Top High-Speed Slitting Machine: Find Out How It Works

By:Admin

In today's fast-paced world, the demand for high-speed and efficient production processes is greater than ever before. With the introduction of the High-Speed Slitting Machine by a leading manufacturing company, the industry's standards have been raised to a whole new level. This cutting-edge machine is revolutionizing the way materials are processed and is setting new benchmarks for speed, precision, and efficiency.

The High-Speed Slitting Machine has been designed and developed by a renowned company that has been at the forefront of innovation in the manufacturing industry for over two decades. With a commitment to delivering cutting-edge solutions and state-of-the-art technology, the company has established itself as a leader in the field.

The High-Speed Slitting Machine is a result of years of research, development, and engineering expertise. It is equipped with the latest advancements in technology, including high-speed servo motors, precision sensors, and advanced control systems, allowing it to operate at unprecedented speeds while maintaining the highest levels of accuracy and consistency.

One of the key features of the High-Speed Slitting Machine is its ability to process a wide range of materials with varying thickness and properties. From paper and plastic to metal and other specialty materials, this versatile machine is capable of handling diverse requirements with ease. This makes it an ideal solution for a wide range of industries, including packaging, printing, automotive, electronics, and more.

The High-Speed Slitting Machine's advanced control systems and intuitive user interface make it easy to set up and operate. With programmable settings and automated features, it streamlines the production process, reduces the risk of errors, and optimizes productivity. This not only saves time and labor costs but also ensures consistent and high-quality output.

Another noteworthy aspect of the High-Speed Slitting Machine is its high-speed capabilities, which significantly increase production throughput and efficiency. By running at speeds of up to [insert speed], it outperforms traditional slitting machines, resulting in faster turnaround times and increased output. This helps manufacturers meet growing demands and stay ahead of the competition.

Furthermore, the High-Speed Slitting Machine incorporates advanced safety features to ensure the well-being of operators and maintain a secure working environment. Its robust construction, emergency stop mechanisms, and comprehensive safety protocols make it a reliable and secure solution for any manufacturing facility.

In addition to its performance and safety benefits, the High-Speed Slitting Machine is designed for ease of maintenance and long-term reliability. With durable components, minimal wear and tear, and simplified maintenance procedures, it offers a low total cost of ownership and a high return on investment over its lifespan.

The introduction of the High-Speed Slitting Machine represents a significant breakthrough in the manufacturing industry. Its unparalleled speed, precision, and efficiency are reshaping the way materials are processed, setting new industry standards and opening up new possibilities for manufacturers worldwide.

Looking ahead, the company behind the High-Speed Slitting Machine is committed to further innovation and continuous improvement. By leveraging its expertise and staying at the forefront of technology, it aims to bring even more groundbreaking solutions to the market in the years to come, further revolutionizing the manufacturing industry and driving progress on a global scale.

In conclusion, the High-Speed Slitting Machine is a game-changer for the manufacturing industry, offering unmatched speed, precision, and efficiency. With its advanced technology, versatile capabilities, and user-friendly design, it is setting new standards and empowering manufacturers to meet the challenges of today's fast-paced world.

