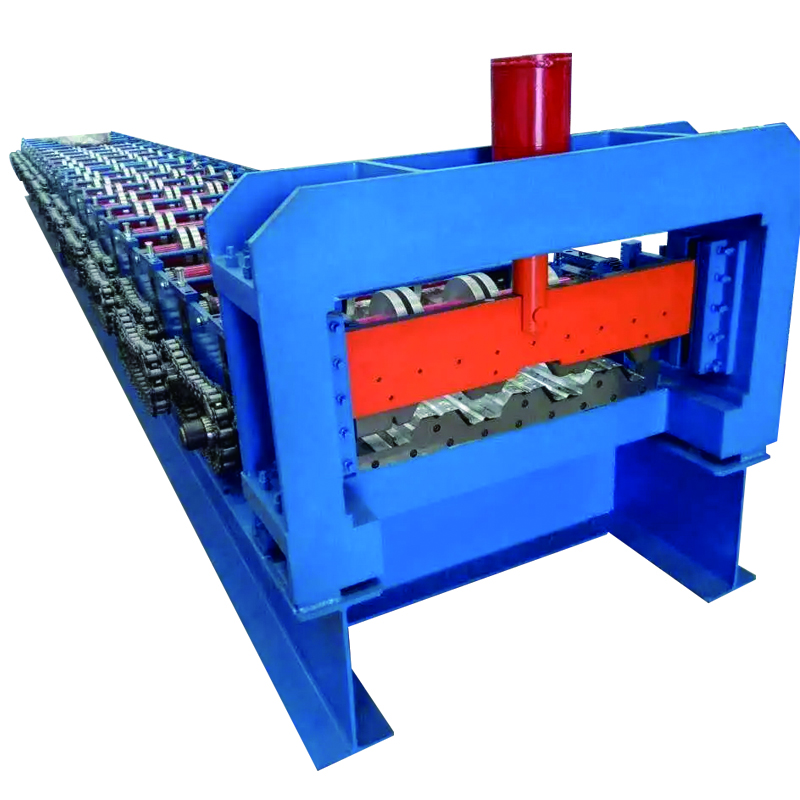

High Quality Z Purlin Roll Forming Machine for Making Building Materials

By:Admin

The Z Purlin Roll Forming Machine is equipped with advanced features that enable it to produce purlins of various sizes and specifications. It is capable of handling different types of raw materials, such as steel and aluminum, and can produce purlins with high precision and consistency. This ensures that the purlins produced by the machine meet the highest standards of quality and reliability, making them ideal for use in building construction.

The machine's advanced technology also allows for easy customization of purlins, enabling manufacturers to meet the specific requirements of their customers. With the ability to adjust the width, height, and thickness of the purlins, the machine offers a high level of flexibility in production. This versatility makes it suitable for a wide range of construction projects, from small-scale residential buildings to large commercial and industrial structures.

In addition to its advanced features, the Z Purlin Roll Forming Machine is designed for efficiency and productivity. Its automated operation minimizes the need for manual intervention, reducing the risk of errors and increasing production output. This not only saves time and labor costs but also ensures consistent quality in the purlins produced.

The company behind the Z Purlin Roll Forming Machine, [Company Name], is a leading manufacturer of roll forming machines and related equipment. With years of experience in the industry, the company has earned a reputation for delivering high-quality products and cutting-edge solutions to its customers. Its team of engineers and technical experts is dedicated to developing innovative technologies that meet the evolving needs of the construction industry.

[Company Name] takes pride in its commitment to customer satisfaction, offering comprehensive support services to ensure the smooth operation and maintenance of its machines. From installation and training to ongoing technical assistance, the company is dedicated to helping its customers maximize the performance and lifespan of their equipment.

The Z Purlin Roll Forming Machine is just one of the many innovative products offered by [Company Name]. Its extensive product range includes a variety of roll forming machines for different applications, as well as auxiliary equipment and accessories. With a focus on quality, reliability, and technological advancement, the company continues to be a trusted partner for manufacturers in the construction and building material industry.

As the demand for high-quality building materials continues to grow, the Z Purlin Roll Forming Machine stands out as a valuable investment for manufacturers looking to stay ahead in the competitive market. Its advanced capabilities, efficiency, and precision make it an essential tool for producing top-of-the-line purlins for a wide range of construction projects.

