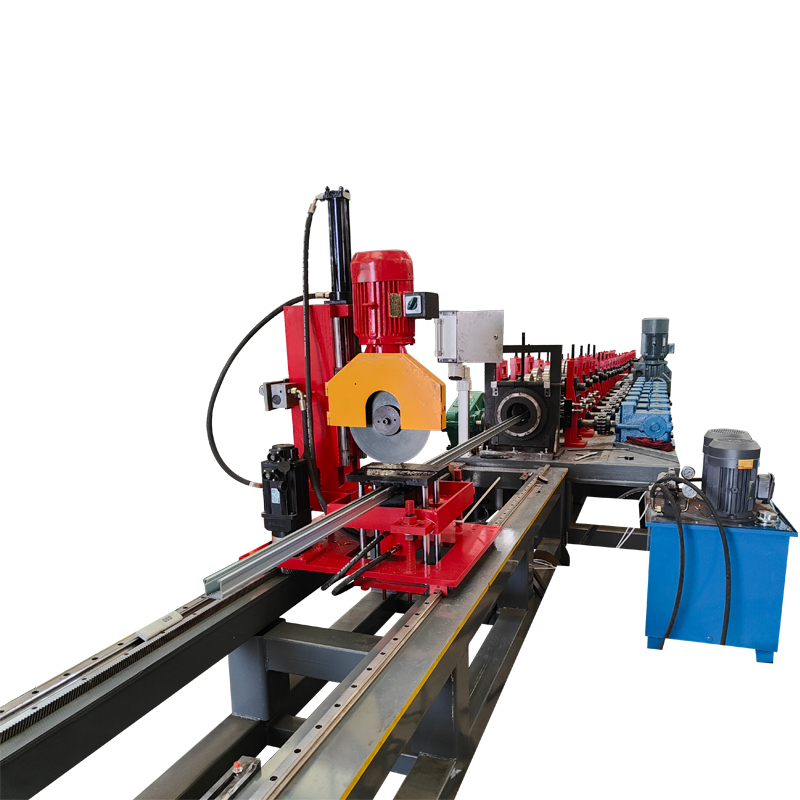

High-Quality Purlin Forming Machine for Efficient Production

By:Admin

The construction industry has seen significant advancements in recent years, with technology playing a crucial role in streamlining processes and improving efficiency. One such innovation that has been making waves in the industry is the CZ Purlin Forming Machine.

The CZ Purlin Forming Machine is a state-of-the-art piece of equipment that has revolutionized the way CZ purlins are manufactured. CZ purlins are widely used in the construction of metal buildings and are essential for providing structural support and stability. Traditionally, the process of manufacturing CZ purlins was time-consuming and labor-intensive. However, with the introduction of the CZ Purlin Forming Machine, this has changed dramatically.

This sophisticated machine is capable of producing high-quality CZ purlins in a fraction of the time it would take using traditional methods. It is equipped with advanced technology and automation features that allow for precise and accurate manufacturing, resulting in purlins that meet the highest industry standards.

The company behind this groundbreaking technology, {Company Name}, is a leading manufacturer of roll forming machines and equipment for the construction industry. With a rich history of engineering excellence and a commitment to innovation, {Company Name} has established itself as a trusted name in the industry.

The CZ Purlin Forming Machine is just one of the many cutting-edge products in {Company Name}'s lineup. The company takes pride in its ability to develop solutions that improve the efficiency and productivity of construction processes, ultimately benefiting its customers.

In addition to its innovative product offerings, {Company Name} is also known for its exceptional customer service and support. The company works closely with its clients to understand their specific needs and requirements, providing personalized solutions that address their unique challenges.

Furthermore, {Company Name} places a strong emphasis on quality and reliability. Its products are built to last and are rigorously tested to ensure they perform consistently and meet the highest industry standards. This commitment to excellence has earned {Company Name} a stellar reputation in the market.

The CZ Purlin Forming Machine has been well-received by industry professionals, with many praising its ability to streamline the manufacturing process and improve overall production efficiency. By investing in this technology, construction companies can significantly reduce their production time and labor costs, ultimately enhancing their competitiveness in the market.

In addition to its efficiency, the CZ Purlin Forming Machine also offers flexibility and versatility, allowing for the production of a wide range of purlin sizes and configurations. This adaptability makes it an ideal solution for companies with diverse project requirements.