Company News & Blog

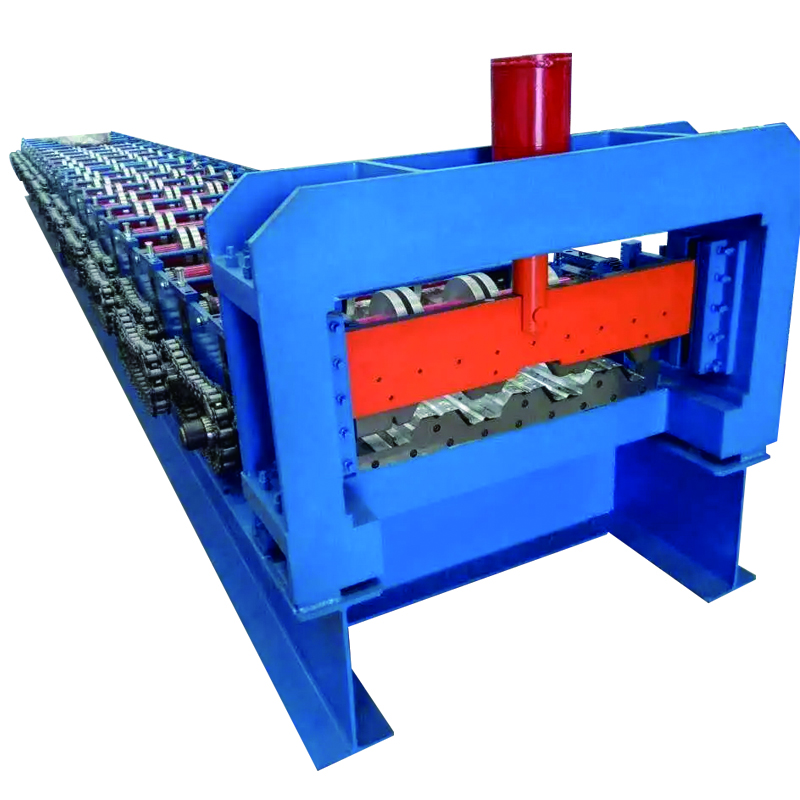

Discover the Benefits of a Roof Tile Roll Forming Machine for Your Construction Business

In a bid to revolutionize the roofing industry, a leading company in the field of roll forming machinery has developed an innovative Roof Tile Roll Forming Machine. This state-of-the-art machine is set to streamline the process of manufacturing roof tiles, providing a cost-effective and efficient solution for roofing companies and construction projects.The Roof Tile Roll Forming Machine is a result of extensive research and development by the industry-leading company, which has a solid reputation for delivering high-quality roll forming machinery. Drawing on their years of experience and expertise in the field, the company has brought forth a machine that is designed to meet the evolving demands of the roofing industry.One of the key features of this Roof Tile Roll Forming Machine is its ability to produce high-quality roof tiles with precision and speed. The machine is equipped with advanced technology that allows for seamless roll forming, ensuring that each tile is produced with consistent quality and accuracy. This not only enhances the overall efficiency of the manufacturing process but also results in a superior end product.Furthermore, the Roof Tile Roll Forming Machine is designed to be highly versatile, capable of producing a wide range of roof tile designs and sizes. This flexibility is essential for meeting the diverse needs of different construction projects and allows for customization according to specific requirements. With this machine, roofing companies and contractors can easily cater to a variety of client preferences, thereby enhancing their competitive edge in the market.In addition to its advanced functionality, the Roof Tile Roll Forming Machine is also built for durability and longevity. Constructed with high-quality materials and precision engineering, the machine is designed to withstand the rigors of continuous production and deliver reliable performance over an extended period of time. This durability not only ensures a consistent output of roof tiles but also minimizes downtime for maintenance and repairs, contributing to overall cost savings for users.Furthermore, the company behind the Roof Tile Roll Forming Machine is committed to providing comprehensive support and service to its customers. With a team of experienced technicians and engineers, the company offers installation, training, and maintenance services to ensure that users can maximize the potential of the machine. This dedication to customer satisfaction reflects the company's mission to not only deliver cutting-edge machinery but also to foster long-term partnerships with its clients.As the roofing industry continues to evolve and demand for efficient manufacturing solutions grows, the introduction of the Roof Tile Roll Forming Machine marks a significant advancement in the field. With its advanced technology, versatility, and durability, this machine is set to elevate the standards of roof tile production and empower roofing companies to achieve greater success in their operations.Overall, the Roof Tile Roll Forming Machine is a testament to the company's commitment to innovation and excellence in roll forming machinery. With its potential to transform the roofing industry, this machine represents a game-changing solution for manufacturers and contractors alike, setting a new benchmark for efficiency and quality in roof tile production.

