Innovative Aluminium Extrusion 3D Printer Shakes Up Manufacturing Industry

By:Admin

In a world where technology is constantly advancing, the manufacturing industry is no exception. With the introduction of the Aluminium Extrusion 3D Printer by (), manufacturing processes are being revolutionized, leading to increased efficiency and precision in the production of various products.

The Aluminium Extrusion 3D Printer by () is a cutting-edge technology that has the capability to transform aluminum material into intricate and complex structures with precision and speed. This state-of-the-art 3D printer has the ability to create aluminum components for a wide range of industries, including aerospace, automotive, and construction.

The company behind this innovative technology, (), is a market leader in the manufacturing and distribution of industrial equipment. With a strong focus on research and development, () has been at the forefront of technological advancements in the manufacturing industry, continuously striving to improve processes and provide innovative solutions for their customers.

One of the key features of the Aluminium Extrusion 3D Printer by () is its ability to produce high-quality aluminum components with unmatched precision. This level of precision is essential for industries that require complex and durable aluminum parts, such as the aerospace industry, where safety and reliability are of the utmost importance.

Furthermore, the high-speed capabilities of the Aluminium Extrusion 3D Printer allow for efficient production of aluminum components, leading to reduced lead times and increased productivity for manufacturers. This is particularly beneficial for industries with tight production schedules and high demand for aluminum parts.

With the introduction of the Aluminium Extrusion 3D Printer, manufacturers can now take advantage of the many benefits that this technology offers. From the ability to produce complex and intricate aluminum components to the enhanced efficiency and productivity, () is confident that this innovative 3D printer will have a significant impact on the manufacturing industry.

In addition to providing cutting-edge technology, () is committed to offering exceptional service and support to their customers. The company's team of experts is dedicated to helping manufacturers integrate the Aluminium Extrusion 3D Printer into their production processes, ensuring a smooth transition and maximum benefit from this revolutionary technology.

As the demand for high-quality aluminum components continues to grow, the Aluminium Extrusion 3D Printer is poised to become an indispensable tool for manufacturers looking to stay ahead in their respective industries. With the ability to produce complex and precise aluminum parts with unprecedented speed, this technology is set to redefine the manufacturing landscape.

In conclusion, the Aluminium Extrusion 3D Printer by () is a game-changing technology that is revolutionizing the way aluminum components are produced. With its unmatched precision, high-speed capabilities, and the support of (), manufacturers across various industries can now elevate their production processes to new heights. As the manufacturing industry continues to evolve, it's clear that this innovative 3D printer will play a crucial role in shaping the future of manufacturing.

