High-Quality Metal Roof Sheet Roll Forming Machine for Sale: A Complete Guide

By:Admin

The metal roof sheet roll forming machine from {} has become a popular choice among manufacturers and construction companies around the world. With its advanced technology and efficient production capabilities, this machine has taken the market by storm, providing a cost-effective solution for the production of high-quality metal roof sheets.

With a focus on innovation and quality, {} has been a leading manufacturer of roll forming machinery for over 20 years. The company's state-of-the-art facilities and experienced engineering team have enabled them to develop a wide range of roll forming machines for various applications, including the metal roof sheet roll forming machine.

The metal roof sheet roll forming machine from {} is designed to produce consistent and precise metal roof sheets with high efficiency. It is equipped with advanced technology, such as PLC control, hydraulic cutting, and automatic stacking, to ensure seamless production and minimal downtime. This machine can handle a variety of materials, including galvanized steel, aluminum, and pre-painted steel, making it versatile for different construction needs.

One of the key features of this roll forming machine is its quick setup and easy operation. With a user-friendly interface and adjustable settings, operators can easily switch between different sheet profiles and dimensions, allowing for flexibility in production. This not only saves time but also reduces the need for additional equipment, making it a cost-effective solution for manufacturers.

In addition to its efficiency, the metal roof sheet roll forming machine also delivers high-quality results. The precision of the forming process ensures that each sheet is uniform in shape and size, meeting the standards required for construction. This level of quality is crucial for ensuring the structural integrity and longevity of metal roofs, making it a reliable choice for builders and contractors.

Furthermore, {} provides comprehensive support and after-sales service for their roll forming machines. From installation and training to maintenance and troubleshooting, the company is dedicated to ensuring that their customers can maximize the performance and lifespan of their equipment. This commitment to customer satisfaction has earned {} a strong reputation in the industry.

The demand for metal roof sheet roll forming machines has been on the rise, driven by the growth in the construction sector and the increasing preference for metal roofing materials. As a result, {} has seen a surge in orders for their roll forming machines, with customers recognizing the value and reliability they offer. From small-scale manufacturers to large construction companies, this machine has become a go-to solution for producing metal roof sheets.

Looking ahead, {} is poised to continue leading the market with their metal roof sheet roll forming machine. With ongoing research and development, the company is committed to enhancing the capabilities and efficiency of their machines, staying ahead of industry trends and customer needs. As the construction industry continues to evolve, the demand for high-quality, cost-effective roll forming solutions will only increase, solidifying the position of {} as a trusted partner for manufacturers and builders alike.

Company News & Blog

High Precision Sheet Metal Profiling Machine - A Game Changer in Metal Fabrication Industry

In today's modern manufacturing industry, the demand for precision and efficiency is constantly driving companies to seek the latest technological advancements. One such advancement is the Sheet Metal Profiling Machine, a cutting-edge piece of equipment that has revolutionized the way sheet metal is processed and shaped. This innovative machine has the ability to precisely cut and shape sheet metal with incredible accuracy, speed, and versatility, making it an invaluable tool for a wide range of industries.With the rise of automation and advanced technology in manufacturing, the Sheet Metal Profiling Machine has quickly become an essential tool for companies looking to improve their production processes. Its high-tech features and capabilities make it a game-changer for businesses that require efficient and accurate sheet metal cutting and profiling. The machine's ability to handle a variety of materials, including stainless steel, aluminum, copper, and brass, makes it a versatile solution for a wide range of applications.The Sheet Metal Profiling Machine utilizes advanced computer numerical control (CNC) technology to accurately and efficiently cut and shape sheet metal to precise specifications. This level of precision and consistency is crucial for industries such as automotive, aerospace, construction, and manufacturing, where even the smallest deviation from design specifications can have significant consequences. By utilizing the Sheet Metal Profiling Machine, companies can ensure that their products are manufactured to the highest standards of quality and precision.With the ability to cut and shape sheet metal in a variety of complex forms and designs, the Sheet Metal Profiling Machine opens up a world of possibilities for manufacturers. Its advanced capabilities allow for intricate and precise cuts, enabling companies to create highly detailed and customized components for their products. This level of precision and flexibility is invaluable for companies looking to stay ahead of the competition and meet the demands of an increasingly complex and diverse market.At the forefront of this industry innovation is {}, a leading manufacturer and provider of advanced sheet metal processing equipment. With a strong focus on research and development, as well as a commitment to quality and innovation, {} has become a trusted name in the manufacturing industry. The company's dedication to creating cutting-edge solutions for its customers has made it a go-to source for businesses looking to improve their production processes and stay ahead of the curve.With a comprehensive range of sheet metal profiling machines, {} offers a variety of options to suit the specific needs and requirements of its customers. Whether it's a small-scale operation or a large-scale industrial production facility, {} has the expertise and technology to provide tailored solutions that deliver exceptional results. The company's commitment to quality, reliability, and customer satisfaction has earned it a reputation as a leader in the industry, setting the standard for excellence in sheet metal processing equipment.As the manufacturing industry continues to evolve and demand for precision and efficiency grows, the Sheet Metal Profiling Machine is poised to play a crucial role in shaping the future of sheet metal processing. With its advanced technology, versatility, and impeccable precision, this cutting-edge machine is set to revolutionize the way companies approach sheet metal cutting and shaping. And with industry leaders like {} at the helm of this innovation, businesses can expect to see even more exciting advancements on the horizon.