As the construction industry continues to evolve and embrace technological advancements, the CZ Purlin Forming Machine stands out as a game-changer that is shaping the future of purlin manufacturing. With the support of {Company Name}, construction companies have access to a reliable and innovative solution that empowers them to meet the demands of modern construction projects.

In conclusion, the CZ Purlin Forming Machine, developed by {Company Name}, is a testament to the company's commitment to driving innovation in the construction industry. With its advanced technology, precision engineering, and focus on customer satisfaction, {Company Name} is set to continue making a significant impact in the market, providing solutions that elevate the industry as a whole.

Company News & Blog

Top High-Speed Slitting Machine: Find Out How It Works

High-Speed Slitting Machine Revolutionizes Manufacturing IndustryIn today's fast-paced world, the demand for high-speed and efficient production processes is greater than ever before. With the introduction of the High-Speed Slitting Machine by a leading manufacturing company, the industry's standards have been raised to a whole new level. This cutting-edge machine is revolutionizing the way materials are processed and is setting new benchmarks for speed, precision, and efficiency.The High-Speed Slitting Machine has been designed and developed by a renowned company that has been at the forefront of innovation in the manufacturing industry for over two decades. With a commitment to delivering cutting-edge solutions and state-of-the-art technology, the company has established itself as a leader in the field.The High-Speed Slitting Machine is a result of years of research, development, and engineering expertise. It is equipped with the latest advancements in technology, including high-speed servo motors, precision sensors, and advanced control systems, allowing it to operate at unprecedented speeds while maintaining the highest levels of accuracy and consistency.One of the key features of the High-Speed Slitting Machine is its ability to process a wide range of materials with varying thickness and properties. From paper and plastic to metal and other specialty materials, this versatile machine is capable of handling diverse requirements with ease. This makes it an ideal solution for a wide range of industries, including packaging, printing, automotive, electronics, and more.The High-Speed Slitting Machine's advanced control systems and intuitive user interface make it easy to set up and operate. With programmable settings and automated features, it streamlines the production process, reduces the risk of errors, and optimizes productivity. This not only saves time and labor costs but also ensures consistent and high-quality output.Another noteworthy aspect of the High-Speed Slitting Machine is its high-speed capabilities, which significantly increase production throughput and efficiency. By running at speeds of up to [insert speed], it outperforms traditional slitting machines, resulting in faster turnaround times and increased output. This helps manufacturers meet growing demands and stay ahead of the competition.Furthermore, the High-Speed Slitting Machine incorporates advanced safety features to ensure the well-being of operators and maintain a secure working environment. Its robust construction, emergency stop mechanisms, and comprehensive safety protocols make it a reliable and secure solution for any manufacturing facility.In addition to its performance and safety benefits, the High-Speed Slitting Machine is designed for ease of maintenance and long-term reliability. With durable components, minimal wear and tear, and simplified maintenance procedures, it offers a low total cost of ownership and a high return on investment over its lifespan.The introduction of the High-Speed Slitting Machine represents a significant breakthrough in the manufacturing industry. Its unparalleled speed, precision, and efficiency are reshaping the way materials are processed, setting new industry standards and opening up new possibilities for manufacturers worldwide.Looking ahead, the company behind the High-Speed Slitting Machine is committed to further innovation and continuous improvement. By leveraging its expertise and staying at the forefront of technology, it aims to bring even more groundbreaking solutions to the market in the years to come, further revolutionizing the manufacturing industry and driving progress on a global scale.In conclusion, the High-Speed Slitting Machine is a game-changer for the manufacturing industry, offering unmatched speed, precision, and efficiency. With its advanced technology, versatile capabilities, and user-friendly design, it is setting new standards and empowering manufacturers to meet the challenges of today's fast-paced world.