In conclusion, the Z Purlin Roll Forming Machine offered by [Company Name] represents a significant advancement in the production of building materials. Its cutting-edge technology, precision manufacturing, and versatility make it an invaluable asset for manufacturers in the construction industry. With the support of a reputable and experienced company, customers can rely on the machine to deliver top-quality purlins that meet the highest standards of performance and durability.

Company News & Blog

Revolutionary Color Steel Glazed Tile Corrugation Machine Promises Unmatched Performance

[Title]: Innovative Color Steel Glazed Tile Corrugation Machine Revolutionizes Roofing Industry[Subtitle]: {Company Name}'s Cutting-edge Solution Takes Roofing Efficiency to New Heights[Date][City], [State] - {Company Name}, a renowned pioneer in the manufacturing industry, has recently unveiled its revolutionary Color Steel Glazed Tile Corrugation Machine, poised to transform the roofing industry worldwide. This cutting-edge technology promises exceptional efficiency and durability, empowering construction companies and homeowners alike with a game-changing roofing solution.With years of industry experience and a commitment to innovative designs, {Company Name} has overcome previous limitations seen in traditional glazed tile corrugation machines. By leveraging advanced engineering techniques, this new machine raises the bar in terms of speed, precision, and quality of output.The Color Steel Glazed Tile Corrugation Machine boasts an impressive range of features specifically designed to address the demands of modern roofing projects. Equipped with an intelligent control system, it offers heightened automation and precision, ensuring a seamless production process. Operators can effortlessly set parameters such as tile size, thickness, and curvature, thus greatly reducing human errors and increasing overall productivity.One of the key benefits of this state-of-the-art machine is its exceptional speed. With a production capacity of up to [X] tiles per minute, it significantly reduces manufacturing time, leading to shorter project timelines and improved customer satisfaction. This increased efficiency is complemented by the machine's ability to produce tiles of varying shapes and colors, allowing for greater customization to suit clients' specific aesthetic requirements.Moreover, the Color Steel Glazed Tile Corrugation Machine prioritizes durability and longevity. By utilizing high-quality materials such as reinforced steel and wear-resistant components, {Company Name} ensures that the machine can withstand continuous use over extended periods. This durability translates into cost savings for roofing companies, as maintenance costs and the frequency of machine replacement are drastically reduced.{Company Name}, an industry leader known for its commitment to environmental sustainability, has also incorporated eco-friendly elements into the design of their Color Steel Glazed Tile Corrugation Machine. By optimizing energy consumption and reducing waste materials during production, the machine aligns with global efforts to encourage sustainable development practices. This commitment not only benefits the environment but also enhances {Company Name}'s reputation as a socially responsible organization.In addition to its technical superiority, {Company Name} provides exceptional customer support and after-sales service. Their team of qualified technicians is readily available to assist clients with installation, training, and troubleshooting, ensuring a seamless transition to the new technology. Continuous software updates and technological advancements further guarantee that {Company Name} remains at the forefront of the roofing industry, offering the latest innovations to their customers.Looking ahead, {Company Name} is excited about the potential of their Color Steel Glazed Tile Corrugation Machine to disrupt the roofing industry on a global scale. With its streamlined production, exceptional durability, and eco-friendly features, this groundbreaking technology sets a new standard in efficiency, quality, and sustainability. Construction companies and homeowners can now benefit from a roofing solution that combines aesthetics with functionality, providing long-lasting protection for years to come.About {Company Name}:{Company Name} is a leading manufacturer and supplier of industrial machinery, renowned for its commitment to innovation and quality. With a rich history spanning over [X] years, they have earned a stellar reputation for providing cutting-edge solutions that empower businesses across various sectors. Committed to sustainable development, {Company Name} constantly strives to deliver eco-friendly and efficient products that meet the evolving needs of their customers.For more information, please visit: [Website URL]Press Contact:[Contact Name][Title][Company Name][Phone Number][Email Address]