Color Steel Glazed Tile Manufacturing Machine Enhances Roofing Industry Efficiency

[Company Introduction][Company Name], a leading manufacturer in the field of steel glazed tile manufacturing, is proud to announce the release of its latest innovation - the Color Steel Glazed Tile Manufacturing Machine (name removed according to the query). With a reputation for delivering high-quality products, [Company Name] has been serving the industry for over a decade. Our team of experienced engineers and technicians constantly strive to develop innovative solutions that meet the evolving needs of the market. Our dedication to quality, reliability, and precision has made us a trusted name in the industry.[Company Name] offers a comprehensive range of cutting-edge machinery and equipment designed for the production of color steel glazed tiles. Our customers span across various sectors such as construction, architecture, and infrastructure. We understand the importance of delivering products that not only withstand extreme weather conditions but also provide aesthetic appeal. Our color steel glazed tile manufacturing machines are engineered with great attention to detail, ensuring flawless performance and durability.As a company, we take pride in our commitment to sustainable practices. We prioritize energy efficiency and strive to develop machines that minimize waste and reduce carbon footprint. By embracing eco-friendly manufacturing processes, we aim to contribute positively to the environment and create a greener future.[Company Name] values customer satisfaction above all else. We believe in building strong relationships with our clients by offering exceptional after-sales support and services. Our team of technical experts is always available to address any queries or concerns our customers may have. We provide comprehensive training programs to ensure that our clients can operate our machines with ease and maximize their productivity.[News Content][City, Date] - [Company Name], a renowned leader in steel glazed tile manufacturing, has announced the launch of its latest state-of-the-art machinery - the Color Steel Glazed Tile Manufacturing Machine (name removed). This cutting-edge technology is set to revolutionize the industry with its innovative features and exceptional performance.The newly developed Color Steel Glazed Tile Manufacturing Machine (name removed) combines the latest advancements in engineering and materials science to deliver unmatched precision and efficiency. Its automated operation streamlines the manufacturing process, increasing productivity and reducing labor costs. The machine offers a high level of customization, allowing for the production of tiles in various colors, shapes, and sizes.Designed for durability, the Color Steel Glazed Tile Manufacturing Machine (name removed) is built to withstand the harshest environmental conditions. Its robust construction and advanced quality control mechanisms ensure consistent output and minimal downtime. This machine is engineered to facilitate efficient material utilization, reducing waste and optimizing production efficiency.One of the key features of the Color Steel Glazed Tile Manufacturing Machine (name removed) is its user-friendly interface. With a comprehensive control system, operators can easily monitor and adjust the production parameters, ensuring precise tile dimensions and perfect finishing. The machine's intuitive design simplifies the learning curve, allowing workers to operate it with minimal training.Speaking about the new product, [Company Name]'s spokesperson said, "We are thrilled to introduce the Color Steel Glazed Tile Manufacturing Machine (name removed) to our customers. This machine represents a significant milestone in our commitment to delivering cutting-edge solutions. With its advanced capabilities and unparalleled performance, we are confident it will exceed our customers' expectations."The Color Steel Glazed Tile Manufacturing Machine (name removed) has already gained significant attention from industry experts and potential customers alike. Its impressive features and competitive pricing make it a highly attractive option for businesses looking to enhance their production capabilities.In conclusion, [Company Name] continues to lead the steel glazed tile manufacturing industry with its commitment to innovation and customer satisfaction. The launch of the Color Steel Glazed Tile Manufacturing Machine (name removed) further solidifies their position as a trusted provider of high-quality machinery. As the industry evolves, [Company Name] remains dedicated to meeting and exceeding market demands while upholding their eco-friendly approach to manufacturing.

