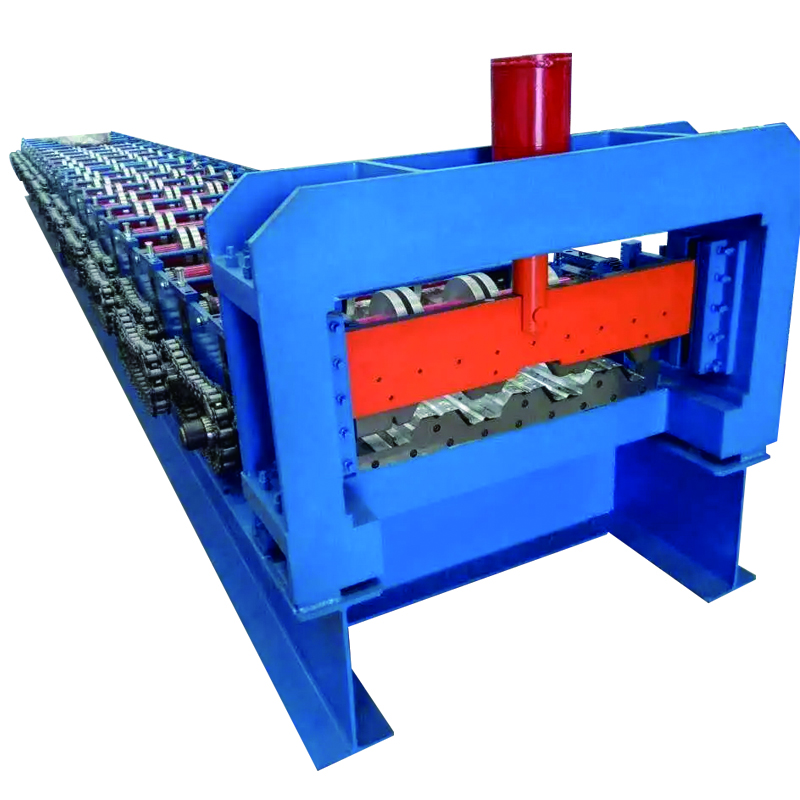

Roll Forming Machine for Light Steel Half Omega Steel Furring Channel

By:Admin

This Roll Former machine has been specifically designed to produce resilient furring channels from light steel, with a unique half omega shape that enhances the structural integrity of the channels. The roll forming process involves feeding a coil of steel through a series of rollers to gradually shape the material into the desired profile. The result is a high-quality furring channel that is not only strong and resilient, but also lightweight and easy to handle.

The key advantage of using a Light Steel Half Omega Steel Furring Channel is its superior performance in supporting and aligning drywall and plasterboard in construction projects. The unique half omega shape provides increased strength and stability, allowing for wider support spacing and reducing the risk of material failure. This translates to cost savings for builders and contractors, as well as improved safety and durability for the end users.

In addition to the roll former machine, [Company Name] also offers a Resilient Furring Channel Keel Roll Forming Machine, which is designed to produce the metal keels that are used in conjunction with the furring channels. The combination of these two machines provides a comprehensive solution for manufacturing high-quality metal furring systems that are essential for modern construction practices.

[Company Name] takes pride in its commitment to innovation and quality, and the development of the Light Steel Half Omega Steel Furring Channel Roll Former and Resilient Furring Channel Keel Roll Forming Machine is a testament to this dedication. With a focus on advanced technology and precise engineering, the company aims to meet the evolving needs of the construction industry and provide solutions that exceed the expectations of its customers.

The roll former machines are designed for efficiency and ease of use, with features that allow for quick setup and adjustment to accommodate different production requirements. This flexibility is essential for meeting the diverse demands of construction projects, where customization and adaptability are key factors in achieving success.

Furthermore, [Company Name] provides comprehensive support and maintenance services for its roll former machines, ensuring that customers can maximize their productivity and minimize downtime. The company's team of skilled technicians is available to provide training, troubleshooting, and ongoing assistance to ensure that the machines operate at peak performance.

As a leading manufacturer in the construction industry, [Company Name] understands the importance of staying ahead of the curve and delivering innovative solutions that address the challenges of modern construction. The Light Steel Half Omega Steel Furring Channel Roll Former and Resilient Furring Channel Keel Roll Forming Machine are prime examples of the company's proactive approach to product development, and its commitment to driving positive change in the industry.

In conclusion, the introduction of the Light Steel Half Omega Steel Furring Channel Roll Former and Resilient Furring Channel Keel Roll Forming Machine by [Company Name] represents a significant advancement in the field of construction materials and manufacturing technology. With a focus on quality, performance, and support, the company is well-positioned to meet the evolving needs of the construction industry and provide solutions that set new standards for resilience and durability.

