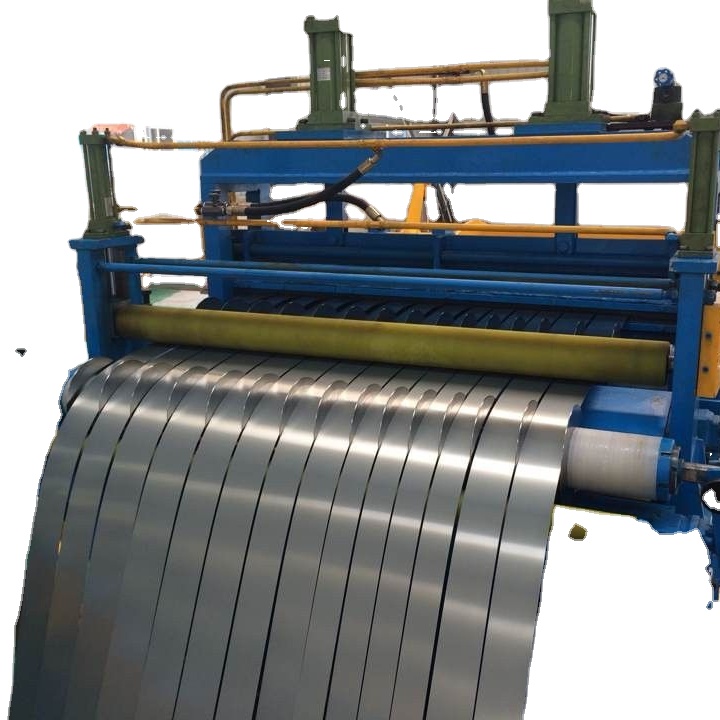

Quality Light Steel Roll Forming Machine for Sale - Get Your Project Done Right!

By:Admin

{} has been in the business for over a decade, specializing in the design, manufacturing, and distribution of light steel roll forming machines. They have a team of highly skilled engineers and technicians who are dedicated to developing cutting-edge technology that meets the needs of their clients. Their machines are known for their high efficiency, accuracy, and reliability, making them an ideal choice for construction companies looking to enhance their productivity and quality of work.

One of the key features of {}'s light steel roll forming machines is their ability to produce a wide range of steel profiles with different sizes and shapes, meeting the diverse needs of the construction industry. These machines are also equipped with advanced control systems, ensuring precise and consistent production of steel frames. Furthermore, {} offers customized solutions to their clients, tailoring their machines to meet specific requirements and preferences, providing a competitive edge in the market.

The company's commitment to innovation and quality has earned them a solid reputation in the industry. They have a strong focus on research and development, continuously striving to improve their machines and develop new technologies to stay ahead of the competition. This dedication to innovation has allowed {} to expand their market reach and serve clients globally, making them a trusted partner for construction companies worldwide.

In addition to their cutting-edge technology, {} also prides themselves on their excellent customer service. They believe in building long-term relationships with their clients, providing them with comprehensive support and maintenance services for their machines. This commitment to customer satisfaction has helped them build a loyal customer base, with many clients choosing {} as their preferred supplier for light steel roll forming machines.

As the construction industry continues to evolve, the demand for efficient and reliable light steel roll forming machines is expected to grow. With their years of experience and expertise in the field, {} is well-positioned to capitalize on this trend and further solidify their position as a leading provider of light steel roll forming machines.

With a focus on quality, innovation, and customer satisfaction, {} is setting new benchmarks in the industry and shaping the future of construction technology. Their dedication to providing top-notch machines and excellent service has made them a trusted partner for construction companies around the world, and they are poised to continue leading the way in the light steel roll forming machine industry.

