per minute, this innovative technology significantly reduces production time, increasing overall efficiency and productivity.2. Durability and Sustainability:In line with the company's commitment to environmentally friendly practices, the Standing Seam Roof Panel Machine employs sustainable materials and construction methods to produce highly durable roofing panels. The machine's design incorporates high-strength steel and state-of-the-art coatings to ensure resistance against harsh weather conditions, corrosion, and UV radiation. These panels offer exceptional longevity, reducing the need for frequent repairs or replacements, ultimately resulting in cost savings for both homeowners and commercial builders.3. Versatility and Customization:One of the standout features of the Standing Seam Roof Panel Machine is its ability to produce a wide range of panel profiles, allowing for extensive customization options. Clients can choose from a variety of panel widths, seam heights, and surface finishes, catering to their specific architectural requirements and aesthetic preferences. This versatility enables architects and designers to create unique roofing designs that harmonize with the overall style of the structure. Additionally, the machine's versatility ensures compatibility with various installation methods, making it suitable for both residential and commercial applications.4. Safety and Ease of Use:The Standing Seam Roof Panel Machine prioritizes operator safety and ease of use. The machine is equipped with advanced safety features, including emergency stop buttons, safety light curtains, and interlocking systems, ensuring a high level of protection during operation. Additionally, it boasts a user-friendly interface, allowing operators to navigate through different settings and controls with ease. The machine's ergonomic design and intuitive controls enable seamless operation, reducing the risk of errors and accidents.5. Training and Technical Support:Recognizing the importance of proper training and continuous technical support, the company offers comprehensive training programs to ensure operators have the necessary skills to operate the Standing Seam Roof Panel Machine effectively. The training covers machine operation, maintenance, troubleshooting, and safety protocols. Additionally, the company provides ongoing technical support to address any queries or concerns raised by customers, further enhancing the overall user experience.Conclusion:The introduction of the Standing Seam Roof Panel Machine marks a significant leap forward in the roofing industry, revolutionizing the way roofs are manufactured and installed. Its exceptional efficiency, precision, versatility, and sustainability make it a game-changer for architects, builders, and homeowners alike. With an unwavering commitment to quality and customer satisfaction, the company behind this advanced technology continues to innovate, ensuring the continuous improvement and development of the roofing industry.

Revolutionizing the Steel Industry: Light Gauge Steel Making Machine Expands Possibilities

Title: Revolutionary Light Gauge Steel Making Machine Revolutionizes Construction IndustryIntroduction: In recent years, the global construction industry has witnessed a surge in the demand for sustainable, cost-effective, and high-quality building materials. In response to this growing need, the innovative (company name), a leader in construction machinery, has unveiled its latest groundbreaking creation - the state-of-the-art Light Gauge Steel Making Machine. This cutting-edge technology promises to revolutionize the construction industry by providing an efficient and environmentally friendly solution for steel structure production.Paragraph 1: The Light Gauge Steel Making Machine developed by (company name) has garnered significant attention within the construction sector due to its remarkable advancements and unprecedented features. This machine adopts an automated production line, combining computer-aided design (CAD) capabilities with high-precision manufacturing processes. The fusion of automation and precision in this advanced machinery ensures that each steel gauge is formed accurately with minimal material wastage.Paragraph 2: One of the key features of (company name)'s Light Gauge Steel Making Machine is its versatility. With customization options available, it effortlessly adapts to diverse building design requirements, enabling the manufacture of varying shapes, lengths, and thicknesses of steel framing elements. This flexibility allows construction companies to optimize their processes and enhance the efficiency of their projects.Paragraph 3: By utilizing this cutting-edge machinery, construction firms can significantly reduce project timelines and labor costs. The Light Gauge Steel Making Machine incorporates an automated production process that streamlines the steel fabrication process. This automation eliminates the need for manual labor, reducing the risk of errors and improving overall productivity. These time and cost-saving advantages provide construction companies a competitive edge in the market.Paragraph 4: Moreover, the Light Gauge Steel Making Machine ensures unparalleled quality and durability in the produced steel structures. Each gauge manufactured by this ingenious machine undergoes strict quality control measures to guarantee compliance with international standards. The precision of the manufacturing process ensures consistent product quality, reinforcing the reliability of steel structures in various construction projects, such as residential buildings, commercial complexes, and industrial facilities.Paragraph 5: In addition to its exceptional technical capabilities, (company name)'s Light Gauge Steel Making Machine is environmentally friendly, contributing to sustainable construction practices. The machine significantly reduces the carbon footprint associated with steel production by minimizing energy consumption and waste generation. By choosing this state-of-the-art technology, construction firms can actively contribute to a greener future.Paragraph 6:Furthermore, by integrating digital systems and data management tools, this innovative machine provides real-time production monitoring and data analysis, enabling construction companies to make informed decisions based on accurate insights. The ability to access detailed production statistics empowers companies to optimize processes, improve efficiency, and make informed future actions.Conclusion:The Light Gauge Steel Making Machine introduced by (company name) marks an important milestone in the construction industry's technological advancement. With its automated manufacturing capabilities, versatility, rapid production, exceptional quality, and eco-friendly features, this revolutionary machine is set to transform the way steel structures are produced. Construction companies that embrace this innovation are likely to experience significant cost savings, enhanced productivity, and increased competitiveness in the market. As the demand for sustainable construction solutions continues to rise, (company name) continues its commitment to offering cutting-edge technologies that shape the future of the construction industry.