Efficient Roll Forming Machine for Light Gauge Steel Keel Production

Title: Revolutionary Light Gauge Steel Keel Roll Forming Machine Revolutionizes Construction IndustryIntroduction: [Company Name], an industry-leading manufacturer of construction machinery, has recently unveiled its latest innovation, a groundbreaking Light Gauge Steel Keel Roll Forming Machine. This state-of-the-art machine is set to revolutionize the construction industry by significantly increasing efficiency and reducing labor costs in the production of light gauge steel frames and structures. With its unique features and advanced technology, the Light Gauge Steel Keel Roll Forming Machine is poised to become an indispensable tool for modern construction projects.Paragraph 1: Traditional methods of constructing light gauge steel structures can be labor-intensive and time-consuming. However, the Light Gauge Steel Keel Roll Forming Machine eliminates these barriers by automating the process with precision and speed. This advanced technology enables the production of consistent and high-quality steel frames, significantly reducing waste material and time spent on manual labor.Paragraph 2: The Light Gauge Steel Keel Roll Forming Machine operates on the principles of roll forming, which involves feeding a coil of flat steel through a series of rollers, gradually shaping it into the desired cross-sectional profile. With precise control and selection of raw materials, this machine provides highly accurate and uniform results, ensuring the structural integrity of the final products.Paragraph 3: The Light Gauge Steel Keel Roll Forming Machine boasts an array of features that set it apart from traditional methods. Its automated nature allows for continuous production without the need for manual intervention. Additionally, its modular design and customizable options cater to various project requirements, offering flexibility and adaptability.Paragraph 4: The Light Gauge Steel Keel Roll Forming Machine incorporates cutting-edge technology, including computer numerical control (CNC) systems. This automation ensures precise measurements and consistent panel lengths, minimizing errors. The machine's user-friendly interface enables easy operation and adjustment of parameters, making it accessible to both experienced professionals and newcomers to the industry.Paragraph 5: [Company Name] has invested significant resources into research and development to create a machine that not only enhances productivity but also prioritizes safety. The Light Gauge Steel Keel Roll Forming Machine is equipped with safety features, such as emergency stop buttons and protective barriers, ensuring a secure working environment for operators.Paragraph 6: The introduction of the Light Gauge Steel Keel Roll Forming Machine is expected to have far-reaching implications for the construction industry. Its efficiency and affordability make it an attractive option for large-scale projects, such as residential buildings, commercial complexes, and industrial facilities. The reduced labor costs associated with this machine represent a significant advantage in today's competitive construction market.Paragraph 7: The Light Gauge Steel Keel Roll Forming Machine aligns with global sustainability goals, as it promotes the use of lightweight steel structures that offer energy efficiency, durability, and recyclability. By minimizing waste and optimizing material utilization, this machine supports environmentally friendly construction practices.Conclusion: With its groundbreaking technology, the Light Gauge Steel Keel Roll Forming Machine is set to redefine the construction industry. By streamlining the production process, increasing precision, and reducing labor costs, this cutting-edge machine will undoubtedly play a crucial role in the development of sustainable and efficient structures worldwide. [Company Name]'s commitment to innovation has once again propelled the industry forward, offering a transformative solution for the construction sector.

Advanced Forming Machine for Creating Profiles

Profile Forming Machine, a leading manufacturer in the machinery industry, has recently introduced its latest innovative machine designed to meet the growing demands of the market. With a strong focus on technology and precision engineering, Profile Forming Machine has been at the forefront of developing advanced solutions for various industries worldwide. The newly launched machine has been developed with the latest advancements in technology, resulting in a state-of-the-art and highly efficient production process. The machine is designed to form profiles with extreme precision and accuracy, catering to the specific needs of industries such as automotive, construction, and manufacturing.The company, founded in 1995, has a proven track record of delivering high-quality machinery and has built a reputation for its commitment to excellence. With a team of experienced engineers and technicians, Profile Forming Machine has consistently set industry standards and has become a trusted partner for businesses seeking reliable and advanced solutions for their production needs.The new machine is the result of extensive research and development, and it embodies the company's dedication to innovation and customer satisfaction. It has been designed to streamline the production process, reduce energy consumption, and maximize output, making it an ideal choice for businesses looking to enhance their efficiency and productivity.One of the key features of the new machine is its versatility, allowing it to handle a wide range of profiles and materials. Whether it is aluminum, steel, or other metals, the machine is capable of forming profiles with precision, consistency, and repeatability, meeting the highest quality standards.In addition to its technical capabilities, the machine also offers user-friendly controls and interface, making it easy to operate and maintain. This ensures that businesses can maximize their production capabilities without compromising on safety or quality."We are excited to introduce our latest Profile Forming Machine to the market," said the company's spokesperson. "With its advanced technology and high precision engineering, we believe that it will significantly benefit our customers and help them stay ahead in their respective industries. We are committed to providing the best solutions for our customers, and this machine is a testament to that commitment."The company also offers comprehensive training and support services to ensure that customers can optimize the performance of the machine and make the most of its capabilities. This personalized approach has been a cornerstone of Profile Forming Machine's success, as it believes in building long-term relationships with its customers and providing ongoing support and assistance.With its latest offering, Profile Forming Machine is poised to further strengthen its position as a market leader and a preferred choice for businesses seeking cutting-edge solutions for their production needs. The company's dedication to continuous improvement and technological advancement sets it apart in the industry, and its commitment to quality and customer satisfaction is unwavering.As the market continues to evolve and demand for high-quality products grows, Profile Forming Machine is well-positioned to meet the needs of industries requiring precision and efficiency in their production processes. The company's new machine is a testament to its vision and capability, and it is set to make a significant impact in the global machinery industry.

