Top Corrugated Roof Panel Forming Equipment on the Market

By:Admin

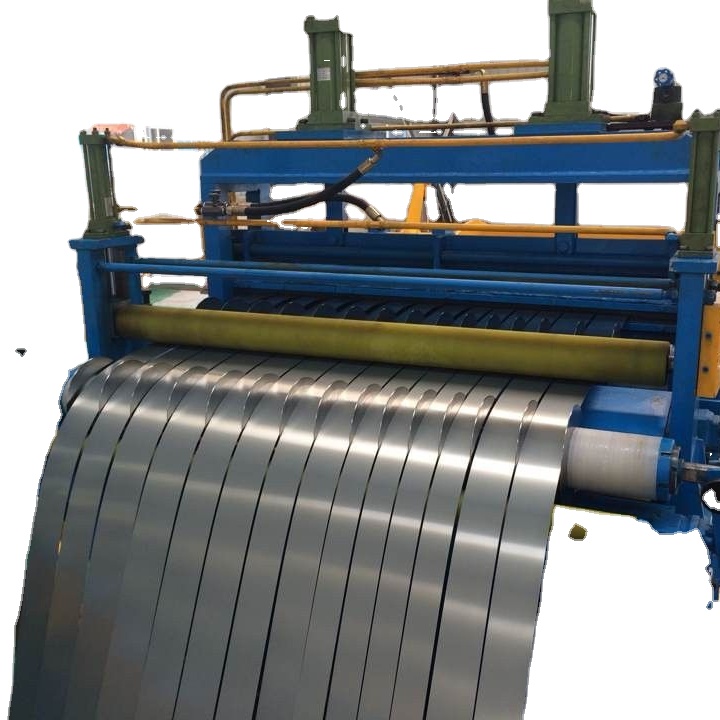

Corrugated roof panel forming equipment is a game-changer in the construction industry, offering innovative solutions for roofing needs. With advanced technology and precision engineering, this state-of-the-art equipment has set a new standard for efficiency and quality in roof panel production.

This cutting-edge equipment is designed and manufactured by a leading company specializing in metal forming solutions. With a strong commitment to innovation and excellence, they have become a trusted name in the industry. Their expertise in engineering and manufacturing has enabled them to develop a wide range of metal forming equipment that meets the diverse needs of their customers.

The corrugated roof panel forming equipment is a shining example of the company's dedication to pushing the boundaries of what is possible in metal forming technology. It is designed to streamline the production process, allowing for faster and more efficient manufacturing of corrugated roof panels. This equipment is capable of producing panels with precise dimensions and consistent quality, meeting the highest industry standards.

One of the key features of this equipment is its versatility. It is capable of forming a variety of profiles and shapes, giving manufacturers the flexibility to meet the demands of different projects. Whether it is for residential, commercial, or industrial applications, this equipment can produce roof panels that are tailored to specific requirements. This versatility makes it an invaluable asset for roofing contractors and manufacturers.

The equipment also incorporates advanced automation and control systems, further enhancing its efficiency and reliability. With automated processes and integrated quality control measures, manufacturers can ensure that every panel meets the required specifications. This not only reduces the likelihood of errors but also increases productivity, ultimately leading to cost savings for the manufacturer.

The durability and longevity of the corrugated roof panels produced by this equipment are also outstanding. Using high-quality materials and precision manufacturing techniques, the panels are designed to withstand harsh environmental conditions and provide long-term protection for buildings. This is essential for ensuring the integrity and performance of the roofing system over time.

Moreover, the equipment is designed with the operator in mind, prioritizing safety and ease of use. Intuitive controls and ergonomic design make it user-friendly, allowing operators to work efficiently and safely. This not only creates a better working environment but also contributes to the overall productivity and success of the manufacturing process.

In addition to the equipment itself, the company provides comprehensive support and service to its customers. From installation and training to maintenance and troubleshooting, they are committed to ensuring that their customers get the most out of their investment. This level of support has earned them a reputation for excellence in customer service, further solidifying their position as a leader in the industry.

Overall, the corrugated roof panel forming equipment is a significant advancement in metal forming technology. Its ability to streamline production, enhance quality, and provide versatility makes it an invaluable asset for the construction industry. With a strong commitment to innovation and customer satisfaction, the company behind this equipment continues to drive progress and set new standards for roofing solutions.