Photos of Cold Rolling Forming Production Line for Stud Profile C Purlin & U Purlin Roll Forming Machine

Zhiye Cold Forming Machinery Co., Ltd. has launched a new product for the construction industry – the Stud Profile C Purlin Cold Rolling Forming Production Line or more commonly known as the stud U purlin roll forming machine.This machine is designed to produce C purlins and U purlins that are commonly used as framing elements in the construction of roofs, walls, and ceilings. The purlins produced by this machine are known for their high strength, versatility, and cost-effectiveness, making them a popular choice for most building projects.The Stud Profile C Purlin Cold Rolling Forming Production Line operates using advanced technology that ensures the production of high-quality purlins with precise dimensions. Its production process involves feeding raw material into the machine where it is pre-cut and fed into the main roll forming machine. The machine then goes through a series of operations such as leveling, punching, cutting, and stacking, before the final product is produced.The C Purlin Profiles Cold Roll Forming Lines produced by Zhiye Cold Forming Machinery Co., Ltd. are all equipped with state-of-the-art control systems that ensure easy operation, smooth production, and high productivity. The machine can produce purlins of different shapes and sizes, ranging from 100mm to 300mm. It can run at speeds of up to 25 meters per minute, making it possible to produce a large volume of purlins in a short period.The Stud Profile C Purlin Cold Rolling Forming Production Line is made using high-quality components and materials, ensuring its durability and long lifespan. The machine is also flexible and can be easily customized to suit specific customer needs. It is designed for ease of maintenance, with minimal downtime required for repairs and servicing.The launch of this new product by Zhiye Cold Forming Machinery Co., Ltd. is expected to have a significant impact on the construction industry, particularly in the roofing and framing sectors. The machine's ability to produce high-quality purlins quickly and efficiently means that construction companies can save time and money on their projects without compromising the quality of the final product. This is essential, given the increasing demand for construction works globally, where cost and time efficiency are critical.In conclusion, the Stud Profile C Purlin Cold Rolling Forming Production Line/stud U purlin roll forming machine from Zhiye Cold Forming Machinery Co., Ltd. is a significant innovation that will revolutionize the construction industry. The machine's advanced technology, coupled with its efficiency and precision, will ensure that construction companies can produce high-quality purlins quickly and cost-effectively. This will ultimately lead to faster project completion times and reduced costs, making it a popular choice in the industry.

High-Quality Deck Floor Forming Machine for Efficient Construction

Deck Floor Forming Machine Revolutionizes Construction IndustryThe construction industry is constantly evolving with new technologies and equipment that help to improve efficiency and productivity. One such innovation is the revolutionary Deck Floor Forming Machine, which is set to significantly impact the way floor decks are formed and constructed.The Deck Floor Forming Machine, developed by an industry-leading company known for their expertise in construction equipment, has been designed to streamline the process of forming floor decks. This state-of-the-art machine is capable of producing precision-engineered floor decks with remarkable speed and accuracy, effectively reducing construction time and labor costs.The machine’s advanced features include an automated system for forming and shaping floor decks, which eliminates the need for manual labor and significantly reduces the margin of error in construction. Its user-friendly interface makes it easy for construction workers to operate, allowing them to quickly and efficiently produce high-quality floor decks.In addition to its advanced capabilities, the Deck Floor Forming Machine is also environmentally friendly, consuming minimal energy and producing low levels of waste. This makes it an attractive option for construction companies looking to reduce their carbon footprint and operate in a more sustainable manner.The company behind the Deck Floor Forming Machine is known for their commitment to innovation and excellence in the construction industry. With a history of delivering cutting-edge equipment and machinery, they have established a reputation for reliability and performance in the market.Their dedication to quality and customer satisfaction has earned them the trust of construction professionals worldwide, who rely on their products to deliver exceptional results on the job site. The introduction of the Deck Floor Forming Machine further solidifies their position as a leader in the industry, offering a solution that addresses the evolving needs of the construction sector.The company’s expertise in engineering and manufacturing sets them apart in the market, allowing them to develop innovative solutions that meet the demands of modern construction projects. The Deck Floor Forming Machine is a testament to their commitment to pushing the boundaries of what is possible in construction technology, and it is poised to make a significant impact on the industry.With the introduction of the Deck Floor Forming Machine, construction companies can expect to see improvements in efficiency, cost-effectiveness, and overall quality of floor deck construction. This innovative solution is set to revolutionize the way floor decks are formed, providing construction professionals with a reliable and advanced tool to optimize their operations.As the construction industry continues to evolve, the demand for efficient and sustainable solutions becomes increasingly important. The Deck Floor Forming Machine represents a significant step forward in meeting these demands, offering a cutting-edge solution that is set to redefine the construction landscape.In conclusion, the introduction of the Deck Floor Forming Machine by this leading company is a testament to their ongoing commitment to innovation and excellence in the construction industry. With its advanced features and potential to optimize construction processes, this revolutionary machine is set to make a lasting impact on the way floor decks are formed and constructed. Construction professionals can look forward to improved efficiency, cost-effectiveness, and overall quality in their operations, thanks to this groundbreaking new technology.

