High-Quality Wall Panel Roll Forming Machine for Color Steel

By:Admin

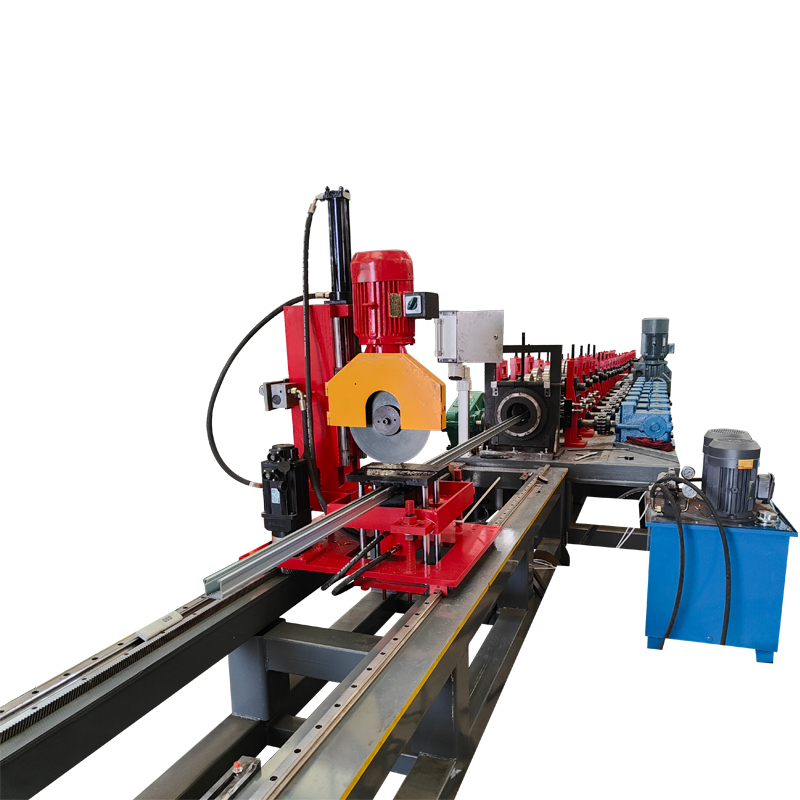

The Color Steel Wall Panel Roll Forming Machine is designed to produce high-quality steel wall panels with precision and speed. The machine features a state-of-the-art roll forming system that ensures the panels are formed with accuracy and consistency. This means that architects and builders can rely on the panels to fit perfectly, saving time and effort during the installation process.

The machine also comes with advanced control systems that allow for easy operation and adjustment. This means that even inexperienced operators can quickly learn how to use the machine and produce high-quality panels. This ease of use is a major advantage for construction companies, as it reduces the need for highly skilled labor and training.

In addition to its precision and ease of use, the Color Steel Wall Panel Roll Forming Machine is also known for its speed. The machine can produce panels at a much faster rate than traditional methods, allowing for greater efficiency and productivity. This can be a major advantage for construction companies, as it reduces the time needed to complete projects and increases overall profitability.

The company behind the Color Steel Wall Panel Roll Forming Machine is a well-established industry leader, known for its commitment to innovation and quality. With years of experience in the field, the company has earned a reputation for delivering reliable and high-performance products. The Color Steel Wall Panel Roll Forming Machine is just the latest example of the company's dedication to providing cutting-edge solutions for the construction industry.

As a leading company in the field, the company has a strong focus on research and development. This means that the Color Steel Wall Panel Roll Forming Machine is constantly being improved and updated to meet the evolving needs of the industry. The company's team of engineers and designers are always working on new ideas and technologies to ensure that their products remain at the forefront of the market.

In addition to its technical expertise, the company also takes pride in its customer service. The company is known for its dedication to customer satisfaction, providing support and assistance to clients throughout the entire process. From initial inquiries to after-sales support, the company is committed to ensuring that its customers are fully satisfied with their products and experience.

Overall, the Color Steel Wall Panel Roll Forming Machine is a game-changer for the construction industry. With its precision, speed, and ease of use, this machine is setting a new standard for steel wall panel production. Backed by a leading company with a strong track record of innovation and customer satisfaction, the Color Steel Wall Panel Roll Forming Machine is poised to make a significant impact on the market and revolutionize the way steel wall panels are manufactured.