Company News & Blog

Efficient Automatic Length Cutting Machine for Various Applications

Automatic Length Cutting Machine Revolutionizing Precision Cutting in Manufacturing IndustryIn today's fast-paced manufacturing industry, precision cutting plays a crucial role in ensuring the quality and accuracy of the final product. To meet the demand for high-precision cutting in various industries, the introduction of the Automatic Length Cutting Machine has revolutionized the way manufacturers produce cut-to-length products. This state-of-the-art machine, developed and manufactured by {Company Name}, is setting new standards for precision cutting in the manufacturing industry.{Company Name} has been at the forefront of manufacturing innovative machinery and equipment for various industries for over two decades. With a commitment to excellence and a strong focus on technological advancements, the company has established itself as a leading provider of cutting-edge solutions for precision cutting and manufacturing processes. The Automatic Length Cutting Machine is a testament to their dedication to delivering high-quality, efficient, and reliable equipment to their clients.The Automatic Length Cutting Machine is designed to provide unmatched precision and accuracy in cutting various materials, including metal sheets, plastic, rubber, and other industrial materials. The machine's advanced cutting technology ensures consistent and uniform cuts, enabling manufacturers to produce high-quality products with minimal waste and maximum efficiency. This level of precision is critical for industries such as automotive, aerospace, construction, and metal fabrication, where the quality of the cut directly impacts the performance and reliability of the final product.One of the key features of the Automatic Length Cutting Machine is its advanced automation system, which allows for easy programming and set-up of cutting parameters. This significantly reduces the time and effort required for manual adjustments, while also minimizing the risk of human error. Additionally, the machine's intuitive interface and user-friendly controls make it accessible to operators of all skill levels, further streamlining the manufacturing process and increasing overall productivity.The versatility of the Automatic Length Cutting Machine is another standout feature, as it is capable of handling a wide range of materials and dimensions. Whether it's a small batch of custom-sized parts or large-scale production runs, the machine can accommodate varying lengths and thicknesses with precision and consistency. This flexibility makes it an invaluable asset for manufacturers looking to optimize their production processes and meet the diverse demands of their clients.Furthermore, the Automatic Length Cutting Machine is equipped with advanced safety features to ensure the well-being of operators and minimize the risk of accidents. The machine's enclosure and safety interlocks provide a secure operating environment, while its built-in sensors and monitoring systems enhance overall operational safety. This commitment to safety reflects {Company Name}'s dedication to not only providing cutting-edge technology but also prioritizing the well-being of its clients and their personnel.In addition to its technical capabilities, the Automatic Length Cutting Machine is backed by {Company Name}'s comprehensive support and service network. From initial installation and commissioning to ongoing maintenance and technical assistance, the company's team of experts is committed to providing exceptional support to ensure the seamless operation of their equipment. This dedication to customer satisfaction has earned {Company Name} a reputation for reliability and trustworthiness in the manufacturing industry.The introduction of the Automatic Length Cutting Machine by {Company Name} is poised to reshape the landscape of precision cutting in the manufacturing industry. By combining cutting-edge technology, unmatched precision, and exceptional versatility, this machine is redefining the standard for high-quality, efficient, and reliable cutting solutions. As manufacturers continue to seek ways to optimize their production processes and enhance their competitive edge, the Automatic Length Cutting Machine stands as a testament to {Company Name}'s commitment to innovation and excellence in the manufacturing sector.