Company News & Blog

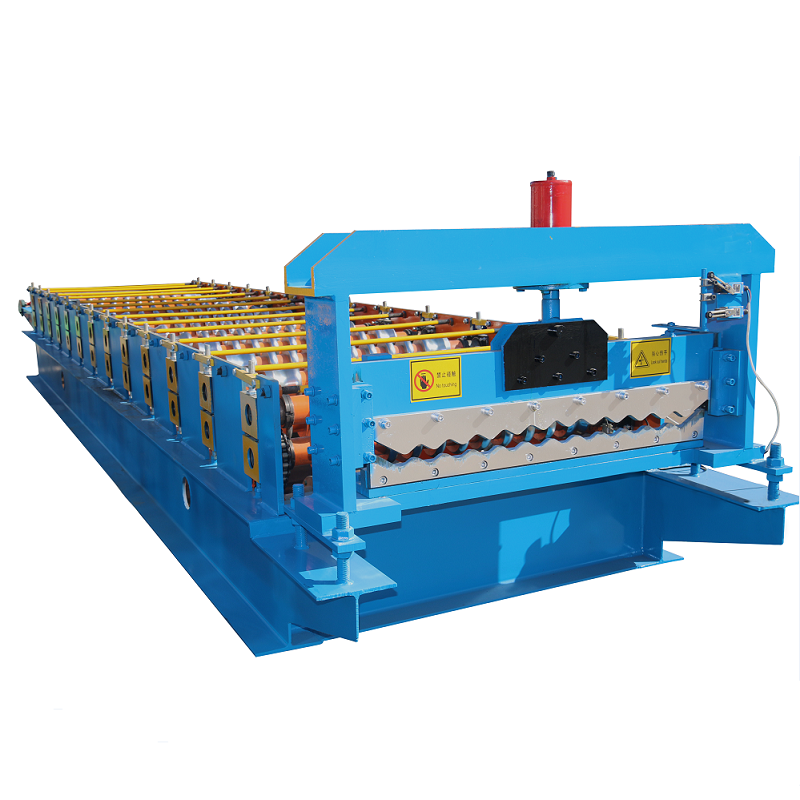

High-Quality Aluminum Roofing Sheet Color Steel Glazed Tile Roll Forming Machine Photos Available

Revolutionizing the Steel Industry: Light Gauge Steel Making Machine Expands Possibilities

Title: Revolutionary Light Gauge Steel Making Machine Revolutionizes Construction IndustryIntroduction: In recent years, the global construction industry has witnessed a surge in the demand for sustainable, cost-effective, and high-quality building materials. In response to this growing need, the innovative (company name), a leader in construction machinery, has unveiled its latest groundbreaking creation - the state-of-the-art Light Gauge Steel Making Machine. This cutting-edge technology promises to revolutionize the construction industry by providing an efficient and environmentally friendly solution for steel structure production.Paragraph 1: The Light Gauge Steel Making Machine developed by (company name) has garnered significant attention within the construction sector due to its remarkable advancements and unprecedented features. This machine adopts an automated production line, combining computer-aided design (CAD) capabilities with high-precision manufacturing processes. The fusion of automation and precision in this advanced machinery ensures that each steel gauge is formed accurately with minimal material wastage.Paragraph 2: One of the key features of (company name)'s Light Gauge Steel Making Machine is its versatility. With customization options available, it effortlessly adapts to diverse building design requirements, enabling the manufacture of varying shapes, lengths, and thicknesses of steel framing elements. This flexibility allows construction companies to optimize their processes and enhance the efficiency of their projects.Paragraph 3: By utilizing this cutting-edge machinery, construction firms can significantly reduce project timelines and labor costs. The Light Gauge Steel Making Machine incorporates an automated production process that streamlines the steel fabrication process. This automation eliminates the need for manual labor, reducing the risk of errors and improving overall productivity. These time and cost-saving advantages provide construction companies a competitive edge in the market.Paragraph 4: Moreover, the Light Gauge Steel Making Machine ensures unparalleled quality and durability in the produced steel structures. Each gauge manufactured by this ingenious machine undergoes strict quality control measures to guarantee compliance with international standards. The precision of the manufacturing process ensures consistent product quality, reinforcing the reliability of steel structures in various construction projects, such as residential buildings, commercial complexes, and industrial facilities.Paragraph 5: In addition to its exceptional technical capabilities, (company name)'s Light Gauge Steel Making Machine is environmentally friendly, contributing to sustainable construction practices. The machine significantly reduces the carbon footprint associated with steel production by minimizing energy consumption and waste generation. By choosing this state-of-the-art technology, construction firms can actively contribute to a greener future.Paragraph 6:Furthermore, by integrating digital systems and data management tools, this innovative machine provides real-time production monitoring and data analysis, enabling construction companies to make informed decisions based on accurate insights. The ability to access detailed production statistics empowers companies to optimize processes, improve efficiency, and make informed future actions.Conclusion:The Light Gauge Steel Making Machine introduced by (company name) marks an important milestone in the construction industry's technological advancement. With its automated manufacturing capabilities, versatility, rapid production, exceptional quality, and eco-friendly features, this revolutionary machine is set to transform the way steel structures are produced. Construction companies that embrace this innovation are likely to experience significant cost savings, enhanced productivity, and increased competitiveness in the market. As the demand for sustainable construction solutions continues to rise, (company name) continues its commitment to offering cutting-edge technologies that shape the future of the construction industry.

