High-quality Slitting Line for CR Metal Processing

By:Admin

The Cr Slitting Line is designed and manufactured by a leading company in the field of metal processing equipment. This company has a strong reputation for delivering high-quality, reliable and cost-effective solutions to its customers. With years of experience and expertise in the industry, the company has continuously pushed the boundaries of innovation to meet the evolving needs of its clients.

The introduction of the Cr Slitting Line is a significant milestone for the company and for the manufacturing industry as a whole. This state-of-the-art equipment is designed to streamline the process of slitting metal sheets, making it faster, more accurate and highly efficient. Its cutting-edge technology and precision engineering ensure superior performance and consistent results, setting a new benchmark in the industry.

One of the key features of the Cr Slitting Line is its ability to handle a wide range of materials and thicknesses, making it a versatile solution for various applications. Whether it's stainless steel, aluminum, carbon steel or other types of metal, this equipment can efficiently process them with ease. Its flexibility and adaptability make it an ideal choice for manufacturers looking to expand their capabilities and improve their production efficiency.

Furthermore, the Cr Slitting Line is equipped with advanced automation and control systems, ensuring optimal performance and ease of operation. Its intuitive interface and user-friendly controls allow operators to set up and run the equipment with minimal effort, reducing the risk of errors and increasing productivity. This makes it an ideal solution for both small-scale and large-scale manufacturers, offering a competitive advantage in today's fast-paced and competitive market.

In addition to its cutting-edge technology, the Cr Slitting Line is also designed with practicality in mind. Its compact footprint and modular design make it easy to integrate into existing production lines, saving valuable floor space and minimizing installation time. Its robust construction and durable components ensure long-term reliability and low maintenance requirements, maximizing uptime and reducing operational costs for manufacturers.

The introduction of the Cr Slitting Line has already garnered widespread attention and positive feedback from industry professionals and customers. Its performance and reliability have been put to the test in real-world applications, demonstrating its ability to deliver consistent and high-quality results. As a result, demand for this innovative equipment is on the rise, with manufacturers keen to take advantage of its benefits and stay ahead of the competition.

Looking ahead, the company behind the Cr Slitting Line remains committed to pushing the boundaries of innovation and delivering cutting-edge solutions to its customers. Its ongoing investment in research and development, combined with its strong focus on customer satisfaction, positions it as a leading provider of metal processing equipment. As the manufacturing industry continues to evolve, the company is well-positioned to meet the changing needs of its clients and drive the industry forward with its advanced technologies.

In conclusion, the introduction of the Cr Slitting Line marks a significant advancement in sheet metal processing technology. With its advanced features, versatile capabilities and exceptional performance, this innovative equipment is set to revolutionize the manufacturing industry. As demand for efficient and reliable metal processing solutions continues to grow, the company behind the Cr Slitting Line is poised to lead the way with its commitment to innovation and customer satisfaction.