Company News & Blog

High-Quality Slitting Line for HR Coils: Find Out How It Can Benefit Your Manufacturing Process

The company, a leading manufacturer of steel processing machinery, has recently announced the launch of their state-of-the-art HR Slitting Line. This new addition to their extensive line of products aims to provide high precision and efficiency in the processing of hot-rolled steel coils, catering to the growing demands of the steel industry.The HR Slitting Line is designed to handle hot-rolled steel coils with precision and speed, thanks to its advanced technology and robust construction. It is equipped with precision slitters that can cut the coils into various widths with remarkable accuracy, ensuring consistent and high-quality output. The line also features a powerful uncoiling and recoiling system that can handle steel coils of varying diameters and weights, making it suitable for a wide range of applications.The key highlight of this new HR Slitting Line is its ability to process steel coils at high speeds, without compromising on the quality and accuracy of the slitting process. This is achieved through the integration of cutting-edge automation and control systems that ensure smooth and efficient operation of the line. The company's commitment to delivering cutting-edge technology is evident in this new addition to their product line, as it offers a reliable solution for manufacturers looking to enhance their steel processing capabilities.In addition to its technical capabilities, the HR Slitting Line is designed with user convenience in mind. The ergonomic layout of the equipment, combined with intuitive controls, makes it easy for operators to set up and operate the line, thereby minimizing downtime and maximizing productivity. The company's dedication to providing user-friendly solutions is evident in the thoughtful design and layout of the HR Slitting Line, ensuring that it meets the diverse needs of steel manufacturers.The launch of the HR Slitting Line is a testament to the company's commitment to innovation and customer satisfaction. With a strong focus on research and development, the company continues to introduce cutting-edge solutions that address the evolving needs of the steel industry. The new line is poised to be a game-changer in steel processing, offering manufacturers a reliable and efficient solution for slitting hot-rolled steel coils.Furthermore, the company's dedication to customer support and service ensures that clients receive comprehensive assistance in installing and operating the HR Slitting Line. From initial consultation to after-sales support, the company's team of experts is committed to helping clients make the most of their investment in the new equipment. This commitment to customer satisfaction has been a cornerstone of the company's success and is evident in their growing base of satisfied clients.As the steel industry continues to evolve, the demand for efficient and reliable steel processing solutions is on the rise. The launch of the HR Slitting Line underscores the company's readiness to meet this demand and provide manufacturers with the tools they need to stay ahead in a competitive market. With its combination of advanced technology, user-friendly design, and dedicated customer support, the new line is set to make a significant impact in the steel processing industry.In conclusion, the introduction of the HR Slitting Line by the company represents a significant milestone in the steel processing industry. With its advanced technology, user-friendly design, and commitment to customer satisfaction, the new line is poised to set new standards for precision and efficiency in the processing of hot-rolled steel coils. As the company continues to innovate and cater to the evolving needs of the industry, the HR Slitting Line stands as a testament to their dedication to providing cutting-edge solutions for steel manufacturers.