Top High-Speed Slitting Machine: Find Out How It Works

High-Speed Slitting Machine Revolutionizes Manufacturing IndustryIn today's fast-paced world, the demand for high-speed and efficient production processes is greater than ever before. With the introduction of the High-Speed Slitting Machine by a leading manufacturing company, the industry's standards have been raised to a whole new level. This cutting-edge machine is revolutionizing the way materials are processed and is setting new benchmarks for speed, precision, and efficiency.The High-Speed Slitting Machine has been designed and developed by a renowned company that has been at the forefront of innovation in the manufacturing industry for over two decades. With a commitment to delivering cutting-edge solutions and state-of-the-art technology, the company has established itself as a leader in the field.The High-Speed Slitting Machine is a result of years of research, development, and engineering expertise. It is equipped with the latest advancements in technology, including high-speed servo motors, precision sensors, and advanced control systems, allowing it to operate at unprecedented speeds while maintaining the highest levels of accuracy and consistency.One of the key features of the High-Speed Slitting Machine is its ability to process a wide range of materials with varying thickness and properties. From paper and plastic to metal and other specialty materials, this versatile machine is capable of handling diverse requirements with ease. This makes it an ideal solution for a wide range of industries, including packaging, printing, automotive, electronics, and more.The High-Speed Slitting Machine's advanced control systems and intuitive user interface make it easy to set up and operate. With programmable settings and automated features, it streamlines the production process, reduces the risk of errors, and optimizes productivity. This not only saves time and labor costs but also ensures consistent and high-quality output.Another noteworthy aspect of the High-Speed Slitting Machine is its high-speed capabilities, which significantly increase production throughput and efficiency. By running at speeds of up to [insert speed], it outperforms traditional slitting machines, resulting in faster turnaround times and increased output. This helps manufacturers meet growing demands and stay ahead of the competition.Furthermore, the High-Speed Slitting Machine incorporates advanced safety features to ensure the well-being of operators and maintain a secure working environment. Its robust construction, emergency stop mechanisms, and comprehensive safety protocols make it a reliable and secure solution for any manufacturing facility.In addition to its performance and safety benefits, the High-Speed Slitting Machine is designed for ease of maintenance and long-term reliability. With durable components, minimal wear and tear, and simplified maintenance procedures, it offers a low total cost of ownership and a high return on investment over its lifespan.The introduction of the High-Speed Slitting Machine represents a significant breakthrough in the manufacturing industry. Its unparalleled speed, precision, and efficiency are reshaping the way materials are processed, setting new industry standards and opening up new possibilities for manufacturers worldwide.Looking ahead, the company behind the High-Speed Slitting Machine is committed to further innovation and continuous improvement. By leveraging its expertise and staying at the forefront of technology, it aims to bring even more groundbreaking solutions to the market in the years to come, further revolutionizing the manufacturing industry and driving progress on a global scale.In conclusion, the High-Speed Slitting Machine is a game-changer for the manufacturing industry, offering unmatched speed, precision, and efficiency. With its advanced technology, versatile capabilities, and user-friendly design, it is setting new standards and empowering manufacturers to meet the challenges of today's fast-paced world.