Light Gauge Steel Frame Roll Forming Machine for CZ Purlin Profiles: Latest News Update

CZ Purlin Profile Light Gauge Steel Frame Roll Forming Machine Launched by Dedication and PrecisionDeveloping new machines that can improve productivity and efficiency is an ongoing challenge in many industries. One company that has recently launched a new machine is a leading manufacturer of roll forming machines for the roofing and walling industry. With a focus on quality and innovation, they have introduced the new CZ Purlin Profile Light Gauge Steel Frame Roll Forming machine. This new machine is expected to help manufacturers streamline their production processes, and ultimately improve the quality of their products.The new CZ Purlin Profile Light Gauge Steel Frame Roll Forming machine is designed to create high-quality, uniform purlin profiles. The machine features a series of rollers, which bend the metal into the desired shape. The process is quick, precise, and consistent, ensuring that each piece meets the exact specifications set by the manufacturer. The machine is also versatile enough to handle a variety of different steel gauges, giving manufacturers the flexibility they need to produce a wide range of products.As noted by the company, the new machine is designed with advanced technology and precision engineering. This means that it is highly efficient, providing manufacturers with a faster, more streamlined production process. Additionally, the machine is durable and requires minimal maintenance, making it a cost-effective investment for companies of all sizes.By introducing the new CZ Purlin Profile Light Gauge Steel Frame Roll Forming machine, the company has shown a clear dedication to improving the quality of roll-formed products. They recognize that consistency and accuracy are essential in the roofing and walling industry, which is why they have developed a machine that can create such high-quality profiles. With this new machine, manufacturers can expect improved efficiency, faster production times, and enhanced product quality.In terms of the broader industry, the launch of the new CZ Purlin Profile Light Gauge Steel Frame Roll Forming machine is a significant development. The roofing and walling industry is highly competitive, and manufacturers are always searching for ways to gain an edge. With this new machine, companies can improve the quality of their products, reduce waste, and increase their output. This can help them remain competitive in the marketplace and enhance their long-term viability.Overall, the launch of the new CZ Purlin Profile Light Gauge Steel Frame Roll Forming machine is an important development for the roofing and walling industry. With its advanced technology, durability, and precision engineering, the machine has the potential to revolutionize the way manufacturers produce purlin profiles. The company behind this new machine has demonstrated a clear commitment to innovation and quality, and it will be interesting to see how the marketplace responds to this new product in the coming months and years.

High Speed Light Steel Keel Roll Forming Machine: Efficient Building Material Solution