Efficient Roll Forming Machine for Light Gauge Steel Keel Production

Title: Revolutionary Light Gauge Steel Keel Roll Forming Machine Revolutionizes Construction IndustryIntroduction: [Company Name], an industry-leading manufacturer of construction machinery, has recently unveiled its latest innovation, a groundbreaking Light Gauge Steel Keel Roll Forming Machine. This state-of-the-art machine is set to revolutionize the construction industry by significantly increasing efficiency and reducing labor costs in the production of light gauge steel frames and structures. With its unique features and advanced technology, the Light Gauge Steel Keel Roll Forming Machine is poised to become an indispensable tool for modern construction projects.Paragraph 1: Traditional methods of constructing light gauge steel structures can be labor-intensive and time-consuming. However, the Light Gauge Steel Keel Roll Forming Machine eliminates these barriers by automating the process with precision and speed. This advanced technology enables the production of consistent and high-quality steel frames, significantly reducing waste material and time spent on manual labor.Paragraph 2: The Light Gauge Steel Keel Roll Forming Machine operates on the principles of roll forming, which involves feeding a coil of flat steel through a series of rollers, gradually shaping it into the desired cross-sectional profile. With precise control and selection of raw materials, this machine provides highly accurate and uniform results, ensuring the structural integrity of the final products.Paragraph 3: The Light Gauge Steel Keel Roll Forming Machine boasts an array of features that set it apart from traditional methods. Its automated nature allows for continuous production without the need for manual intervention. Additionally, its modular design and customizable options cater to various project requirements, offering flexibility and adaptability.Paragraph 4: The Light Gauge Steel Keel Roll Forming Machine incorporates cutting-edge technology, including computer numerical control (CNC) systems. This automation ensures precise measurements and consistent panel lengths, minimizing errors. The machine's user-friendly interface enables easy operation and adjustment of parameters, making it accessible to both experienced professionals and newcomers to the industry.Paragraph 5: [Company Name] has invested significant resources into research and development to create a machine that not only enhances productivity but also prioritizes safety. The Light Gauge Steel Keel Roll Forming Machine is equipped with safety features, such as emergency stop buttons and protective barriers, ensuring a secure working environment for operators.Paragraph 6: The introduction of the Light Gauge Steel Keel Roll Forming Machine is expected to have far-reaching implications for the construction industry. Its efficiency and affordability make it an attractive option for large-scale projects, such as residential buildings, commercial complexes, and industrial facilities. The reduced labor costs associated with this machine represent a significant advantage in today's competitive construction market.Paragraph 7: The Light Gauge Steel Keel Roll Forming Machine aligns with global sustainability goals, as it promotes the use of lightweight steel structures that offer energy efficiency, durability, and recyclability. By minimizing waste and optimizing material utilization, this machine supports environmentally friendly construction practices.Conclusion: With its groundbreaking technology, the Light Gauge Steel Keel Roll Forming Machine is set to redefine the construction industry. By streamlining the production process, increasing precision, and reducing labor costs, this cutting-edge machine will undoubtedly play a crucial role in the development of sustainable and efficient structures worldwide. [Company Name]'s commitment to innovation has once again propelled the industry forward, offering a transformative solution for the construction sector.

Latest Updates on W Beam Crash Barrier Roll Forming Machine: Breaking News and Key Insights

Title: A Revolutionary W Beam Crash Barrier Machine for Enhanced Road SafetyIntroduction:In an era where road safety is of paramount importance, the development and utilization of the W Beam Crash Barrier Machine have become crucial. Designed to withstand high-impact collisions and prevent vehicles from crossing into opposing lanes, this state-of-the-art machine is revolutionizing the road infrastructure sector. In this blog, we will delve into the concept, manufacturing process, and several benefits of the W Beam Crash Barrier Machine, ensuring safer roads for all.Understanding the W Beam Crash Barrier Machine:The W Beam Crash Barrier Machine is a cutting-edge roll forming machine that plays a vital role in manufacturing W-shaped steel beams, popularly known as W beams. These beams serve as a protective barrier on highways and roads, significantly reducing the risk of fatal accidents. The machine features advanced technology, enabling precise and efficient production of the barriers to meet international safety standards.Manufacturing Process:The manufacturing process of the W Beam Crash Barrier Machine involves several crucial steps. Firstly, high-quality galvanized steel strips are selected for their superior strength and durability. These strips are then fed into the roll forming machine, which shapes them into the distinctive W beam profile.The machine's advanced automation system ensures accurate dimensions and consistent quality during the roll forming process. After the beams are formed, they undergo prompt and reliable galvanization. The galvanizing treatment protects the beams from corrosion caused by harsh weather conditions, thereby extending their lifespan.Advantages of the W Beam Crash Barrier Machine:1. Enhanced Road Safety: The primary purpose of the W Beam Crash Barrier Machine is to create crash barriers that offer robust protection for drivers and passengers. The sturdy W-shaped beams ensure the containment of vehicles, minimizing the chance of crossover accidents and promoting overall road safety.2. Durability and Longevity: The utilization of high-quality galvanized steel strips and effective galvanization techniques equips W beams with exceptional durability. These barriers can withstand high-impact collisions and harsh weather conditions, reducing the need for frequent replacements or maintenance.3. Cost-Effectiveness: The W Beam Crash Barrier Machine optimizes production efficiency, resulting in reduced manufacturing costs. Additionally, the long lifespan of the W beams translates into cost savings by minimizing repair expenses and replacement needs.4. Regulatory Compliance: The W Beam Crash Barrier Machine aligns with international safety standards, ensuring that the produced W beams meet all necessary regulatory guidelines. This compliance provides peace of mind for road authorities and enhances the overall road infrastructure.5. Versatility: The machine can be easily adjusted to produce W beams of various shapes, sizes, and specifications, making it adaptable to different road infrastructure requirements. This versatility makes the machine invaluable for road authorities and construction companies.Conclusion:In conclusion, the W Beam Crash Barrier Machine represents a significant advancement in road safety measures. Its ability to manufacture durable, high-quality crash barriers ensures the protection of drivers, passengers, and road infrastructure alike. By promoting containment and minimizing crossover accidents, these machines have revolutionized the road construction sector. With their exceptional versatility and regulatory compliance, it is evident that the W Beam Crash Barrier Machine will continue to play a vital role in enhancing road safety worldwide.Keywords: W Beam Crash Barrier Machine, road safety, roll forming machine, manufacturing process, highway barriers, galvanization, durability, longevity, cost-effectiveness, regulatory compliance, versatility.