Precision Metal Profile Machine: A Complete Guide

Metal Profile Machine: Revolutionizing the Manufacturing IndustryIn the fast-paced world of manufacturing, efficiency and precision are key factors in determining the success of a business. With the advancement of technology, companies are continually seeking innovative solutions to improve their manufacturing processes. One such groundbreaking solution is the Metal Profile Machine, which has been garnering attention for its ability to revolutionize the manufacturing industry.Metal Profile Machine, developed by a leading machinery manufacturer, is a state-of-the-art equipment that is designed to streamline the process of creating metal profiles with unparalleled precision. The machine is equipped with cutting-edge technology and advanced features, making it a game-changer for companies looking to enhance their production capabilities.The Metal Profile Machine is capable of fabricating a wide range of metal profiles, including beams, channels, angles, tubes, and more. Its versatility allows for greater flexibility in manufacturing, empowering companies to meet diverse production requirements with ease. The machine is also built to accommodate different metal materials, from steel to aluminum, ensuring that manufacturers can adapt to various project demands.One of the key features that sets Metal Profile Machine apart is its precision engineering. The machine is equipped with advanced automation and computerized controls, allowing for highly accurate and consistent production of metal profiles. This not only ensures superior quality in the finished products but also reduces material waste, ultimately leading to cost savings for manufacturers.Additionally, the Metal Profile Machine boasts high-speed operation, significantly increasing the output capacity for manufacturers. Its rapid processing capabilities enable companies to meet tight deadlines and fulfill large-scale orders with efficiency. This heightened productivity is a significant advantage for businesses seeking to maximize their manufacturing capabilities and stay ahead of the competition.The introduction of Metal Profile Machine into the manufacturing landscape represents a significant shift in the industry, offering companies a competitive edge through improved efficiency and quality. As the demand for precision-engineered metal products continues to rise, the machine is poised to play a pivotal role in satisfying market needs.For companies looking to integrate the Metal Profile Machine into their operations, the benefits extend beyond enhanced production capabilities. The manufacturer provides comprehensive support, including installation, training, and ongoing maintenance services. This ensures that businesses can seamlessly integrate the machine into their workflow and make the most of its advanced capabilities.Furthermore, the Metal Profile Machine is designed with user-friendly interfaces and intuitive controls, making it accessible to operators with varying levels of expertise. This empowers manufacturing teams to leverage the machine's capabilities to their fullest potential, driving productivity and success for the business.The impact of Metal Profile Machine on the manufacturing industry is already being felt, with early adopters reporting significant improvements in their production processes. From greater precision and speed to reduced operational costs, the machine is proving to be a transformative investment for companies across the board.As the manufacturing landscape continues to evolve, the Metal Profile Machine is poised to play a central role in shaping the future of the industry. With its cutting-edge technology and unparalleled capabilities, the machine is set to redefine manufacturing standards and empower businesses to thrive in an increasingly competitive market.The Metal Profile Machine represents a new era of innovation in manufacturing, one that places a premium on efficiency, precision, and adaptability. As companies seek to stay ahead of the curve, this revolutionary machine is proving to be a game-changer that sets new benchmarks for success in the industry.