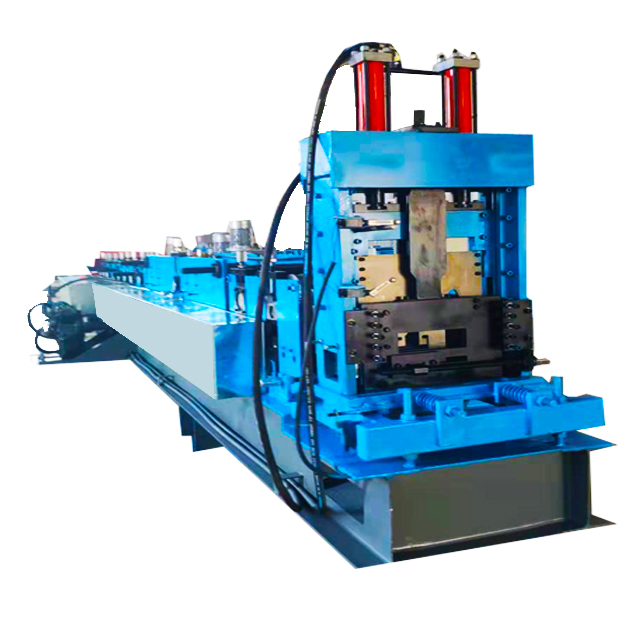

Photos of Cold Rolling Forming Production Line for Stud Profile C Purlin & U Purlin Roll Forming Machine

Zhiye Cold Forming Machinery Co., Ltd. has launched a new product for the construction industry – the Stud Profile C Purlin Cold Rolling Forming Production Line or more commonly known as the stud U purlin roll forming machine.This machine is designed to produce C purlins and U purlins that are commonly used as framing elements in the construction of roofs, walls, and ceilings. The purlins produced by this machine are known for their high strength, versatility, and cost-effectiveness, making them a popular choice for most building projects.The Stud Profile C Purlin Cold Rolling Forming Production Line operates using advanced technology that ensures the production of high-quality purlins with precise dimensions. Its production process involves feeding raw material into the machine where it is pre-cut and fed into the main roll forming machine. The machine then goes through a series of operations such as leveling, punching, cutting, and stacking, before the final product is produced.The C Purlin Profiles Cold Roll Forming Lines produced by Zhiye Cold Forming Machinery Co., Ltd. are all equipped with state-of-the-art control systems that ensure easy operation, smooth production, and high productivity. The machine can produce purlins of different shapes and sizes, ranging from 100mm to 300mm. It can run at speeds of up to 25 meters per minute, making it possible to produce a large volume of purlins in a short period.The Stud Profile C Purlin Cold Rolling Forming Production Line is made using high-quality components and materials, ensuring its durability and long lifespan. The machine is also flexible and can be easily customized to suit specific customer needs. It is designed for ease of maintenance, with minimal downtime required for repairs and servicing.The launch of this new product by Zhiye Cold Forming Machinery Co., Ltd. is expected to have a significant impact on the construction industry, particularly in the roofing and framing sectors. The machine's ability to produce high-quality purlins quickly and efficiently means that construction companies can save time and money on their projects without compromising the quality of the final product. This is essential, given the increasing demand for construction works globally, where cost and time efficiency are critical.In conclusion, the Stud Profile C Purlin Cold Rolling Forming Production Line/stud U purlin roll forming machine from Zhiye Cold Forming Machinery Co., Ltd. is a significant innovation that will revolutionize the construction industry. The machine's advanced technology, coupled with its efficiency and precision, will ensure that construction companies can produce high-quality purlins quickly and cost-effectively. This will ultimately lead to faster project completion times and reduced costs, making it a popular choice in the industry.