Local Machine Shops & Manufacturing Services in Corman Park - Find Metal Connections and Quality Craftsmanship

Title: Streamlining Metal Profiles: Enhancing Machine Shop ManufacturingIntroduction:In today's ever-evolving industrial landscape, machine shops and manufacturing units play a crucial role in the production of metal profiles. These precise and essential components cater to the diverse needs of various industries. However, finding trustworthy and capable machine shops that specialize in metal profile manufacturing can be a challenge. In this blog, we will explore the significance of metal profile manufacturing, the role of machine shops in the process, and how businesses can benefit from high-quality and efficient services.Understanding Metal Profile Manufacturing:Metal profile manufacturing involves the creation of custom metal profiles using various techniques like cutting, bending, welding, and assembly. These profiles find extensive applications across industries ranging from aerospace and automotive to construction and machinery. Precision, accuracy, and durability are vital aspects of metal profile manufacturing, as these components often withstand demanding conditions and require reliable performance.The Importance of Machine Shops:Machine shops serve as the backbone of metal profile manufacturing, utilizing state-of-the-art machinery and a skilled workforce to craft precision profiles with utmost accuracy. These shops play a critical role in implementing and refining the manufacturing processes, ensuring that the final product meets the specific requirements and industry standards. A well-equipped machine shop possesses the machinery and expertise to handle projects of varying complexities and scales, delivering on time and within budget.Streamlining Manufacturing Processes:Modern machine shops leverage advanced technologies, such as computer numerical control (CNC) machines, to optimize the manufacturing process. CNC machines offer superior precision, consistency, and speed, resulting in reduced lead times, minimized waste, and enhanced product quality. By integrating cutting-edge software solutions, machine shops can create intricate profiles and streamline complex manufacturing procedures, offering clients highly customized and efficient solutions.Delivering Unparalleled Quality:When it comes to metal profile manufacturing, quality is of utmost importance. A reputable machine shop understands this requirement and employs rigorous quality control measures at every stage of the manufacturing process. From material selection and raw material inspection to final finishing and inspection, these shops adhere to strict quality standards, ensuring that the end product meets or exceeds client expectations. By partnering with reliable machine shops, businesses can secure access to high-quality metal profiles that are built to withstand tough conditions and deliver exceptional performance.Collaboration and Customization:Collaboration between machine shops and clients is crucial for successful metal profile manufacturing. Experienced machine shops work closely with businesses to understand their unique needs, providing comprehensive consultation and design assistance. By involving clients throughout the design and manufacturing stages, machine shops can ensure that the end product perfectly aligns with specific project requirements. This collaborative approach results in customized profiles that maximize efficiency, reliability, and cost-effectiveness.Conclusion:Metal profile manufacturing is a specialized field that requires the expertise of machine shops capable of meeting the specific needs of various industries. By embracing advanced technologies, implementing stringent quality control measures, and fostering collaborative relationships with clients, reputable machine shops deliver customized metal profiles that enhance efficiency, durability, and performance. Businesses looking for superior metal profiles must partner with trustworthy machine shops and reap the benefits of streamlined manufacturing processes and unparalleled quality.Keywords:Metal profile manufacturing, machine shops, precision, manufacturing processes, CNC machines, quality control, customization, collaboration, advanced technologies, efficiency, durability, performance.

High-quality Glazed Metal Tile Roll Forming Machine for Efficient Tile Production