Highly Efficient Slitter with Razor and Rotating Knife Cutting Systems for Flexible and Rigid Materials, 1300mm Width

Title: Slitter - BRASIA LTDA Introduces 1300 mm Wide Automatic Roll Slitter for Versatile Material CuttingSubtitle: Cutting-Edge Technology Enhances Precision and Efficiency in Material Processing[date][City], [Country] – Slitter - BRASIA LTDA, a leading provider of innovative cutting solutions, has recently unveiled its latest offering, an advanced 1300 mm wide Automatic Roll Slitter. With its exceptional razor and rotating knife cutting systems, this versatile machine is capable of handling a wide range of flexible and rigid materials, empowering industries with enhanced productivity and precision.1- Efficient Cutting of Flexible Materials:Equipped with a razor cutting system and special articulated support, the 1300 mm Automatic Roll Slitter is specifically designed to cater to the cutting needs of flexible materials. From BOPP, PP, PE, PVC, to non-printed materials, this cutting-edge machine ensures clean and precise cuts, enhancing the efficiency of production processes.2- Seamless Cutting of Rigid and Semi-Rigid Materials:In addition to its razor cutting system, this innovative slitter also features a rotating knife cutting system. This unique capability enables the machine to effortlessly handle rigid and semi-rigid materials such as card paper, cardboard, stamped paper, felt, and laminated materials, expanding its application across various industries.3- Wide Roll Entry and Smooth Alignment:The 1300 mm Automatic Roll Slitter boasts a spacious roll entry point with a diameter of 1000 mm. This not only allows for easy loading and unloading of materials but also ensures smooth alignment, minimizing downtime during operation. The inclusion of an aligner, air shaft, and electromagnetic control further optimizes the slitting process.4- Enhanced Output and Control:To maximize productivity, the slitter is equipped with double articulated air shafts, ensuring efficient winding of slit materials. With individual electromagnetic control, operators have precise control over the winding process, preventing any potential material damage or inconsistency.5- Accurate Reading with Electric Photo Cell:Incorporating cutting-edge technology, the 1300 mm Automatic Roll Slitter is equipped with an electric photo cell. This feature enables the machine to accurately read lengthwise printing, allowing for precise cutting based on specific patterns or designs.6- Convenient Meter Counter:This sophisticated slitter also features a meter counter with an electronic sensor. This enables operators to track the length of materials being processed, ensuring precise measurements and reducing waste.7- Advanced Automatic Stop Sensor:The Automatic Roll Slitter is designed with an automatic stop sensor, which halts the machine upon completion of the programmed measurement. This ensures optimal efficiency and prevents any potential material waste.8- Speed Control at Your Fingertips:To cater to diverse processing needs, this state-of-the-art slitter offers speed control through digital programming. Operators can easily adjust the cutting speed to meet the requirements of different materials, providing versatility and convenience.9- User-Friendly Digital Control Panel:All operational functions of the 1300 mm Automatic Roll Slitter are effortlessly programmed using a digital control panel. With programmed memory functions, users can conveniently store and recall specific settings, streamlining the overall production process.Slitter - BRASIA LTDA's new 1300 mm Automatic Roll Slitter represents a significant advancement in material cutting technology. Its superior cutting systems, precise controls, and user-friendly features make it an unrivaled choice for industries seeking to enhance productivity, streamline processes, and achieve impeccable cutting results.For more information on the 1300 mm Automatic Roll Slitter and its wide range of applications, please contact:[Contact Information]About Slitter - BRASIA LTDA:Slitter - BRASIA LTDA specializes in the development and production of advanced cutting solutions. With a commitment to innovation, reliability, and customer satisfaction, the company has established itself as a trusted provider of cutting-edge technologies in the industry.