, Stud Truss Roll Forming Machine, High Speed Roll Forming Machine, Metal Stud Roll Forming Machine.With the advancement in technology, the construction industry also has advanced equipment and machines to produce high-quality materials. One such essential machine is the stud truss high speed light steel keel roll forming machine. This machine is used to make light keel studs and trusses that are used for constructing the roof and walls of a building. It is known for its efficiency, reliability, and high speed.The light steel keel machine is designed differently based on the model and the customer's specifications. The metal stud roll-forming machine produces rolls of metal that are used as roofing or wall material in places such as factories, warehouses, garages, gymnasiums, and exhibition centers. These products are popular because of their lightweight, high strength, and easy installation.One of the many advantages of using a stud truss high speed light steel keel roll forming machine is its speed. The machine is designed to produce large quantities of metal strips rapidly, therefore, allowing for mass production, this significantly reduces the time taken to construct a building. The machine is also straightforward to operate, reducing the need for large labor forces on construction sites.Another benefit of using the light steel keel machine is the quality of the material produced; the metal strips produced are of a consistent thickness, length, and size, eliminating the possibility of defects that could lead to the loss of material. The machines are also low-maintenance as they are designed to be robust and long-lasting, thus reducing the operators' servicing costs.In conclusion, the stud truss high speed light steel keel roll forming machine is a must-have piece of equipment in the construction industry. It's easy operation, and high-speed production makes it a favorite among operators globally. The machine's accuracy and quality of the material produced make it an indispensable tool in the construction of buildings. For cost-effective construction materials, the light steel keel machine is the way to go. So if you are in the construction industry, it's essential to invest in a high-quality stud truss roll forming machine that will provide the best results.

Top 5 Benefits of Using a Step Tile Roll Forming Machine

Step Tile Roll Forming Machine has recently gained a lot of attention in the manufacturing industry for its efficient and precise tile forming capabilities. The machine is designed to create step-tile roofing sheets, which are widely used for residential and commercial buildings. With its advanced technology and high-speed production, the Step Tile Roll Forming Machine is set to revolutionize the roofing industry.The Step Tile Roll Forming Machine is a product of {}, a leading manufacturing company specializing in metal forming machinery. With over 20 years of experience in the industry, {} has established itself as a reliable and innovative provider of roll forming solutions. The company's commitment to quality, efficiency, and customer satisfaction has made it a trusted partner for businesses around the world.The Step Tile Roll Forming Machine is equipped with state-of-the-art features that set it apart from traditional roll forming machines. Its precision and speed make it possible to produce high-quality step-tile roofing sheets in a fraction of the time compared to manual methods. This not only increases productivity but also ensures consistent quality, which is crucial for meeting the demands of the construction industry.One of the key advantages of the Step Tile Roll Forming Machine is its versatility. It is capable of forming a variety of step-tile profiles, allowing for customization and flexibility in design. This makes it suitable for a wide range of roofing projects, from residential homes to large commercial buildings. Whether it's a simple or complex pattern, the machine can produce it with ease, making it an ideal solution for businesses of all sizes.In addition to its high-speed production and flexibility, the Step Tile Roll Forming Machine is also known for its durability and reliability. It is built to withstand continuous use and harsh working conditions, ensuring a long lifespan and minimal downtime. This is especially important for businesses with demanding production schedules, as the machine's reliability can significantly impact overall operations.Furthermore, the Step Tile Roll Forming Machine is designed with user-friendliness in mind. It is equipped with intuitive controls and an easy-to-understand interface, making it accessible to operators of varying skill levels. This not only reduces the need for extensive training but also minimizes the risk of errors during operation, maximizing efficiency and safety in the workplace.As the demand for efficient and cost-effective roofing solutions continues to grow, the Step Tile Roll Forming Machine is poised to make a significant impact on the industry. Its advanced technology, combined with the expertise of {}, makes it a valuable asset for businesses looking to streamline their production processes and stay ahead of the competition.With its exceptional performance, versatility, and durability, the Step Tile Roll Forming Machine is set to become a game-changer in the roofing industry. As businesses seek to meet the evolving needs of their customers, this innovative machine offers a solution that is both practical and profitable. For those looking to invest in a reliable and high-quality roll forming solution, the Step Tile Roll Forming Machine from {} is undoubtedly a top choice.