The demand for construction materials continues to grow as the construction industry booms. With this in mind, a leading manufacturer in the construction machinery industry has introduced a new product that promises to revolutionize the way glazed metal tiles are produced. The company, which has been in the business for over 20 years, is proud to unveil their latest innovation - the Glazed Metal Tile Roll Forming Machine.The Glazed Metal Tile Roll Forming Machine is a state-of-the-art equipment that is designed to produce glazed metal tiles with high precision and efficiency. This machine is equipped with advanced technology and features, making it the perfect solution for companies looking to increase their production capacity and improve the quality of their products.One of the key features of the Glazed Metal Tile Roll Forming Machine is its ability to produce glazed metal tiles with different profiles and sizes. This flexibility allows companies to meet the varying demands of their clients and expand their product offerings. Additionally, the machine is easy to operate and maintain, reducing downtime and increasing productivity.Another standout feature of the Glazed Metal Tile Roll Forming Machine is its high-speed production capability. With a speed of up to 20 meters per minute, this machine can produce a large number of glazed metal tiles in a short amount of time. This not only helps companies meet tight deadlines but also reduces labor costs, making it a cost-effective solution for businesses.The Glazed Metal Tile Roll Forming Machine is also equipped with a cutting-edge control system, allowing for precise control of the production process. This ensures that each glazed metal tile is produced to the highest quality standards, meeting the stringent requirements of the construction industry. With this level of precision, companies can deliver superior products to their customers, enhancing their reputation and competitiveness in the market.In addition to its advanced features, the Glazed Metal Tile Roll Forming Machine is also designed with durability and reliability in mind. The machine is made of high-quality materials and components, ensuring long-term performance and minimal maintenance requirements. This reliability gives companies the peace of mind that their production line will run smoothly and efficiently, without unexpected downtime or costly repairs.Upon its launch, the Glazed Metal Tile Roll Forming Machine has received positive feedback from industry experts and customers alike. Many have praised its cutting-edge technology, high-speed production, and exceptional quality of output. Companies that have integrated this machine into their production line have reported significant improvements in their operational efficiency and product quality, leading to increased customer satisfaction and business growth.With the introduction of the Glazed Metal Tile Roll Forming Machine, this leading manufacturer has reaffirmed its commitment to driving innovation in the construction machinery industry. The company's dedication to research and development has resulted in a product that not only meets the current demands of the market but also sets new standards for quality and performance in glazed metal tile production.As the construction industry continues to expand, the demand for high-quality construction materials, such as glazed metal tiles, will only increase. The Glazed Metal Tile Roll Forming Machine offers companies a competitive edge, allowing them to meet the growing demand and deliver superior products to their customers. With its advanced technology, high-speed production, and exceptional quality, this machine is set to become a game-changer in the construction machinery industry.

Revolutionary Color Steel Glazed Tile Corrugation Machine Promises Unmatched Performance

[Title]: Innovative Color Steel Glazed Tile Corrugation Machine Revolutionizes Roofing Industry[Subtitle]: {Company Name}'s Cutting-edge Solution Takes Roofing Efficiency to New Heights[Date][City], [State] - {Company Name}, a renowned pioneer in the manufacturing industry, has recently unveiled its revolutionary Color Steel Glazed Tile Corrugation Machine, poised to transform the roofing industry worldwide. This cutting-edge technology promises exceptional efficiency and durability, empowering construction companies and homeowners alike with a game-changing roofing solution.With years of industry experience and a commitment to innovative designs, {Company Name} has overcome previous limitations seen in traditional glazed tile corrugation machines. By leveraging advanced engineering techniques, this new machine raises the bar in terms of speed, precision, and quality of output.The Color Steel Glazed Tile Corrugation Machine boasts an impressive range of features specifically designed to address the demands of modern roofing projects. Equipped with an intelligent control system, it offers heightened automation and precision, ensuring a seamless production process. Operators can effortlessly set parameters such as tile size, thickness, and curvature, thus greatly reducing human errors and increasing overall productivity.One of the key benefits of this state-of-the-art machine is its exceptional speed. With a production capacity of up to [X] tiles per minute, it significantly reduces manufacturing time, leading to shorter project timelines and improved customer satisfaction. This increased efficiency is complemented by the machine's ability to produce tiles of varying shapes and colors, allowing for greater customization to suit clients' specific aesthetic requirements.Moreover, the Color Steel Glazed Tile Corrugation Machine prioritizes durability and longevity. By utilizing high-quality materials such as reinforced steel and wear-resistant components, {Company Name} ensures that the machine can withstand continuous use over extended periods. This durability translates into cost savings for roofing companies, as maintenance costs and the frequency of machine replacement are drastically reduced.{Company Name}, an industry leader known for its commitment to environmental sustainability, has also incorporated eco-friendly elements into the design of their Color Steel Glazed Tile Corrugation Machine. By optimizing energy consumption and reducing waste materials during production, the machine aligns with global efforts to encourage sustainable development practices. This commitment not only benefits the environment but also enhances {Company Name}'s reputation as a socially responsible organization.In addition to its technical superiority, {Company Name} provides exceptional customer support and after-sales service. Their team of qualified technicians is readily available to assist clients with installation, training, and troubleshooting, ensuring a seamless transition to the new technology. Continuous software updates and technological advancements further guarantee that {Company Name} remains at the forefront of the roofing industry, offering the latest innovations to their customers.Looking ahead, {Company Name} is excited about the potential of their Color Steel Glazed Tile Corrugation Machine to disrupt the roofing industry on a global scale. With its streamlined production, exceptional durability, and eco-friendly features, this groundbreaking technology sets a new standard in efficiency, quality, and sustainability. Construction companies and homeowners can now benefit from a roofing solution that combines aesthetics with functionality, providing long-lasting protection for years to come.About {Company Name}:{Company Name} is a leading manufacturer and supplier of industrial machinery, renowned for its commitment to innovation and quality. With a rich history spanning over [X] years, they have earned a stellar reputation for providing cutting-edge solutions that empower businesses across various sectors. Committed to sustainable development, {Company Name} constantly strives to deliver eco-friendly and efficient products that meet the evolving needs of their customers.For more information, please visit: [Website URL]Press Contact:[Contact Name][Title][Company Name][Phone Number][Email Address]