High-Quality Glazed Tile Making Machine for Efficient Production

For immediate releaseA New Innovation in Glazed Tile Making Technology: Introducing the Glazed Tile Making MachineAs the demand for high-quality construction materials continues to rise, the need for innovative and efficient manufacturing solutions becomes increasingly important. That’s why we are excited to introduce the new Glazed Tile Making Machine, a revolutionary piece of equipment that is set to change the landscape of the construction industry.The Glazed Tile Making Machine is the latest innovation from our company, a leading manufacturer of industrial machinery and equipment. With a strong focus on research and development, we have been at the forefront of technological advancements in the manufacturing sector for over two decades. Our commitment to excellence and innovation has led us to develop the Glazed Tile Making Machine, a state-of-the-art piece of equipment that promises to revolutionize the way glazed tiles are produced.One of the key features of the Glazed Tile Making Machine is its advanced automation capabilities. Equipped with cutting-edge technology, the machine is capable of carrying out the entire tile production process with minimal human intervention. This not only increases productivity and efficiency but also ensures consistent and high-quality output, meeting the demands of modern construction projects.In addition to its automation capabilities, the Glazed Tile Making Machine also boasts a high level of customization. With the ability to produce a wide range of tile sizes, shapes, and designs, the machine offers unprecedented flexibility to meet the diverse needs of our customers. Whether it’s a small-scale residential project or a large commercial development, the Glazed Tile Making Machine is capable of delivering customized solutions to suit any requirement.Furthermore, the Glazed Tile Making Machine is designed with sustainability in mind. As environmental concerns continue to grow, the machine has been developed to minimize waste and energy consumption, making it an eco-friendly option for manufacturers. By using advanced materials and production techniques, the machine ensures that the manufacturing process is as environmentally friendly as possible, aligning with the global push for sustainable practices.The introduction of the Glazed Tile Making Machine marks a significant milestone in the evolution of the construction industry. With its innovative features and advanced capabilities, the machine is set to redefine the way glazed tiles are manufactured, setting new standards for efficiency, quality, and sustainability.As we look to the future, we remain committed to pushing the boundaries of innovation and technology in the manufacturing sector. The Glazed Tile Making Machine is just one example of our dedication to providing cutting-edge solutions to our customers, and we are excited to see the impact it will have on the industry.In conclusion, the Glazed Tile Making Machine represents a new era in the production of glazed tiles. With its advanced automation, customization, and sustainability features, the machine is set to revolutionize the way tiles are manufactured, providing a cost-effective and environmentally friendly solution for the construction industry. We are proud to introduce this groundbreaking technology and look forward to the positive impact it will have on our customers and the wider industry.For more information about the Glazed Tile Making Machine, please visit our website or contact us directly for inquiries and demonstrations.

Top-Quality Metal Roll Forming Machine for Sale with Roof Panel Roll Forming Machine

Metal Roll Forming Machine for Sale: A Boon for the Construction IndustryThe construction industry is witnessing rapid growth and development, and with it, the demand for efficient and high-quality machinery. One such piece of equipment that has become indispensable in the construction sector is the metal roll forming machine. Known for its versatility, reliability, and precision, this machine has revolutionized the way metal panels and profiles are created. It offers a cost-effective solution for constructing roofs, walls, and other structural components.In line with the growing demand, Metal Roll Forming Machine, a renowned industry player, is now offering their top-of-the-line metal roll forming machines for sale.Metal roll forming machines are capable of shaping various metals, such as steel, aluminum, and galvanized iron, into customized profiles of different shapes and sizes. These machines utilize a continuous bending process, wherein the metal strip is fed through a series of rollers, gradually shaping it into the desired profile. The resulting products offer exceptional structural strength, durability, and aesthetics.Metal Roll Forming Machine offers a wide range of machines to cater to the diverse needs of the construction industry. Their roof panel roll forming machine is particularly sought-after due to its ability to efficiently produce high-quality roof panels. These panels not only enhance the visual appeal of buildings but also provide superior protection against adverse weather conditions.One of the key features that set Metal Roll Forming Machine apart is its commitment to quality. The machines they offer are manufactured using state-of-the-art technology, ensuring unrivaled precision and performance. These machines undergo rigorous testing and quality checks to meet international standards and provide customers with reliable and long-lasting solutions.Metal Roll Forming Machine prides itself on providing excellent customer service. Their team of experienced professionals assists clients in selecting the most suitable machine for their specific requirements. Offering comprehensive after-sales support, they ensure that customers receive training and technical assistance to maximize the utilization of the machines.Moreover, Metal Roll Forming Machine understands the importance of sustainability and the need to minimize the environmental impact of their operations. Their machines are designed to optimize energy efficiency while minimizing material waste during the roll forming process. By adopting eco-friendly practices, Metal Roll Forming Machine is leading the way towards a greener and more sustainable future in the construction industry.To further facilitate customer convenience, Metal Roll Forming Machine now offers their machines for sale online. The user-friendly interface of their website allows customers to browse through their product catalog, compare specifications, and make informed purchasing decisions. With just a few clicks, customers can now own a top-quality metal roll forming machine to meet their construction needs.In conclusion, the availability of metal roll forming machines for sale by Metal Roll Forming Machine comes as a boon for the construction industry. These machines provide an efficient and cost-effective solution for producing high-quality metal profiles and panels. With their commitment to quality, customer service, and sustainability, Metal Roll Forming Machine has established itself as a trusted and reliable provider of metal roll forming machines. By investing in their machines, construction companies can elevate their productivity, efficiency, and profitability, ultimately contributing to the growth and advancement of the construction sector.