Discover the Innovation of Colored Metal Trapezoidal Sheet Roll Forming Machine

Colored Metal Trapezoidal Sheet Roll Forming Machine Brings Efficiency and Quality to Roofing IndustryThe roofing industry is set to witness a significant boost in efficiency and quality with the introduction of the advanced Colored Metal Trapezoidal Sheet Roll Forming Machine. This innovative machinery, manufactured by a leading company in the industry, aims to revolutionize the way metal roofing sheets are produced.Metal roofing has gained popularity in recent years due to its durability, energy efficiency, and aesthetic appeal. However, the process of manufacturing metal roofing sheets has often been time-consuming, labor-intensive, and prone to errors. The introduction of the Colored Metal Trapezoidal Sheet Roll Forming Machine seeks to address these challenges, ultimately leading to improved productivity and customer satisfaction.The key feature of this roll forming machine is its ability to efficiently produce trapezoidal-shaped metal sheets. This shape is commonly used in roofing applications due to its excellent water drainage capabilities, structural strength, and ease of installation. The machine's precision engineering ensures accurate dimensions, uniformity, and high-quality finishes, meeting the stringent requirements of the roofing industry.Furthermore, the Colored Metal Trapezoidal Sheet Roll Forming Machine can process various types of colored metal sheets, catering to the diverse needs and preferences of customers. It allows for the production of a wide range of colors and coatings, including but not limited to, galvanized steel, galvalume steel, and pre-painted steel sheets. This versatility empowers roofing contractors and manufacturers to meet the specific demands of different projects, further enhancing their competitiveness in the market.The use of this advanced machinery also significantly reduces manual labor and associated costs. The integration of automated procedures and computerized controls ensures precise and consistent results, eliminating the likelihood of human errors. Moreover, the machine's speed and efficiency enable manufacturers to meet tight project deadlines and handle large-scale orders efficiently.The company behind the Colored Metal Trapezoidal Sheet Roll Forming Machine has established itself as a leader in the metal processing industry. With a strong commitment to research and development, their team of experts continually innovate to provide cutting-edge solutions that deliver superior performance and durability. By collaborating with roofing industry professionals, they ensure that their machines meet the specific requirements of the market, ultimately driving the growth and progress of the entire sector.In addition to manufacturing state-of-the-art machinery, the company also offers comprehensive training programs and technical support to its customers. Recognizing the importance of knowledge transfer and skill development, they equip their clients with the necessary expertise to operate the Colored Metal Trapezoidal Sheet Roll Forming Machine optimally. This commitment to customer service further solidifies the company's reputation as a reliable and trusted provider in the industry.The introduction of the Colored Metal Trapezoidal Sheet Roll Forming Machine marks a significant milestone in the roofing industry. By leveraging the capabilities of this efficient and versatile machinery, contractors and manufacturers can enhance productivity, improve product quality, and boost customer satisfaction. This innovative solution showcases the company's dedication to driving progress and innovation in the metal roofing sector, solidifying their position as a leader in the market.

High-Quality Steel Coil Slitting Machine for Sale - Find Out More!