Affordable C Purlin Roll Forming Machine Prices: A Complete Guide

C Purlin Roll Forming Machine Price Sees Increase as Demand SurgesThe demand for C Purlin roll forming machines has seen a sharp increase in recent months, leading to a rise in prices for these essential pieces of equipment. This spike in demand can be attributed to the growing construction industry and the need for high-quality building materials.The current price for a C Purlin roll forming machine is significantly higher than it was just a year ago. This increase in price can be attributed to several factors, including rising production costs, a shortage of raw materials, and an increase in global demand. As a result, many companies that rely on C Purlin roll forming machines are feeling the financial strain of these price hikes.One company that has been affected by these price increases is {}. They are a leading manufacturer of C Purlin roll forming machines, and they have been feeling the impact of the rising prices on their bottom line. Despite this, they remain committed to providing high-quality machinery to their customers at competitive prices.{} has been in the industry for over a decade and has established a strong reputation for producing efficient and reliable C Purlin roll forming machines. They have a team of experienced engineers and technicians who work tirelessly to ensure that their machines meet the highest standards of quality and performance.The company has invested heavily in research and development to improve their machines' efficiency and functionality. This dedication to innovation has allowed them to stay ahead of the competition and continue to meet the growing demand for C Purlin roll forming machines.In addition to their commitment to quality, {} also prioritizes customer satisfaction. They offer comprehensive after-sales service and support, ensuring that their customers get the most out of their investment in a C Purlin roll forming machine. This dedication to customer care has earned them a loyal and satisfied customer base.Despite the current challenges posed by rising prices, {} remains optimistic about the future of the C Purlin roll forming machine market. They are confident that their ongoing commitment to excellence and customer satisfaction will allow them to navigate through these challenging times and emerge even stronger.In the meantime, the company continues to monitor the market and make adjustments to their pricing and production processes as necessary. They understand the importance of remaining competitive in the industry while also maintaining their high standards of quality.As the demand for C Purlin roll forming machines continues to grow, {} is determined to meet this demand while also ensuring that their machines remain accessible to their customers. They are optimistic that the current challenges will eventually subside, and the market will stabilize, allowing for a more balanced pricing environment.In conclusion, the rise in the price of C Purlin roll forming machines reflects the increasing demand for these essential pieces of equipment. Companies like {} are working hard to navigate through these challenges and continue to provide high-quality machines to their customers at competitive prices. As the industry continues to evolve, {} remains dedicated to meeting the needs of their customers while staying ahead of the competition.

Metal Corrugated Roof Roll Forming Machine - A Comprehensive Guide for Roofing Applications