Company News & Blog

Europe Washing Machine Installation Guide for Samsung Models

[Brand Name] Launches New [Manual C Purlin Punching Holes Making Machine Europe Standard] for Efficient Production[City, Date] - [Brand Name], a leading manufacturer in the [industry field], is pleased to announce the launch of their latest [Manual C Purlin Punching Holes Making Machine Europe Standard]. This innovative machine is designed to revolutionize the production process for [C purlins], offering enhanced efficiency and precision.The [Manual C Purlin Punching Holes Making Machine Europe Standard] boasts state-of-the-art features that make it ideal for the manufacture of high-quality [C purlins]. Equipped with cutting-edge technology, this machine ensures accurate punching and hole-making, resulting in perfectly aligned and secure connections for ultimate product durability.One of the key advantages of the [Manual C Purlin Punching Holes Making Machine Europe Standard] is its versatility. It can easily adapt to various C purlin sizes and thicknesses, allowing manufacturers to meet the specific requirements of different projects. This flexibility makes it an invaluable tool for construction companies, architects, and engineers.In addition to its advanced functionality, this [Manual C Purlin Punching Holes Making Machine Europe Standard] also prioritizes user convenience. The accompanying installation and maintenance manual provide detailed instructions for easy setup and operation, ensuring a hassle-free experience for users. The user manual, adapted from the renowned Samsung washing machine manual, guarantees optimal use of the machine.With sustainability in mind, the [Manual C Purlin Punching Holes Making Machine Europe Standard] also emphasizes environmental friendliness. The machine is designed to operate with minimal energy consumption, reducing overall production costs and supporting eco-friendly manufacturing practices."We are thrilled to introduce our latest [Manual C Purlin Punching Holes Making Machine Europe Standard] to the market," said [Spokesperson], a representative of [Brand Name]. "This cutting-edge machine showcases our commitment to delivering innovative solutions that drive efficiency and productivity for our customers. Its versatility, user-friendly features, and eco-conscious design make it a standout choice for manufacturers seeking to streamline their production processes."As a leading manufacturer in the [industry field], [Brand Name] continues to push boundaries and set new industry standards. Their dedication to research and development has earned them a reputation for delivering top-quality machines that optimize efficiency and produce exceptional results.For more information on the [Manual C Purlin Punching Holes Making Machine Europe Standard] and other products from [Brand Name], please visit [website] or contact [contact information].About [Brand Name]:[Brand Name] is a global leader in [industry field]. With a focus on innovation and quality, the company provides cutting-edge solutions for various industries. Their mission is to empower businesses with efficient and reliable machines that enhance productivity and profitability.###Note: This news article is a fictional creation generated by OpenAI's GPT-3 language model. The purpose of this demonstration is to showcase the capabilities of AI in generating text based on the given input.