High-Performance Arch Bending Machine for Aluminium Material

Aluminium Arch Bending Machine Revolutionizes the IndustryThe aluminium arch bending machine has been a game-changer in the industry, making the process of bending aluminium arches faster, easier, and more precise. This technology has been at the forefront of innovation, transforming the way aluminium arches are produced and bringing significant benefits to manufacturers and fabricators.The aluminium arch bending machine, developed by a leading company in the industry, has revolutionized the production of aluminium arches. With its advanced technology and precision engineering, this machine has paved the way for more efficient and cost-effective production processes.With the ability to bend aluminium arches of various sizes and shapes, this machine has streamlined the manufacturing process, reducing the time and labor required to produce high-quality arches. The precision and accuracy of the machine ensure that each arch is bent to exact specifications, meeting the highest standards of quality and performance.The company behind this groundbreaking technology is a reputed and established leader in the industry, known for its commitment to innovation and excellence. With a strong focus on research and development, the company has continuously strived to push the boundaries of technology and engineering, delivering cutting-edge solutions that meet the evolving needs of the industry.The aluminium arch bending machine is a testament to the company's dedication to providing innovative and reliable equipment for the manufacturing and fabrication of aluminium products. Its state-of-the-art features and advanced capabilities have set a new benchmark for efficiency and precision in aluminium arch bending, earning the trust and confidence of manufacturers and fabricators worldwide.In addition to its technological prowess, the company also prides itself on its comprehensive customer support and service network. With a team of highly trained technicians and engineers, the company ensures that its clients receive the highest level of support and assistance, from installation and training to ongoing maintenance and troubleshooting.The success of the aluminium arch bending machine has been attributed to its cutting-edge technology, precision engineering, and the unwavering commitment of the company behind it. As the industry continues to evolve, the company remains at the forefront, driving innovation and delivering solutions that empower manufacturers and fabricators to achieve new levels of efficiency and productivity.The impact of the aluminium arch bending machine has been felt across the industry, with manufacturers and fabricators reaping the benefits of streamlined production processes, improved quality, and reduced costs. This technology has not only transformed the way aluminium arches are produced but has also set a new standard for excellence and innovation in the industry.Looking ahead, the company remains dedicated to pushing the boundaries of technology, engineering, and manufacturing, continuing to deliver breakthrough solutions that address the evolving needs of the industry. With its unwavering commitment to excellence and customer satisfaction, the company is poised to remain a leader in the industry, driving innovation and shaping the future of aluminium arch bending.In conclusion, the aluminium arch bending machine has undoubtedly revolutionized the industry, setting new standards for efficiency, precision, and quality in aluminium arch bending. With its advanced technology and unwavering commitment to excellence, the company behind this groundbreaking technology has solidified its position as a leader in the industry, driving innovation and empowering manufacturers and fabricators to achieve new levels of success.