High-Quality Corrugated Sheet Rolling Machine for Sale: A Complete Guide

[Company Name], a leading manufacturer of industrial machinery, has recently introduced a new Corrugated Sheet Rolling Machine that is set to revolutionize the industry. This state-of-the-art machine is designed to cater to the growing demand for high-quality corrugated sheets in the construction and manufacturing sectors.The Corrugated Sheet Rolling Machine is equipped with advanced technology and features that make it stand out in the market. It is capable of rolling corrugated sheets of varying thickness and widths, making it versatile and adaptable to different production needs. The machine is also designed for efficiency and productivity, ensuring a smooth and seamless production process.One of the key highlights of the Corrugated Sheet Rolling Machine is its durability and reliability. It is built to withstand heavy-duty usage and is engineered to deliver consistent results over an extended period of time. This makes it an ideal investment for companies looking to enhance their production capabilities and meet the growing demand for corrugated sheets.In addition to its technical capabilities, the Corrugated Sheet Rolling Machine is also designed with user-friendly features that make it easy to operate and maintain. This includes an intuitive control panel and a compact design that maximizes floor space in the production facility.[Company Name] has a long-standing reputation for delivering high-quality industrial machinery to its clients. With a track record of excellence in manufacturing and engineering, the company has established itself as a trusted partner for businesses in the construction and manufacturing sectors. The introduction of the Corrugated Sheet Rolling Machine further solidifies the company's commitment to innovation and customer satisfaction."We are delighted to introduce the new Corrugated Sheet Rolling Machine to the market," said [Spokesperson Name], the CEO of [Company Name]. "This is a testament to our dedication to providing cutting-edge solutions that empower our clients to achieve their production goals. We believe that this machine will set a new standard for quality and efficiency in the industry."The Corrugated Sheet Rolling Machine is set to make a significant impact on the industry, offering a reliable and efficient solution for businesses looking to streamline their production processes. With its advanced technology, robust construction, and user-friendly design, it is poised to become an indispensable asset for companies involved in the production of corrugated sheets.The launch of the Corrugated Sheet Rolling Machine is a reflection of [Company Name]'s commitment to providing innovative solutions that address the evolving needs of the industry. As the demand for high-quality corrugated sheets continues to grow, the company remains at the forefront of delivering machinery that empowers businesses to meet these demands with confidence and efficiency.With its reputation for excellence and its dedication to technological innovation, [Company Name] is poised to make a lasting impact with the introduction of the Corrugated Sheet Rolling Machine. As the industry looks towards the future, the company remains at the forefront, driving progress and delivering solutions that shape the way corrugated sheets are produced and utilized.

