High-Quality Stud and Track Machine for Efficient Construction Operations

By:Admin

The construction industry has seen impressive advancements in technology over the past few decades, and one of the most noteworthy innovations in recent years is the stud and track machine. This cutting-edge piece of equipment has completely revolutionized the way construction projects are carried out, making the entire process more efficient, cost-effective, and precise.

The stud and track machine, produced by {Company Name}, is a state-of-the-art piece of equipment that is used for rapidly producing metal studs and tracks, which are essential components in modern construction projects. This machine has the capability to automatically feed, punch, and cut metal coils into specific lengths and shapes, drastically reducing the time and labor required for these tasks.

{Company Name} is a leading manufacturer of construction machinery, with a proven track record of delivering high-quality, innovative solutions to the industry. The company is committed to staying at the forefront of technology, and the stud and track machine is a testament to their dedication to providing cutting-edge equipment to their customers.

The stud and track machine has a range of features that set it apart from traditional construction methods. One of the most significant advantages is the speed at which it can produce metal studs and tracks. The machine is capable of producing up to 600 studs per hour, significantly faster than traditional methods, which require manual cutting and punching. This increased production rate allows construction projects to be completed in a shorter timeframe, saving both time and money for contractors and developers.

In addition to its speed, the stud and track machine also ensures precision and accuracy in the production of metal studs and tracks. The machine is equipped with advanced technology that allows for precise measurements and cuts, resulting in uniformly sized and shaped components. This level of precision is crucial in construction projects, as it ensures that the components fit together seamlessly, leading to a more structurally sound and aesthetically pleasing finished product.

Furthermore, the stud and track machine also offers flexibility in terms of the types of metal it can work with. The machine is capable of processing various types of metal coils, including galvanized steel, stainless steel, and aluminum, allowing for versatility in construction projects. This flexibility is invaluable as construction projects often require different types of metal components, and the ability to produce them on-site is a major advantage.

Another significant benefit of the stud and track machine is its cost-effectiveness. By automating the production of metal studs and tracks, the machine reduces the need for manual labor, thus cutting down on labor costs. Additionally, the increased production rate means that contractors can complete projects more quickly, saving on overall project costs. This cost-effectiveness makes the stud and track machine a highly desirable investment for construction companies, as it not only saves money but also increases productivity and efficiency.

{Company Name} has received overwhelmingly positive feedback from its customers who have integrated the stud and track machine into their construction projects. Contractors and developers have praised the machine for its speed, precision, and cost-effectiveness, stating that it has significantly enhanced the efficiency of their operations. The machine has also received recognition from industry experts, earning awards and accolades for its innovative design and impact on the construction industry.

In conclusion, the stud and track machine produced by {Company Name} has made a significant impact on the construction industry, revolutionizing the way metal studs and tracks are produced. Its speed, precision, flexibility, and cost-effectiveness make it an invaluable asset for contractors and developers, allowing them to complete projects more efficiently and economically. As technology continues to advance, it is innovations like the stud and track machine that will drive the construction industry forward into the future.