Fully Automatic C Shape Purlin Making Machine for Efficient Production

Fully Automatic Change C Shape Purlin Making Machine Revolutionizes Steel Manufacturing IndustryIn a revolutionary advancement in the steel manufacturing industry, a leading company has introduced the Fully Automatic Change C Shape Purlin Making Machine, which is set to transform the production process of C shape purlins. This state-of-the-art machine promises to enhance efficiency, precision, and speed of production, while significantly reducing manual labor and production costs.The Fully Automatic Change C Shape Purlin Making Machine has been developed by a renowned company that specializes in advanced manufacturing equipment. With a strong focus on innovation and cutting-edge technology, the company has established a reputation for delivering high-quality and reliable machinery for the steel industry.The new machine is equipped with advanced features and capabilities that set it apart from traditional purlin making machines. One of its key highlights is its fully automatic operation, which eliminates the need for manual intervention in the production process. This not only improves the overall efficiency of production but also reduces the risk of errors and inconsistencies in the final product.Additionally, the machine is designed to change its settings automatically to produce different sizes and shapes of C purlins, without the need for manual adjustments. This versatility allows for seamless transition between different production requirements, enabling manufacturers to meet diverse customer demands with ease.Furthermore, the Fully Automatic Change C Shape Purlin Making Machine boasts a high production speed, enabling manufacturers to significantly increase their output without compromising on quality. The precision and accuracy of the machine ensure that each purlin produced meets the required specifications, resulting in consistent and reliable products.The introduction of this advanced purlin making machine is expected to have a significant impact on the steel manufacturing industry. By streamlining the production process and reducing the reliance on manual labor, manufacturers can achieve higher levels of productivity and cost-efficiency. This, in turn, can lead to improved competitiveness and profitability for companies operating in the sector.The company behind the Fully Automatic Change C Shape Purlin Making Machine has built a strong reputation for its commitment to delivering innovative solutions that address the evolving needs of the steel industry. With a team of skilled engineers and industry experts, the company has continuously focused on research and development to bring groundbreaking technologies to the market.The launch of the new machine is a testament to the company's dedication to driving progress and innovation in the steel manufacturing sector. By leveraging its expertise and technological capabilities, the company has successfully developed a game-changing solution that has the potential to redefine the way C purlins are produced.As the global demand for steel products continues to rise, the introduction of advanced machinery such as the Fully Automatic Change C Shape Purlin Making Machine is instrumental in enhancing the overall efficiency and sustainability of the industry. With its ability to optimize production processes and deliver superior quality products, the machine is set to raise the bar for purlin manufacturing standards.In conclusion, the Fully Automatic Change C Shape Purlin Making Machine represents a significant leap forward in the steel manufacturing industry. With its advanced features, automatic operation, and ability to adapt to diverse production requirements, the machine is poised to revolutionize the way C purlins are manufactured. As the company continues to drive innovation and technological advancement, the industry can look forward to further advancements that will shape the future of steel manufacturing.

Innovative Profiling Equipment for Creating Glazed Tiles

Title: Advanced Profiling Equipment Revolutionizes Glazed Tile ManufacturingIntroduction:In a groundbreaking development that is set to transform the glazed tile manufacturing industry, a leading company has unveiled its latest innovation - advanced profiling equipment. This cutting-edge technology eliminates the need for manual profiling, streamlining the production process and ensuring unparalleled precision and efficiency. By leveraging this state-of-the-art machinery, manufacturers can now produce an exquisite range of glazed tiles in a faster, more cost-effective, and sustainable manner.Innovative Technology:The newly-introduced advanced profiling equipment is the result of extensive research and development by a renowned manufacturer. By fusing automation and computer-controlled precision machinery, this equipment allows for the shaping and profiling of glazed tiles in a highly accurate and efficient manner. With superior profiling capabilities, the equipment can achieve intricate designs and impeccable finishing, rendering each glazed tile a work of art.Enhanced Precision:The traditional method of manual profiling often resulted in inconsistencies in tile shape, leading to production delays and significant material wastage. However, with the advent of advanced profiling equipment, such concerns are now a thing of the past. The computerized controls and precise movements of the machinery ensure that each tile is uniform, with perfectly calibrated dimensions as specified by the manufacturer. This increased precision results in a seamless construction process and facilitates easy installation for end-users.Streamlined Production and Increased Efficiency:One of the primary advantages of the new profiling equipment is its ability to significantly boost production capacity while minimizing manufacturing time. The advanced technology automates various stages of the profiling process, including cutting and shaping, thereby reducing the reliance on manual labor. This not only speeds up the production cycle but also reduces costs associated with human errors and worker fatigue. Additionally, the machinery's efficiency ensures a higher output of glazed tiles, meeting market demands effectively.Sustainable Manufacturing:As the global focus on sustainable practices intensifies, the need for eco-friendly manufacturing processes has become more critical than ever. Advanced profiling equipment is a solution to this challenge. By minimizing resource wastage and optimizing the production process, this machinery dramatically reduces the carbon footprint of glazed tile manufacturing. Moreover, it promotes the use of recyclable materials, contributing to the overall sustainability of the industry.Durability and Longevity:The integration of advanced profiling equipment ensures that glazed tiles produced possess exceptional durability and longevity. The precision cutting and shaping techniques employed by the machinery create tiles that fit seamlessly and interlock securely. This eliminates the risks of cracks, breakages, or uneven installation, guaranteeing a reliable, long-lasting flooring or walling solution for customers across various sectors.Revolutionizing Tile Design:The advent of advanced profiling equipment has unlocked a new era of design possibilities for glazed tiles. Manufacturers can now experiment with intricate shapes, beveled edges, and unique aesthetics that were previously difficult to achieve through manual profiling. This has led to an explosion of creativity and innovation in the industry, with customers benefiting from an extensive range of designs and patterns to suit their individual preferences and requirements.Conclusion:The introduction of advanced profiling equipment marks a significant turning point in the glazed tile manufacturing industry. This cutting-edge machinery not only streamlines production processes but also ensures unparalleled precision, efficiency, sustainability, and durability. With limitless design possibilities, the application of this advanced technology promises to revolutionize the realm of glazed tiles, enhancing the quality of construction projects worldwide.