Company News & Blog

High-Quality Ag Panel Roll Forming Machine: A Must-Have for Efficient Farming

Ag Panel Roll Forming Machine Revolutionizes Farming IndustryIn the ever-evolving world of agriculture, technological advancements continue to change the way farmers operate. One such innovation, the Ag Panel Roll Forming Machine, is revolutionizing the farming industry by providing a cost-effective and efficient solution for producing high-quality agricultural panels.The Ag Panel Roll Forming Machine, developed and produced by a leading manufacturing company, is a state-of-the-art piece of equipment designed to streamline the process of manufacturing agricultural panels. These panels are essential for constructing buildings, barns, and other structures on farms, providing much-needed shelter and protection for livestock, equipment, and crops.This innovative machine is equipped with advanced technology and precision engineering, allowing it to produce consistent and precise agricultural panels with minimal waste. Its high-speed production capabilities enable farmers to meet their construction needs in a timely manner, reducing downtime and increasing overall productivity.The company behind this groundbreaking machine has a solid reputation in the manufacturing industry, known for its commitment to producing top-quality equipment that is built to last. With a focus on innovation and customer satisfaction, the company has been a trusted partner for farmers and agricultural businesses for many years.In addition to its cutting-edge technology, the Ag Panel Roll Forming Machine is also designed with user-friendliness in mind. It is easy to operate and requires minimal training, making it accessible to farmers of all experience levels. This accessibility is essential for ensuring that farmers can take advantage of the benefits offered by this innovative equipment.The impact of the Ag Panel Roll Forming Machine extends beyond its immediate users. By increasing the efficiency of agricultural panel production, this machine has the potential to positively influence the entire farming industry. With quicker access to high-quality panels, farmers can expedite construction projects and improve the overall infrastructure of their operations, leading to increased safety and productivity.Furthermore, the machine's ability to minimize waste and optimize material usage contributes to a more sustainable approach to farming. By reducing the environmental impact of panel manufacturing, farmers can align their operations with modern sustainability standards, appealing to environmentally conscious consumers and stakeholders.The Ag Panel Roll Forming Machine is a testament to the ongoing technological advancements in the agriculture sector. Its introduction represents a significant step forward in modernizing farm operations, offering a glimpse into the future of farming technology.With its impressive capabilities and potential to transform the industry, the Ag Panel Roll Forming Machine is set to become a staple in farming operations of all sizes. The company's dedication to innovation and customer satisfaction, combined with its track record of manufacturing excellence, positions it as a key player in shaping the future of agriculture.As the farming industry continues to evolve, it is clear that solutions like the Ag Panel Roll Forming Machine will play a vital role in driving progress and success for farming operations around the world. As more farmers adopt this innovative technology, the industry as a whole stands to benefit from increased efficiency, sustainability, and productivity.

Glazed Steel Profile Roll Forming Machine for Construction with PLC Control - High-Quality Product

article as follows:China-based steel roll forming machine manufacturer, [Brand Name Removed], has announced the launch of its top-of-the-line product, the Steel Tile 750 glazed steel profile roll forming machine.This innovative roll forming machine is designed to offer a superior solution for all construction materials needs. It is expertly engineered to deliver high-quality glazed tile sheets that are highly durable, strong and capable of offering long-lasting performance that withstands the rigors of construction.With a profound understanding of the construction industry, [Brand Name Removed] has always been committed to providing unparalleled products that cater to the specific needs of its clients. The Steel Tile 750 roll forming machine is a prime example of that dedication.Manufactured using the latest technology, the Steel Tile 750 boasts of a robust design that is guaranteed to withstand heavy-duty usage. This machine is powered by PLC control technology, which delivers optimum automation and efficiency.The Steel Tile 750 roll forming machine comes with an automated hydraulic cutting system that ensures precise cuts and eliminates wastage. The machine can produce versatile, glazed tiles ranging in thickness from 0.3-0.8mm and a width of up to 1000mm.The innovation and quality of the Steel Tile 750 roll forming machine are a testament to [Brand Name Removed]'s reputation as a leading manufacturer of roll-forming and other related steel machines serving the global construction industry.According to the company spokesperson, "we understand the importance of quality and durability in the construction industry, and that's why we ensure that every product we manufacture is made to last. With our Steel Tile 750, our customers can enjoy a solution that will save them both time and money. We take pride in manufacturing machines that can remain in use for years."Designing the Steel Tile 750 roll forming machine took into account the varying construction needs of clients across the globe. The machine's versatility is perhaps its most significant selling point, as it can adapt to different building configurations and designs while still maintaining the same standard of quality.With years of experience in the steel roll-forming and construction industry, [Brand Name Removed] has earned a reputation for quality, reliability and exceptional customer service. Its team of qualified engineers and professionals is dedicated to designing machines that exceed customer expectations and meet the industry's specific needs.The Steel Tile 750 is an excellent example of [Brand Name Removed]'s commitment to offering state-of-the-art machinery at an affordable price while maintaining stringent quality control measures. Every machine's quality is checked and tested thoroughly to ensure optimal performance.The launch of the Steel Tile 750 roll forming machine is set to transform the construction industry, offering architects, contractors, and builders a solution that is both reliable and efficient. With this machine, they can speed up the construction process, reduce downtime and achieve the desired results without sacrificing quality.In conclusion, [Brand Name Removed] has once again demonstrated its expertise and focus on quality and innovation with the launch of the Steel Tile 750 glazed steel profile roll forming machine. It is an excellent addition to the company's portfolio, offering clients reliable and top-quality construction solutions at an affordable price. The industry can now look forward to faster and more efficient construction without compromising on quality.