Company News & Blog

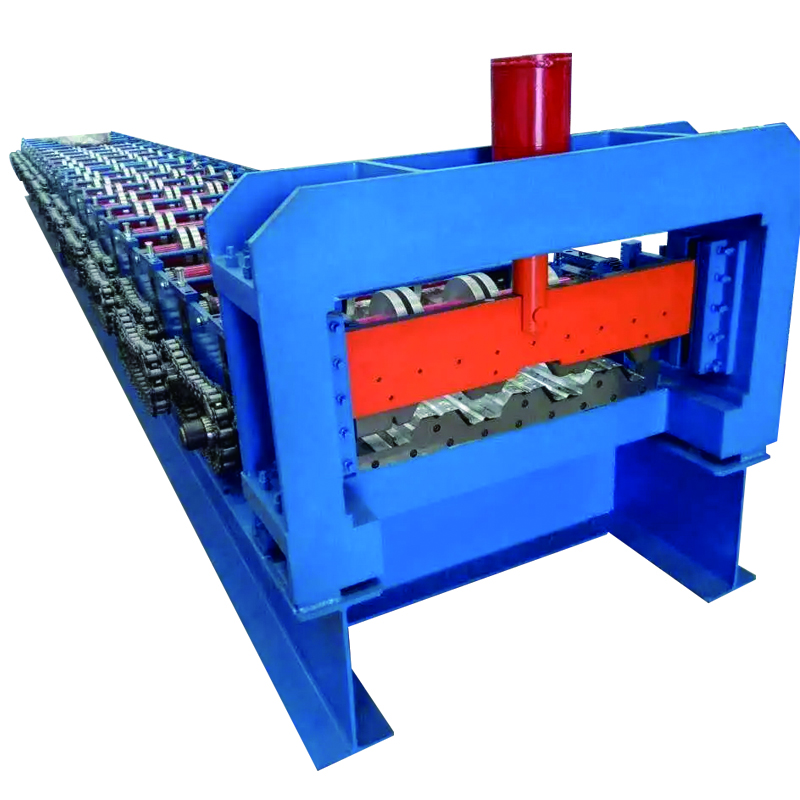

High-Quality Floor Deck Forming Machine for Efficient Construction Projects

Floor Deck Forming Machine Revolutionizes Construction Industry{Company Name}, a leading manufacturer in the construction machinery industry, has recently launched its latest innovation - the Floor Deck Forming Machine. This revolutionary machine is set to transform the way floor decking is produced in the construction industry, bringing about increased efficiency, accuracy, and cost savings.The Floor Deck Forming Machine is designed to streamline the process of manufacturing floor decks, which are essential components in construction projects. Traditionally, floor decks are formed using manual labor or outdated machinery, leading to inconsistencies in production and higher costs. However, with the introduction of {Company Name}'s Floor Deck Forming Machine, these challenges are set to become a thing of the past.The machine is equipped with state-of-the-art technology and the latest advancements in engineering, allowing for the precise production of floor decks in a highly efficient manner. With the ability to produce a wide range of floor deck profiles and sizes, the machine is versatile and adaptable to various construction project requirements.One of the key features of the Floor Deck Forming Machine is its high-speed production capabilities. The machine is capable of producing floor decks at a rapid pace, significantly reducing lead times and increasing overall production output. This not only improves project timelines but also allows for cost savings in labor and resources.In addition to speed, the Floor Deck Forming Machine also boasts exceptional accuracy and consistency in production. The machine's advanced automation ensures that each floor deck is manufactured to precise specifications, resulting in high-quality and uniform products every time. This level of precision is essential in ensuring structural integrity and safety in construction projects.Furthermore, the Floor Deck Forming Machine is designed with user-friendliness in mind. Its intuitive interface and easy-to-use controls make operation straightforward, allowing for seamless integration into existing manufacturing processes. This ease of use minimizes the need for extensive training and reduces the likelihood of errors during production.{Company Name} has a strong reputation for delivering reliable and innovative machinery to the construction industry. With a commitment to quality and customer satisfaction, the company's Floor Deck Forming Machine is backed by comprehensive technical support and after-sales service. This provides peace of mind to customers, knowing that they can rely on {Company Name} for ongoing assistance and maintenance of their machinery.The introduction of the Floor Deck Forming Machine is expected to have a significant impact on the construction industry. Its ability to streamline production, improve efficiency, and deliver high-quality results is set to benefit construction companies, contractors, and builders alike. The machine's cost-effective production process also has the potential to reduce overall project costs, making it an attractive investment for businesses in the construction sector.In conclusion, {Company Name}'s Floor Deck Forming Machine is a game-changer for the construction industry. Its advanced technology, high-speed production capabilities, and precision engineering set a new standard for floor deck manufacturing. With a focus on delivering reliable and innovative solutions, {Company Name} continues to demonstrate its commitment to driving progress and excellence in the construction machinery industry.