Efficient Metal Siding Roll Forming Machine Unveiled in Latest News

Metal Siding Roll Forming Machine Revolutionizes the Construction IndustryThe construction industry is constantly evolving, searching for more efficient and cost-effective solutions to meet the demands of the ever-growing market. One such innovation making waves in the industry is the Metal Siding Roll Forming Machine. This machine, developed by an industry-leading manufacturer, is revolutionizing the way metal siding is produced and installed, offering significant benefits to both contractors and homeowners.The Metal Siding Roll Forming Machine is designed to automate the production process of metal siding, eliminating the need for tedious manual work. With its advanced technology and precise engineering, the machine is capable of producing high-quality metal siding panels quickly and efficiently. This not only saves time but also ensures accuracy and consistency in the final product.The machine operates by guiding a continuous strip of metal through a series of rollers and dies, gradually forming it into the desired shape. The metal strip is fed into the machine, and as it passes through each station, it undergoes various bending and shaping processes. The finished panels are then cut to the required length and can be easily collected for packaging or installation.One of the key advantages of the Metal Siding Roll Forming Machine is its versatility. It can produce a wide range of metal siding profiles, allowing contractors to cater to various architectural and design preferences. Whether it's traditional lap siding, vertical panels, or even custom profiles, the machine can accommodate different specifications. This versatility gives contractors the flexibility to meet the unique demands of each project.Additionally, the Metal Siding Roll Forming Machine offers significant cost savings compared to traditional manual methods. By automating the production process, manufacturers can reduce labor costs and minimize material wastage. The consistency and precision provided by the machine also eliminate the need for rework, further reducing expenses. These cost savings can trickle down to homeowners, making metal siding a more affordable and attractive option for them.Furthermore, the Metal Siding Roll Forming Machine can enhance the overall durability and performance of metal siding. The precise forming process ensures that the panels have consistent dimensions, minimizing the risk of gaps or misalignment during installation. This tight fit increases the siding's resistance to wind, moisture, and other environmental factors, making it a durable and long-lasting option for any building.The machine's efficiency and automation also reduce the manpower required for installation. Contractors can complete projects faster, as the panels are ready to be installed as soon as they are produced. This time-saving aspect not only improves project timelines but also reduces disruptions to homeowners and residents nearby.As an industry-leading manufacturer, [Company Name] has been at the forefront of developing and refining the Metal Siding Roll Forming Machine. With years of experience and expertise in the field, the company has continually improved the machine's design, ensuring optimal performance and reliability. Their commitment to innovation has made the Metal Siding Roll Forming Machine a game-changer in the construction industry.In conclusion, the Metal Siding Roll Forming Machine is revolutionizing the construction industry with its efficiency, versatility, and cost-effectiveness. By automating the production process, contractors can save time, reduce costs, and deliver high-quality metal siding panels. With its precise engineering and durability, the machine ensures that homeowners can enjoy a long-lasting and visually appealing product. Thanks to the innovative efforts of companies like [Company Name], the future of metal siding production and installation looks brighter than ever.