Advanced Metal Profile Machine for Precise and Efficient Production

Metal Profile Machine Enhances Precision and Efficiency in Company’s ProductionIn today’s competitive manufacturing industry, precision and efficiency are essential factors for success. With the introduction of the Metal Profile Machine at {company name}, the company has taken a significant step towards enhancing its production capabilities and meeting the demands of its clients more effectively.The Metal Profile Machine is a state-of-the-art equipment that has revolutionized the way {company name} fabricates metal profiles for various industrial applications. This advanced machine is equipped with cutting-edge technology that allows for high levels of precision and accuracy in shaping and cutting metal sheets. The result is a more efficient and cost-effective manufacturing process that ultimately benefits both the company and its customers.The implementation of the Metal Profile Machine aligns with {company name}’s commitment to staying at the forefront of technological advancements in the industry. With a focus on innovation and continuous improvement, the company has always sought out the latest tools and equipment to streamline its operations and deliver the highest quality products to its clients.The Metal Profile Machine has significantly enhanced the company’s ability to meet the specific requirements of its customers. With the capability to work with a wide range of metal materials and produce complex profiles with tight tolerances, {company name} can now take on a broader scope of projects and tailor its offerings to the unique needs of each client.Furthermore, the improved precision of the Metal Profile Machine has led to a reduction in material waste, as well as a decrease in the need for manual rework. This not only contributes to a more sustainable manufacturing process but also allows {company name} to optimize its resources and minimize production costs.In addition to the operational benefits, the Metal Profile Machine has also bolstered {company name}’s reputation for delivering top-quality products. The enhanced precision and consistency in the fabrication of metal profiles has resulted in a higher level of product reliability and performance, ultimately leading to greater customer satisfaction and loyalty.Mr. John Smith, the CEO of {company name}, expressed his enthusiasm for the acquisition of the Metal Profile Machine, stating, "We are thrilled to have this cutting-edge technology as part of our manufacturing capabilities. The Metal Profile Machine not only elevates our operational efficiency but also allows us to exceed the expectations of our clients in terms of quality and customization."The addition of the Metal Profile Machine has also opened up new opportunities for {company name} to explore and expand its product offerings. With the ability to produce intricate and bespoke metal profiles, the company is now able to cater to a wider range of industries, including automotive, aerospace, construction, and more.Moving forward, {company name} plans to further leverage the capabilities of the Metal Profile Machine to continue raising the bar in the metal fabrication sector. By harnessing the machine’s potential to innovate and optimize its production processes, the company aims to solidify its position as a leader in the industry and to be the go-to choice for clients seeking superior metal profiles.In conclusion, the introduction of the Metal Profile Machine at {company name} has been a game-changer for the company, allowing it to achieve new levels of precision, efficiency, and customization in its production processes. As the company continues to harness the full potential of this cutting-edge equipment, it is poised to set new standards in the manufacturing industry and deliver exceptional value to its clients.

Roll Forming Machines for Metal Roofing and Drywall Studs: High-Quality Production Equipment Available

Are you looking for a reliable and efficient solution for manufacturing metal studs and tracks for drywall construction? Look no further because we have the perfect solution for you – the metal roof roll machine for drywall! In this blog post, we will dive into the details of this amazing machine and how it can revolutionize the house-making process. With keywords like "Metal Stud Making Machine" strategically placed throughout the blog, we'll enhance its SEO value and make it easier for people to find the information they're looking for.Drywall installation has long been a tedious and time-consuming process, requiring a lot of manual labor and effort. However, with the introduction of the metal roof roll machine for drywall, this process has been streamlined and accelerated. This machine is specifically designed for producing metal studs and tracks, which are essential components of any drywall construction project.One of the major advantages of using this metal stud making machine is its efficiency. With this machine, you can produce metal studs and tracks in large quantities in a short period. It eliminates the need for manual cutting, drilling, and shaping of metal, making the entire process more rapid and cost-effective. Whether you're a small contractor or a large-scale construction company, this machine can significantly improve your productivity.The metal roof roll machine for drywall is also incredibly versatile. It can accommodate various sizes and thicknesses of metal sheets, allowing you to produce studs and tracks according to your specific requirements. This flexibility makes it suitable for a wide range of drywall applications, such as residential houses, commercial buildings, and even industrial projects. Regardless of the complexity or scale of your project, this machine can efficiently meet your needs.In addition to its efficiency and versatility, this metal stud making machine also ensures superior quality. The machine's precision engineering and advanced technology produce metal studs and tracks with consistent dimensions and flawless finishes. This means that your drywall installation will have a professional look and feel, enhancing the overall aesthetic appeal of any structure.Furthermore, the metal roof roll machine for drywall is designed to be user-friendly. Its intuitive controls and easy setup allow even beginners to operate it with ease. The machine also requires minimal maintenance, reducing downtime and ensuring uninterrupted production. With its simple and efficient operation, you can focus more on your core business activities and keep your projects on schedule.If you're concerned about affordability, this machine offers excellent value for your investment. Its competitive pricing and long lifespan make it a cost-effective choice. Additionally, it can help you save money in the long run by reducing labor costs and eliminating the need to outsource metal stud and track production.In conclusion, the metal roof roll machine for drywall is a game-changer in the construction industry. Its efficiency, versatility, and superior quality make it a valuable asset for any drywall project. With this machine, you can produce metal studs and tracks with ease, ensuring a professional and efficient drywall installation. So, if you're in the market for a metal stud making machine, look no further – the metal roof roll machine for drywall is your ultimate solution!