High Precision Cut To Length Line Metal Sheet Cutting Machine for Efficient Sheet Metal Slitting

and Sheet Metal Slitter Machine.When it comes to cutting metal sheets, it is imperative to have a reliable and precise Cut-To-Length Machine and Sheet Metal Slitter Machine. These machines are designed to offer efficient precision cutting of metal sheets, which is essential in most metal fabrication industries. The High Precision Cut-To-Length Line Metal Sheet Cutting Machine/Sheet Metal Slitter Machine is among the most sought after machines in the market today.This machine is made using high-quality materials that guarantee its durability and efficiency. The machine is specifically designed to cut metal sheets into specific sizes, lengths, and widths, making it ideal for various metal fabrication projects. It utilizes high precision sensors that measure and cut metal sheets according to the desired lengths.One of the benefits of this machine is its ability to deliver high precision cutting. The machine is designed to deliver accurate and consistent cuts that meet your specifications. This is essential in ensuring that the finished products meet the required standards, and there is no wastage of materials.The High Precision Cut-To-Length Line Metal Sheet Cutting Machine/Sheet Metal Slitter Machine is also versatile. It can be used to cut different types of metal sheets, including aluminum, galvanized, cold-rolled, and stainless steel. This makes it ideal for use in different industries such as construction, automotive, and aerospace.Another advantage of this machine is its efficiency. The machine is designed to operate at high speeds, enabling it to cut several metal sheets within a short period. This not only saves time but also increases production capacity, which is essential in meeting high demand in the market.In conclusion, the High Precision Cut-To-Length Line Metal Sheet Cutting Machine/Sheet Metal Slitter Machine is a vital investment for any metal fabricator. It offers high precision cutting, versatility, and efficiency, which are essential in meeting the demands of the market. If you are looking to enhance your metal fabrication business's productivity, then this machine is a must-have.

Looking for a Quality Horizontal 3D Panel Machine at Factory Price? Check Out Top China Manufacturers Now!

article as follows:A breakthrough technology in the construction industry has taken the market by surprise. The Horizontal Barrel Vault Panel Manufacturing Machine has revolutionized the way buildings are made. With its innovative design and high-quality production, it has become the new standard for construction.The Horizontal Barrel Vault Panel Manufacturing Machine was created by industry experts to address the growing demand for more efficient and reliable building solutions. It produces a unique and durable product that significantly reduces construction time, labor, and cost. It is a game-changer in the construction industry that has been waiting for a new, more efficient way to build.The technology behind the Horizontal Barrel Vault Panel Manufacturing Machine is state-of-the-art, incorporating the latest in manufacturing technologies. It uses horizontal 3D panel technology, which results in panels that are extremely strong, rigid, and lightweight. This means that builders can construct taller, more extensive structures faster and with less cost.The Horizontal Barrel Vault Panel Manufacturing Machine was developed with a focus on energy efficiency, and environmental sustainability. It uses eco-friendly materials that are environmentally friendly, making it a go-to choice for architects and engineers. It has a low carbon footprint, uses less energy, and reduces waste, making it a cost-effective and sustainable solution.The machine’s use of horizontal 3D panels makes it more versatile and adaptable than traditional construction methods. The panels can be used to create long spans, and the machine can produce panels of various shapes and sizes. This flexibility opens up a whole new world of possibilities for architects and builders to create complex and visually appealing structures.The Horizontal Barrel Vault Panel Manufacturing Machine is user-friendly and efficient, with excellent automation features that reduce the likelihood of human error. It has an integrated control system that allows users to input specific measurements, produces the desired panels, and reduces waste. The intuitive interface makes it easy for beginners to operate, and the machine requires minimal maintenance.Several companies in China manufacture and supply the Horizontal Barrel Vault Panel Manufacturing Machine. The cost of the machine varies. However, buyers should expect a higher initial investment in exchange for long-term cost savings and faster construction. The suppliers offer after-sale services such as installation, training, and maintenance, ensuring a seamless switch to the new construction method.The Horizontal Barrel Vault Panel Manufacturing Machine has proved its value in several projects worldwide. It has been used in the construction of commercial buildings, residential homes, and industrial facilities. Its use reduces construction time by up to 50 percent, lowers labor costs, and produces more durable buildings that withstand earthquakes and natural disasters.In conclusion, the Horizontal Barrel Vault Panel Manufacturing Machine is the future of the construction industry. It offers innovative and sustainable solutions that make construction cheaper, faster, and safer. Its benefits are immense, and it’s only a matter of time before it becomes the norm in the construction industry. As the market becomes more competitive and demanding, the Horizontal Barrel Vault Panel Manufacturing Machine offers a significant edge, providing builders with the tools they need to build better, more sustainable, and efficient structures.