Metal Corrugated Roof Roll Forming Machine Revolutionizes the Roofing Industry In the highly competitive world of construction and architecture, innovation and technology have played a significant role in shaping the industry. One of the areas that have seen a lot of technological advancements is roofing, which has come a long way from traditional roofing materials such as asphalt shingles, clay tiles, and wood shingles. New roofing options such as metal corrugated roofing have become more popular for their durability, versatility, and aesthetic appeal, especially in commercial and industrial buildings.Metal corrugated roofing has gained its popularity because of its durability and strong resistance to weather and corrosion. Additionally, it’s lightweight compared to other traditional roofing materials, which makes it easier and cheaper to install. To meet the growing demand for metal corrugated roofing, companies have developed specialized machinery that can manufacture these roofing materials efficiently. The Metal Corrugated Roof Roll Forming Machine by (Company name removed) is a prime example of such innovation and technology in the roofing industry.The Metal Corrugated Roof Roll Forming Machine is a specialized device designed to bend and shape metal sheet materials into corrugated roof panels. The machine is computer-controlled, which ensures uniform accuracy in its operation. The machine works by feeding metal sheets through the straightening system; then, it passes through the rolling stations, which bend the sheets into corrugated shape. The machine has specialized shears designed to cut the length of the sheets, producing panels in a variety of dimensions, shapes, and gauges.The metal corrugated roofing panels produced using the Metal Corrugated Roof Roll Forming Machine are among the most durable roofing materials in the industry. They are resistant to many environmental factors, including water, wind, and fire. They have excellent thermal insulation properties that help maintain a comfortable indoor temperature, reducing energy costs. Unlike other roofing materials, which require frequent repair, metal corrugated roofs have minimal maintenance costs, making them an excellent investment for any property owner.Several factors make the Metal Corrugated Roof Roll Forming Machine stand out from other roll forming machines in the market. First, it’s highly customizable, allowing the machine to produce roofing panels in different shapes, dimensions, and gauges. The machine can also produce different coatings, including galvanized, pre-painted, or aluminum-zinc, providing customers with options to choose from. Additionally, the machine is highly efficient, capable of producing large volumes of corrugated roofing panels in a short time, thanks to its computer-controlled operation.The Metal Corrugated Roof Roll Forming Machine’s design has incorporated safety features such as guards, emergency stop buttons, and interlock systems to ensure the safety of the operator and enhance the machine's efficiency. The machine's design also allows for easy maintenance, with the operator having access to all critical components.The Metal Corrugated Roof Roll Forming Machine by (Company name removed) not only revolutionizes the roofing industry but also sets the standard for future roll forming machines. The machine's advanced technology, versatility, and efficiency enable users to produce high-quality metal corrugated panels that meet the roofing industry's stringent standards. The machine's design ensures that customers receive materials that are durable, cost-effective, and environmentally friendly.In conclusion, the Metal Corrugated Roof Roll Forming Machine has played a vital role in revolutionizing the roofing industry. Its advanced technology, versatility, and efficiency have set the standard for future roll forming machines, ensuring that customers receive high-quality metal corrugated panels that meet their roofing needs. The roofing industry will continue to benefit from such technological advancements that improve the efficiency of roofing material production, reducing costs while producing quality building materials.

Steel Sheet Metal Cut To Length Machine: The Latest in Color Technology

Color Steel Sheet Metal Cut To Length Machine Boosts Production EfficiencyIn today's fast-paced and demanding market, efficiency in production processes can often be the difference between success and failure for many businesses. With this in mind, {Company Name} is proud to announce the acquisition of the latest state-of-the-art Color Steel Sheet Metal Cut To Length Machine, a cutting-edge addition to their advanced manufacturing facility.The new Color Steel Sheet Metal Cut To Length Machine is a highly efficient and precise piece of equipment that is designed to streamline the process of cutting steel sheets to specific lengths. This innovative machine is capable of handling a wide range of steel sheets, and its advanced technology ensures clean and accurate cuts every time. With the ability to cut large volumes of steel sheets in a fraction of the time it would take using traditional methods, the Color Steel Sheet Metal Cut To Length Machine is set to revolutionize {Company Name}'s production capabilities.The acquisition of this cutting-edge technology reflects {Company Name}'s commitment to staying ahead of the curve and continuously investing in the latest advancements in manufacturing. By incorporating the Color Steel Sheet Metal Cut To Length Machine into their production operations, {Company Name} aims to significantly enhance their production efficiency and output, ultimately translating into improved product quality and customer satisfaction.Not only does the Color Steel Sheet Metal Cut To Length Machine streamline the production process, but it also offers a level of precision and consistency that is unparalleled. With its advanced cutting mechanisms and integrated quality control systems, the machine ensures that each steel sheet is cut to the exact specifications, leaving no room for error. This level of precision not only increases the overall quality of the products manufactured by {Company Name}, but also minimizes material wastage, leading to cost savings and a more sustainable manufacturing process.Additionally, the Color Steel Sheet Metal Cut To Length Machine is designed to be user-friendly and easily customizable. This means that {Company Name}'s skilled technicians can quickly and efficiently set up the machine to handle various sheet sizes and thicknesses, allowing for seamless transitions between different production runs. The versatility of the machine further enhances {Company Name}'s ability to meet the diverse needs of their clients and adapt to changing market demands with ease.With the installation of the Color Steel Sheet Metal Cut To Length Machine, {Company Name} is poised to significantly increase their production capacity and shorten lead times. By automating and optimizing the cutting process, the company can fulfill orders more efficiently and respond to customer demands in a timelier manner. This increased agility and responsiveness will undoubtedly set {Company Name} apart in the competitive manufacturing landscape, giving them a distinct edge in meeting the evolving needs of their clients.The investment in the Color Steel Sheet Metal Cut To Length Machine aligns with {Company Name}'s overarching goal of delivering top-tier products and services to their customers. By incorporating this cutting-edge technology into their manufacturing operations, the company is not only positioning itself for future growth, but also solidifying its reputation as a reliable and innovative partner in the industry.As {Company Name} continues to push the boundaries of manufacturing excellence, the acquisition of the Color Steel Sheet Metal Cut To Length Machine stands as a testament to their unwavering dedication to continuous improvement and advancement. With this cutting-edge addition to their production facility, {Company Name} is well-positioned to drive productivity, efficiency, and quality to new heights, setting a standard for excellence in the industry.