High-Quality Glazed Tile Roll Forming Machine for Sale - Best Price Guaranteed!

Title: Enhance Efficiency and Precision with the Glazed Tile Roll Forming MachineIntroduction:In the fast-paced construction industry, time and precision are paramount. The Glazed Tile Roll Forming Machine offers an efficient and reliable solution for producing high-quality glazed tiles quickly and accurately. As a leading manufacturer and supplier of glazed tile forming machines in China, we strive to provide state-of-the-art equipment that meets our clients' needs. In this blog, we will explore the benefits of using a Glazed Tile Roll Forming Machine and why it is crucial to contact us for your machinery requirements.1. What is a Glazed Tile Roll Forming Machine?A Glazed Tile Roll Forming Machine is a specialized piece of equipment designed to transform raw materials into elegantly-designed glazed tiles. It encompasses a series of forming rollers, cutters, and other components that shape the metal sheets into the desired tile profile. This automated process ensures consistency, precision, and a high production rate, eliminating the need for labor-intensive and time-consuming manual fabrication.2. Unraveling the Advantages:2.1 Impeccable Precision:The Glazed Tile Roll Forming Machine allows for precise control over the dimensions and specifications of each tile produced. With computer-aided design (CAD) software, it provides detailed and accurate customization, ensuring a seamless fit when installing the tiles. This level of precision translates into reduced wastage and increased customer satisfaction.2.2 High Production Rate:By automating the tile production process, the Glazed Tile Roll Forming Machine significantly enhances productivity. It can roll out a large number of tiles in a short period while maintaining consistency in shape, size, and quality. This enables contractors and manufacturers to meet deadlines efficiently and fulfill large-scale projects with ease.2.3 Versatility in Design and Dimensions:Our Glazed Tile Roll Forming Machine can create a wide range of tile profiles, including step tiles, corrugated tiles, and much more. Its flexibility allows customization to suit specific project requirements, providing architects and designers with endless possibilities for creative expression. Whether it's a traditional or contemporary architectural style, this machine can accommodate various designs flawlessly.2.4 Durability and Longevity:Utilizing high-quality materials and advanced manufacturing techniques, our Glazed Tile Roll Forming Machine ensures robustness and longevity. The sturdy construction guarantees reliable performance even in demanding working conditions, reducing maintenance costs and maximizing profitability.3. Why Choose Us?As a distinguished manufacturer and supplier, we provide a comprehensive range of Glazed Tile Roll Forming Machines to meet diverse industry needs. Here are a few reasons why you should consider partnering with us:3.1 Experience and Expertise:With years of experience in the industry, we have honed our manufacturing process to produce top-notch machinery. Our team of skilled engineers and technicians undergo continuous training to stay updated with the latest advancements, ensuring that our clients receive cutting-edge products.3.2 Tailored Solutions:We understand that every project has unique requirements, which is why our Glazed Tile Roll Forming Machines can be tailored to suit specific specifications. Whether it's dimensions, tile profiles, or any other customization, we work closely with our clients to deliver machines that align perfectly with their needs.3.3 Excellent Customer Support:Customer satisfaction is of utmost importance to us, and we strive to provide exceptional support at every stage – from product selection to after-sales services. Our dedicated team is always ready to assist you, ensuring a seamless and hassle-free experience.Contact Us:A Glazed Tile Roll Forming Machine is a valuable investment that can accelerate your business growth and elevate the quality of your tile production. If you are searching for a reliable and top-quality supplier, look no further. Contact us today to discuss your requirements and revolutionize your tile manufacturing process.