Essential Guide to Corrugated Roof Rollers: What You Need to Know

Corrugated Roof Roller: Revolutionizing Roofing Solutions{Company name}, a leading innovator in the construction and roofing industry, has recently unveiled its latest product - the Corrugated Roof Roller. This cutting-edge tool is set to revolutionize the way corrugated roofing is installed, bringing efficiency and precision to the roofing process.The Corrugated Roof Roller is designed to effortlessly roll and shape corrugated roofing materials, providing a seamless and uniform finish that is both aesthetically pleasing and durable. With its ergonomic design and advanced technology, this innovative tool is set to streamline the roofing process, saving time and labor costs for construction and roofing professionals.{Company name} has been a pioneer in providing high-quality and innovative solutions to the construction industry for over two decades. Their commitment to excellence and dedication to meeting the evolving needs of the market has propelled them to the forefront of the industry. With a team of experienced engineers and technicians, {company name} continuously strives to develop cutting-edge tools and equipment that redefine industry standards.The Corrugated Roof Roller is a testament to {company name}'s ingenuity and commitment to innovation. By understanding the challenges faced by construction and roofing professionals, {company name} has developed a tool that not only simplifies the roofing process but also enhances the overall quality of the finished product.One of the key features of the Corrugated Roof Roller is its versatility. It is designed to work with a wide range of corrugated roofing materials, including metal, plastic, and composite materials. This versatility makes it an indispensable tool for roofing professionals who work with different types of roofing materials on a regular basis.In addition, the Corrugated Roof Roller is equipped with advanced control systems, allowing users to adjust the rolling speed and pressure according to the specific requirements of the roofing material being used. This level of precision ensures a consistent and flawless finish, eliminating the need for manual adjustments and reducing the margin for error.The ergonomic design of the Corrugated Roof Roller also sets it apart from conventional roofing tools. Its lightweight and portable construction make it easy to handle, reducing strain and fatigue for the user. This ultimately leads to improved productivity and efficiency on the job site.Furthermore, the Corrugated Roof Roller is designed with durability in mind. Constructed with high-quality materials and precision engineering, this tool is built to withstand the rigors of the construction site, ensuring reliable performance and longevity.{Company name} is dedicated to providing comprehensive support to its customers, and the launch of the Corrugated Roof Roller is no exception. In addition to offering the latest in roofing technology, {company name} provides comprehensive training and technical support to ensure that customers can maximize the benefits of this innovative tool. With a commitment to customer satisfaction, {company name} sets itself apart as a trusted partner for construction and roofing professionals.The launch of the Corrugated Roof Roller marks a significant milestone for {company name} as it continues to lead the way in providing innovative solutions to the construction industry. With a track record of excellence and a commitment to pushing the boundaries of innovation, {company name} remains a driving force in shaping the future of construction and roofing.In conclusion, the Corrugated Roof Roller from {company name} represents a significant advancement in roofing technology. With its advanced features, versatility, and commitment to quality, this revolutionary tool is set to redefine the standard of corrugated roofing installation. As {company name} continues to push the boundaries of innovation, the Corrugated Roof Roller stands as a testament to their dedication to providing industry-leading solutions to construction professionals.