Durable and Efficient Double Deck Roll Forming Machine for High-Volume Production

The Double Deck Roll Forming Machine has recently gained popularity in the metal forming industry, and {} is at the forefront of this innovative technology. This advanced machine has the capability to produce double-layered metal sheets, which offers significant advantages in terms of cost efficiency and production speed.With a focus on providing high-quality roll forming solutions to meet the evolving needs of the industry, {} has been a key player in the development and deployment of the Double Deck Roll Forming Machine. This state-of-the-art equipment is designed to increase productivity and optimize the production process, making it an essential part of modern metal forming operations.One of the key features of the Double Deck Roll Forming Machine is its ability to produce two different profiles simultaneously. This capability enables manufacturers to achieve greater flexibility in their production processes, as well as the ability to meet diverse customer requirements. With this machine, {} has empowered its clients to deliver a wide range of customized metal products, while also improving their overall production efficiency.In addition to its dual-profile capability, the Double Deck Roll Forming Machine also offers enhanced efficiency through its advanced control system. With precise control over the forming process, this machine ensures consistent quality and accuracy in the production of metal sheets. This level of control not only enhances the overall product quality but also minimizes material waste, ultimately leading to cost savings for manufacturers.Moreover, the Double Deck Roll Forming Machine is designed with a modular configuration, allowing for easy customization to suit specific production needs. This flexibility has been a game-changer for many manufacturers, as it enables them to adapt their production lines to accommodate various design requirements and material specifications. As a result, {} has empowered its clients to expand their product offerings and capture new business opportunities in the competitive metal forming market.Furthermore, {} has positioned itself as a leading provider of turnkey solutions for the roll forming industry, offering comprehensive support and expertise in the implementation of the Double Deck Roll Forming Machine. From initial consultation to installation and training, the company is committed to ensuring that its clients fully maximize the potential of this cutting-edge technology. This customer-centric approach has earned {} a reputation for reliability and excellence in the industry.Looking ahead, {} continues to innovate and develop new technologies to further advance the roll forming industry. With a strong focus on research and development, the company is dedicated to staying ahead of market trends and delivering innovative solutions that meet the evolving needs of manufacturers. As the demand for efficient, high-quality metal forming equipment continues to grow, {} remains committed to providing state-of-the-art solutions that drive success for its clients.In conclusion, the Double Deck Roll Forming Machine is a game-changing technology that has revolutionized the metal forming industry, and {} is at the forefront of this innovation. Through its commitment to excellence and customer satisfaction, the company has cemented its position as a trusted partner for manufacturers seeking to optimize their production processes and achieve new levels of efficiency and productivity. As the industry evolves, {} will continue to lead the way in delivering advanced roll forming solutions that empower manufacturers to thrive in the competitive market.

High-Quality Aluminum Roofing Sheet Color Steel Glazed Tile Roll Forming Machine Photos Available