Steel Coil Slitting Machine is a cutting-edge piece of equipment that plays a crucial role in the metal processing industry. It is designed to cut wide coils of metal into narrower coils, which are then used in various applications across different industries. This machine has revolutionized the process of metal slitting, making it more efficient and precise than ever before.As a leading manufacturer of metal processing equipment, {} has recently introduced its latest Steel Coil Slitting Machine to the market. With a strong focus on innovation and quality, {} has become a trusted name in the industry, known for delivering cutting-edge solutions to its customers. The new Steel Coil Slitting Machine is a testament to the company's commitment to excellence and its dedication to meeting the evolving needs of the metal processing industry.One of the key features of {}'s Steel Coil Slitting Machine is its high level of precision. This machine is equipped with state-of-the-art technology that allows for accurate and consistent slitting of metal coils, ensuring that the end product meets the required specifications. This level of precision is critical in the metal processing industry, where small variations can have a significant impact on the quality of the final product.In addition to precision, the new Steel Coil Slitting Machine also offers high efficiency and productivity. It is designed to handle a wide range of metal materials, including stainless steel, aluminum, and carbon steel, with ease. This versatility makes it a valuable asset for metal processing companies that work with different types of metal coils. The machine is also equipped with advanced automation features, which help to streamline the slitting process and improve overall productivity.Another standout feature of {}'s Steel Coil Slitting Machine is its user-friendly design. The machine is easy to operate and requires minimal maintenance, making it an ideal choice for companies looking to optimize their production processes. Its intuitive controls and interface make it easy for operators to set up the machine and monitor the slitting process, reducing the risk of errors and downtime.Furthermore, {}'s Steel Coil Slitting Machine is built with durability in mind. It is constructed using high-quality materials and components, ensuring that it can withstand the rigors of continuous use in a demanding industrial environment. This durability translates to long-term reliability, helping companies minimize the risk of equipment failure and costly downtime.With the introduction of its new Steel Coil Slitting Machine, {} is poised to further solidify its position as a leading provider of metal processing equipment. The company's commitment to innovation and quality is evident in this latest offering, which brings together cutting-edge technology, high precision, efficiency, and durability in one comprehensive package. By investing in this machine, metal processing companies can streamline their operations, improve productivity, and deliver high-quality products to their customers.As the metal processing industry continues to evolve, the demand for advanced equipment like the Steel Coil Slitting Machine is expected to grow. Companies that invest in this technology will be well-positioned to stay ahead of the competition and meet the ever-changing needs of the market. With {}'s reputation for excellence and its dedication to providing top-of-the-line solutions, the new Steel Coil Slitting Machine is set to make a significant impact in the industry.In conclusion, the introduction of {}'s Steel Coil Slitting Machine represents a significant milestone for the company and the metal processing industry as a whole. With its advanced features, user-friendly design, and unwavering durability, this machine is poised to set new standards for precision and efficiency in metal coil slitting. As companies look to enhance their production processes and maintain a competitive edge, the new Steel Coil Slitting Machine offers a compelling solution that is sure to deliver impressive results.

Steel Profile Roll Forming Machine: The Ultimate Guide

Color Steel Profile Roll Forming Machine revolutionizes the steel industry with its advanced technology and efficient production capabilities. This state-of-the-art machine is a game-changer for the company, as it significantly improves their manufacturing process and allows them to produce high-quality steel profiles at a much faster pace.The Color Steel Profile Roll Forming Machine is equipped with the latest technology and advanced features, making it the most reliable and efficient machine in the industry. Its precision and accuracy in shaping and forming steel profiles have set a new standard for quality and productivity. The machine is capable of producing a wide range of steel profiles, including C-shaped, U-shaped, and Z-shaped profiles, with exceptional consistency and precision.One of the key advantages of this machine is its high-speed production capabilities. The Color Steel Profile Roll Forming Machine is capable of producing up to 30 meters of steel profiles per minute, which is significantly higher than traditional roll forming machines. This increased production capacity allows the company to meet the growing demand for steel profiles in the market while maintaining high quality and consistency.In addition to its high-speed production capabilities, the Color Steel Profile Roll Forming Machine also offers a high level of flexibility and customization. The machine is equipped with a user-friendly interface that allows operators to easily adjust the settings and parameters for each specific profile, allowing for quick and easy changeovers between different profiles. This flexibility is crucial for the company as it allows them to cater to a wide range of customer needs and requirements.The company behind this innovative machine, {}, is a renowned leader in the steel manufacturing industry. With decades of experience and expertise, they have earned a solid reputation for producing high-quality steel products. The addition of the Color Steel Profile Roll Forming Machine to their production line further solidifies their position as a leader in the industry and demonstrates their commitment to innovation and excellence.{} has always been at the forefront of technology and innovation in the steel industry. The addition of the Color Steel Profile Roll Forming Machine is a testament to their dedication to staying ahead of the curve and providing their customers with the best possible products. This new machine will not only improve their production capabilities but also allow them to offer a wider range of high-quality steel profiles to their customers.The Color Steel Profile Roll Forming Machine has already made a significant impact on the company's production process. With its advanced technology and efficient production capabilities, the machine has allowed {} to increase their production capacity, reduce production times, and improve the overall quality of their steel profiles. This has translated to increased customer satisfaction and has helped the company strengthen its position in the market.The Color Steel Profile Roll Forming Machine has truly revolutionized the steel industry, and {} is proud to be at the forefront of this innovation. With this new machine, they have not only improved their own production process but have also raised the bar for the entire industry. The company is excited about the endless possibilities that this machine offers and looks forward to continuing to lead the way in steel manufacturing with the help of this advanced technology.