High-Quality Aluminum Profile Bending Machine for CNC Applications

In recent years, the demand for high-quality aluminum profile bending machines has been steadily increasing in various industries such as construction, manufacturing, and automotive. As a response to this growing demand, (Company name) has introduced a cutting-edge CNC aluminum profile bending machine that is set to revolutionize the industry.The CNC aluminum profile bending machine is a state-of-the-art piece of equipment that is designed to bend aluminum profiles with precision and efficiency. The machine is equipped with advanced CNC technology that allows for accurate and repeatable bending of aluminum profiles, resulting in high-quality finished products. This is especially crucial in industries such as construction and manufacturing where precision and quality are of utmost importance.One of the key features of the CNC aluminum profile bending machine is its flexibility. The machine is capable of bending aluminum profiles of various shapes and sizes, making it suitable for a wide range of applications. Additionally, the machine is designed to be user-friendly, with intuitive controls and easy programming, allowing for seamless operation by both experienced and novice operators.In addition to its precision and flexibility, the CNC aluminum profile bending machine is also known for its speed and efficiency. The machine is capable of bending aluminum profiles at a rapid pace, thereby increasing productivity and reducing lead times. This is essential for businesses looking to meet tight deadlines and stay ahead of the competition.(Company name) takes pride in offering products that are not only innovative but also reliable and durable. The CNC aluminum profile bending machine is no exception. It is built with high-quality materials and components, ensuring its longevity and robust performance even in the most demanding working environments. This makes it a valuable investment for businesses looking for a long-term solution for their aluminum profile bending needs.Furthermore, (company name) provides comprehensive technical support and after-sales service for its CNC aluminum profile bending machine. This includes installation, training, maintenance, and troubleshooting assistance, ensuring that customers can maximize the potential of the machine and minimize any downtime.The introduction of the CNC aluminum profile bending machine by (company name) is poised to have a significant impact on the industry. With its cutting-edge technology, precision, flexibility, and efficiency, the machine is set to meet the evolving demands of businesses across various sectors. It is expected to streamline the aluminum profile bending process, improve productivity, and elevate the quality of finished products.In conclusion, the CNC aluminum profile bending machine by (company name) represents a significant advancement in the industry. Its innovative features, coupled with the company's commitment to quality and customer support, make it a game-changer for businesses looking to enhance their aluminum profile bending capabilities. As the industry continues to evolve, (company name) remains at the forefront, delivering solutions that exceed expectations and set new standards for excellence.