Color Steel Glazed Tile Manufacturing Machine Enhances Roofing Industry Efficiency

[Company Introduction][Company Name], a leading manufacturer in the field of steel glazed tile manufacturing, is proud to announce the release of its latest innovation - the Color Steel Glazed Tile Manufacturing Machine (name removed according to the query). With a reputation for delivering high-quality products, [Company Name] has been serving the industry for over a decade. Our team of experienced engineers and technicians constantly strive to develop innovative solutions that meet the evolving needs of the market. Our dedication to quality, reliability, and precision has made us a trusted name in the industry.[Company Name] offers a comprehensive range of cutting-edge machinery and equipment designed for the production of color steel glazed tiles. Our customers span across various sectors such as construction, architecture, and infrastructure. We understand the importance of delivering products that not only withstand extreme weather conditions but also provide aesthetic appeal. Our color steel glazed tile manufacturing machines are engineered with great attention to detail, ensuring flawless performance and durability.As a company, we take pride in our commitment to sustainable practices. We prioritize energy efficiency and strive to develop machines that minimize waste and reduce carbon footprint. By embracing eco-friendly manufacturing processes, we aim to contribute positively to the environment and create a greener future.[Company Name] values customer satisfaction above all else. We believe in building strong relationships with our clients by offering exceptional after-sales support and services. Our team of technical experts is always available to address any queries or concerns our customers may have. We provide comprehensive training programs to ensure that our clients can operate our machines with ease and maximize their productivity.[News Content][City, Date] - [Company Name], a renowned leader in steel glazed tile manufacturing, has announced the launch of its latest state-of-the-art machinery - the Color Steel Glazed Tile Manufacturing Machine (name removed). This cutting-edge technology is set to revolutionize the industry with its innovative features and exceptional performance.The newly developed Color Steel Glazed Tile Manufacturing Machine (name removed) combines the latest advancements in engineering and materials science to deliver unmatched precision and efficiency. Its automated operation streamlines the manufacturing process, increasing productivity and reducing labor costs. The machine offers a high level of customization, allowing for the production of tiles in various colors, shapes, and sizes.Designed for durability, the Color Steel Glazed Tile Manufacturing Machine (name removed) is built to withstand the harshest environmental conditions. Its robust construction and advanced quality control mechanisms ensure consistent output and minimal downtime. This machine is engineered to facilitate efficient material utilization, reducing waste and optimizing production efficiency.One of the key features of the Color Steel Glazed Tile Manufacturing Machine (name removed) is its user-friendly interface. With a comprehensive control system, operators can easily monitor and adjust the production parameters, ensuring precise tile dimensions and perfect finishing. The machine's intuitive design simplifies the learning curve, allowing workers to operate it with minimal training.Speaking about the new product, [Company Name]'s spokesperson said, "We are thrilled to introduce the Color Steel Glazed Tile Manufacturing Machine (name removed) to our customers. This machine represents a significant milestone in our commitment to delivering cutting-edge solutions. With its advanced capabilities and unparalleled performance, we are confident it will exceed our customers' expectations."The Color Steel Glazed Tile Manufacturing Machine (name removed) has already gained significant attention from industry experts and potential customers alike. Its impressive features and competitive pricing make it a highly attractive option for businesses looking to enhance their production capabilities.In conclusion, [Company Name] continues to lead the steel glazed tile manufacturing industry with its commitment to innovation and customer satisfaction. The launch of the Color Steel Glazed Tile Manufacturing Machine (name removed) further solidifies their position as a trusted provider of high-quality machinery. As the industry evolves, [Company Name] remains dedicated to meeting and exceeding market demands while upholding their eco-friendly approach to manufacturing.