Company News & Blog

Precision Coil Cut To Length Machine for Perfect Sheet Metal Cutting

Today, [Company Name] is excited to announce the launch of their new Coil Cut To Length Machine. This state-of-the-art machine is designed to revolutionize the metal processing industry by providing precision cutting and length measurement for a wide range of coil materials.The Coil Cut To Length Machine is the latest addition to [Company Name]'s extensive line of metal processing equipment. With over 20 years of experience in the industry, [Company Name] has earned a reputation for delivering high-quality, innovative solutions for metal fabrication and processing. The introduction of the new Coil Cut To Length Machine further solidifies their commitment to meeting the evolving needs of their customers.This cutting-edge machine offers unparalleled accuracy and efficiency, making it an essential tool for metal processing facilities of all sizes. The Coil Cut To Length Machine is capable of handling a variety of coil materials, including stainless steel, aluminum, copper, and more. Its advanced cutting technology ensures clean, precise cuts, while its length measurement system provides unmatched reliability and consistency.One of the standout features of the Coil Cut To Length Machine is its user-friendly interface. [Company Name] has prioritized ease of use in the design of this machine, ensuring that operators can quickly and effortlessly set up and operate the equipment. This not only enhances productivity but also reduces the potential for errors, ultimately saving time and resources for businesses.Furthermore, the Coil Cut To Length Machine is built to last. [Company Name] has incorporated robust, durable materials and components into the machine's construction, ensuring that it can withstand the rigors of continuous, heavy-duty use. Its longevity and durability make it a sound investment for metal processing facilities looking to optimize their operations for the long term.In addition to its cutting and length measurement capabilities, the Coil Cut To Length Machine also offers flexibility in terms of customization. [Company Name] understands that different businesses have unique requirements, which is why they offer the option to tailor the machine to specific needs. Whether it's adjusting cutting parameters, implementing additional safety features, or integrating the machine into an existing production line, [Company Name] is committed to delivering a solution that perfectly aligns with their customers' needs.The introduction of the Coil Cut To Length Machine represents [Company Name]'s ongoing dedication to innovation and customer satisfaction. By continuously developing and enhancing their product offerings, [Company Name] aims to empower metal processing facilities to achieve new levels of efficiency, productivity, and quality in their operations.In conclusion, the launch of the Coil Cut To Length Machine marks an exciting milestone for [Company Name] and the metal processing industry as a whole. With its cutting-edge technology, user-friendly design, and customizable features, this machine is poised to set a new standard for precision and reliability in coil cutting and length measurement. Businesses can trust [Company Name] to deliver a solution that not only meets but exceeds their expectations, driving success and growth in their metal processing endeavors.

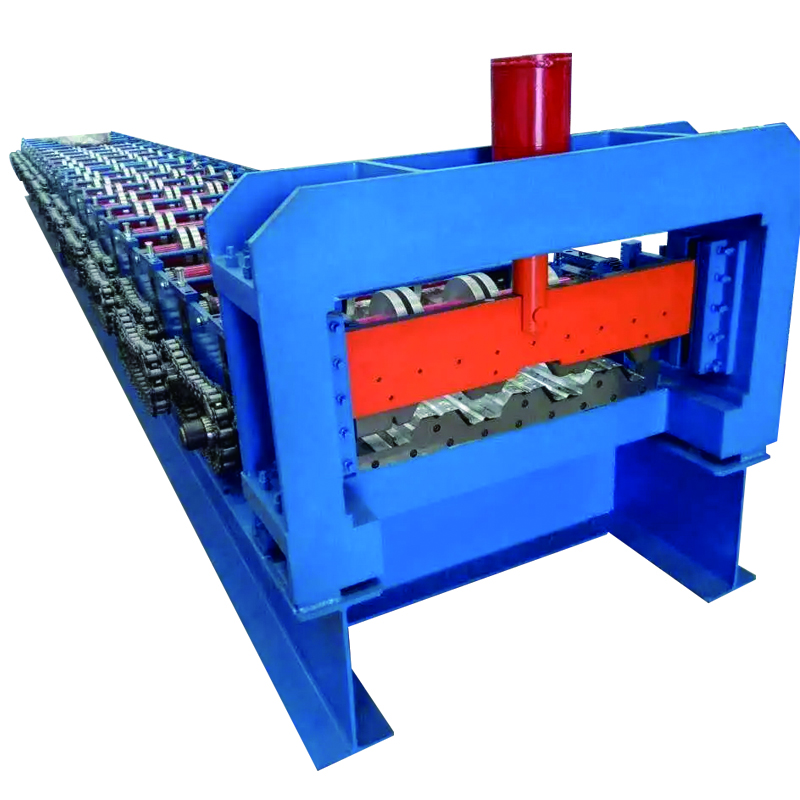

Durable and Efficient Double Deck Roll Forming Machine for High-Volume Production