Top Portable Metal Roll Forming Machine on the Market

Portable Metal Roll Forming Machine Revolutionizes On-Site ConstructionWith the rise of remote construction projects and the need for on-site customization, the demand for portable metal roll forming machines has been steadily increasing. This innovative piece of equipment has revolutionized the way metal roofing and siding is installed on construction sites, allowing for greater flexibility and efficiency in the construction process.The portable metal roll forming machine, also commonly referred to as a portable roll former, is a compact and mobile piece of equipment that is designed to produce metal panels of various shapes and sizes directly on the job site. This eliminates the need for pre-fabricated panels to be transported and handled, reducing transportation costs and the risk of damage during transit.One of the leading manufacturers in the industry is {}, a company that has been at the forefront of roll forming technology for over 30 years. They have recently introduced their latest portable metal roll forming machine, which boasts advanced features and capabilities that set it apart from traditional roll formers.The {} portable metal roll forming machine is designed to be easy to transport and set up, making it ideal for remote construction sites and projects with limited space. Its compact size and lightweight construction allow it to be easily maneuvered into position, while its robust build ensures durability and reliability in the harshest of environments.One of the key benefits of the {} portable metal roll forming machine is its ability to produce custom metal panels on-site, eliminating the need for off-site fabrication and reducing lead times. This enables construction contractors to respond quickly to design changes and project variations, ultimately saving time and costs associated with re-work and delays.In addition to its flexibility, the {} portable metal roll forming machine is also known for its precision and efficiency. With advanced control systems and automated processes, it can consistently produce high-quality metal panels with tight tolerances and accurate dimensions. This level of precision is crucial in ensuring the integrity and performance of the metal roofing and siding systems installed on construction projects.Furthermore, the {} portable metal roll forming machine is equipped with safety features and ergonomic designs to ensure the well-being of operators and workers on the job site. This includes safety guards, emergency stop mechanisms, and user-friendly controls that minimize the risk of accidents and injuries during operation.The introduction of the {} portable metal roll forming machine has been met with great enthusiasm from the construction industry, with many contractors recognizing the significant advantages it offers in terms of flexibility, efficiency, and quality. Its ability to streamline the metal panel production process on-site has been particularly appealing to those involved in remote and custom construction projects.With the growing demand for portable metal roll forming machines, {} has been actively expanding its distribution network to serve a wider range of customers around the world. From small-scale contractors to large construction firms, the company is committed to providing access to its innovative roll forming technology and supporting its customers with comprehensive training and technical support.In conclusion, the introduction of the {} portable metal roll forming machine has marked a significant advancement in on-site construction technology. Its ability to produce custom metal panels with precision and efficiency directly at the job site has not only improved productivity and cost-effectiveness but has also opened up new opportunities for innovation in the construction industry. As the demand for portable metal roll forming machines continues to grow, {} remains dedicated to driving the evolution of roll forming technology and empowering construction professionals with the tools they need to succeed.

High-Quality Glazed Tile Profile Corrugating Machine: Everything You Need to Know