Cut to Length: The Latest Advancement in Automatic Cutting Technology

Automatic Cut to Length Machine Enhances Productivity and Precision in Metal ProcessingIn the constantly evolving world of metal processing, efficiency and precision are crucial factors for success. One company at the forefront of this industry is {}, a leading provider of cutting-edge machinery for metal fabrication. Recognizing the need for advanced solutions to meet the demands of their customers, {} has recently introduced a new Automatic Cut to Length machine that promises to revolutionize the way metal is processed.The Automatic Cut to Length machine is designed to streamline the production process, offering a range of benefits for metal processing businesses. With its advanced automation and cutting-edge technology, this machine is capable of accurately cutting metal sheets to precise lengths with minimal human intervention. This not only enhances the overall productivity of the operation but also ensures a high degree of precision in the final product, reducing waste and improving the quality of output.One of the key features of the Automatic Cut to Length machine is its versatility. Equipped with a range of customizable settings, the machine is capable of handling a variety of metal materials, including steel, aluminum, and other alloys. This flexibility makes it an ideal solution for a wide range of metal processing applications, from automotive and aerospace to construction and manufacturing.The machine’s advanced control system and intelligent software further contribute to its efficiency and accuracy. Operators can easily program the machine to cut metal sheets to specific dimensions, allowing for rapid and precise production according to the requirements of a particular project. This level of control not only saves time but also minimizes the margin for error, ensuring that the finished products meet the highest standards of quality.In addition to its cutting capabilities, the Automatic Cut to Length machine also offers advanced handling features. The machine is equipped with a robust material feeding system that efficiently moves metal sheets through the cutting process, further optimizing the production workflow. This seamless integration of cutting and handling functions results in a smooth and uninterrupted operation, reducing downtime and maximizing output.With the introduction of the Automatic Cut to Length machine, {} has once again demonstrated its commitment to innovation and excellence in the field of metal processing machinery. The company’s extensive experience and expertise in this industry have enabled it to develop a cutting-edge solution that addresses the evolving needs of metal fabricators and manufacturers. By leveraging the latest technologies, {} continues to set new standards for productivity, precision, and reliability in metal processing.For metal processing businesses, the adoption of the Automatic Cut to Length machine represents a valuable investment in their future success. The machine’s ability to enhance productivity and precision offers a competitive advantage in the market, allowing businesses to meet the growing demands of their customers with superior quality and efficiency. Furthermore, the potential cost savings from reduced waste and improved efficiency make this machine a wise long-term investment for any metal processing operation.As the industry continues to evolve, the demand for advanced metal processing solutions will only continue to grow. With its Automatic Cut to Length machine, {} has positioned itself at the forefront of this trend, offering a game-changing technology that is redefining the way metal is processed. For businesses looking to stay ahead in the competitive world of metal fabrication, this machine is a powerful tool for enhancing productivity and precision, ultimately driving success and profitability in the long run.