High-Quality Automatic Wire Length Cutter for Precision Cutting

[Company Logo]Automatic Wire Length Cutter Streamlines Production Process for Manufacturing Industry[Town, Date] – Manufacturing companies and businesses in need of a reliable wire length cutting solution can now turn to the innovative Automatic Wire Length Cutter, developed and produced by [Company Name]. This state-of-the-art machine is designed to revolutionize the wire cutting process, providing unparalleled precision, efficiency, and speed. With its cutting-edge technology and advanced features, the Automatic Wire Length Cutter is set to become a game-changer for the manufacturing industry.[Company Name] is a leading provider of industrial automation and machinery solutions, specializing in the development and production of cutting-edge equipment for a wide range of industries. With a strong focus on innovation and technological advancement, the company is dedicated to providing its clients with the most advanced and reliable solutions to meet their specific needs.The Automatic Wire Length Cutter is the latest addition to [Company Name]'s extensive lineup of industrial automation products. This cutting-edge machine is designed to streamline the wire cutting process, offering unmatched precision and efficiency. With its advanced technology and innovative features, the Automatic Wire Length Cutter is capable of cutting wires of various materials and thicknesses with unparalleled accuracy and speed.One of the key features of the Automatic Wire Length Cutter is its advanced cutting mechanism, which ensures clean and precise cuts without compromising on speed. This is particularly important for manufacturing companies that require high-quality wire cutting solutions to meet the demands of their production processes. In addition, the machine is equipped with a user-friendly interface and intuitive controls, making it easy to operate and highly efficient in a production environment.The Automatic Wire Length Cutter is also designed with versatility in mind, capable of handling a wide range of wire types and sizes. This makes it an ideal solution for manufacturers working with different materials and specifications. With its ability to accommodate various wire cutting requirements, the machine offers a cost-effective and reliable solution for businesses looking to enhance their production processes.Moreover, the Automatic Wire Length Cutter is engineered to meet the highest safety standards, ensuring the protection of operators and personnel in the production environment. With its robust construction and advanced safety features, the machine provides a secure and reliable cutting solution for manufacturing companies and industrial facilities.In addition to its cutting-edge technology and advanced features, the Automatic Wire Length Cutter is backed by [Company Name]'s commitment to customer satisfaction and support. The company's team of experienced professionals is dedicated to providing comprehensive installation, training, and maintenance services to ensure the seamless integration and operation of the machine in a production environment.As a trusted provider of industrial automation solutions, [Company Name] is proud to introduce the Automatic Wire Length Cutter as the latest addition to its lineup of cutting-edge machinery. With its unparalleled precision, efficiency, and reliability, the machine is set to become an indispensable tool for manufacturing companies and businesses in need of a reliable wire cutting solution.For more information about the Automatic Wire Length Cutter and [Company Name]'s complete range of industrial automation solutions, please visit [company website] or contact [contact information].[Company Name] is a leading provider of industrial automation and machinery solutions, specializing in the development and production of cutting-edge equipment for a wide range of industries. With a strong focus on innovation and technological advancement, the company is dedicated to providing its clients with the most advanced and reliable solutions to meet their specific needs.