High-Quality Floor Tile Making Machine for Efficient Production

[Company Introduction]{Company Name} is a leading manufacturer of floor tile making machines, dedicated to providing innovative and high-quality products to meet the increasing demand in the construction industry. With years of experience and a strong commitment to research and development, {Company Name} has established itself as a trusted partner for businesses looking to invest in advanced machinery for their tile production needs.The company's state-of-the-art manufacturing facility, combined with a talented team of engineers and technicians, enables {Company Name} to design and produce cutting-edge floor tile making machines that are efficient, reliable, and cost-effective. Their focus on customer satisfaction and continuous improvement has earned them a reputation for excellence in the market.[News Content]In response to the growing demand for modern and durable floor tiles, {Company Name} has announced the launch of a new and improved floor tile making machine. This innovative machine is designed to revolutionize the tile manufacturing process, offering enhanced productivity, precision, and versatility.The new floor tile making machine boasts a range of advanced features that set it apart from traditional models. Equipped with the latest technology, the machine is capable of producing a wide variety of floor tiles in different sizes, shapes, and patterns, catering to the diverse needs of the construction industry. This versatility makes it an ideal choice for businesses looking to expand their product offerings and meet the evolving demands of the market.One of the key highlights of {Company Name}'s new floor tile making machine is its advanced automation capabilities. With intuitive controls and programmable settings, the machine allows for seamless operation and efficient production, minimizing the need for manual intervention and reducing the risk of errors. This not only enhances the overall productivity of the manufacturing process but also ensures consistently high-quality output, meeting the stringent standards of the industry.Furthermore, the new floor tile making machine is designed with durability and sustainability in mind. Constructed with robust materials and precision engineering, the machine is built to withstand the rigors of continuous operation, delivering reliable performance over the long term. In addition, it incorporates energy-efficient technologies that minimize power consumption and reduce the environmental impact of tile production, aligning with the growing emphasis on sustainability in the construction sector."We are thrilled to introduce our latest floor tile making machine to the market," said a spokesperson from {Company Name}. "With its advanced capabilities and enhanced performance, we believe that this machine will empower our customers to elevate their tile manufacturing processes and stay ahead in a competitive industry. We are committed to equipping businesses with the tools they need to succeed, and we are confident that our new machine will set new standards for efficiency and quality in tile production."{Company Name} is dedicated to providing comprehensive support to its customers, offering installation assistance, training, and ongoing technical service to ensure the seamless integration and optimal performance of the new floor tile making machine. Their commitment to customer satisfaction and industry leadership positions them as a trusted partner for businesses seeking reliable and innovative solutions for their tile manufacturing needs.In conclusion, the launch of {Company Name}'s new floor tile making machine represents a significant advancement in the industry, offering businesses the potential to enhance their production capabilities, expand their product offerings, and achieve greater efficiency and sustainability. With its cutting-edge features and proven track record of excellence, the machine is poised to make a meaningful impact on the tile manufacturing sector, reinforcing {Company Name}'s position as a leading provider of state-of-the-art machinery for the construction industry.

New Machine Technology Streamlines Panel Roll Forming Process

Panel Roll Forming Machine Revolutionizes the Manufacturing IndustryPanel roll forming machines have emerged as a game-changer in the manufacturing industry, allowing for faster, more efficient, and cost-effective production of various panel products. These machines eliminate the need for multiple steps and human intervention, automating the entire process and significantly increasing productivity.A panel roll forming machine, also known as a roll former, is a specialized equipment used for shaping metal sheets into desired profiles by continuous bending operations. This technology has revolutionized the manufacturing processes of different industries, including construction, automotive, aerospace, and many others.The use of panel roll forming machines has surged in recent years due to their ability to produce panel products with high precision and quality. By employing highly precise control systems, these machines ensure consistent shaping and bending of metal sheets, resulting in flawless end products. This precision has made them a go-to solution for industries that require uniformity and accuracy in their panel products.One of the key advantages of panel roll forming machines is their high production speed. Unlike traditional manufacturing processes, which involve multiple steps and longer lead times, roll forming machines enable continuous production without interruptions. By feeding metal sheets through the machine, it produces a constant flow of shaped panels, vastly reducing production time and enhancing efficiency.Furthermore, panel roll forming machines offer outstanding versatility. They can be adjusted to produce a wide range of profiles, such as C and Z purlins, roof and wall panels, decking sheets, and more. This flexibility allows manufacturers to cater to diverse customer needs without investing in separate machines for each profile. By simply adjusting the settings, a single roll forming machine can handle different profiles, leading to significant cost savings.The advent of computer numerical control (CNC) technology has further enhanced the capabilities of panel roll forming machines. CNC systems allow for precise control over the entire manufacturing process, ensuring consistent quality and reducing the chances of errors. With the help of CNC, manufacturers can create complex panel designs, intricate patterns, and embossments more accurately than ever before.In addition to increased productivity and versatility, panel roll forming machines contribute to sustainability efforts. By eliminating the need for excessive scrap material and reducing energy consumption, these machines help minimize environmental impacts. Manufacturers can optimize material usage, resulting in less waste generation, while the efficient energy utilization of panel roll forming machines significantly reduces carbon footprints.Company Introduction: {}With its commitment to innovation and excellence, the company has emerged as a leading provider of panel roll forming machines. Its state-of-the-art manufacturing facilities and cutting-edge research and development team ensure the quality and reliability of their products.The company's panel roll forming machines are known for their robust construction and advanced features. Equipped with modern control systems, these machines guarantee precise shaping and bending operations, delivering panel products of superior quality.At the core of the company's philosophy is customer satisfaction. It offers comprehensive after-sales service, including installation, training, and technical support, ensuring the smooth integration of their machines into the customers' production lines. The company's dedication to providing outstanding customer experiences has earned them a strong reputation in the industry.In conclusion, panel roll forming machines have revolutionized the manufacturing industry by automating and streamlining the production of panel products. These machines offer high precision, versatility, and increased production speed, resulting in cost-effective and efficient manufacturing processes. With their commitment to excellence, the company {} has become a reliable provider of panel roll forming machines, helping businesses across various industries thrive.