Color Steel Glazed Tile Profile Corrugating Machine Revolutionizes Roofing IndustryThe roofing industry is witnessing a revolutionary transformation with the introduction of the state-of-the-art Color Steel Glazed Tile Profile Corrugating Machine. This cutting-edge technology is set to redefine the standards of roofing, bringing in a new era of efficiency, precision, and high-quality production.The Color Steel Glazed Tile Profile Corrugating Machine, developed by a leading manufacturing company, is equipped with advanced features that make it stand out in the market. With its high-speed performance, accurate profile shaping, and superior durability, this machine is set to become a game-changer in the roofing industry.This groundbreaking technology has been specifically designed to meet the growing demand for high-quality roofing materials that not only provide protection but also add an aesthetic appeal to buildings. The Color Steel Glazed Tile Profile Corrugating Machine is capable of producing a wide range of glazed tiles with different profiles, colors, and finishes, offering versatility and flexibility to meet diverse customer requirements.The company behind this innovative machine has a rich history of expertise and experience in the manufacturing industry. With a strong focus on research and development, they have a track record of introducing cutting-edge technologies that have redefined various sectors. Their commitment to quality and innovation has earned them a reputation as a trusted and reliable partner in the industry.The Color Steel Glazed Tile Profile Corrugating Machine is a testament to the company's dedication to delivering advanced solutions that cater to the evolving needs of the market. By integrating the latest manufacturing techniques and technologies, they have been able to create a product that not only meets industry standards but also sets new benchmarks for excellence.One of the key highlights of this machine is its efficiency in production. With its high-speed performance and precision engineering, it is capable of delivering large volumes of high-quality glazed tiles in a short span of time. This not only increases productivity for manufacturers but also ensures timely delivery to meet customer demands.Moreover, the Color Steel Glazed Tile Profile Corrugating Machine is designed to prioritize durability and longevity. Built with high-quality materials and components, it is capable of withstanding the rigors of continuous operation, making it a reliable investment for manufacturers looking for long-term sustainability.In addition to its performance and durability, the machine also offers ease of operation and maintenance. It is designed with user-friendly features that make it convenient for operators to set up, monitor, and maintain, reducing downtime and optimizing overall efficiency.The introduction of the Color Steel Glazed Tile Profile Corrugating Machine is expected to have a significant impact on the roofing industry. Its ability to produce high-quality glazed tiles with precision and efficiency is set to transform the way roofing materials are manufactured, setting new standards for quality and performance.As the demand for superior roofing solutions continues to grow, the Color Steel Glazed Tile Profile Corrugating Machine is poised to become a sought-after technology for manufacturers striving to meet the evolving needs of the market. With its unparalleled capabilities and advanced features, it is set to lead the way in shaping the future of the roofing industry.

High-Quality Roll Forming Machine for Wall Panel Production

The Wall Panel Roll Forming Machine is a cutting-edge piece of equipment designed to revolutionize the production of wall panels. This innovative machine, which is manufactured by a company specializing in roll forming machinery, has been hailed as a game-changer in the industry due to its advanced technology and impressive capabilities.The Wall Panel Roll Forming Machine features state-of-the-art engineering, precision manufacturing, and high-quality components. Its cutting-edge design allows for the rapid and efficient production of wall panels, making it an ideal choice for companies looking to improve their manufacturing processes and increase their productivity.One of the key features of the Wall Panel Roll Forming Machine is its versatility. It is capable of producing a wide range of wall panel designs, including standard panels, insulated panels, and decorative panels. This flexibility makes it suitable for a variety of applications, from residential construction to commercial and industrial projects.In addition to its flexibility, the Wall Panel Roll Forming Machine is also known for its high-speed production capabilities. Thanks to its advanced technology and precision engineering, this machine is able to produce wall panels at an impressive rate, significantly reducing production time and costs for manufacturers.Furthermore, the Wall Panel Roll Forming Machine is designed with user-friendly features, making it easy to operate and maintain. This user-friendly design ensures that operators can quickly and efficiently set up the machine for production, minimizing downtime and maximizing productivity.The company behind the Wall Panel Roll Forming Machine is renowned for its expertise in roll forming machinery. With a strong focus on research and development, the company has consistently pushed the boundaries of innovation in the industry, leading to the creation of cutting-edge machines like the Wall Panel Roll Forming Machine.In addition to its commitment to innovation, the company also places a strong emphasis on quality and reliability. Each machine is built to the highest standards, using top-grade materials and advanced manufacturing processes to ensure that it meets the strictest performance and durability requirements.Moreover, the company has an impressive track record of delivering exceptional customer service and support. From the initial consultation to installation and ongoing maintenance, the company provides comprehensive assistance to its customers, ensuring that they are fully satisfied with their investment in the Wall Panel Roll Forming Machine.The Wall Panel Roll Forming Machine is set to have a significant impact on the wall panel manufacturing industry, offering manufacturers a highly efficient and versatile solution for their production needs. With its advanced technology, high-speed production capabilities, and user-friendly design, this machine is poised to become a key asset for companies looking to improve their manufacturing processes and stay ahead of the competition.In conclusion, the Wall Panel Roll Forming Machine is a groundbreaking piece of equipment that is set to transform the way wall panels are produced. With its advanced technology, high-speed production capabilities, and user-friendly design, it offers manufacturers an efficient and versatile solution for their production needs. Combined with the company's dedication to innovation, quality, and customer service, the Wall Panel Roll Forming Machine is undoubtedly a game-changer in the industry.