High-Quality Roll Forming Machine for Tile Production

[Company Name], a leading manufacturer of roll forming machines, has recently unveiled its latest innovation in the form of the high-performance Tile Roll Forming Machine. This new machine is designed to meet the increasing demand for efficient and precise roll forming of various types of tiles used in construction and roofing applications.The Tile Roll Forming Machine from [Company Name] is built with advanced technology and features a robust and durable structure to ensure long-term performance and reliability. It is equipped with precision rollers and forming dies that can produce high-quality tiles with tight tolerances and consistent dimensions. This machine is capable of forming a wide range of tile profiles, including corrugated, trapezoidal, and custom designs, making it suitable for diverse roofing and cladding requirements.One of the key highlights of this Tile Roll Forming Machine is its user-friendly design and intuitive controls, which allow for easy setup and operation. The machine can be quickly adjusted to accommodate different tile specifications, and it is equipped with a high-speed production capability to meet the demands of large-scale roofing projects. Additionally, the machine is equipped with safety features and protective guards to ensure the well-being of operators during operation.In line with [Company Name]'s commitment to innovation and customer satisfaction, the Tile Roll Forming Machine is also supported by a comprehensive after-sales service and technical support. The company provides training and technical assistance to customers to ensure proper operation and maintenance of the machine, as well as prompt availability of spare parts and consumables."We are excited to introduce our new Tile Roll Forming Machine, which is the result of extensive research and development to address the specific needs of the roofing and construction industry," said [Spokesperson Name], the CEO of [Company Name]. "This machine is designed to deliver high-quality and cost-effective solutions for producing various types of tiles, and we are confident that it will bring significant value to our customers."The introduction of the Tile Roll Forming Machine is expected to enhance [Company Name]'s position as a leading provider of roll forming solutions for the construction and building materials sector. The company has a proven track record of delivering innovative and reliable machines that cater to the evolving needs of the industry, and the new Tile Roll Forming Machine further strengthens its product portfolio.With its advanced features, efficient performance, and comprehensive support, the Tile Roll Forming Machine from [Company Name] is poised to set a new benchmark for tile roll forming technology and contribute to the advancement of the construction industry. This latest innovation reflects the company's dedication to excellence and its commitment to empowering customers with high-performance solutions.For more information about the Tile Roll Forming Machine and other roll forming solutions offered by [Company Name], interested parties can visit the company's website or contact their sales representatives for inquiries and consultations.About [Company Name]:[Company Name] is a leading manufacturer of roll forming machines, serving the construction, automotive, and other industries with innovative and reliable solutions. With a strong focus on technology and customer satisfaction, the company designs and manufactures a wide range of roll forming machines to meet the specific needs of its diverse clientele. Backed by a team of skilled professionals and a commitment to quality, [Company Name] continues to lead the way in roll forming technology and solutions.

Efficient Roof Tin Making Machine Empowers Seamless Roofing Production

Roof Tin Making Machine Revolutionizes the Manufacturing ProcessIn the ever-evolving world of manufacturing, technological advancements continue to reshape industries and revolutionize production processes. One such innovation is the Roof Tin Making Machine, a groundbreaking tool that promises to streamline and improve the manufacturing of roof tins. By integrating cutting-edge technology with efficient design, this machine is set to transform the roofing industry.The Roof Tin Making Machine, developed by an industry-leading company, is an impressive piece of machinery built to enhance productivity, improve output quality, and reduce overall costs. Its state-of-the-art features and functionalities make it an invaluable asset for manufacturers in the roofing sector.This cutting-edge machine is equipped with advanced automation and precision engineering, resulting in enhanced productivity and reduced manual labor. The elimination of manual intervention increases efficiency and minimizes the chance of human errors, resulting in a more streamlined manufacturing process. By automating various steps involved in roof tin production, this machine significantly boosts overall output and eliminates delays caused by manual labor.The Roof Tin Making Machine incorporates sophisticated control systems and software that enable manufacturers to achieve unparalleled precision and accuracy. Precision is crucial in the production of roof tins as even the slightest deviation can compromise the quality and performance of the final product. With this machine, manufacturers can achieve consistent results with minimal variations, ensuring that every roof tin produced meets the highest standards.Moreover, this innovative machine allows for rapid adjustment and customization, enabling manufacturers to cater to diverse client requirements. Its flexible design can adapt to different roof tin sizes, shapes, and specifications, empowering manufacturers to deliver personalized solutions to customers with ease. This versatility not only enhances customer satisfaction but also opens doors for new business opportunities.With sustainability becoming a paramount concern in manufacturing, the Roof Tin Making Machine incorporates eco-friendly features to promote green practices. By optimizing energy consumption and minimizing waste generation, this machine plays a role in reducing the carbon footprint associated with roof tin production. Manufacturers can contribute to a cleaner environment without compromising on quality or efficiency.Additionally, the Roof Tin Making Machine is designed with robust safety features to protect operators and minimize the risk of accidents. This machine adheres to stringent safety standards and is equipped with multiple safety devices. It also includes comprehensive training and support materials to ensure operators are well-versed in operating the machine safely.As a market leader in roof tin manufacturing technology, the company behind the Roof Tin Making Machine prides itself on delivering cutting-edge solutions that drive the industry forward. With a wealth of experience and expertise, the company has developed a strong reputation for delivering high-quality machinery that meets the evolving needs of manufacturers.The Roof Tin Making Machine is a testament to the company's commitment to innovation and customer satisfaction. By combining advanced technology with efficient design, this machine acts as a game-changer in the roofing industry, empowering manufacturers to reach new levels of productivity and excellence.In conclusion, the Roof Tin Making Machine is set to revolutionize the manufacturing process of roof tins. With its automation, precision, customization, sustainability, and safety features, this machine offers a plethora of advantages to manufacturers. By embracing this innovative technology, manufacturers can enhance their production capabilities, stay ahead of the competition, and provide superior products to customers.