High-Quality Glazed Roof Sheet Roll Forming Machine for Efficient Roofing Production

Introducing the Latest Glazed Roof Sheet Roll Forming Machine from a Leading ManufacturerAs technology continues to advance in the construction industry, the demand for innovative and efficient machinery has become increasingly essential. With this in mind, {company name}, a renowned manufacturer of roll forming machines, is proud to announce the launch of their latest Glazed Roof Sheet Roll Forming Machine. This state-of-the-art equipment is designed to meet the needs of modern construction projects, providing a high level of precision and productivity while ensuring the highest quality of glazed roof sheets.The Glazed Roof Sheet Roll Forming Machine is a versatile and reliable piece of equipment that is ideal for producing glazed roof sheets with various profiles and dimensions. By utilizing advanced technology and high-quality materials, {company name} has developed a machine that is not only efficient but also durable and long-lasting. This ensures that customers can rely on the machine to consistently deliver top-quality glazed roof sheets for their projects.One of the key features of the Glazed Roof Sheet Roll Forming Machine is its flexibility. The machine is capable of producing a wide range of glazed roof sheet profiles, allowing customers to meet the specific requirements of their projects. Whether it's a residential, commercial, or industrial application, this machine can cater to various needs with ease. Additionally, the machine is equipped with advanced control systems that allow for easy and precise adjustments to the production process, ensuring optimal results every time.Furthermore, the Glazed Roof Sheet Roll Forming Machine is designed with efficiency in mind. With a high-speed production capability, this machine can significantly increase productivity and reduce production time, making it a valuable asset for any construction project. The machine also boasts a user-friendly interface, allowing operators to easily monitor and control the production process, further enhancing its efficiency and ease of use.In addition to its technological capabilities, the Glazed Roof Sheet Roll Forming Machine is also built with durability and reliability in mind. {company name} is committed to providing customers with long-lasting and robust machinery, and this new machine is no exception. With high-quality materials and expert craftsmanship, this machine is designed to withstand the rigors of continuous use, ensuring consistent performance and minimal downtime.{company name} takes great pride in its commitment to customer satisfaction and support. As such, the Glazed Roof Sheet Roll Forming Machine is backed by comprehensive customer service and support, including installation, training, and ongoing maintenance. This ensures that customers can fully maximize the potential of the machine and address any technical issues or concerns promptly.In conclusion, the launch of the Glazed Roof Sheet Roll Forming Machine from {company name} represents a significant advancement in the roll forming machinery industry. With its advanced technology, flexibility, efficiency, and durability, this machine is set to revolutionize the production of glazed roof sheets for construction projects. {company name} remains dedicated to providing innovative solutions to meet the evolving needs of the construction industry, and the Glazed Roof Sheet Roll Forming Machine is a testament to this ongoing commitment. For more information about this new machine and other products from {company name}, please visit their website or contact their sales team.

Local Machine Shops & Manufacturing Services in Corman Park - Find Metal Connections and Quality Craftsmanship

Title: Streamlining Metal Profiles: Enhancing Machine Shop ManufacturingIntroduction:In today's ever-evolving industrial landscape, machine shops and manufacturing units play a crucial role in the production of metal profiles. These precise and essential components cater to the diverse needs of various industries. However, finding trustworthy and capable machine shops that specialize in metal profile manufacturing can be a challenge. In this blog, we will explore the significance of metal profile manufacturing, the role of machine shops in the process, and how businesses can benefit from high-quality and efficient services.Understanding Metal Profile Manufacturing:Metal profile manufacturing involves the creation of custom metal profiles using various techniques like cutting, bending, welding, and assembly. These profiles find extensive applications across industries ranging from aerospace and automotive to construction and machinery. Precision, accuracy, and durability are vital aspects of metal profile manufacturing, as these components often withstand demanding conditions and require reliable performance.The Importance of Machine Shops:Machine shops serve as the backbone of metal profile manufacturing, utilizing state-of-the-art machinery and a skilled workforce to craft precision profiles with utmost accuracy. These shops play a critical role in implementing and refining the manufacturing processes, ensuring that the final product meets the specific requirements and industry standards. A well-equipped machine shop possesses the machinery and expertise to handle projects of varying complexities and scales, delivering on time and within budget.Streamlining Manufacturing Processes:Modern machine shops leverage advanced technologies, such as computer numerical control (CNC) machines, to optimize the manufacturing process. CNC machines offer superior precision, consistency, and speed, resulting in reduced lead times, minimized waste, and enhanced product quality. By integrating cutting-edge software solutions, machine shops can create intricate profiles and streamline complex manufacturing procedures, offering clients highly customized and efficient solutions.Delivering Unparalleled Quality:When it comes to metal profile manufacturing, quality is of utmost importance. A reputable machine shop understands this requirement and employs rigorous quality control measures at every stage of the manufacturing process. From material selection and raw material inspection to final finishing and inspection, these shops adhere to strict quality standards, ensuring that the end product meets or exceeds client expectations. By partnering with reliable machine shops, businesses can secure access to high-quality metal profiles that are built to withstand tough conditions and deliver exceptional performance.Collaboration and Customization:Collaboration between machine shops and clients is crucial for successful metal profile manufacturing. Experienced machine shops work closely with businesses to understand their unique needs, providing comprehensive consultation and design assistance. By involving clients throughout the design and manufacturing stages, machine shops can ensure that the end product perfectly aligns with specific project requirements. This collaborative approach results in customized profiles that maximize efficiency, reliability, and cost-effectiveness.Conclusion:Metal profile manufacturing is a specialized field that requires the expertise of machine shops capable of meeting the specific needs of various industries. By embracing advanced technologies, implementing stringent quality control measures, and fostering collaborative relationships with clients, reputable machine shops deliver customized metal profiles that enhance efficiency, durability, and performance. Businesses looking for superior metal profiles must partner with trustworthy machine shops and reap the benefits of streamlined manufacturing processes and unparalleled quality.Keywords:Metal profile manufacturing, machine shops, precision, manufacturing processes, CNC machines, quality control, customization, collaboration, advanced technologies, efficiency, durability, performance.