The Double Deck Roll Forming Machine has recently gained popularity in the metal forming industry, and {} is at the forefront of this innovative technology. This advanced machine has the capability to produce double-layered metal sheets, which offers significant advantages in terms of cost efficiency and production speed.With a focus on providing high-quality roll forming solutions to meet the evolving needs of the industry, {} has been a key player in the development and deployment of the Double Deck Roll Forming Machine. This state-of-the-art equipment is designed to increase productivity and optimize the production process, making it an essential part of modern metal forming operations.One of the key features of the Double Deck Roll Forming Machine is its ability to produce two different profiles simultaneously. This capability enables manufacturers to achieve greater flexibility in their production processes, as well as the ability to meet diverse customer requirements. With this machine, {} has empowered its clients to deliver a wide range of customized metal products, while also improving their overall production efficiency.In addition to its dual-profile capability, the Double Deck Roll Forming Machine also offers enhanced efficiency through its advanced control system. With precise control over the forming process, this machine ensures consistent quality and accuracy in the production of metal sheets. This level of control not only enhances the overall product quality but also minimizes material waste, ultimately leading to cost savings for manufacturers.Moreover, the Double Deck Roll Forming Machine is designed with a modular configuration, allowing for easy customization to suit specific production needs. This flexibility has been a game-changer for many manufacturers, as it enables them to adapt their production lines to accommodate various design requirements and material specifications. As a result, {} has empowered its clients to expand their product offerings and capture new business opportunities in the competitive metal forming market.Furthermore, {} has positioned itself as a leading provider of turnkey solutions for the roll forming industry, offering comprehensive support and expertise in the implementation of the Double Deck Roll Forming Machine. From initial consultation to installation and training, the company is committed to ensuring that its clients fully maximize the potential of this cutting-edge technology. This customer-centric approach has earned {} a reputation for reliability and excellence in the industry.Looking ahead, {} continues to innovate and develop new technologies to further advance the roll forming industry. With a strong focus on research and development, the company is dedicated to staying ahead of market trends and delivering innovative solutions that meet the evolving needs of manufacturers. As the demand for efficient, high-quality metal forming equipment continues to grow, {} remains committed to providing state-of-the-art solutions that drive success for its clients.In conclusion, the Double Deck Roll Forming Machine is a game-changing technology that has revolutionized the metal forming industry, and {} is at the forefront of this innovation. Through its commitment to excellence and customer satisfaction, the company has cemented its position as a trusted partner for manufacturers seeking to optimize their production processes and achieve new levels of efficiency and productivity. As the industry evolves, {} will continue to lead the way in delivering advanced roll forming solutions that empower manufacturers to thrive in the competitive market.

C Purlin Roll Forming Machine: All You Need to Know

C purlin is an essential component of steel structures, widely used in purlins and wall beams of industrial and civil buildings. The C purlin roll forming machine is an advanced technological equipment that can automatically complete the forming process of C purlins according to the given size or drawing profiles.The C purlin roll forming machine is a single roll-forming unit that can produce a variety of C purlins. It is mainly composed of a passive loading frame, leveling device, punching device, cutting device after forming, hydraulic station, computer control system, and more. This machine adopts automatic flying saw punching and is easy to operate. The C purlin products rolled by this machine have good tensile and bending properties, excellent straightness, fully automatic fixed length cutting, automatic punching, high degree of automation, quick and convenient installation, and can be used as the main force structure, such as factory buildings, warehouses, garages, hangars, exhibition halls, theaters, stadiums, market sheds, and more.Cold-formed steel is the primary material used for making lightweight steel structures. It is processed by cold-bending the forming of steel plates or steel strips. C purlin is an excellent component because of its various properties, such as its lightweight and high strength. It is commonly used in industrial buildings because it can provide substantial support and load-bearing capacity without sacrificing the structural integrity of the building.The C purlin roll forming machine has a wide range of applications and is widely used in various fields. It is often used in the construction of roofs, walls, and floors of commercial and residential buildings, as well as in the manufacturing of mechanical equipment. The machine can produce C purlins with different specifications according to the height, such as 100, 120, 140, 160, 180, 200, 220, 250, and 300. The length can be determined according to the engineering design, but generally, the full length is no more than 12 meters to facilitate transportation and installation.The Fully Automatic C Purlin Roll Forming Machine is an advanced and efficient machine that can produce high-quality C purlins. It can improve the productivity and quality of C purlin production, save labor costs, and reduce the production time required for C purlin production. With the growth of the global construction industry, the demand for C purlins is on the rise. Therefore, the C purlin roll forming machine has become a crucial tool for steel fabricators, contractors, and construction companies to meet the growing demand for C purlins.In conclusion, the C purlin roll forming machine is an essential equipment in the steel structure industry. It is an advanced and efficient machine that can improve the quality and productivity of C purlin production. With the growth of the global construction industry, the demand for C purlins is increasing rapidly, which makes the C purlin roll forming machine even more important. The Fully Automatic C Purlin Roll Forming Machine is an excellent investment for steel fabricators, contractors, and construction companies, as it can result in significant cost savings and improve production efficiency.