High-Quality Glazed Tile Sheet Corrugation Equipment for Color Steel

Color Steel Glazed Tile Sheet Corrugation Equipment Revolutionizing the Roofing IndustryThe roofing industry has been revolutionized with the introduction of the Color Steel Glazed Tile Sheet Corrugation Equipment by [Company Name]. This state-of-the-art equipment is set to change the way roofing materials are manufactured and installed, offering a range of benefits to both manufacturers and consumers alike.[Company Name] is a leading manufacturer of innovative machinery for the construction industry, with a strong focus on developing products that improve efficiency, durability, and cost-effectiveness. With a commitment to research and development, [Company Name] has continuously strived to create cutting-edge solutions that meet the evolving needs of the industry.The Color Steel Glazed Tile Sheet Corrugation Equipment is the latest addition to [Company Name]'s portfolio, and it promises to revolutionize the production of roofing materials. The equipment is designed to produce high-quality glazed tile sheets from color steel coils, providing a durable and aesthetic roofing solution for residential and commercial buildings.One of the key features of the Color Steel Glazed Tile Sheet Corrugation Equipment is its ability to produce glazed tile sheets with a corrugated profile. This not only enhances the aesthetic appeal of the roofing material but also improves its structural strength and weather resistance. The equipment is capable of producing a wide range of tile profiles, allowing manufacturers to cater to diverse customer preferences.In addition to its versatility, the Color Steel Glazed Tile Sheet Corrugation Equipment is also highly efficient. It boasts a high production capacity, allowing manufacturers to meet the demands of large-scale projects without compromising on quality. Moreover, the equipment is equipped with advanced automation features, reducing the need for manual intervention and minimizing the risk of errors during the production process.Furthermore, [Company Name] has incorporated innovative technology into the equipment to enhance its performance and reliability. The Color Steel Glazed Tile Sheet Corrugation Equipment is designed to ensure uniform and precise shaping of the tile sheets, resulting in consistent quality across the entire production batch. Additionally, the equipment is engineered to minimize material wastage, optimizing resource utilization for manufacturers.Aside from its benefits for manufacturers, the Color Steel Glazed Tile Sheet Corrugation Equipment also offers advantages to consumers. The glazed tile sheets produced by this equipment are renowned for their durability, weather resistance, and low maintenance requirements. This makes them an ideal roofing solution for diverse climatic conditions, providing long-term protection for buildings and reducing the need for frequent repairs and replacements.Moreover, the aesthetic appeal of the glazed tile sheets adds value to properties, enhancing their visual appeal and curb appeal. With a range of colors and finishes available, consumers have the flexibility to choose roofing materials that complement their architectural style and personal preferences. Additionally, the superior quality of the glazed tile sheets translates to long-term cost savings for consumers, as they are less likely to incur expenses related to repairs and replacements.As the construction industry continues to prioritize sustainability, the Color Steel Glazed Tile Sheet Corrugation Equipment is aligned with this trend. The equipment is designed to minimize energy consumption and material wastage, contributing to the efficient use of resources and the reduction of environmental impact. Furthermore, the durable nature of the glazed tile sheets ensures a longer lifespan, reducing the need for raw material extraction and production in the long run.The introduction of the Color Steel Glazed Tile Sheet Corrugation Equipment by [Company Name] marks a significant milestone in the roofing industry. With its combination of advanced technology, efficiency, durability, and aesthetic appeal, this equipment is set to transform the way roofing materials are manufactured and installed. As the demand for high-quality and sustainable roofing solutions continues to grow, the Color Steel Glazed Tile Sheet Corrugation Equipment is well-positioned to meet the needs of manufacturers and consumers alike, shaping the future of the roofing industry.