The Complete Guide to Slitting Process in Metal Manufacturing

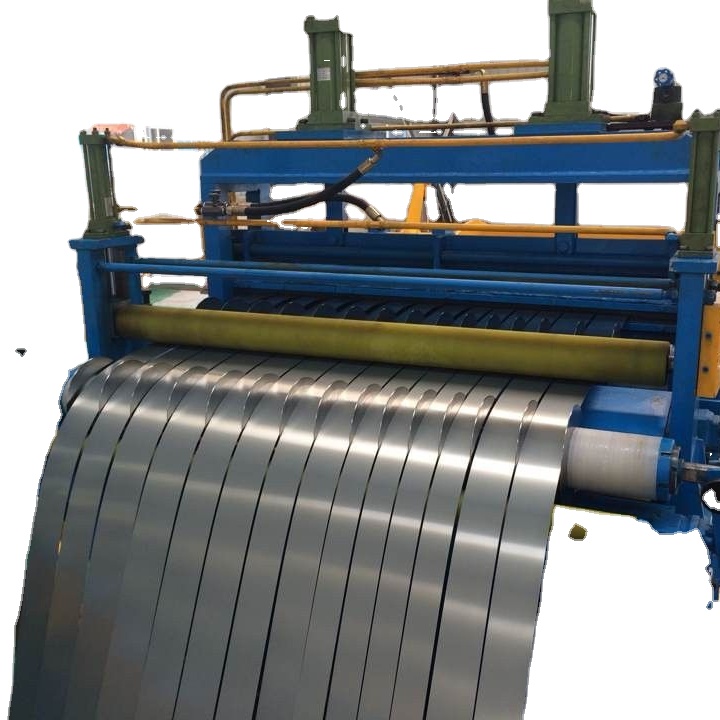

Coil Slitting Process: A Game-Changer in Metal Fabrication IndustryIn the world of metal fabrication, efficiency and precision are key. That's why the innovative coil slitting process has been a game-changer for many companies in this industry. This process, which involves cutting large coils of metal into smaller, narrower coils, has revolutionized the way metal is fabricated and has allowed companies to increase their productivity and output. One company that has fully embraced this cutting-edge technology is {company name}.{Company name} is a leading player in the metal fabrication industry, known for its commitment to quality, innovation, and customer satisfaction. With state-of-the-art facilities and a team of experienced professionals, {company name} has been at the forefront of adopting the latest technologies to stay ahead of the competition. The company specializes in providing custom metal solutions for a wide range of industries, including automotive, aerospace, construction, and more. The coil slitting process has been a significant boon for {company name}, enabling them to meet the diverse needs of their clients with unparalleled precision and efficiency. This advanced cutting process allows {company name} to take large coils of metal and precisely cut them into multiple narrower coils, according to the specifications provided by their clients. This level of accuracy and customization has allowed {company name} to offer a wide range of product options to their customers, further solidifying their position as a market leader in the metal fabrication sector.The coil slitting process is not just about cutting metal; it's about optimizing resources and minimizing waste. By using this process, {company name} has been able to maximize the yield from each coil of metal, resulting in cost savings for both the company and its clients. Additionally, the ability to create narrower coils has also allowed {company name} to offer more tailored solutions, catering to the specific needs of each customer. This level of flexibility and customization has set {company name} apart from its competitors, establishing the company as a go-to source for high-quality, precision-cut metal products.Furthermore, the coil slitting process has also enhanced {company name}'s production capabilities, allowing them to handle larger volumes of metal with ease and efficiency. This has been particularly beneficial in serving clients with high-volume requirements, as well as in meeting tight deadlines without compromising on quality. The streamlined nature of the coil slitting process has significantly reduced lead times for {company name}, enabling them to deliver superior products to their clients in a timely manner.With a keen focus on innovation and continuous improvement, {company name} has not only adopted the coil slitting process but has also optimized and fine-tuned it to meet their exacting standards. This dedication to excellence has earned {company name} a stellar reputation within the industry, garnering trust and loyalty from their clients and partners alike. As a result, {company name} has seen a steady increase in demand for their metal products, further solidifying their position as a leading force in the metal fabrication sector.In conclusion, the coil slitting process has been a transformative force for {company name}, revolutionizing their production capabilities and setting new standards for quality and efficiency in the metal fabrication industry. With this cutting-edge technology at their disposal, {company name} is well-equipped to continue delivering exceptional metal solutions to their clients, further cementing their status as a trailblazer in the field. As the industry continues to evolve, {company name} remains committed to staying ahead of the curve and embracing innovations that will shape the future of metal fabrication.