Discover the Efficiency of Full Automatic C/Z Purlin Roll Forming Machines in the News

Full Automatic C/Z Purlin Roll Forming Machine Revolutionizes the Construction IndustryThe construction industry is undergoing a transformation, and the latest development is the full automatic C/Z purlin roll forming machine. This innovative machine is designed to simplify the production process of purlins, which are the structural elements used in roofing and wall frames of buildings, bridges, and other structures.The Full Automatic C/Z Purlin Roll Forming Machine is the result of years of research and development by a leading company in the industry. With advanced technology and precision manufacturing, this machine helps to save on production costs, reduce lead times, and improve the overall quality of the final product.The machine features a highly-advanced control system that enables operators to easily adjust its settings to fit the specific needs of their production. The machine also has a high level of automation, making it possible to produce purlins of consistent quality and accuracy.This new machine is expected to become the new standard in purlin production, as it offers benefits that traditional manufacturing methods cannot match. With its high degree of automation and precision, the machine can produce purlins that are perfectly straight and dimensionally accurate.In addition to its innovations in production technology, the Full Automatic C/Z Purlin Roll Forming Machine is also known for its safety features. The machine’s safety systems are designed to prevent accidents and ensure that operators can work safely and efficiently.The company behind the machine has a proven track record of success in the industry. With a commitment to quality and customer satisfaction, the company has become a leading provider of roll forming machines and related equipment.In addition to its expertise in machine design and manufacturing, the company also provides top-quality customer service. Its team of highly skilled technicians is available to provide support and assistance every step of the way, from installation and commissioning to maintenance and repair.The Full Automatic C/Z Purlin Roll Forming Machine is just the latest innovation from this company, which has been at the forefront of the industry for many years. By staying ahead of the curve and investing in advanced technology, the company has helped to drive the growth and success of the construction industry.Overall, the Full Automatic C/Z Purlin Roll Forming Machine is set to revolutionize the construction industry by introducing a new level of efficiency and precision to purlin production. With its advanced technology and user-friendly design, the machine is sure to become a key part of many successful companies’ operations and ultimately, the building of safer and better-quality structures.

Advanced Machine for Manufacturing Metal Steel Floor Webdeck with Roll Forming Technology