High-Quality Steel Frame Roll Forming Machine for Efficient Production

Steel Frame Roll Forming Machine has become an essential equipment in the construction industry, especially for the production of steel frames for buildings. With the increasing demand for sustainable and cost-effective building solutions, the importance of efficient and high-quality roll forming machines cannot be overstated.One company that has been making a significant impact in the roll forming machine industry is {}. They have been leading the way in manufacturing and supplying state-of-the-art roll forming machines for various applications, including steel frame production. Their commitment to innovation and quality has made them a trusted name in the industry.The Steel Frame Roll Forming Machine produced by {} is designed to meet the specific requirements of the construction industry. It is capable of producing high-quality steel frames with precision and efficiency, making it an ideal choice for construction companies looking to streamline their production processes. The machine is equipped with advanced features such as automatic control systems, quick changeover capabilities, and high-speed production, ensuring superior performance and productivity.In addition to its impressive technical capabilities, the Steel Frame Roll Forming Machine from {} is also known for its durability and reliability. The machine is built with high-quality materials and components, ensuring long-term performance and low maintenance costs. This makes it a cost-effective investment for construction companies looking to enhance their production capabilities.Furthermore, {} offers comprehensive support and after-sales services for their Steel Frame Roll Forming Machine, including installation, training, and maintenance. This ensures that their customers can maximize the potential of the machine and achieve the best possible results in their steel frame production.The company's commitment to customer satisfaction and excellence has earned them a strong reputation in the industry. They work closely with their clients to understand their specific requirements and provide tailored solutions that meet and exceed expectations. Their dedication to quality and innovation has set them apart as a leading provider of roll forming machines for the construction industry.As the construction industry continues to grow and evolve, the demand for efficient and reliable steel frame production equipment is expected to rise. Companies like {} are well-positioned to meet this demand with their advanced Steel Frame Roll Forming Machine, innovative technologies, and exceptional customer service.In conclusion, the Steel Frame Roll Forming Machine from {} is a testament to the company's commitment to excellence and innovation. With its advanced features, exceptional performance, and reliable support services, it is no wonder that {} has become a trusted name in the roll forming machine industry. As the construction industry continues to embrace sustainable and cost-effective building solutions, the demand for high-quality steel frame production equipment is expected to grow, and {} is well-prepared to meet this demand with their cutting-edge roll forming machines.

Discover an Efficient and High-Quality Light Steel Roll Forming Machine

Title: Innovative Light Steel Roll Forming Machine Revolutionizes Construction IndustryIntroduction:In an era driven by innovation and technology, the construction industry has witnessed a remarkable breakthrough with the introduction of the Light Steel Roll Forming Machine. This cutting-edge machine is set to transform the traditional construction methods by providing a fast, efficient, and cost-effective solution for the production of light steel frames. By eliminating the need for labor-intensive and time-consuming practices, this technology promises to revolutionize the construction industry worldwide.Revolutionizing Construction with Light Steel Roll Forming Machine:With the growing demand for faster and more sustainable construction processes, the Light Steel Roll Forming Machine has emerged as a game-changer. The machine works by passing steel coil strips through a series of precisely aligned rollers, effectively shaping them into specific profiles required for constructing lightweight steel frames. This automated process not only ensures consistency in manufacturing but also significantly reduces manual labor, minimizing the risk of human error.The Benefits of Light Steel Roll Forming Machine:1. Efficiency: The Light Steel Roll Forming Machine can achieve high production speeds, leading to faster completion of projects. It has the ability to produce lightweight steel frames at a rate of several meters per minute, accelerating the construction process considerably. This increased efficiency translates into shorter project timelines and reduced labor costs.2. Cost-effectiveness: By automating the manufacturing process, the Light Steel Roll Forming Machine significantly reduces labor costs. Furthermore, its sophisticated design ensures minimal material wastage, optimizing resource utilization. As the machine requires fewer workers and allows for higher productivity, construction companies can achieve significant cost savings.3. Quality and Precision: The Light Steel Roll Forming Machine boasts advanced technology that guarantees superior quality and precision in the manufacturing process. Each steel profile is precisely molded according to the required specifications, ensuring consistency throughout the construction project. The machine also allows for customization, enabling architects and builders to create unique designs effortlessly.4. Sustainability: As environmental concerns become increasingly crucial, the Light Steel Roll Forming Machine offers a sustainable alternative to conventional construction methods. Light steel frames are recyclable, minimizing waste and reducing the carbon footprint. Moreover, the machine's efficient production process requires less energy compared to traditional techniques, contributing to a greener and more sustainable construction industry.Market Potential and Company Introduction:The global construction industry is witnessing rapid expansion, presenting immense opportunities for manufacturers of the Light Steel Roll Forming Machine. The market demand for faster and cost-effective construction methods continues to rise, making the machine a highly sought-after solution. One prominent manufacturer in this industry, {}, has gained recognition for its innovative approach and commitment to excellence.With years of experience in designing and producing roll forming machines, {} has positioned itself at the forefront of the industry. By leveraging cutting-edge technology and expertise, the company has developed a range of Light Steel Roll Forming Machines that cater to diverse construction needs. With a focus on quality, efficiency, and customer satisfaction, {} continues to revolutionize the construction industry worldwide.Conclusion:The introduction of the Light Steel Roll Forming Machine marks a significant milestone in the construction industry. This advanced technology offers an efficient, cost-effective, and sustainable solution for the production of lightweight steel frames. With the potential to streamline construction processes and deliver high-quality results, this machine promises to shape the future of the industry. As manufacturers like {} continue to innovate, the adoption of the Light Steel Roll Forming Machine is expected to become widespread, transforming construction practices on a global scale.