Discover High-Quality Roll Forming Machines from China's Top Supplier

As much as architecture has evolved over the years, the use of different materials has remained constant, one of which being steel. The durability, strength, and versatility of steel make it a go-to material for various structural applications, from high-rise buildings to residential homes. Therefore, to meet the demands of this ever-growing market, the roll forming industry has evolved and continues to extend its limits by offering innovative and modernized products. Today, we will discuss everything about the Color Steel Roll Forming Machine Factory.What is a Roll Forming Machine?A Roll Forming Machine refers to a piece of equipment that produces shapes of different sizes and profiles from metallic coils or sheets. The machine achieves this by passing these sheets through a series of rollers that gradually bend and form them into the desired shape. This process is known as roll forming, and the entire unit consists of a de-coiler, a roller system, a cutting system, and a control system. These machines offer several advantages over other manufacturing techniques, such as reduced material wastage, faster production speeds, and increased precision.What is a Color Steel Roll Forming Machine Factory?A Color Steel Roll Forming Machine Factory refers to a production facility that is specifically designed for manufacturing various types of color coated steel products. These machines provide a convenient solution for meeting the demand of the modern construction industry. The color steel material produced is attractive and durable, making it an ideal choice for the roofing, walling, and cladding systems.The Color Steel Roll Forming Machine Factory is highly flexible, which means it can produce a wide range of profiles and shapes with high precision and consistently. This flexibility, combined with the ability to customize profiles and shapes, makes it the ideal choice for architects, contractors, and manufacturers, who need to create unique products suited to their specific requirements.Features of the Color Steel Roll Forming Machine FactoryThe Color Steel Roll Forming Machine Factory is a versatile piece of equipment that can handle multiple projects. Some of the features that make it stand out include;1. High Precision and ConsistencyThe high precision and consistency of the roll forming process means that all the products produced are uniform in quality, size, and shape.2. VersatilityA color steel roll forming machine factory can create different profiles and shapes. The factory can produce panels of different profiles, including corrugated or ribbed, standing seams, box profiles, and curved products.3. Reduced Material WastageBy eliminating the need for manual cutting and forming, roll forming machines reduce the amount of wastage generated during the manufacturing process.4. High-Speed ProductionOne of the primary advantages of using a color steel roll forming machine factory is the high-speed production cycle that reduces lead times while maintaining the quality of the products.ConclusionIn conclusion, the Color Steel Roll Forming Machine Factory is an integral part of the steel industry, providing a modern and innovative alternative to traditional steel products. With a wide range of features designed to cater to the needs of the modern construction industry, the possibilities for color steel roll forming machines are endless. As a leading manufacturer of Roll Forming Machines, (brand name removed) offers high-quality machines, unmatched customer service, and competitive prices. Contact us today for further inquiries or visit our website for more information about our products and services.

High-Quality Corrugated Roll Making Machine for Manufacturing Purposes

Corrugated Roll Making Machine: A New Milestone for Manufacturing ExcellenceIn the world of modern industry, the need for efficient and high-quality machinery is paramount. This is especially true in the manufacturing of corrugated rolls, essential components in packaging and shipping. In response to this demand, a leading machinery manufacturer has recently introduced a state-of-the-art Corrugated Roll Making Machine, setting a new milestone for manufacturing excellence.The Corrugated Roll Making Machine, developed by a company with a long-standing reputation for innovation and quality in the industry, represents the latest advancement in corrugated roll manufacturing technology. This machine is designed to streamline the production process, allowing for increased efficiency and consistency in the manufacturing of corrugated rolls. In addition, it incorporates cutting-edge features that ensure the high quality and durability of the final product.With a focus on precision engineering and advanced automation, the Corrugated Roll Making Machine is capable of producing a wide range of corrugated roll sizes and specifications to meet the diverse needs of the industry. Its versatility and flexibility make it an ideal solution for manufacturers seeking to enhance their production capabilities and stay ahead of the competition.Furthermore, the company behind the Corrugated Roll Making Machine has a proven track record of delivering reliable and durable machinery to its customers. With a commitment to continuous research and development, they have consistently pushed the boundaries of innovation in the industry, and the introduction of this new machine is a testament to their dedication to excellence.The company's extensive experience in the manufacturing industry, combined with their in-depth knowledge of customer needs, has enabled them to develop a machine that not only meets the current demands of the market but also anticipates future trends. By investing in the Corrugated Roll Making Machine, manufacturers can be confident that they are acquiring a cutting-edge solution that will support their growth and success for years to come.In addition to the advanced technological capabilities of the Corrugated Roll Making Machine, the company also provides comprehensive support and service to its customers. From installation and training to ongoing maintenance and technical assistance, they ensure that their customers are equipped with the knowledge and resources to maximize the potential of their investment.As the global demand for corrugated rolls continues to rise, the introduction of the Corrugated Roll Making Machine represents a significant opportunity for manufacturers to elevate their production capabilities and meet the evolving needs of the market. By harnessing the power of this innovative machine, manufacturers can improve efficiency, reduce waste, and deliver superior quality products to their customers.In conclusion, the Corrugated Roll Making Machine is a game-changer for the manufacturing industry. With its advanced technology, precision engineering, and unwavering commitment to excellence, it is set to redefine the standards for corrugated roll production. As manufacturers embrace this new milestone in manufacturing excellence, they can look forward to a future of increased productivity, profitability, and success.