In the world of construction, commercial and industrial buildings require a strong foundation. And a solid floor deck is an integral part of laying the groundwork for any building's structure. In order to create a durable and robust floor deck, high-quality machines like the Floor Deck Roll Forming Machine are essential.Deck Floor Roll Forming Machines are designed to manufacture metal steel floor web decks. They are highly automated machines that can be customized according to specific requirements. The machine is used for producing metal floor decks of various design shapes and sizes. It makes it a crucial piece of equipment for the construction industry.One of the most significant advantages of the Roll Forming Machine is its versatility. It can produce metal decks with high precision and consistency, which cuts down waste and ensures quality control. Besides, you can quickly change the machine's settings to create different types of floor decks with varying thicknesses and sheet sizes.The Floor Deck Roll Forming Machine is also easy to operate, and it has a user-friendly interface. It comes with a control panel that makes it simple to set up the machine and adjust the speed. The machine is designed to produce decks at high speed, which enhances the productivity of the operation. The machine's efficiency is also boosted by its hydraulic system, which ensures stable and reliable performance.Additionally, the CZ Purlin Machine is ideal for producing metal floor decks with profiles for light steel framing. It has the capability of producing C and Z-shaped profiles that are commonly used for roof and wall framing. The machine has a simple and easy-to-use adjustment system that allows operators to tweak the profile's shape and size for different applications.In conclusion, the Floor Deck Roll Forming Machine is a must-have equipment for any construction or manufacturing company. It offers versatility, precision and consistency, which translates to quality products. It also has an efficient design, user-friendly interface and hydraulic system for high productivity. It's worth noting that manufacturers should limit themselves to remove brand names during promotions. So, if you're looking to produce metal floor decks for your construction projects, consider investing in a high-quality Roll Forming Machine.

Roll Forming Machine for Deck Floors: Enhancing Efficiency and Precision

[Company Introduction]With a strong reputation for excellence in the manufacturing industry, our company has been a leading provider of innovative machinery and equipment for the construction sector for over two decades. We are dedicated to continuously improving our products and services to meet the ever-evolving needs of our customers. Our commitment to quality and customer satisfaction has propelled us to the forefront of the industry.[News Content]In the realm of construction machinery, one particularly noteworthy addition to our product lineup is the highly efficient Deck Floor Roll Forming Machine. Designed to revolutionize the process of creating durable and reliable deck floors, this advanced equipment offers unprecedented precision and speed.The Deck Floor Roll Forming Machine effectively eliminates the traditional method of manually constructing deck floors, saving both time and labor costs. With its automated capabilities, it can swiftly and accurately produce high-quality deck floors that meet the stringent requirements of modern construction projects. The machine's cutting-edge technology ensures consistency and durability in every finished product.One of the key features of this machine is its versatility. It can produce a wide range of deck floor profiles, catering to the diverse needs of different construction projects. Whether it is a simple residential deck or a complex commercial structure, the machine can adapt to the specific requirements with ease. This flexibility makes it an ideal choice for construction companies of all sizes.Safety is paramount in any construction project, and the Deck Floor Roll Forming Machine prioritizes this aspect as well. The machine is equipped with the latest safety features, including emergency stop buttons, safety guards, and sensors to detect any potential malfunctions. This ensures a secure working environment for operators, minimizing the risk of accidents and injuries.To enhance productivity, the machine has been meticulously designed for ease of operation. Its user-friendly interface allows operators to quickly understand and control the various parameters of the roll forming process. Additionally, the machine's automated functions reduce the need for constant monitoring, allowing operators to focus on other essential aspects of the project.Moreover, the Deck Floor Roll Forming Machine is built to withstand the rigors of continuous operation. Its robust construction and high-grade materials ensure longevity and reliability, reducing downtime and maintenance costs. As a result, construction companies can seamlessly integrate this machine into their workflow, improving overall efficiency and profitability.As sustainability becomes an increasingly important consideration in the construction industry, the Deck Floor Roll Forming Machine aligns with eco-conscious practices. By significantly reducing material waste and minimizing energy consumption, the machine contributes to a more environmentally friendly approach to construction.With our extensive experience in the manufacturing industry, we provide comprehensive support and after-sales services for the Deck Floor Roll Forming Machine. Our team of skilled professionals is always on hand to offer technical assistance, training, and troubleshooting, ensuring that our customers receive uninterrupted productivity and optimum results.In summary, the Deck Floor Roll Forming Machine represents a significant advancement in the construction machinery sector. Its precision, versatility, safety features, ease of operation, and durability make it an invaluable asset for any construction company. Our company remains committed to delivering innovative solutions that meet the evolving needs of the industry, and we are confident that this machine will revolutionize deck floor production processes.