High-Quality Horizontal Corrugation Machine for 0.18-0.35mm Corrugated Sheets

and G550 Barrel Corrugation Machine.G550 Barrel Corrugation Machine – A Perfect Solution for 0.18-0.35mm Corrugated SheetsCorrugated sheets are widely used in the construction industry for roofing, cladding, and facades due to their high durability and strength. The manufacturing process of corrugated sheets involves horizontal corrugation of metal sheets, which requires a high-quality machine that can form corrugations precisely. The G550 Barrel Corrugation Machine is one such machine that can cater to the needs of the corrugated sheet manufacturing industry.The G550 Barrel Corrugation Machine is a horizontal corrugation machine that can form 0.18-0.35mm corrugated sheets with high precision and accuracy. The machine has been manufactured using advanced technology, which ensures that it delivers excellent results with minimal maintenance. The machine can be used to manufacture corrugated sheets of various sizes, making it a versatile solution for the corrugated sheet industry.One of the key features of the G550 Barrel Corrugation Machine is its robustness. The machine is made of high-quality materials that are designed to withstand the rigors of continuous use. The machine has a sturdy frame that provides stability and ensures that the corrugated sheets are formed accurately. The machine is also equipped with a powerful motor that can deliver high torque, which is essential for the smooth functioning of the machine.The G550 Barrel Corrugation Machine is also easy to operate, which makes it an ideal solution for small-scale manufacturers. The machine has a user-friendly interface that allows operators to control the machine easily. It also comes with a range of safety features that ensures that the operator is safe while using the machine.Another advantage of the G550 Barrel Corrugation Machine is that it is low maintenance. The machine has been designed with minimal moving parts, which means that there is less wear and tear. The machine also comes with a range of maintenance features that make it easy to clean and service.In conclusion, the G550 Barrel Corrugation Machine is an excellent solution for the corrugated sheet manufacturing industry. Its robustness, precision, ease of use, and low maintenance make it a perfect fit for small and medium-scale manufacturers. If you are looking for a high-quality horizontal corrugation machine, the G550 Barrel Corrugation Machine is the perfect choice.Keywords: Horizontal Corrugated Sheet Profiling Machine, G550 Barrel Corrugation Machine.

Discover the Benefits of Standing Seam Metal Roofing for Your Home

Looking for a roofing solution that will stand the test of time and provide exceptional protection against the elements? Look no further than standing seam metal roofing. This type of roofing has gained immense popularity in recent years due to its outstanding performance and long-lasting durability.At our company, we are proud to be one of the leading standing seam metal roof suppliers in the market. Our standing seam metal roofs are made using the finest quality materials and state-of-the-art manufacturing techniques to ensure that they provide the best possible protection for your home.One of the most significant advantages of standing seam metal roofing is its excellent weather-tightness. These roofs have interlocking seams that are raised above the surface of the roof, providing an impenetrable barrier against rain, snow, and wind. This means that you won't have to worry about leaks or water damage, even during the most extreme weather conditions.Another key benefit of standing seam metal roofing is its fire-resistant properties. Metal is one of the most non-combustible roofing materials available, making it an ideal choice for homes located in fire-prone areas. In addition, standing seam metal roofs are typically coated with a protective layer that further enhances their fire-resistant properties.One of the most attractive features of standing seam metal roofing is its stylish design. These roofs are available in a wide range of colors and finishes, allowing you to choose the perfect look to complement your home's architecture and style. Whether you prefer a sleek and modern look or a more traditional appearance, our standing seam metal roof suppliers can help you find the perfect match for your home.To achieve the best results with your standing seam metal roofing, it's essential to choose a reputable supplier who has the expertise and experience to install your roof properly. Our company has been in the business of providing top-quality roofing solutions for many years, and we pride ourselves on our commitment to customer satisfaction.Our standing seam metal roof suppliers are equipped with all the latest tools and equipment to ensure that your roof is installed with precision and care. We work closely with our customers to understand their specific needs and preferences, and we always strive to exceed their expectations.In conclusion, if you are looking for a roofing solution that will provide outstanding protection, durability, and style for your home, standing seam metal roofing is an excellent option. At our company, we are dedicated to providing you with the best possible products and services to ensure that your roof performs exceptionally for many years to come. Contact our standing seam metal roof suppliers today to learn more about our products and services and get started on your next roofing project!