Revolutionary Aluminum Profile Bending Machine Unveiled in Latest News

Title: Revolutionary CNC Aluminum Profile Bending Machine Transforming the Manufacturing IndustryIntroduction:In a rapidly evolving manufacturing industry, technological advancements have always played a crucial role in enhancing efficiency and precision. A groundbreaking solution has emerged in the form of a CNC Aluminum Profile Bending Machine, which is revolutionizing the way aluminum profiles are bent and shaped. By seamlessly merging technology and precision engineering, this innovative machine promises to deliver unprecedented results in terms of accuracy, speed, and versatility.Technological Features:The CNC Aluminum Profile Bending Machine is equipped with state-of-the-art computer numerical control (CNC) technology, allowing for precise control and automation of the bending process. It utilizes advanced algorithms to calculate the required bending angles, eliminating human errors and ensuring consistent quality.The machine is designed to accommodate a wide range of aluminum profiles, from simple extrusions to complex designs, catering to the diverse needs of industries such as architecture, construction, automotive, and aerospace. Its adjustable mandrel enables the bending of profiles in various sizes and shapes, offering infinite possibilities for customization.Furthermore, the CNC Aluminum Profile Bending Machine boasts a user-friendly interface, making it accessible to operators with varying levels of expertise. The intuitive controls allow for easy programming and quick set-up, reducing downtime and enhancing overall productivity.Benefits and Advantages:The introduction of this cutting-edge machine brings several benefits to the manufacturing industry, including:1. Enhanced Precision: The CNC technology ensures consistent results, minimizing deviations and errors. The machine's ability to bend aluminum profiles with exceptional accuracy and repeatability guarantees a high-quality end product.2. Improved Efficiency: By automating the bending process, the machine significantly reduces production time. Its high-speed operation enables rapid bending without compromising precision, making it ideal for large-scale manufacturing.3. Cost Savings: The CNC Aluminum Profile Bending Machine optimizes material usage, reducing waste. Its efficiency also translates into lower labor costs and increased production capacity, ultimately contributing to enhanced profitability.4. Versatility: The machine accommodates various aluminum profiles, allowing manufacturers to explore new design possibilities. It empowers engineers and designers to create complex and intricate shapes with ease, thus expanding the scope of their creative capabilities.5. Safety and Reliability: With advanced safety features and robust construction, the CNC Aluminum Profile Bending Machine prioritizes operator well-being. Its reliability ensures minimal maintenance requirements, leading to minimal downtime.Company's Commitment to Innovation:In keeping with its commitment to innovation and customer satisfaction, the company responsible for the CNC Aluminum Profile Bending Machine continually invests in research and development. It employs a team of highly skilled engineers and technicians dedicated to enhancing the machine's capabilities and exploring new possibilities for aluminum profile bending.The company possesses a solid track record, having successfully introduced several revolutionary machines to the manufacturing industry. Its relentless pursuit of excellence and customer-centric approach have earned it a reputation as a leading innovator in the field.Conclusion:The introduction of the CNC Aluminum Profile Bending Machine marks a significant technological breakthrough in the manufacturing industry. Its advanced CNC technology, precision engineering, and versatility empower manufacturers to achieve unprecedented precision, efficiency, and design possibilities. With its numerous benefits and the company's commitment to innovation, this machine is set to redefine the aluminum profile bending process and contribute to the advancement of the manufacturing sector as a whole.