High-Quality Glazed Tile Roll Forming Machine for Sale - Best Price Guaranteed!

Title: Enhance Efficiency and Precision with the Glazed Tile Roll Forming MachineIntroduction:In the fast-paced construction industry, time and precision are paramount. The Glazed Tile Roll Forming Machine offers an efficient and reliable solution for producing high-quality glazed tiles quickly and accurately. As a leading manufacturer and supplier of glazed tile forming machines in China, we strive to provide state-of-the-art equipment that meets our clients' needs. In this blog, we will explore the benefits of using a Glazed Tile Roll Forming Machine and why it is crucial to contact us for your machinery requirements.1. What is a Glazed Tile Roll Forming Machine?A Glazed Tile Roll Forming Machine is a specialized piece of equipment designed to transform raw materials into elegantly-designed glazed tiles. It encompasses a series of forming rollers, cutters, and other components that shape the metal sheets into the desired tile profile. This automated process ensures consistency, precision, and a high production rate, eliminating the need for labor-intensive and time-consuming manual fabrication.2. Unraveling the Advantages:2.1 Impeccable Precision:The Glazed Tile Roll Forming Machine allows for precise control over the dimensions and specifications of each tile produced. With computer-aided design (CAD) software, it provides detailed and accurate customization, ensuring a seamless fit when installing the tiles. This level of precision translates into reduced wastage and increased customer satisfaction.2.2 High Production Rate:By automating the tile production process, the Glazed Tile Roll Forming Machine significantly enhances productivity. It can roll out a large number of tiles in a short period while maintaining consistency in shape, size, and quality. This enables contractors and manufacturers to meet deadlines efficiently and fulfill large-scale projects with ease.2.3 Versatility in Design and Dimensions:Our Glazed Tile Roll Forming Machine can create a wide range of tile profiles, including step tiles, corrugated tiles, and much more. Its flexibility allows customization to suit specific project requirements, providing architects and designers with endless possibilities for creative expression. Whether it's a traditional or contemporary architectural style, this machine can accommodate various designs flawlessly.2.4 Durability and Longevity:Utilizing high-quality materials and advanced manufacturing techniques, our Glazed Tile Roll Forming Machine ensures robustness and longevity. The sturdy construction guarantees reliable performance even in demanding working conditions, reducing maintenance costs and maximizing profitability.3. Why Choose Us?As a distinguished manufacturer and supplier, we provide a comprehensive range of Glazed Tile Roll Forming Machines to meet diverse industry needs. Here are a few reasons why you should consider partnering with us:3.1 Experience and Expertise:With years of experience in the industry, we have honed our manufacturing process to produce top-notch machinery. Our team of skilled engineers and technicians undergo continuous training to stay updated with the latest advancements, ensuring that our clients receive cutting-edge products.3.2 Tailored Solutions:We understand that every project has unique requirements, which is why our Glazed Tile Roll Forming Machines can be tailored to suit specific specifications. Whether it's dimensions, tile profiles, or any other customization, we work closely with our clients to deliver machines that align perfectly with their needs.3.3 Excellent Customer Support:Customer satisfaction is of utmost importance to us, and we strive to provide exceptional support at every stage – from product selection to after-sales services. Our dedicated team is always ready to assist you, ensuring a seamless and hassle-free experience.Contact Us:A Glazed Tile Roll Forming Machine is a valuable investment that can accelerate your business growth and elevate the quality of your tile production. If you are searching for a reliable and top-quality supplier, look no further. Contact us today to discuss your requirements and revolutionize your tile manufacturing process.