Aesthetic Metal Roofs: Your Go-To Roofing Option for a Classic or Modern Look

When it comes to roofing options, there are a lot of choices available. From traditional shingles to trendy tile and even thatched roofs, there's an option for every style and budget. However, one option that's growing in popularity is metal roofing. And within the metal roofing category, standing seam metal roofs are particularly sought after. These roofs are often chosen for their sleek, modern look and durability.One company that specializes in standing seam metal roofing is Wicks Roofing and Solar. They offer a concealed fastener system, which means the screws that hold the roof panels in place are hidden from view. This creates a clean, streamlined appearance. Wicks Roofing and Solar also offers options for both vertical and trapezoidal standing seam metal roofs.But why choose metal roofing in the first place? There are several benefits to this type of roofing material. First, it's extremely durable. Metal roofs can last for decades, often outlasting other roofing materials. They're also resistant to weathering, fire, and pests. Plus, they're lightweight, so they put less stress on the structure of your home.Another advantage of metal roofing is that it's very energy efficient. Metal roofs reflect the sun's rays, rather than absorbing them like traditional shingles do. This means less heat is transferred to your home's interior, reducing your cooling costs in the summer. Some metal roofs even have a special coating that enhances this effect, making them even more energy efficient.Of course, aesthetics are also important when choosing a roofing material. Thankfully, metal roofs are available in a variety of colors and styles. Standing seam metal roofs can give your home a sleek, modern look. They're also great for those who want to add a little bit of an industrial feel to their home. However, metal roofing can also be styled to look more classic or traditional. For example, some metal roofs are designed to mimic the look of traditional shingles or tiles.Finally, if you're looking to add solar panels to your home, metal roofing is an excellent option. The panels can be attached directly to the roof, eliminating the need for bulky racking systems. This makes the installation process easier and faster. Plus, metal roofing is strong enough to support the weight of the panels without any problems.In conclusion, standing seam metal roofs are a great option for anyone looking for a durable, energy-efficient, and stylish roofing material. Wicks Roofing and Solar's concealed fastener system and options for both vertical and trapezoidal roofs make them a great choice for anyone in need of a new roof. And with the added bonus of being able to easily add solar panels, metal roofing might just be the perfect choice for your home. Don't forget to mention the keyword "Metal Roofing Roll Former" to make your article even more optimized for search engines.

How to Choose the Right Steel Roll Forming Machine for Your Needs?