Metal Step Tile Forming Machine with Filming Capabilities

Metal Step Tile With Filming Forming Machine Showcases Cutting-Edge TechnologyIn the world of construction and manufacturing, technological advancements are constantly changing the landscape of the industry. One such advancement is the introduction of the Metal Step Tile With Filming Forming Machine, a revolutionary piece of equipment that is poised to revolutionize the way metal step tiles are produced.The Metal Step Tile With Filming Forming Machine is a product of cutting-edge technology and innovation. It is designed to streamline the process of manufacturing metal step tiles, in order to make it more efficient and cost-effective. The machine is equipped with state-of-the-art features that enable it to produce high-quality metal step tiles with precision and consistency.One of the key features of the Metal Step Tile With Filming Forming Machine is its ability to produce metal step tiles with a variety of profiles and dimensions. This flexibility allows manufacturers to cater to a wide range of customer needs and preferences, and to produce custom metal step tiles that are tailored to specific project requirements.Another notable feature of the Metal Step Tile With Filming Forming Machine is its use of filming technology, which allows for the application of protective coatings to the metal step tiles during the production process. This not only enhances the aesthetic appeal of the tiles, but also provides a layer of protection against corrosion and wear, making them more durable and long-lasting.The company behind this innovative piece of technology, {}, has established itself as a leader in the field of manufacturing equipment and machinery. With a strong focus on research and development, the company has been able to stay at the forefront of technological advancements in the industry, and has earned a reputation for producing high-quality and reliable products.{} has a team of highly skilled engineers and technicians who are dedicated to pushing the boundaries of innovation, and who work tirelessly to develop new and improved manufacturing solutions. The Metal Step Tile With Filming Forming Machine is a testament to the company's commitment to excellence and its ability to deliver cutting-edge technology to its customers.The introduction of the Metal Step Tile With Filming Forming Machine has generated a significant amount of excitement and interest within the construction and manufacturing industries. Manufacturers are eager to take advantage of the machine's capabilities in order to improve their production processes and to enhance the quality of their metal step tiles.In addition to its technological advantages, the Metal Step Tile With Filming Forming Machine is also being lauded for its potential to reduce production costs and increase efficiency. By streamlining the manufacturing process and minimizing waste, the machine allows manufacturers to maximize their productivity and to operate more sustainably.The Metal Step Tile With Filming Forming Machine is already making waves in the industry, and it is expected to have a significant impact on the way metal step tiles are produced in the future. As technology continues to advance, it is innovations like this that will shape the future of manufacturing, and contribute to the ongoing evolution of the construction and building materials industries.In conclusion, the Metal Step Tile With Filming Forming Machine represents a major advancement in the field of manufacturing technology. With its cutting-edge features and capabilities, this machine has the potential to revolutionize the way metal step tiles are produced, and to drive significant improvements in the efficiency, quality, and sustainability of the manufacturing process. As the construction and manufacturing industries continue to evolve, the Metal Step Tile With Filming Forming Machine stands as a testament to the power of innovation and the potential for technological advancements to shape the future of the industry.

Top-Quality Metal Roll Forming Machine for Sale with Roof Panel Roll Forming Machine

Metal Roll Forming Machine for Sale: A Boon for the Construction IndustryThe construction industry is witnessing rapid growth and development, and with it, the demand for efficient and high-quality machinery. One such piece of equipment that has become indispensable in the construction sector is the metal roll forming machine. Known for its versatility, reliability, and precision, this machine has revolutionized the way metal panels and profiles are created. It offers a cost-effective solution for constructing roofs, walls, and other structural components.In line with the growing demand, Metal Roll Forming Machine, a renowned industry player, is now offering their top-of-the-line metal roll forming machines for sale.Metal roll forming machines are capable of shaping various metals, such as steel, aluminum, and galvanized iron, into customized profiles of different shapes and sizes. These machines utilize a continuous bending process, wherein the metal strip is fed through a series of rollers, gradually shaping it into the desired profile. The resulting products offer exceptional structural strength, durability, and aesthetics.Metal Roll Forming Machine offers a wide range of machines to cater to the diverse needs of the construction industry. Their roof panel roll forming machine is particularly sought-after due to its ability to efficiently produce high-quality roof panels. These panels not only enhance the visual appeal of buildings but also provide superior protection against adverse weather conditions.One of the key features that set Metal Roll Forming Machine apart is its commitment to quality. The machines they offer are manufactured using state-of-the-art technology, ensuring unrivaled precision and performance. These machines undergo rigorous testing and quality checks to meet international standards and provide customers with reliable and long-lasting solutions.Metal Roll Forming Machine prides itself on providing excellent customer service. Their team of experienced professionals assists clients in selecting the most suitable machine for their specific requirements. Offering comprehensive after-sales support, they ensure that customers receive training and technical assistance to maximize the utilization of the machines.Moreover, Metal Roll Forming Machine understands the importance of sustainability and the need to minimize the environmental impact of their operations. Their machines are designed to optimize energy efficiency while minimizing material waste during the roll forming process. By adopting eco-friendly practices, Metal Roll Forming Machine is leading the way towards a greener and more sustainable future in the construction industry.To further facilitate customer convenience, Metal Roll Forming Machine now offers their machines for sale online. The user-friendly interface of their website allows customers to browse through their product catalog, compare specifications, and make informed purchasing decisions. With just a few clicks, customers can now own a top-quality metal roll forming machine to meet their construction needs.In conclusion, the availability of metal roll forming machines for sale by Metal Roll Forming Machine comes as a boon for the construction industry. These machines provide an efficient and cost-effective solution for producing high-quality metal profiles and panels. With their commitment to quality, customer service, and sustainability, Metal Roll Forming Machine has established itself as a trusted and reliable provider of metal roll forming machines. By investing in their machines, construction companies can elevate their productivity, efficiency, and profitability, ultimately contributing to the growth and advancement of the construction sector.