High-quality Aluminum Extrusion Bending Machine for Precision Bends

Aluminum Extrusion Bending Machine Revolutionizing the IndustryThe [Company Name] has recently introduced a cutting-edge aluminum extrusion bending machine that is set to revolutionize the industry. This state-of-the-art machine is designed to streamline the process of bending aluminum extrusions, providing increased efficiency, accuracy, and flexibility in manufacturing operations.The advanced bending machine has the capability to bend aluminum extrusions of various shapes and sizes, offering a wide range of applications in industries such as automotive, aerospace, construction, and more. Its precision bending technology ensures consistent, high-quality results, meeting the demands of the most intricate and complex designs.With a focus on innovation and cutting-edge technology, the [Company Name] is committed to pushing the boundaries of what is possible in the field of aluminum extrusion bending. The new machine represents a significant leap forward in the company's ongoing efforts to provide the most advanced and reliable manufacturing solutions to its clients.The [Company Name] has a long-standing reputation for excellence in the industry, with a track record of delivering top-notch equipment and services to a wide range of clients across the globe. The introduction of the aluminum extrusion bending machine is yet another testament to the company's commitment to driving innovation and pushing the boundaries of what is possible in manufacturing.In addition to its cutting-edge technology, the aluminum extrusion bending machine also offers enhanced efficiency and cost-effectiveness. Its automated features and precision controls enable faster production cycles and reduced material waste, ultimately leading to substantial savings for manufacturers.Moreover, the machine's flexibility allows for rapid reconfiguration to accommodate different bending requirements, making it an ideal solution for businesses with diverse product portfolios. This adaptability ensures that manufacturers can meet the evolving needs of their clients while maintaining high standards of quality and precision.The introduction of the aluminum extrusion bending machine is a clear demonstration of the [Company Name]'s commitment to providing comprehensive solutions that cater to the evolving needs of the industry. By leveraging cutting-edge technology, the company continues to set new standards for excellence in manufacturing and remains at the forefront of innovation in the field.As the demand for high-quality aluminum extrusions continues to grow across various industries, the [Company Name] is well-positioned to meet the needs of its clients with this groundbreaking machine. Its advanced capabilities and unparalleled performance make it a game-changer in the industry, offering manufacturers a competitive edge in an increasingly dynamic market.The [Company Name] remains dedicated to delivering innovative solutions that drive efficiency, reliability, and precision in manufacturing operations. With the introduction of the aluminum extrusion bending machine, the company reaffirms its commitment to excellence and its ability to meet the evolving needs of the industry.In conclusion, the aluminum extrusion bending machine is a game-changer for the industry, offering manufacturers a cutting-edge solution that combines precision, efficiency, and flexibility. With its advanced technology and unmatched capabilities, the [Company Name] continues to lead the way in providing innovative manufacturing solutions that set new standards for excellence. As the demand for high-quality aluminum extrusions continues to rise, the introduction of this groundbreaking machine is set to have a significant impact on the industry, paving the way for a new era of manufacturing excellence.