Metal Corrugated Roof Roll Forming Machine - A Comprehensive Guide for Roofing Applications

Metal Corrugated Roof Roll Forming Machine Revolutionizes the Roofing Industry In the highly competitive world of construction and architecture, innovation and technology have played a significant role in shaping the industry. One of the areas that have seen a lot of technological advancements is roofing, which has come a long way from traditional roofing materials such as asphalt shingles, clay tiles, and wood shingles. New roofing options such as metal corrugated roofing have become more popular for their durability, versatility, and aesthetic appeal, especially in commercial and industrial buildings.Metal corrugated roofing has gained its popularity because of its durability and strong resistance to weather and corrosion. Additionally, it’s lightweight compared to other traditional roofing materials, which makes it easier and cheaper to install. To meet the growing demand for metal corrugated roofing, companies have developed specialized machinery that can manufacture these roofing materials efficiently. The Metal Corrugated Roof Roll Forming Machine by (Company name removed) is a prime example of such innovation and technology in the roofing industry.The Metal Corrugated Roof Roll Forming Machine is a specialized device designed to bend and shape metal sheet materials into corrugated roof panels. The machine is computer-controlled, which ensures uniform accuracy in its operation. The machine works by feeding metal sheets through the straightening system; then, it passes through the rolling stations, which bend the sheets into corrugated shape. The machine has specialized shears designed to cut the length of the sheets, producing panels in a variety of dimensions, shapes, and gauges.The metal corrugated roofing panels produced using the Metal Corrugated Roof Roll Forming Machine are among the most durable roofing materials in the industry. They are resistant to many environmental factors, including water, wind, and fire. They have excellent thermal insulation properties that help maintain a comfortable indoor temperature, reducing energy costs. Unlike other roofing materials, which require frequent repair, metal corrugated roofs have minimal maintenance costs, making them an excellent investment for any property owner.Several factors make the Metal Corrugated Roof Roll Forming Machine stand out from other roll forming machines in the market. First, it’s highly customizable, allowing the machine to produce roofing panels in different shapes, dimensions, and gauges. The machine can also produce different coatings, including galvanized, pre-painted, or aluminum-zinc, providing customers with options to choose from. Additionally, the machine is highly efficient, capable of producing large volumes of corrugated roofing panels in a short time, thanks to its computer-controlled operation.The Metal Corrugated Roof Roll Forming Machine’s design has incorporated safety features such as guards, emergency stop buttons, and interlock systems to ensure the safety of the operator and enhance the machine's efficiency. The machine's design also allows for easy maintenance, with the operator having access to all critical components.The Metal Corrugated Roof Roll Forming Machine by (Company name removed) not only revolutionizes the roofing industry but also sets the standard for future roll forming machines. The machine's advanced technology, versatility, and efficiency enable users to produce high-quality metal corrugated panels that meet the roofing industry's stringent standards. The machine's design ensures that customers receive materials that are durable, cost-effective, and environmentally friendly.In conclusion, the Metal Corrugated Roof Roll Forming Machine has played a vital role in revolutionizing the roofing industry. Its advanced technology, versatility, and efficiency have set the standard for future roll forming machines, ensuring that customers receive high-quality metal corrugated panels that meet their roofing needs. The roofing industry will continue to benefit from such technological advancements that improve the efficiency of roofing material production, reducing costs while producing quality building materials.