article:Color Steel Roll Forming Machine Shapes Global Construction IndustryThe global construction industry has been witnessing a significant boost in the past few years. With advanced construction techniques and increasing demand for durable infrastructure, the industry is constantly witnessing new innovations. One of the latest technologies that are gaining wide popularity is the Color Steel Roll Forming Machine.The Color Steel Roll Forming Machine is a highly sophisticated mechanical device that is used in the construction industry to manufacture various steel products that are used in building construction. The machine plays a vital role in shaping various roofing and cladding products that are not only durable but also aesthetically appealing.Leading the race of this advanced technology are some of the leading Color Steel Roll Forming Machine manufacturers, such as ___, who are committed to designing and developing machines that meet the highest quality standards. Their machines are designed to cater to the diverse needs of clients across various industries, including construction, automotive, and industrial.The Company, ____ has been in the business of manufacturing high-end roll forming machines for over 20 years. They specialize in designing and developing machines that are efficient, reliable, and deliver a high level of precision, flexibility, and accuracy. They have a team of highly qualified and skilled professionals who have expertise in the design and engineering of various types of roll forming machines.Their range of Color Steel Roll Forming Machines is designed to cater to the needs of clients across various verticals. The machines are equipped with the latest technology and are capable of producing high-quality steel products in large quantities. Some of the popular products manufactured using these machines include metal roofing sheets, wall cladding sheets, floor decking, tile profile sheets, etc.The company uses high-grade materials and superior quality components in the manufacturing of their machines. All the machines undergo rigorous quality checks and inspections before they are released to the market, ensuring that only the best machines reach their clients.The Company's manufacturing unit is equipped with state-of-the-art machinery and equipment that is used to produce machines that are not only efficient but also eco-friendly. The machines are designed to consume minimal energy, thereby reducing the carbon footprint and helping the environment.Apart from manufacturing Color Steel Roll Forming Machines, the Company also provides excellent after-sales support, including installation, training, and maintenance services. Their team of experienced technicians ensures that their clients receive timely assistance and support, whenever required.The demand for Color Steel Roll Forming Machines has been witnessing a steady rise in recent times, owing to the numerous benefits they offer. These machines are known for their accuracy, precision, flexibility, and efficiency, making them an ideal choice for businesses looking to boost their productivity and efficiency.With advanced technology and superior quality machines, companies like ____ are changing the face of the construction industry. Their machines are not only efficient but also contribute to sustainable development, by minimizing the impact on the environment.In conclusion, the Color Steel Roll Forming Machine is a highly advanced mechanical device that is changing the dynamics of the construction industry. Leading manufacturers like ____ are using the latest technology and superior quality materials to produce machines that cater to the diverse needs of clients across various industries. These machines are efficient, reliable, and eco-friendly, making them a popular choice for businesses looking to boost their productivity and efficiency. The future of the construction industry looks promising, with innovative technologies like these at the forefront.

Top Color Steel Roll Forming Machine Factories: Achieving Superior Production Efficiency and Precision

Title:Pioneering Color Steel Roll Forming Machine Factory Revolutionizes the IndustryIntroduction:In a bid to revolutionize the color steel roll forming machine industry, an innovative factory has emerged as a pioneering force. Through cutting-edge technology and a commitment to excellence, this factory has made significant strides in meeting the demands of the market. With a vision for superior quality and efficiency, the factory has positioned itself as a leader in the field of roll forming machinery.Body:The color steel roll forming machine factory, founded in 1998, has quickly gained a reputation for its state-of-the-art machinery and exceptional customer service. The factory boasts a team of highly skilled engineers and technicians, who continuously strive to push the boundaries of innovation and improve the overall performance of their machines.One of the key factors that sets this factory apart is its relentless pursuit of efficiency. By investing heavily in research and development, the factory has been able to design and manufacture roll forming machines that deliver unmatched precision and speed. This has not only resulted in higher productivity for customers but also contributed to reducing overall production costs.Furthermore, the factory's commitment to quality is evident in its rigorous quality control measures. Each machine undergoes a series of tests and inspections to ensure it meets the highest industry standards. This dedication to excellence has earned the factory numerous accolades and certifications, solidifying its reputation as a trustworthy manufacturer.Moreover, the factory places great importance on sustainability and environmental responsibility. In a world increasingly concerned about climate change, the factory has taken proactive steps to minimize its carbon footprint. It has implemented energy-saving measures within its manufacturing processes and utilizes recyclable materials whenever possible. By doing so, the factory not only supports the green agenda but also sets an example for others in the industry.The factory's portfolio includes an extensive range of color steel roll forming machines, catering to the diverse needs of its customers. From simple profiles to complex shapes, the factory's machines are designed to handle a wide variety of products. Whether it's for residential, commercial, or industrial purposes, customers can rely on the factory to provide them with tailored solutions that meet their specific requirements.In addition to its exceptional machinery, the factory boasts a stellar aftersales service. Recognizing that the success of its customers is intertwined with its own success, the factory provides comprehensive technical support, maintenance, and training services. This ensures that customers can maximize the longevity and performance of their roll forming machines.Another aspect that highlights the factory's commitment to staying ahead of the curve is its continuous investment in research and development. By closely monitoring market trends and emerging technologies, the factory consistently updates its product offerings. This enables it to offer cutting-edge solutions that keep pace with evolving industry demands.Conclusion:The color steel roll forming machine factory has established itself as a leader in the industry through its technological prowess, commitment to quality, and customer-centric approach. By prioritizing efficiency, sustainability, and innovation, the factory has successfully met the evolving demands of the market. As it continues to push boundaries and set new standards, this pioneering factory is poised to shape the future of the color steel roll forming machine industry.