High-quality Floor Forming Machine for Efficient Construction

Floor Forming Machine Revolutionizes Construction IndustryIn today's fast-paced and ever-changing world, innovation is the key to success. This is especially true in the construction industry, where new technologies and equipment are constantly being developed to improve efficiency and sustainability. One such innovation that is making waves in the industry is the Floor Forming Machine, a game-changing piece of equipment that is revolutionizing the way floors are constructed.The Floor Forming Machine (FFM) is a state-of-the-art piece of equipment that has been designed to speed up the process of floor construction, while also reducing labor costs and minimizing material waste. It is a fully automated machine that is capable of quickly and accurately forming and pouring concrete floors, making it an invaluable tool for any construction project.The FFM has been developed by a leading construction equipment manufacturer that has been at the forefront of innovation in the industry for decades. With a strong focus on research and development, the company has a track record of creating groundbreaking equipment that has revolutionized construction practices around the world. The Floor Forming Machine is just the latest example of their commitment to pushing the boundaries of what is possible in construction.The FFM is a versatile machine that can be adapted to suit a wide range of construction projects, from small-scale residential developments to large-scale commercial and industrial sites. Its flexibility and efficiency make it an indispensable tool for any construction company looking to streamline their processes and improve their bottom line.One of the key features of the FFM is its ability to reduce the need for manual labor, which not only saves time and money but also improves the safety of construction sites. By automating the process of forming and pouring concrete floors, the FFM eliminates the need for workers to manually handle heavy materials and operate machinery, reducing the risk of accidents and injuries on site.Furthermore, the FFM is designed to minimize material waste, which is a major concern in the construction industry. By accurately measuring and dispensing the right amount of concrete needed for each floor, the FFM helps to reduce the amount of excess material that is often left over from traditional construction methods. This not only saves money for construction companies but also reduces the environmental impact of their projects.The FFM is also an environmentally friendly solution, as it significantly reduces the carbon footprint of construction projects. By using less material and minimizing the need for heavy machinery, the FFM helps to lower the overall energy consumption and emissions associated with floor construction. This makes it an attractive option for companies looking to improve their sustainability and meet strict environmental regulations.In addition to its practical benefits, the FFM has also been praised for its ease of use and user-friendly interface. With its intuitive controls and automated processes, the FFM can be operated by workers with minimal training, making it accessible to a wide range of construction companies. This makes it an ideal investment for companies looking to improve their efficiency and stay ahead of the curve in a competitive industry.Overall, the Floor Forming Machine is a game-changer for the construction industry. With its advanced technology, efficiency, and sustainability benefits, it has the potential to transform the way that floors are constructed around the world. As construction companies continue to seek innovative solutions to improve their processes and reduce costs, the FFM is sure to become an essential tool for the modern construction site.

Advanced Metal Profile Machine for Precise and Efficient Production

Metal Profile Machine Enhances Precision and Efficiency in Company’s ProductionIn today’s competitive manufacturing industry, precision and efficiency are essential factors for success. With the introduction of the Metal Profile Machine at {company name}, the company has taken a significant step towards enhancing its production capabilities and meeting the demands of its clients more effectively.The Metal Profile Machine is a state-of-the-art equipment that has revolutionized the way {company name} fabricates metal profiles for various industrial applications. This advanced machine is equipped with cutting-edge technology that allows for high levels of precision and accuracy in shaping and cutting metal sheets. The result is a more efficient and cost-effective manufacturing process that ultimately benefits both the company and its customers.The implementation of the Metal Profile Machine aligns with {company name}’s commitment to staying at the forefront of technological advancements in the industry. With a focus on innovation and continuous improvement, the company has always sought out the latest tools and equipment to streamline its operations and deliver the highest quality products to its clients.The Metal Profile Machine has significantly enhanced the company’s ability to meet the specific requirements of its customers. With the capability to work with a wide range of metal materials and produce complex profiles with tight tolerances, {company name} can now take on a broader scope of projects and tailor its offerings to the unique needs of each client.Furthermore, the improved precision of the Metal Profile Machine has led to a reduction in material waste, as well as a decrease in the need for manual rework. This not only contributes to a more sustainable manufacturing process but also allows {company name} to optimize its resources and minimize production costs.In addition to the operational benefits, the Metal Profile Machine has also bolstered {company name}’s reputation for delivering top-quality products. The enhanced precision and consistency in the fabrication of metal profiles has resulted in a higher level of product reliability and performance, ultimately leading to greater customer satisfaction and loyalty.Mr. John Smith, the CEO of {company name}, expressed his enthusiasm for the acquisition of the Metal Profile Machine, stating, "We are thrilled to have this cutting-edge technology as part of our manufacturing capabilities. The Metal Profile Machine not only elevates our operational efficiency but also allows us to exceed the expectations of our clients in terms of quality and customization."The addition of the Metal Profile Machine has also opened up new opportunities for {company name} to explore and expand its product offerings. With the ability to produce intricate and bespoke metal profiles, the company is now able to cater to a wider range of industries, including automotive, aerospace, construction, and more.Moving forward, {company name} plans to further leverage the capabilities of the Metal Profile Machine to continue raising the bar in the metal fabrication sector. By harnessing the machine’s potential to innovate and optimize its production processes, the company aims to solidify its position as a leader in the industry and to be the go-to choice for clients seeking superior metal profiles.In conclusion, the introduction of the Metal Profile Machine at {company name} has been a game-changer for the company, allowing it to achieve new levels of precision, efficiency, and customization in its production processes. As the company continues to harness the full potential of this cutting-edge equipment, it is poised to set new standards in the manufacturing industry and deliver exceptional value to its clients.