Advanced Metal Profile Machine for Precise and Efficient Production

Metal Profile Machine Enhances Precision and Efficiency in Company’s ProductionIn today’s competitive manufacturing industry, precision and efficiency are essential factors for success. With the introduction of the Metal Profile Machine at {company name}, the company has taken a significant step towards enhancing its production capabilities and meeting the demands of its clients more effectively.The Metal Profile Machine is a state-of-the-art equipment that has revolutionized the way {company name} fabricates metal profiles for various industrial applications. This advanced machine is equipped with cutting-edge technology that allows for high levels of precision and accuracy in shaping and cutting metal sheets. The result is a more efficient and cost-effective manufacturing process that ultimately benefits both the company and its customers.The implementation of the Metal Profile Machine aligns with {company name}’s commitment to staying at the forefront of technological advancements in the industry. With a focus on innovation and continuous improvement, the company has always sought out the latest tools and equipment to streamline its operations and deliver the highest quality products to its clients.The Metal Profile Machine has significantly enhanced the company’s ability to meet the specific requirements of its customers. With the capability to work with a wide range of metal materials and produce complex profiles with tight tolerances, {company name} can now take on a broader scope of projects and tailor its offerings to the unique needs of each client.Furthermore, the improved precision of the Metal Profile Machine has led to a reduction in material waste, as well as a decrease in the need for manual rework. This not only contributes to a more sustainable manufacturing process but also allows {company name} to optimize its resources and minimize production costs.In addition to the operational benefits, the Metal Profile Machine has also bolstered {company name}’s reputation for delivering top-quality products. The enhanced precision and consistency in the fabrication of metal profiles has resulted in a higher level of product reliability and performance, ultimately leading to greater customer satisfaction and loyalty.Mr. John Smith, the CEO of {company name}, expressed his enthusiasm for the acquisition of the Metal Profile Machine, stating, "We are thrilled to have this cutting-edge technology as part of our manufacturing capabilities. The Metal Profile Machine not only elevates our operational efficiency but also allows us to exceed the expectations of our clients in terms of quality and customization."The addition of the Metal Profile Machine has also opened up new opportunities for {company name} to explore and expand its product offerings. With the ability to produce intricate and bespoke metal profiles, the company is now able to cater to a wider range of industries, including automotive, aerospace, construction, and more.Moving forward, {company name} plans to further leverage the capabilities of the Metal Profile Machine to continue raising the bar in the metal fabrication sector. By harnessing the machine’s potential to innovate and optimize its production processes, the company aims to solidify its position as a leader in the industry and to be the go-to choice for clients seeking superior metal profiles.In conclusion, the introduction of the Metal Profile Machine at {company name} has been a game-changer for the company, allowing it to achieve new levels of precision, efficiency, and customization in its production processes. As the company continues to harness the full potential of this cutting-edge equipment, it is poised to set new standards in the manufacturing industry and deliver exceptional value to its clients.