Metal Steel IBR Roof Panel Roll Forming Machine - 820 Model for Quality Roof Sheet Making

If you're in the market for top-quality roofing panels, then look no further than the 820 Model Metal Steel IBR Roof Panel Roll Forming Machine. This impressive piece of machinery has been designed to provide roofing manufacturers with the ultimate in speed, accuracy, and ease of use, making it ideal for both small-scale operations and larger industrial applications.One of the standout features of the 820 Model Metal Steel IBR Roof Panel Roll Forming Machine is its use of advanced rolling technology that ensures consistent and precise shaping of the metal panels. This means that you can expect nothing but the very best quality products from this machine, with every panel guarantied to be of equal and consistent dimensional accuracy.Another great feature of this machine is its exceptional versatility. It's been designed to work with a range of different metal materials, including aluminum, copper, and zinc, making it a highly valuable tool for any roofing manufacturing business. This machine has been used successfully to create a wide range of roofing panels, including those designed specifically for industrial, commercial and residential properties.The 820 Model Metal Steel IBR Roof Panel Roll Forming Machine is also incredibly fast, with the ability to produce up to 25 meters of roofing per minute. This cutting-edge machine is perfect for those businesses that need to keep up with the demands of their customers. With such a fast output capacity, you can be sure that your business will be able to produce large volumes of roofing panels quickly and efficiently.Additionally, this particular model is incredibly easy to operate, thanks to its user-friendly design. Its integrated control panel makes operation a breeze, and the machine is fully automated, which means that it requires very little intervention from workers. As a result, it's perfect for businesses looking to increase efficiency and productivity by reducing the amount of manual labor required.In conclusion, the 820 Model Metal Steel IBR Roof Panel Roll Forming Machine is one of the best machines in its class when it comes to creating high-quality roofing panels. Its advanced rolling technology ensures consistent and precise shaping of the panels every time. Additionally, it's incredibly versatile, fast, and easy to operate, making it an excellent investment for any roofing manufacturing business. So, if you're in the market for a top-of-the-line Ibr Sheet Making Machine, this one should be at the top of your list.

C Shape Purlin Forming Machine: Transforming the Construction Industry

article.C Shape Purlin Forming Machine: The Ultimate Solution for Construction IndustryIn recent years, the global construction industry has undergone massive creativity and innovation, giving rise to new designs and architectures. One of the critical components of these new designs is the C-shaped purlin, which provides structural support and stability to the buildings. However, the traditional manual production of C-shaped purlin is cumbersome, time-consuming, and sometimes inaccurate.To address this challenge, many construction companies are turning to C Shape Purlin Forming Machine. This advanced machine offers a fast, efficient, and accurate way to manufacture C-shaped purlins, thus improving the quality of the final product.One of the leading manufacturers of C shape purlin forming machines in the global market is a reputable manufacturing company (). The company has been in the industry for several years and has built a reputation for producing high-quality and durable machinery to cater to various industrial needs.The C shape purlin forming machine from the company has a unique design and features that make it ideal for any construction project. It is made of high-grade materials, ensuring durability, longevity, and reliability. Additionally, it has an advanced electronic control system that enables automatic production, further enhancing efficiency.The machine's versatility allows it to produce different sizes and shapes of purlins, making it an ideal choice for any construction project. Whether you are working on a commercial, residential, or industrial structure, the C shape purlin forming machine will deliver quality and efficiency.Another critical aspect of the machine is its user-friendly nature. Operators can easily control and adjust the forming parameters, ensuring that the final product meets the required standards. Additionally, the machine has a low maintenance cost, thus allowing business owners to save on expenses.The C Shape Purlin Forming Machine has revolutionized the construction industry by providing an efficient, cost-effective, and accurate method of producing C-shaped purlins. The machine has been a game-changer, enabling business owners to meet the increasing demand for high-quality and reliable purlins.Furthermore, the machine's electronic controls and advanced features enable it to produce purlins with high precision and accuracy, further improving the final product's quality. This has led to increased customer satisfaction and repeat business, further boosting profitability.In conclusion, the C Shape Purlin Forming Machine is the ultimate solution for the construction industry. Its advanced features, durability, and versatility make it an ideal choice for any construction project. Additionally, its user-friendly nature and low maintenance cost make it an excellent investment for business owners. With the increasing demand for high-quality and reliable purlins, investing in this machine is a wise decision for any construction company. Contact reputable manufacturing company () today and take your construction business to the next level.