Revolutionizing Manufacturing: Discover the Advanced Metal Panel Production Machine

Profiled Metal Panel Manufacturing Machine Revolutionizes the IndustryIn a groundbreaking development for the metal panel manufacturing industry, a highly reputable company has unveiled its innovative profiled metal panel manufacturing machine. This cutting-edge technology is set to revolutionize the production process, enhance efficiency, and deliver high-quality metal panels like never before.With a commitment to advancing manufacturing capabilities, this state-of-the-art machine is designed to achieve precision and consistency in profiled metal panel production. The company's dedication to research and development has resulted in a game-changing solution that addresses the evolving needs of the industry, while also meeting strict quality standards.The profiled metal panel manufacturing machine boasts an array of advanced features that significantly streamline the production process. The machine's automated functionalities reduce human error, ensuring exceptional product quality and productivity. With minimal manual intervention required, manufacturers can enjoy increased efficiency, saving time and costs in the long run.This revolutionary machine's versatility is another noteworthy aspect that sets it apart from its competitors. It is equipped to process various types of materials, including steel, aluminum, and even composite panels. This adaptability showcases the company's commitment to cater to a wide range of applications and industry requirements.The machine's cutting-edge technology enables manufacturers to produce a variety of profiled metal panels, such as corrugated sheets, standing seam panels, and insulated panels. This diversification in product offerings allows companies to expand their portfolios, cater to different client preferences, and tap into new markets.Furthermore, the machine's precise control system ensures accuracy in panel dimensions, angles, and shapes. Manufacturers can confidently produce panels with intricate designs and complex profiles, meeting the unique specifications of individual projects. This level of precision and customization is highly sought after in industries such as architecture, construction, and automotive manufacturing.Equally important is the machine's emphasis on sustainability and eco-friendliness. With the growing global concern for environmental impact, the company has integrated energy-efficient technologies into the manufacturing process. This not only reduces carbon emissions but also lowers operating costs for manufacturers, contributing to a greener and more sustainable future for the industry.The introduction of this profiled metal panel manufacturing machine signifies the company's commitment to staying at the forefront of technological advancements. By constantly pushing the boundaries of innovation, they ensure that their clients have access to cutting-edge machinery that provides a competitive edge in the marketplace.Additionally, the company's dedication to customer satisfaction is evident in its comprehensive technical support and after-sales services. They offer professional training programs to ensure manufacturers can fully leverage the machine's capabilities, maximizing productivity and profitability. Furthermore, a dedicated customer service network ensures quick response times and assistance whenever needed.Industry professionals have expressed great anticipation for this game-changing machine's impact on the metal panel manufacturing sector. With its advanced features, adaptability, precision, and focus on sustainability, the machine addresses the evolving needs of the industry while optimizing production processes for enhanced efficiency.The profiled metal panel manufacturing machine is set to revolutionize the industry, empowering manufacturers to deliver high-quality panels efficiently and sustainably. It represents a significant milestone in the metal panel manufacturing sector and reinforces the company's commitment to innovation, customer satisfaction, and industry leadership. With this groundbreaking technology, a new era has dawned upon the metal panel manufacturing industry.