High-Quality Iron Sheets Making Machine for Efficient Production

Iron Sheets Making Machine Unveiled by Leading Manufacturer{Company Name}, a leading manufacturer of industrial equipment, has unveiled its latest innovation - the Iron Sheets Making Machine. The new machine is expected to revolutionize the production of iron sheets, making the process more efficient and cost-effective for manufacturers in the construction and manufacturing industries.The Iron Sheets Making Machine is designed to produce high-quality iron sheets with precision and speed. It is equipped with state-of-the-art technology that enables it to cut, bend, and shape iron sheets with incredible accuracy. The machine also has a high production capacity, allowing manufacturers to meet the growing demand for iron sheets in the market.{Company Name} has a long-standing reputation for producing top-of-the-line industrial equipment, and the Iron Sheets Making Machine is no exception. The company has invested heavily in research and development to ensure that the new machine meets the highest standards of quality and performance. The result is a cutting-edge machine that is poised to set a new benchmark in the industry.In addition to its impressive technical capabilities, the Iron Sheets Making Machine is also designed with user-friendliness in mind. The machine features intuitive controls and a user-friendly interface, making it easy for operators to set up and operate the machine with minimal training. This will help manufacturers streamline their production processes and reduce the time and resources required to produce iron sheets.As a company, {Company Name} is committed to driving innovation in the industrial sector. The unveiling of the Iron Sheets Making Machine is a testament to this commitment, showcasing the company's dedication to pushing the boundaries of what is possible in industrial equipment design and manufacturing. The company's team of engineers and technicians have worked tirelessly to bring this cutting-edge machine to the market, and the results speak for themselves.The Iron Sheets Making Machine is expected to have a significant impact on the iron sheet manufacturing industry. With its ability to produce high-quality iron sheets at a rapid pace, the machine will allow manufacturers to increase their production capacity and meet the growing demand from the construction and manufacturing sectors. This, in turn, will contribute to the overall growth and development of the industry.{Company Name}'s unwavering commitment to quality and innovation has positioned it as a leader in the industrial equipment market. The unveiling of the Iron Sheets Making Machine is yet another milestone in the company's journey to provide cutting-edge solutions to its customers. With its track record of delivering reliable and high-performance equipment, it comes as no surprise that the company's latest offering has already generated significant interest and excitement in the market.In conclusion, the introduction of the Iron Sheets Making Machine by {Company Name} represents a significant advancement in industrial equipment technology. The machine's advanced capabilities, user-friendly design, and potential to drive efficiency and productivity in the manufacturing sector make it a game-changer for the industry. As the demand for iron sheets continues to grow, {Company Name} is well-positioned to meet the needs of manufacturers with its latest innovation.