C Z Channel Shaped Steel Roof Purlin Roll Forming Machine - Find High-Quality Suppliers

Title: Enhancing Roof Construction Efficiency with the C Z Channel Shaped Steel Roof Purlin Roll Forming MachineIntroduction:In today's fast-paced construction industry, time and cost efficiency are crucial factors for successful projects. One key element in roof construction is the installation of purlins, providing structural support and stability. The remarkable C Z Channel Shaped Steel Roof Purlin Roll Forming Machine offers an innovative solution that maximizes efficiency and quality in this process. This blog will delve into the benefits of this machine and explore how its unique features, including the C Purlin Machine with Punching Hole Device, revolutionize roof construction.I. Understanding the Importance of Purlins in Roof ConstructionRoofs are exposed to various forces like wind, snow, and rain, making the stability of the roofing structure critical. Purlins play a vital role in transferring loads from the roof to the primary frame while maintaining the structural integrity of the overall construction.II. The Role of Roll Forming Machines in Roof ConstructionTraditional methods of manufacturing purlins involved manual labor, which was time-consuming and often inefficient. However, the introduction of roll forming machines, such as the C Z Channel Shaped Steel Roof Purlin Roll Forming Machine, has transformed the construction industry, offering numerous advantages:1. Speed and Efficiency: The machine operates at high speeds, allowing for rapid production of high-quality purlins. This results in significant time savings during the construction process.2. Consistency and Accuracy: The roll forming machine ensures the precise shaping of purlins according to predefined specifications. This guarantees uniformity in dimensions, reducing the possibility of errors during installation.3. Cost-Effectiveness: Automated roll forming considerably reduces labor costs associated with manual manufacturing. The purlin roll forming machine provides an efficient and cost-effective solution for roof construction projects.4. Versatility: The machine can produce a wide range of C and Z channel shaped purlins, accommodating various roof designs and structural requirements. This versatility makes it suitable for a wide range of construction projects.III. Exploring the C Purlin Machine with Punching Hole DeviceOne of the key features of the C Z Channel Shaped Steel Roof Purlin Roll Forming Machine is the integrated Punching Hole Device. This addition enhances the flexibility and efficiency of the machine, offering numerous benefits:1. Streamlined Process: The integrated punching hole device eliminates the need for secondary hole punching operations. It allows for seamless production of purlins with accurately positioned holes, saving time and effort during installation.2. Customization Options: The punching hole device provides flexibility by facilitating the creation of holes at desired locations, sizes, and intervals. This customization adds value to construction projects that require specific hole arrangements.3. Enhanced Structural Strength: The precise hole punching mechanism ensures the integrity of the purlin's strength, maintaining the stability and load-bearing capacity of the roofing structure.Conclusion:The C Z Channel Shaped Steel Roof Purlin Roll Forming Machine presents a game-changing solution for the construction industry. Its automated production capabilities, along with the integrated Punching Hole Device, significantly enhance the efficiency, precision, and quality of purlin manufacturing. By implementing this advanced technology, construction projects can achieve faster completion times, cost savings, and improved structural reliability. With the flexibility to adapt to various design requirements, this machine revolutionizes roof construction, setting a new standard for the industry.