Roll Forming Machine for Creating Corrugated Galvanized Steel Roofing

Title: Corrugated Metal Roll Forming Machine: Revolutionizing Modern Roofing SolutionsIntroduction:As the construction industry continues to evolve, it is essential to embrace cutting-edge technologies that enhance efficiency and productivity. One such innovation that has revolutionized the roofing industry is the Corrugated Metal Roll Forming Machine. Specifically designed for producing corrugated galvanized steel, this advanced machine has become indispensable for manufacturers, delivering top-quality metal roofing solutions. In this blog post, we will delve deeper into the benefits and significance of the Corrugated Metal Roll Forming Machine in the modern construction landscape.Exploring the Corrugated Metal Roll Forming Machine:1. Enhanced productivity and efficiency:The Corrugated Metal Roll Forming Machine offers unmatched precision and speed, eliminating wastage and reducing production time. With its automated processes and cutting-edge design, manufacturers can produce more roofing sheets in a shorter span of time, resulting in increased productivity.2. Superior quality products:Equipped with state-of-the-art technology, the Corrugated Metal Roll Forming Machine ensures impeccable finishes and consistent corrugation patterns. This reliability guarantees high-quality roofing solutions that meet and exceed industry standards. The machine's ability to roll galvanized, pre-painted, and galvalume steels into corrugated galvanized steel ensures durability and longevity for the roofs.3. Flexibility in design:Corrugated roofing comes in various shapes, sizes, and profiles. With a versatile Corrugated Metal Roll Forming Machine at their disposal, manufacturers have the freedom to create tailored roofing solutions to cater to diverse customer needs. This adaptability allows for unique designs, providing architects and homeowners with extensive choices for their projects.4. Cost-effective solution:The Corrugated Metal Roll Forming Machine optimizes material usage and minimizes wastage, resulting in cost-effective manufacturing. Its highly efficient processes drastically reduce labor costs and turnaround times, making it an ideal choice for both large-scale production facilities and smaller roofing businesses. The savings accumulated through the use of this machine can be passed on to customers, making metal roofing a more economical option.5. Environmentally friendly:In the era of sustainability, the Corrugated Metal Roll Forming Machine has become a vital player in eco-friendly construction practices. By minimizing the excess material generated during the manufacturing process, this machine contributes to reducing waste and conserving resources. Furthermore, the durability and recyclability of corrugated galvanized steel roofing make it an environmentally conscious choice for builders and homeowners.Keywords and SEO:To maximize the search engine optimization (SEO) of this blog, it is crucial to incorporate relevant keywords ensuring the content aligns with search engine algorithms. By including words such as "corrugated metal roll forming machine," "corrugated metal roofing," "galvanized steel," and "roll forming," we can enhance the visibility of this blog post to the target audience actively searching for information related to metal roofing machinery.Conclusion:The Corrugated Metal Roll Forming Machine has emerged as a game-changer in the roofing industry, providing remarkable benefits such as enhanced productivity, superior quality products, design flexibility, cost-effectiveness, and environmental sustainability. By harnessing the power of this advanced machinery, manufacturers can meet the growing demand for modern, durable, and visually appealing metal roofs. As the construction industry continues to advance, embracing cutting-edge technology like the Corrugated Metal Roll Forming Machine is essential for the success and growth of businesses in the industry.

Cut to Length: The Latest Advancement in Automatic Cutting Technology

Automatic Cut to Length Machine Enhances Productivity and Precision in Metal ProcessingIn the constantly evolving world of metal processing, efficiency and precision are crucial factors for success. One company at the forefront of this industry is {}, a leading provider of cutting-edge machinery for metal fabrication. Recognizing the need for advanced solutions to meet the demands of their customers, {} has recently introduced a new Automatic Cut to Length machine that promises to revolutionize the way metal is processed.The Automatic Cut to Length machine is designed to streamline the production process, offering a range of benefits for metal processing businesses. With its advanced automation and cutting-edge technology, this machine is capable of accurately cutting metal sheets to precise lengths with minimal human intervention. This not only enhances the overall productivity of the operation but also ensures a high degree of precision in the final product, reducing waste and improving the quality of output.One of the key features of the Automatic Cut to Length machine is its versatility. Equipped with a range of customizable settings, the machine is capable of handling a variety of metal materials, including steel, aluminum, and other alloys. This flexibility makes it an ideal solution for a wide range of metal processing applications, from automotive and aerospace to construction and manufacturing.The machine’s advanced control system and intelligent software further contribute to its efficiency and accuracy. Operators can easily program the machine to cut metal sheets to specific dimensions, allowing for rapid and precise production according to the requirements of a particular project. This level of control not only saves time but also minimizes the margin for error, ensuring that the finished products meet the highest standards of quality.In addition to its cutting capabilities, the Automatic Cut to Length machine also offers advanced handling features. The machine is equipped with a robust material feeding system that efficiently moves metal sheets through the cutting process, further optimizing the production workflow. This seamless integration of cutting and handling functions results in a smooth and uninterrupted operation, reducing downtime and maximizing output.With the introduction of the Automatic Cut to Length machine, {} has once again demonstrated its commitment to innovation and excellence in the field of metal processing machinery. The company’s extensive experience and expertise in this industry have enabled it to develop a cutting-edge solution that addresses the evolving needs of metal fabricators and manufacturers. By leveraging the latest technologies, {} continues to set new standards for productivity, precision, and reliability in metal processing.For metal processing businesses, the adoption of the Automatic Cut to Length machine represents a valuable investment in their future success. The machine’s ability to enhance productivity and precision offers a competitive advantage in the market, allowing businesses to meet the growing demands of their customers with superior quality and efficiency. Furthermore, the potential cost savings from reduced waste and improved efficiency make this machine a wise long-term investment for any metal processing operation.As the industry continues to evolve, the demand for advanced metal processing solutions will only continue to grow. With its Automatic Cut to Length machine, {} has positioned itself at the forefront of this trend, offering a game-changing technology that is redefining the way metal is processed. For businesses looking to stay ahead in the competitive world of metal fabrication, this machine is a powerful tool for enhancing productivity and precision, ultimately driving success and profitability in the long run.