High-Quality Floor Production Roll Forming Machine for Efficient Manufacturing

Floor Production Roll Forming Machine: Revolutionizing the Manufacturing IndustryIn the competitive world of manufacturing, efficiency and quality are paramount. Manufacturers are constantly seeking state-of-the-art machinery and equipment to streamline their production processes and improve the overall quality of their products. With this in mind, the industry leader in roll forming machine technology, {Company Name}, is proud to introduce its latest innovation - the Floor Production Roll Forming Machine. This cutting-edge machine is set to revolutionize the production of floor panels, offering unparalleled precision, speed, and reliability.The Floor Production Roll Forming Machine is designed to meet the demands of modern manufacturing, offering a range of features that set it apart from traditional roll forming machines. With its advanced technology and innovative design, this machine is capable of producing high-quality floor panels with exceptional speed and accuracy. Its precision-engineered rollers and cutting tools ensure that each panel is produced to exact specifications, with minimal wastage and defects. This level of precision is essential for manufacturers seeking to meet the stringent quality standards of today's market.One of the key advantages of the Floor Production Roll Forming Machine is its versatility. Whether producing standard floor panels or custom-designed components, this machine is capable of handling a wide range of materials, including steel, aluminum, and other alloys. This flexibility makes it an invaluable asset for manufacturers looking to diversify their product range and meet the unique specifications of their clients. In addition, the machine can be easily reconfigured and adapted to accommodate different panel sizes and designs, further enhancing its versatility.The Floor Production Roll Forming Machine is also renowned for its speed and efficiency. Its high-speed production capabilities enable manufacturers to significantly increase their output, reducing the time and resources required to produce floor panels. This improved efficiency not only reduces production costs but also allows manufacturers to meet tight deadlines and satisfy the demands of their clients. Furthermore, the machine's automated operation minimizes the need for manual intervention, further optimizing the production process and reducing the risk of human error.In addition to its technical features, the Floor Production Roll Forming Machine is backed by {Company Name}'s renowned expertise and support. With years of experience in roll forming technology, the company is dedicated to providing comprehensive customer support, including installation, training, and ongoing maintenance services. This ensures that manufacturers can fully optimize the capabilities of the machine and maximize their return on investment. Furthermore, {Company Name}'s commitment to innovation and continuous improvement means that the machine is regularly updated with the latest advancements in technology, keeping it at the forefront of roll forming innovation.The introduction of the Floor Production Roll Forming Machine marks a significant milestone for {Company Name}, reinforcing its position as a leading provider of roll forming technology. With its state-of-the-art features, versatility, and exceptional performance, this machine is set to transform the manufacturing industry, empowering manufacturers to produce high-quality floor panels with unprecedented speed and precision. As the demands of the market continue to evolve, {Company Name} remains committed to driving innovation and delivering cutting-edge solutions that empower manufacturers to succeed in a competitive industry.

Top CNC Machine for Aluminum Profile Processing

Aluminum Profile CNC Machine: A Game-Changer for {Company Name}In today's fast-paced manufacturing industry, precision and efficiency are key factors in staying ahead of the competition. With the increasing demand for high-quality aluminum products, {Company Name} has taken a significant leap forward by investing in state-of-the-art Aluminum Profile CNC Machine. This cutting-edge technology is set to revolutionize the way aluminum profiles are processed and manufactured, ultimately setting {Company Name} apart as a leader in the industry.The Aluminum Profile CNC Machine is designed to provide exceptional precision and accuracy in cutting, milling, drilling, and tapping aluminum profiles. With its advanced software and high-speed cutting capabilities, this machine is capable of producing complex and intricate designs with unparalleled efficiency. This means that {Company Name} can now offer a wider range of aluminum profiles with precise and consistent quality, meeting the diverse needs of their customers.{Company Name} has always been committed to embracing the latest technological advancements to improve their manufacturing processes. With the addition of the Aluminum Profile CNC Machine, they have taken a significant step towards achieving their goal of delivering superior products that exceed customer expectations. This investment reflects {Company Name}'s dedication to staying at the forefront of the industry and providing innovative solutions to their clients.The implementation of the Aluminum Profile CNC Machine is another example of {Company Name}'s commitment to sustainability and environmental responsibility. With its advanced cutting and milling capabilities, this machine minimizes material waste and energy consumption, contributing to a more sustainable manufacturing process. This aligns with {Company Name}'s values and commitment to reducing their environmental footprint while maintaining the highest standards of quality.Moreover, the Aluminum Profile CNC Machine has allowed {Company Name} to expand its product offerings and cater to a wider range of industries and applications. From construction and architecture to transportation and industrial manufacturing, the precision and versatility of this machine enable {Company Name} to meet the diverse needs of their clients across different sectors. This strategic expansion positions {Company Name} as a one-stop solution provider for aluminum profiles, further strengthening their position in the market.The introduction of the Aluminum Profile CNC Machine has also had a positive impact on the workforce at {Company Name}. With the machine's automated capabilities, the production process has become more streamlined, allowing employees to focus on more specialized tasks that require human expertise. This has not only improved productivity and efficiency but has also created opportunities for upskilling and professional development within the company.In conclusion, the acquisition of the Aluminum Profile CNC Machine has propelled {Company Name} to new heights in the aluminum manufacturing industry. From its advanced capabilities to its positive impact on sustainability and workforce development, this investment exemplifies {Company Name}'s commitment to innovation and excellence. As they continue to harness the power of cutting-edge technology, {Company Name} is well-positioned to set new standards for quality and efficiency in the industry, solidifying their reputation as a leader in aluminum profile manufacturing.