Top 5 Benefits of Using a Step Tile Roll Forming Machine

Step Tile Roll Forming Machine has recently gained a lot of attention in the manufacturing industry for its efficient and precise tile forming capabilities. The machine is designed to create step-tile roofing sheets, which are widely used for residential and commercial buildings. With its advanced technology and high-speed production, the Step Tile Roll Forming Machine is set to revolutionize the roofing industry.The Step Tile Roll Forming Machine is a product of {}, a leading manufacturing company specializing in metal forming machinery. With over 20 years of experience in the industry, {} has established itself as a reliable and innovative provider of roll forming solutions. The company's commitment to quality, efficiency, and customer satisfaction has made it a trusted partner for businesses around the world.The Step Tile Roll Forming Machine is equipped with state-of-the-art features that set it apart from traditional roll forming machines. Its precision and speed make it possible to produce high-quality step-tile roofing sheets in a fraction of the time compared to manual methods. This not only increases productivity but also ensures consistent quality, which is crucial for meeting the demands of the construction industry.One of the key advantages of the Step Tile Roll Forming Machine is its versatility. It is capable of forming a variety of step-tile profiles, allowing for customization and flexibility in design. This makes it suitable for a wide range of roofing projects, from residential homes to large commercial buildings. Whether it's a simple or complex pattern, the machine can produce it with ease, making it an ideal solution for businesses of all sizes.In addition to its high-speed production and flexibility, the Step Tile Roll Forming Machine is also known for its durability and reliability. It is built to withstand continuous use and harsh working conditions, ensuring a long lifespan and minimal downtime. This is especially important for businesses with demanding production schedules, as the machine's reliability can significantly impact overall operations.Furthermore, the Step Tile Roll Forming Machine is designed with user-friendliness in mind. It is equipped with intuitive controls and an easy-to-understand interface, making it accessible to operators of varying skill levels. This not only reduces the need for extensive training but also minimizes the risk of errors during operation, maximizing efficiency and safety in the workplace.As the demand for efficient and cost-effective roofing solutions continues to grow, the Step Tile Roll Forming Machine is poised to make a significant impact on the industry. Its advanced technology, combined with the expertise of {}, makes it a valuable asset for businesses looking to streamline their production processes and stay ahead of the competition.With its exceptional performance, versatility, and durability, the Step Tile Roll Forming Machine is set to become a game-changer in the roofing industry. As businesses seek to meet the evolving needs of their customers, this innovative machine offers a solution that is both practical and profitable. For those looking to invest in a reliable and high-quality roll forming solution, the Step Tile Roll Forming Machine from {} is undoubtedly a top choice.

High-Quality Roof Panel Machine for Efficient Panel Production

PBR Roof Panel Machine: Revolutionizing Roofing SolutionsIn the world of construction and roofing, innovation plays a crucial role in creating efficient and durable solutions. The PBR Roof Panel Machine has been a game-changer in the industry, offering advanced technology and exceptional quality in the production of roof panels. This state-of-the-art machine, manufactured by a leading company in the field, has significantly transformed the way roofing panels are manufactured and installed.The PBR Roof Panel Machine is designed to efficiently produce high-quality PBR roof panels, which are known for their strength and durability. This machine utilizes advanced technology to precisely roll-form steel into the desired profile, creating panels that are not only aesthetically pleasing but also able to withstand harsh weather conditions and environmental factors. The precision and accuracy of the machine ensure that every panel produced is of consistent quality, meeting the highest standards of the industry.The company behind the PBR Roof Panel Machine is a renowned manufacturer of roofing and construction machinery. With decades of experience and expertise in the field, the company is committed to providing innovative solutions that meet the evolving needs of the construction industry. Their dedication to research and development has led to the creation of cutting-edge machinery that enhances productivity and delivers exceptional results.One of the key features of the PBR Roof Panel Machine is its versatility. The machine is capable of producing a wide range of panel sizes and thicknesses, giving users the flexibility to cater to various project requirements. This flexibility has made the machine a popular choice among roofing contractors, manufacturers, and construction companies, enabling them to meet the diverse needs of their customers with ease.In addition to its efficiency and versatility, the PBR Roof Panel Machine is also known for its user-friendly design. The machine is equipped with intuitive controls and features that make it easy to operate and maintain. This user-friendly approach has been well-received by professionals in the industry, as it reduces the learning curve and allows for seamless integration into existing operations.Furthermore, the company provides comprehensive support and training for customers who invest in the PBR Roof Panel Machine. Their team of experts offers training programs and technical assistance to ensure that users can maximize the capabilities of the machine and achieve optimal results. This commitment to customer satisfaction sets the company apart and has established them as a trusted partner in the roofing and construction sector.The impact of the PBR Roof Panel Machine on the industry has been profound. Its ability to streamline the production process, enhance product quality, and improve efficiency has resulted in significant cost savings for users. The machine has also contributed to the advancement of sustainable construction practices, as the durable panels it produces contribute to the longevity of buildings and reduce the need for frequent repairs and replacements.Looking ahead, the company is dedicated to further enhancing the capabilities of the PBR Roof Panel Machine, as well as developing new technologies that continue to push the boundaries of what is possible in the industry. With a focus on innovation and a commitment to excellence, they are poised to remain at the forefront of the roofing and construction machinery sector, delivering state-of-the-art solutions that empower their customers to succeed.In conclusion, the PBR Roof Panel Machine has redefined the standards of roofing panel production and installation. Its advanced technology, versatility, and user-friendly design have made it a preferred choice for professionals in the industry. Coupled with the support and expertise of the manufacturing company, the machine has become a symbol of quality, efficiency, and innovation in the construction sector. As the industry continues to evolve, the PBR Roof Panel Machine is likely to play a pivotal role in shaping its future.