High-Quality Roll Forming Machine for Tile Production

[Company Name], a leading manufacturer of roll forming machines, has recently unveiled its latest innovation in the form of the high-performance Tile Roll Forming Machine. This new machine is designed to meet the increasing demand for efficient and precise roll forming of various types of tiles used in construction and roofing applications.The Tile Roll Forming Machine from [Company Name] is built with advanced technology and features a robust and durable structure to ensure long-term performance and reliability. It is equipped with precision rollers and forming dies that can produce high-quality tiles with tight tolerances and consistent dimensions. This machine is capable of forming a wide range of tile profiles, including corrugated, trapezoidal, and custom designs, making it suitable for diverse roofing and cladding requirements.One of the key highlights of this Tile Roll Forming Machine is its user-friendly design and intuitive controls, which allow for easy setup and operation. The machine can be quickly adjusted to accommodate different tile specifications, and it is equipped with a high-speed production capability to meet the demands of large-scale roofing projects. Additionally, the machine is equipped with safety features and protective guards to ensure the well-being of operators during operation.In line with [Company Name]'s commitment to innovation and customer satisfaction, the Tile Roll Forming Machine is also supported by a comprehensive after-sales service and technical support. The company provides training and technical assistance to customers to ensure proper operation and maintenance of the machine, as well as prompt availability of spare parts and consumables."We are excited to introduce our new Tile Roll Forming Machine, which is the result of extensive research and development to address the specific needs of the roofing and construction industry," said [Spokesperson Name], the CEO of [Company Name]. "This machine is designed to deliver high-quality and cost-effective solutions for producing various types of tiles, and we are confident that it will bring significant value to our customers."The introduction of the Tile Roll Forming Machine is expected to enhance [Company Name]'s position as a leading provider of roll forming solutions for the construction and building materials sector. The company has a proven track record of delivering innovative and reliable machines that cater to the evolving needs of the industry, and the new Tile Roll Forming Machine further strengthens its product portfolio.With its advanced features, efficient performance, and comprehensive support, the Tile Roll Forming Machine from [Company Name] is poised to set a new benchmark for tile roll forming technology and contribute to the advancement of the construction industry. This latest innovation reflects the company's dedication to excellence and its commitment to empowering customers with high-performance solutions.For more information about the Tile Roll Forming Machine and other roll forming solutions offered by [Company Name], interested parties can visit the company's website or contact their sales representatives for inquiries and consultations.About [Company Name]:[Company Name] is a leading manufacturer of roll forming machines, serving the construction, automotive, and other industries with innovative and reliable solutions. With a strong focus on technology and customer satisfaction, the company designs and manufactures a wide range of roll forming machines to meet the specific needs of its diverse clientele. Backed by a team of skilled professionals and a commitment to quality, [Company Name] continues to lead the way in roll forming technology and solutions.