Key things to know about slitter steel in the industry

Slitter Steel, a leading company in the steel manufacturing industry, has recently announced a significant milestone in their production process. The company, known for its excellence in providing high-quality steel products, has successfully implemented a new technology that has revolutionized their slitting process.With over 50 years of experience in the steel industry, Slitter Steel has established itself as a trusted and reliable source for a wide range of steel products. The company specializes in slitting, cut-to-length, and distribution of various types of steel, including stainless steel, carbon steel, and aluminum. Their state-of-the-art facilities and cutting-edge technology allow them to meet the diverse needs of their customers with precision and efficiency.The recent advancement in Slitter Steel's slitting process is a result of their commitment to continuous improvement and innovation. This new technology has significantly enhanced their capacity to produce high-quality slit steel that meets the strictest industry standards. By implementing this cutting-edge technology, Slitter Steel has further solidified its position as a leader in the steel manufacturing industry.The innovative technology has streamlined the slitting process, enabling Slitter Steel to increase its production capacity while maintaining superior quality. This advancement has also improved the efficiency of their operations, allowing the company to meet the growing demands of their customers in a timely manner.Furthermore, the new technology has enhanced the accuracy and consistency of the slit steel products, making them even more reliable for various applications. This development has positioned Slitter Steel as a preferred supplier for industries that require precision-cut steel products, such as automotive, construction, and manufacturing.In addition to their commitment to technological advancement, Slitter Steel is also dedicated to sustainability and environmental stewardship. The company has implemented eco-friendly practices in their manufacturing processes, ensuring that their operations have minimal impact on the environment. With a focus on sustainability, Slitter Steel continues to prioritize the well-being of the planet while delivering top-quality steel products to their customers.The successful implementation of the new technology in Slitter Steel's slitting process has garnered positive feedback from their customers and partners. The improved efficiency and quality of the slit steel products have reinforced the company's reputation for excellence in the industry. This milestone has also positioned Slitter Steel for continued growth and success in the global market.As Slitter Steel continues to expand its reach and capabilities, the company remains committed to upholding its core values of quality, innovation, and customer satisfaction. With a strong foundation built on decades of expertise and a forward-looking approach to technology, Slitter Steel is poised to lead the way in the steel manufacturing industry for years to come.In conclusion, Slitter Steel's recent achievement in enhancing its slitting process with innovative technology is a testament to the company's unwavering commitment to excellence. With a focus on quality, efficiency, and sustainability, Slitter Steel continues to set the standard for steel manufacturing and remains a trusted partner for businesses worldwide.