Top-rated Roof Panel Machine: A Game-Changer in Construction Industry

Roof Panel Machine Revolutionizes the Manufacturing IndustryThe manufacturing industry has seen a significant breakthrough with the introduction of the state-of-the-art Roof Panel Machine by a leading company. This innovative machine has redefined the process of manufacturing roof panels, making it faster, more efficient, and cost-effective.The Roof Panel Machine is designed to streamline the production of roof panels, providing manufacturers with a high-quality and reliable solution for their production needs. With advanced technology and precision engineering, this machine has the capability to produce a wide range of roof panels with varying thickness, length, and design specifications. This level of flexibility allows manufacturers to meet the diverse needs of their customers, while maintaining a high standard of quality and consistency.One of the key features of the Roof Panel Machine is its automated operation, which minimizes the need for manual labor and reduces the risk of errors in the production process. This automated system is equipped with intelligent controls and sensors that ensure the accurate and precise fabrication of roof panels, resulting in a higher level of efficiency and productivity. As a result, manufacturers can increase their output and meet tight production deadlines without compromising on the quality of their products.In addition, the Roof Panel Machine is designed for ease of use, with a user-friendly interface and intuitive controls that make it accessible to operators of varying skill levels. This allows manufacturers to train their staff quickly and efficiently, reducing the time and resources required for onboarding new employees. The simplified operation of the machine also minimizes the risk of human error, resulting in a more consistent and reliable production process.Furthermore, the Roof Panel Machine is engineered for durability and longevity, ensuring a reliable and long-lasting solution for manufacturers. With robust construction and high-quality components, this machine is designed to withstand the rigors of continuous use in a manufacturing environment, providing a dependable and low-maintenance option for production facilities.The introduction of the Roof Panel Machine has significantly impacted the manufacturing industry, offering a transformative solution for the production of roof panels. With its advanced technology, automated operation, ease of use, and durability, this machine has redefined the standards of manufacturing, setting new benchmarks for efficiency, productivity, and quality.Company Introduction:The company behind the Roof Panel Machine is a leading innovator in the field of manufacturing technology. With a strong focus on research and development, this company has consistently introduced cutting-edge solutions that address the evolving needs of the industry. The Roof Panel Machine is the latest addition to their portfolio of advanced machinery, and it reflects their commitment to driving innovation and excellence in manufacturing.In addition to their dedication to technological advancement, the company is also known for their comprehensive support and service network. They offer a range of services, including installation, training, maintenance, and technical support, to ensure that their customers can fully maximize the benefits of their machinery. This level of support reinforces the company's dedication to customer satisfaction and their commitment to delivering value beyond the sale of their products.With a strong track record of success and a reputation for delivering superior technology, the company is poised to continue leading the way in the manufacturing industry. The Roof Panel Machine is just one example of their innovative solutions, and it serves as a testament to their vision of shaping the future of manufacturing with cutting-edge technology and unmatched expertise.In conclusion, the Roof Panel Machine has ushered in a new era of manufacturing, offering a game-changing solution for the production of roof panels. With its advanced technology, automated operation, ease of use, and durability, this machine has set a new standard for efficiency, productivity, and quality in the industry. As a testament to the company's commitment to innovation and excellence, the Roof Panel Machine stands as a pioneering achievement that is revolutionizing the manufacturing landscape.