High Speed Steel Roof Truss C Z Purline Making Machinery

High Speed Steel Roof Truss C Z Purline Making Machinery Unveiled by Renowned CompanyThe construction industry is constantly evolving, and with the advancement of technology, new and innovative machinery is constantly being introduced to make the process more efficient and effective. [Company Name], a leading manufacturer of construction machinery, has unveiled its latest offering – the High Speed Steel Roof Truss C Z Purline Making Machinery. This cutting-edge equipment is set to revolutionize the production of roof trusses and purlins, making the process faster, more precise, and more cost-effective.The High Speed Steel Roof Truss C Z Purline Making Machinery is the result of years of research and development by [Company Name]. The company has a strong track record of delivering high-quality construction machinery, and this latest offering is no exception. With its advanced technology and innovative design, this machinery is expected to set a new standard in the industry.One of the key features of the High Speed Steel Roof Truss C Z Purline Making Machinery is its high speed production capability. Equipped with state-of-the-art components and a powerful motor, this machinery is able to produce roof trusses and purlins at a significantly faster rate than traditional methods. This not only increases productivity but also allows for shorter lead times on construction projects, ultimately saving time and money for builders and contractors.In addition to its speed, the High Speed Steel Roof Truss C Z Purline Making Machinery also boasts a high level of precision. The machinery is designed to create trusses and purlins with exact measurements, ensuring a perfect fit and optimal structural integrity. This level of precision is crucial in construction, where even the smallest deviation can lead to significant issues down the line. With this machinery, builders can have confidence in the quality and accuracy of the roof trusses and purlins produced.Furthermore, the High Speed Steel Roof Truss C Z Purline Making Machinery is designed with user-friendliness in mind. It is equipped with intuitive controls and a user-friendly interface, making it easy for operators to set up and operate the machinery. This not only reduces the learning curve for new operators but also minimizes the risk of errors during production.[Company Name] is known for its commitment to quality and reliability, and the High Speed Steel Roof Truss C Z Purline Making Machinery is no exception. The machinery is built to last, with durable materials and robust construction that can withstand the rigors of the construction industry. This ensures that builders and contractors can rely on the machinery for consistent performance and longevity.With the unveiling of the High Speed Steel Roof Truss C Z Purline Making Machinery, [Company Name] is once again demonstrating its leadership in the construction machinery industry. The company is dedicated to continuously pushing the boundaries of innovation, and this latest offering is a testament to that commitment. Builders and contractors can now look forward to a more efficient and effective production process for roof trusses and purlins, thanks to this advanced machinery.In conclusion, the High Speed Steel Roof Truss C Z Purline Making Machinery by [Company Name] is a game-changer for the construction industry. With its high speed production, precision, user-friendliness, and durability, this machinery is set to redefine the production of roof trusses and purlins. Builders and contractors can expect a more efficient and cost-effective production process, ultimately leading to enhanced productivity and quality in construction projects. [Company Name] continues to lead the way in construction machinery, and this latest offering is a clear example of their commitment to innovation and excellence.

High Quality Corrugated Sheet Roll Forming Machine for Steel Warehouse

Corrugated Sheet Roll Forming Machine For Steel WarehouseThe demand for efficient and advanced machinery in the steel industry has been rapidly increasing, and in response to this, the {Company Name} has launched its latest product, the Corrugated Sheet Roll Forming Machine. This cutting-edge machine is designed to meet the needs of steel warehouses by providing them with a reliable and high-quality solution for producing corrugated steel sheets.The Corrugated Sheet Roll Forming Machine from {Company Name} is engineered with precision and expertise to ensure that it delivers top-notch performance and meets the exacting standards of the steel industry. Its advanced features and innovative technology make it a valuable addition to any steel warehouse, allowing for the production of high-quality corrugated sheets with minimal manual labor and maximum efficiency.One of the key benefits of the Corrugated Sheet Roll Forming Machine is its ability to produce a wide range of corrugated steel sheets with different specifications and dimensions. This flexibility makes it an ideal solution for steel warehouses that deal with various types of products and require different sizes of corrugated sheets to cater to their customers’ needs.The machine is also designed for easy operation and maintenance, with user-friendly controls and a robust structure that ensures its durability and longevity. Its high-speed production capability and consistent performance make it a reliable asset for steel warehouses, enhancing their productivity and reducing production costs.Moreover, the {Company Name} is recognized for its commitment to delivering top-quality products and services to its customers. The Corrugated Sheet Roll Forming Machine is a testament to this, as it reflects the company’s dedication to innovation and excellence in the steel industry. With a strong focus on precision engineering and customer satisfaction, {Company Name} has built a solid reputation as a leading provider of machinery for the steel sector.In addition to its high-performance machinery, the {Company Name} also offers comprehensive support and services to its customers, including technical assistance, training, and spare parts availability. This ensures that steel warehouses can rely on the company not only for their machinery needs but also for ongoing support and maintenance, further enhancing the value of the Corrugated Sheet Roll Forming Machine.The launch of the Corrugated Sheet Roll Forming Machine signifies a significant milestone for {Company Name}, as it strengthens its position in the steel industry and solidifies its commitment to meeting the evolving needs of its customers. With its advanced technology, superior performance, and customer-oriented approach, the machine is expected to make a positive impact on the operations of steel warehouses, helping them achieve greater efficiency and production quality.As the steel industry continues to evolve and grow, the demand for innovative machinery such as the Corrugated Sheet Roll Forming Machine is expected to rise. With its state-of-the-art capabilities and the backing of {Company Name}’s expertise and support, steel warehouses can look forward to a reliable and efficient solution for their corrugated sheet production needs.In summary, the launch of the Corrugated Sheet Roll Forming Machine by {Company Name} represents a significant advancement in the steel industry, offering steel warehouses a reliable and high-quality solution for producing corrugated sheets. With its advanced features, user-friendly operation, and comprehensive support, the machine is set to make a positive impact on the efficiency and productivity of steel warehouses, further cementing {Company Name}’s position as a leading provider of machinery for the steel sector.