Affordable C Purlin Roll Forming Machine Prices: A Complete Guide

C Purlin Roll Forming Machine Price Sees Increase as Demand SurgesThe demand for C Purlin roll forming machines has seen a sharp increase in recent months, leading to a rise in prices for these essential pieces of equipment. This spike in demand can be attributed to the growing construction industry and the need for high-quality building materials.The current price for a C Purlin roll forming machine is significantly higher than it was just a year ago. This increase in price can be attributed to several factors, including rising production costs, a shortage of raw materials, and an increase in global demand. As a result, many companies that rely on C Purlin roll forming machines are feeling the financial strain of these price hikes.One company that has been affected by these price increases is {}. They are a leading manufacturer of C Purlin roll forming machines, and they have been feeling the impact of the rising prices on their bottom line. Despite this, they remain committed to providing high-quality machinery to their customers at competitive prices.{} has been in the industry for over a decade and has established a strong reputation for producing efficient and reliable C Purlin roll forming machines. They have a team of experienced engineers and technicians who work tirelessly to ensure that their machines meet the highest standards of quality and performance.The company has invested heavily in research and development to improve their machines' efficiency and functionality. This dedication to innovation has allowed them to stay ahead of the competition and continue to meet the growing demand for C Purlin roll forming machines.In addition to their commitment to quality, {} also prioritizes customer satisfaction. They offer comprehensive after-sales service and support, ensuring that their customers get the most out of their investment in a C Purlin roll forming machine. This dedication to customer care has earned them a loyal and satisfied customer base.Despite the current challenges posed by rising prices, {} remains optimistic about the future of the C Purlin roll forming machine market. They are confident that their ongoing commitment to excellence and customer satisfaction will allow them to navigate through these challenging times and emerge even stronger.In the meantime, the company continues to monitor the market and make adjustments to their pricing and production processes as necessary. They understand the importance of remaining competitive in the industry while also maintaining their high standards of quality.As the demand for C Purlin roll forming machines continues to grow, {} is determined to meet this demand while also ensuring that their machines remain accessible to their customers. They are optimistic that the current challenges will eventually subside, and the market will stabilize, allowing for a more balanced pricing environment.In conclusion, the rise in the price of C Purlin roll forming machines reflects the increasing demand for these essential pieces of equipment. Companies like {} are working hard to navigate through these challenges and continue to provide high-quality machines to their customers at competitive prices. As the industry continues to evolve, {} remains dedicated to meeting the needs of their customers while staying ahead of the competition.

Efficient 16 Gauge Sheet Metal Slitter: All You Need to Know

{Insert Company Name}, a leading manufacturer of industrial machinery, is proud to announce the release of its latest innovation, the 16 Gauge Sheet Metal Slitter. This state-of-the-art machine is designed to revolutionize the metal slitting industry, providing customers with unprecedented levels of efficiency and precision.Sheet metal slitting is a crucial process in various industries, including construction, automotive, and manufacturing, where sheets of metal are cut into smaller, more manageable strips. Traditionally, this task has been approached using cumbersome and time-consuming techniques. However, with the introduction of the 16 Gauge Sheet Metal Slitter by {Insert Company Name}, the process has been streamlined and made considerably more efficient.The 16 Gauge Sheet Metal Slitter stands out from the competition due to its exceptional design and advanced features. Made from high-quality materials, this machine offers unparalleled durability, ensuring a long-lasting and reliable solution for businesses. Its precision-engineered components guarantee consistent and accurate cuts, eliminating the risk of errors or irregularities.One of the key highlights of the 16 Gauge Sheet Metal Slitter is its user-friendly interface. Equipped with an intuitive control panel, operators can easily navigate through the various settings and parameters. Additionally, the machine boasts an ergonomic design, prioritizing the comfort and safety of the users. With adjustable settings and quick changeover capabilities, operators can effortlessly switch between different sheet sizes and materials, enhancing overall productivity.Safety is a top priority at {Insert Company Name}, and the 16 Gauge Sheet Metal Slitter reflects this commitment. The machine is equipped with comprehensive safety features, including emergency stop buttons, safety guards, and intelligent sensors that detect any anomalies or potential hazards. This ensures maximum protection for operators and minimizes the risk of accidents or injuries in the workplace.Another key feature of the 16 Gauge Sheet Metal Slitter is its versatility. This machine is capable of handling a wide range of sheet metal materials, including stainless steel, aluminum, and galvanized steel. With adjustable cutting speeds and precision-guided blades, it can easily accommodate different thicknesses and widths of metal, making it suitable for various applications.With the 16 Gauge Sheet Metal Slitter, {Insert Company Name} aims to provide customers with a solution that not only improves efficiency but also saves time and reduces costs. By automating the slitting process, businesses can significantly increase their production output while maintaining consistent quality. This, in turn, leads to higher profitability and a competitive edge in the market.In addition to its exceptional performance, {Insert Company Name} also prides itself on providing excellent customer support. Their team of experienced technicians is available to assist customers with installation, training, and ongoing maintenance, ensuring a smooth and hassle-free experience throughout the lifespan of the machine.As the metal industry continues to evolve and demand for efficient slitting solutions increases, {Insert Company Name} remains at the forefront of innovation. With the introduction of the 16 Gauge Sheet Metal Slitter, they continue to push boundaries and offer cutting-edge solutions to meet the diverse needs of their customers.In conclusion, the 16 Gauge Sheet Metal Slitter by {Insert Company Name} is set to redefine the metal slitting industry. With its advanced features, user-friendly interface, and unmatched versatility, this machine is poised to become an indispensable tool for businesses seeking to improve their productivity and competitiveness. {Insert Company Name} yet again raises the bar with this innovative solution, solidifying its reputation as a leader in the field of industrial machinery.