Discover an Efficient and High-Quality Light Steel Roll Forming Machine

Title: Innovative Light Steel Roll Forming Machine Revolutionizes Construction IndustryIntroduction:In an era driven by innovation and technology, the construction industry has witnessed a remarkable breakthrough with the introduction of the Light Steel Roll Forming Machine. This cutting-edge machine is set to transform the traditional construction methods by providing a fast, efficient, and cost-effective solution for the production of light steel frames. By eliminating the need for labor-intensive and time-consuming practices, this technology promises to revolutionize the construction industry worldwide.Revolutionizing Construction with Light Steel Roll Forming Machine:With the growing demand for faster and more sustainable construction processes, the Light Steel Roll Forming Machine has emerged as a game-changer. The machine works by passing steel coil strips through a series of precisely aligned rollers, effectively shaping them into specific profiles required for constructing lightweight steel frames. This automated process not only ensures consistency in manufacturing but also significantly reduces manual labor, minimizing the risk of human error.The Benefits of Light Steel Roll Forming Machine:1. Efficiency: The Light Steel Roll Forming Machine can achieve high production speeds, leading to faster completion of projects. It has the ability to produce lightweight steel frames at a rate of several meters per minute, accelerating the construction process considerably. This increased efficiency translates into shorter project timelines and reduced labor costs.2. Cost-effectiveness: By automating the manufacturing process, the Light Steel Roll Forming Machine significantly reduces labor costs. Furthermore, its sophisticated design ensures minimal material wastage, optimizing resource utilization. As the machine requires fewer workers and allows for higher productivity, construction companies can achieve significant cost savings.3. Quality and Precision: The Light Steel Roll Forming Machine boasts advanced technology that guarantees superior quality and precision in the manufacturing process. Each steel profile is precisely molded according to the required specifications, ensuring consistency throughout the construction project. The machine also allows for customization, enabling architects and builders to create unique designs effortlessly.4. Sustainability: As environmental concerns become increasingly crucial, the Light Steel Roll Forming Machine offers a sustainable alternative to conventional construction methods. Light steel frames are recyclable, minimizing waste and reducing the carbon footprint. Moreover, the machine's efficient production process requires less energy compared to traditional techniques, contributing to a greener and more sustainable construction industry.Market Potential and Company Introduction:The global construction industry is witnessing rapid expansion, presenting immense opportunities for manufacturers of the Light Steel Roll Forming Machine. The market demand for faster and cost-effective construction methods continues to rise, making the machine a highly sought-after solution. One prominent manufacturer in this industry, {}, has gained recognition for its innovative approach and commitment to excellence.With years of experience in designing and producing roll forming machines, {} has positioned itself at the forefront of the industry. By leveraging cutting-edge technology and expertise, the company has developed a range of Light Steel Roll Forming Machines that cater to diverse construction needs. With a focus on quality, efficiency, and customer satisfaction, {} continues to revolutionize the construction industry worldwide.Conclusion:The introduction of the Light Steel Roll Forming Machine marks a significant milestone in the construction industry. This advanced technology offers an efficient, cost-effective, and sustainable solution for the production of lightweight steel frames. With the potential to streamline construction processes and deliver high-quality results, this machine promises to shape the future of the industry. As manufacturers like {} continue to innovate, the adoption of the Light Steel Roll Forming Machine is expected to become widespread, transforming construction practices on a global scale.

High-Quality Aluminum Profile Bending Machine for CNC Applications

In recent years, the demand for high-quality aluminum profile bending machines has been steadily increasing in various industries such as construction, manufacturing, and automotive. As a response to this growing demand, (Company name) has introduced a cutting-edge CNC aluminum profile bending machine that is set to revolutionize the industry.The CNC aluminum profile bending machine is a state-of-the-art piece of equipment that is designed to bend aluminum profiles with precision and efficiency. The machine is equipped with advanced CNC technology that allows for accurate and repeatable bending of aluminum profiles, resulting in high-quality finished products. This is especially crucial in industries such as construction and manufacturing where precision and quality are of utmost importance.One of the key features of the CNC aluminum profile bending machine is its flexibility. The machine is capable of bending aluminum profiles of various shapes and sizes, making it suitable for a wide range of applications. Additionally, the machine is designed to be user-friendly, with intuitive controls and easy programming, allowing for seamless operation by both experienced and novice operators.In addition to its precision and flexibility, the CNC aluminum profile bending machine is also known for its speed and efficiency. The machine is capable of bending aluminum profiles at a rapid pace, thereby increasing productivity and reducing lead times. This is essential for businesses looking to meet tight deadlines and stay ahead of the competition.(Company name) takes pride in offering products that are not only innovative but also reliable and durable. The CNC aluminum profile bending machine is no exception. It is built with high-quality materials and components, ensuring its longevity and robust performance even in the most demanding working environments. This makes it a valuable investment for businesses looking for a long-term solution for their aluminum profile bending needs.Furthermore, (company name) provides comprehensive technical support and after-sales service for its CNC aluminum profile bending machine. This includes installation, training, maintenance, and troubleshooting assistance, ensuring that customers can maximize the potential of the machine and minimize any downtime.The introduction of the CNC aluminum profile bending machine by (company name) is poised to have a significant impact on the industry. With its cutting-edge technology, precision, flexibility, and efficiency, the machine is set to meet the evolving demands of businesses across various sectors. It is expected to streamline the aluminum profile bending process, improve productivity, and elevate the quality of finished products.In conclusion, the CNC aluminum profile bending machine by (company name) represents a significant advancement in the industry. Its innovative features, coupled with the company's commitment to quality and customer support, make it a game-changer for businesses looking to enhance their aluminum profile bending capabilities. As the industry continues to evolve, (company name) remains at the forefront, delivering solutions that exceed expectations and set new standards for excellence.