High-quality Steel Roofing Sheet Roof Tile Forming Machine: A Reliable Solution for 0.6mm 1219mm Sheets

Title: High-Quality Steel Roofing Sheet Roof Tile Forming Machine Now Available in ChinaIntroduction:China has become a global leader in manufacturing machinery and equipment, offering cutting-edge solutions for a wide range of industries. Adding to its repertoire is the introduction of a high-quality 0.6mm 1219mm Steel Roofing Sheet Roof Tile Forming Machine. Produced by a renowned Chinese manufacturer, this machine promises to revolutionize the roofing industry with its superior performance and durability.Advancements in technology have significantly contributed to the development of more efficient roofing solutions. The new 0.6mm 1219mm Steel Roofing Sheet Roof Tile Forming Machine offers exceptional features that ensure the production of top-notch roofing tiles. With strict quality control measures in place, this advanced machinery is proving to be a game-changer in the field of cold roll forming.Product Features:The 0.6mm 1219mm Steel Roofing Sheet Roof Tile Forming Machine boasts an array of impressive features that set it apart from other machines in the market. Let's take a closer look:1. Robust Construction: The machine is manufactured using high-quality materials, ensuring durability and reliability in its performance. Its sturdy frame and components make it a long-lasting asset in any manufacturing setup.2. Precision Engineering: This machine utilizes advanced technology to ensure precision and accuracy in the production of roofing tiles. Every detail is meticulously crafted, resulting in consistent and uniform tiles that meet the highest industry standards.3. Efficient Production: Equipped with a powerful motor, the machine operates at optimal speeds, enabling high-volume production without compromising on quality. Its automated processes reduce manual labor and increase efficiency, minimizing production time and costs.4. Versatility: The machine is designed to work with a wide range of materials, including steel, to produce various types of roofing tiles. This versatility allows manufacturers to cater to different consumer demands, expanding their market reach.5. User-Friendly Interface: The machine's user-friendly interface ensures easy operation, even for those with minimal experience in roll forming. Its intuitive controls and clear instructions make it accessible to a broader range of users, accelerating production and minimizing errors.Company Introduction:The 0.6mm 1219mm Steel Roofing Sheet Roof Tile Forming Machine is manufactured by a prominent Chinese company well-known for its expertise in sheet roll forming machinery. With years of experience and a commitment to excellence, this manufacturer has established itself as a reliable and trusted provider of innovative machinery solutions.The company's state-of-the-art manufacturing facility and skilled workforce enable the production of high-quality machines that meet global standards. Along with the 0.6mm 1219mm Steel Roofing Sheet Roof Tile Forming Machine, they offer a comprehensive range of sheet roll forming machines tailored to various industries.Conclusion:The introduction of the high-quality 0.6mm 1219mm Steel Roofing Sheet Roof Tile Forming Machine from China marks a significant advancement in the roofing industry. With its robust construction, precision engineering, efficient production capabilities, and user-friendly interface, this machine empowers manufacturers to produce superior-quality roofing tiles with ease.As China continues to lead in technological advancements, this latest offering further strengthens its position as a global powerhouse in machinery manufacturing. Manufacturers worldwide can now benefit from this excellent roofing sheet roll forming machine, ensuring increased productivity, improved product quality, and ultimately, enhanced customer satisfaction.