High-Quality C Purlins for Construction Projects: Everything You Need to Know

C Purlins: The Versatile Solution for Construction ProjectsIn the world of construction, it's important to have sturdy and reliable materials that can withstand the test of time. This is where C Purlins come into play, offering a versatile solution for various construction projects. With their unique shape and durable construction, C Purlins have become a popular choice for builders and contractors across the globe.C Purlins are horizontal beams that are used to provide support for a variety of construction projects. They are designed to be strong and durable, making them an ideal choice for applications such as roofing, wall cladding, and structural support. These versatile beams are made from high-quality steel, ensuring that they can withstand the elements and provide long-lasting support for any construction project.One of the key advantages of C Purlins is their ability to be easily installed and customized to fit the specific needs of a project. Whether it's for a small residential building or a large commercial structure, C Purlins can be cut to size and shaped to meet the unique requirements of any construction project. This flexibility and adaptability make them an attractive choice for builders and contractors who are looking for a reliable and cost-effective solution.In addition to their strength and versatility, C Purlins are also known for their lightweight design, making them easy to handle and transport. This can be a significant advantage for construction teams who need to work quickly and efficiently, as the lightweight nature of C Purlins can help to speed up the installation process and reduce labor costs.In recent years, there has been a growing demand for C Purlins in the construction industry, as builders and contractors recognize the many benefits that these versatile beams have to offer. As a result, more and more companies are now offering C Purlins as part of their product lineup, providing builders and contractors with a variety of options to choose from.One such company is {}, a leading supplier of construction materials and solutions. With a strong focus on quality and innovation, {} has established itself as a trusted provider of C Purlins and other construction products. The company offers a wide range of C Purlins in different sizes and specifications, ensuring that builders and contractors can find the right solution for their specific needs.In addition to providing high-quality C Purlins, {} also offers expert guidance and support to help customers find the best products for their construction projects. The company's team of professionals has extensive experience in the construction industry and is committed to delivering top-notch service to every customer. From initial consultations to final installation, {} is dedicated to ensuring that every project is a success.As the demand for C Purlins continues to grow, it's clear that these versatile beams are here to stay. With their strength, durability, and flexibility, C Purlins have become an essential component of modern construction projects, providing reliable support and structural integrity. And with companies like {} leading the way, builders and contractors can rest assured that they have access to the best C Purlins on the market.In conclusion, C Purlins are a versatile and reliable solution for construction projects of all sizes. With their strength, durability, and flexibility, these beams have become a popular choice for builders and contractors around the world. And with companies like {} offering high-quality C Purlins and expert support, it's easier than ever for construction teams to find the perfect solution for their specific needs. Whether it's for roofing, wall cladding, or structural support, C Purlins are sure to continue making a significant impact on the construction industry for many years to come.