High-Quality Sheet Metal Punching Machine with 22KW Power – C Frame Casting Fuselage J23 Series

Title: Leading Manufacturer Introduces High-Quality Sheet Metal Punching Machine for Enhanced Efficiency Introduction:With the rising demand for precision and efficiency in the metalworking industry, {Company Name}, a prominent player in the manufacturing sector, has unveiled its latest innovation, the 22KW Power Steel Hole Punching Machine C Frame Casting Fuselage J23 Series. This cutting-edge machine promises to revolutionize the sheet metal punching process, providing unparalleled quality and performance for diverse industrial applications.Innovative Features and Superior Quality:The 22KW Power Steel Hole Punching Machine demonstrates the company's unwavering commitment to delivering outstanding products. This state-of-the-art machine incorporates a robust C Frame Casting Fuselage, enhancing its stability and durability. The use of high-quality materials ensures that it can withstand the rigorous demands of heavy-duty industrial operations.The machine boasts an impressive 22KW power capacity, allowing it to effortlessly handle various sheet metal materials. Whether it is stainless steel, aluminum, or mild steel, this punching machine guarantees a smooth and precise punching process, resulting in impeccable finished products.Uncompromising Precision and Efficiency:The J23 Series Sheet Metal Punching Machine is designed to deliver exceptional precision and efficiency. Equipped with advanced technology, the machine ensures accurate hole punching and seamless integration with other fabrication processes. Its cutting-edge control system allows operators to program and execute complex punching patterns effortlessly, reducing human error and enhancing overall efficiency.Additionally, the J23 Series offers superior versatility, enabling manufacturers to produce a wide range of products without compromising quality. From intricate designs to high-volume production, this machine can meet the diverse needs of various industries, including automotive, electronics, and appliances.High-Performance Components and Enhanced Safety:{Company Name} understands the significance of incorporating safety features into their machines. The 22KW Power Steel Hole Punching Machine ensures the well-being of operators with comprehensive safety mechanisms. These include emergency stop buttons, overload protection, and protective guards to prevent accidents and injuries in the workplace.Furthermore, the company's commitment to sustainability and energy efficiency is evident in the machine's design. The J23 Series implements energy-saving technologies, optimizing power consumption during operation. This not only reduces the carbon footprint but also delivers cost savings for businesses, aligning with the global push for sustainable manufacturing practices.Commitment to Customer Satisfaction and Service:{Company Name} prides itself on its dedication to customer satisfaction. With the introduction of the 22KW Power Steel Hole Punching Machine, the company aims to meet and exceed the expectations of clients worldwide. {Company Name}'s team of highly skilled technicians and engineers are readily available to provide training, installation support, and routine maintenance for seamless machine operation.Conclusion:The introduction of the 22KW Power Steel Hole Punching Machine C Frame Casting Fuselage J23 Series solidifies {Company Name}'s position as a leading manufacturer in the industry. With its superior quality, precise performance, enhanced efficiency, and commitment to customer satisfaction, this machine is set to revolutionize the sheet metal punching process, empowering manufacturers to achieve exceptional results.