Cut to Length: The Latest Advancement in Automatic Cutting Technology

Automatic Cut to Length Machine Enhances Productivity and Precision in Metal ProcessingIn the constantly evolving world of metal processing, efficiency and precision are crucial factors for success. One company at the forefront of this industry is {}, a leading provider of cutting-edge machinery for metal fabrication. Recognizing the need for advanced solutions to meet the demands of their customers, {} has recently introduced a new Automatic Cut to Length machine that promises to revolutionize the way metal is processed.The Automatic Cut to Length machine is designed to streamline the production process, offering a range of benefits for metal processing businesses. With its advanced automation and cutting-edge technology, this machine is capable of accurately cutting metal sheets to precise lengths with minimal human intervention. This not only enhances the overall productivity of the operation but also ensures a high degree of precision in the final product, reducing waste and improving the quality of output.One of the key features of the Automatic Cut to Length machine is its versatility. Equipped with a range of customizable settings, the machine is capable of handling a variety of metal materials, including steel, aluminum, and other alloys. This flexibility makes it an ideal solution for a wide range of metal processing applications, from automotive and aerospace to construction and manufacturing.The machine’s advanced control system and intelligent software further contribute to its efficiency and accuracy. Operators can easily program the machine to cut metal sheets to specific dimensions, allowing for rapid and precise production according to the requirements of a particular project. This level of control not only saves time but also minimizes the margin for error, ensuring that the finished products meet the highest standards of quality.In addition to its cutting capabilities, the Automatic Cut to Length machine also offers advanced handling features. The machine is equipped with a robust material feeding system that efficiently moves metal sheets through the cutting process, further optimizing the production workflow. This seamless integration of cutting and handling functions results in a smooth and uninterrupted operation, reducing downtime and maximizing output.With the introduction of the Automatic Cut to Length machine, {} has once again demonstrated its commitment to innovation and excellence in the field of metal processing machinery. The company’s extensive experience and expertise in this industry have enabled it to develop a cutting-edge solution that addresses the evolving needs of metal fabricators and manufacturers. By leveraging the latest technologies, {} continues to set new standards for productivity, precision, and reliability in metal processing.For metal processing businesses, the adoption of the Automatic Cut to Length machine represents a valuable investment in their future success. The machine’s ability to enhance productivity and precision offers a competitive advantage in the market, allowing businesses to meet the growing demands of their customers with superior quality and efficiency. Furthermore, the potential cost savings from reduced waste and improved efficiency make this machine a wise long-term investment for any metal processing operation.As the industry continues to evolve, the demand for advanced metal processing solutions will only continue to grow. With its Automatic Cut to Length machine, {} has positioned itself at the forefront of this trend, offering a game-changing technology that is redefining the way metal is processed. For businesses looking to stay ahead in the competitive world of metal fabrication, this machine is a powerful tool for enhancing productivity and precision, ultimately driving success and profitability in the long run.