High-Quality Steel Roof Making Machine for Industrial Applications

Steel Roof Making Machine Revolutionizing the Roofing IndustryThe introduction of the groundbreaking Steel Roof Making Machine by [Company Name] has been heralded as a game-changer in the roofing industry. This innovative machine is set to revolutionize the way steel roofs are manufactured, offering a wide range of benefits for both manufacturers and consumers alike.The Steel Roof Making Machine is a state-of-the-art piece of equipment that is designed to streamline the manufacturing process for steel roofing panels. With its advanced technology and precision engineering, the machine is capable of producing high-quality and durable steel roof panels in a fraction of the time it takes with traditional methods. This not only improves efficiency but also allows for greater production capacity, meeting the growing demand for steel roofs in the construction industry.One of the key features of the Steel Roof Making Machine is its versatility. It is capable of producing a wide variety of steel roof panel profiles, from corrugated to standing seam, with customizable options for panel width and length. This flexibility allows for greater customization and innovation in the design of steel roofs, meeting the unique needs and preferences of different markets and consumers.In addition to its versatility, the Steel Roof Making Machine is also equipped with advanced automation and control systems, minimizing the need for manual labor and reducing the risk of human error. This not only improves the overall quality of the steel roof panels but also enhances workplace safety for employees.Furthermore, the machine is designed for easy maintenance and operation, with user-friendly interfaces and intuitive controls. This ensures that manufacturers can maximize their productivity with minimal downtime and training requirements, ultimately leading to cost savings and improved profitability.The Steel Roof Making Machine also incorporates sustainable and environmentally friendly practices, such as energy-efficient processes and the use of recyclable materials. This aligns with the growing demand for eco-friendly building materials and construction practices, positioning manufacturers as responsible and forward-thinking leaders in the industry.As a result, the Steel Roof Making Machine has been met with a positive reception from manufacturers and consumers alike. The machine has already been adopted by leading steel roofing manufacturers, who have praised its performance, efficiency, and reliability. In turn, consumers can expect to benefit from a wider range of high-quality steel roof options that are cost-effective and sustainable.[Company Name] is at the forefront of this innovation. As a leading manufacturer of machinery and equipment for the construction industry, the company has a strong track record of delivering cutting-edge solutions that improve productivity, quality, and safety. With the introduction of the Steel Roof Making Machine, [Company Name] is further solidifying its position as a trusted partner for manufacturers seeking to stay ahead in a competitive market.Looking ahead, [Company Name] is committed to ongoing research and development, ensuring that the Steel Roof Making Machine continues to set new standards in the roofing industry. The company is also dedicated to providing comprehensive support and service for its customers, helping them maximize the potential of the machine and stay ahead of market demands.In conclusion, the Steel Roof Making Machine by [Company Name] represents a significant advancement in the manufacturing of steel roofs. With its advanced technology, versatility, efficiency, and sustainability, the machine is poised to drive innovation and growth in the roofing industry, benefiting manufacturers, consumers, and the environment as a whole.

High-quality Glazed Tile Roll Forming Machine for Color Steel - Complete Guide

Color Steel Glazed Tile Roll Forming Machine Revolutionizes the Roofing Industry[City, State] - With the continuous advancement of technology, the roofing industry is experiencing a significant transformation. The introduction of the Color Steel Glazed Tile Roll Forming Machine has revolutionized the way roofing materials are manufactured, making the process faster, more efficient, and more cost-effective. This innovative machine, developed by a leading machinery manufacturer, has caught the attention of the construction and roofing industries worldwide.The Color Steel Glazed Tile Roll Forming Machine is designed to produce high-quality glazed tiles made of color steel, which are widely used for roofing and cladding applications. It is capable of forming and cutting the glazed tiles with high precision, ensuring consistency and uniformity in the finished product. This state-of-the-art machine has the ability to produce a wide range of glazed tile profiles, giving manufacturers the flexibility to meet diverse customer demands.One of the key features of this roll forming machine is its advanced control system, which allows for easy operation and monitoring of the production process. With user-friendly controls and automation capabilities, the machine enables manufacturers to maximize productivity and minimize material waste. In addition, the machine is equipped with safety features to ensure the protection of workers and prevent accidents in the workplace.The company behind this groundbreaking innovation, [Company Name], is a renowned manufacturer of roll forming machines and other industrial equipment. With years of experience and expertise in the field, the company has established a reputation for delivering high-quality, reliable, and innovative machinery solutions to its customers. The Color Steel Glazed Tile Roll Forming Machine is a testament to the company's commitment to advancing the industry through technological innovation.In addition to its cutting-edge technology, the company also provides comprehensive services to support its customers, including installation, training, and after-sales support. This ensures that manufacturers can fully optimize the performance of the roll forming machine and achieve the best possible results in their production processes. With a global presence and a dedicated team of professionals, the company is capable of meeting the needs of customers around the world.The introduction of the Color Steel Glazed Tile Roll Forming Machine has already made a significant impact on the roofing industry. Manufacturers who have adopted this technology have reported improvements in their production efficiency, product quality, and overall business performance. The machine's ability to produce high-quality glazed tiles at a faster pace has allowed manufacturers to meet growing market demands and stay ahead of the competition.Furthermore, the use of color steel for roofing and cladding applications offers numerous benefits, including durability, weather resistance, and aesthetic appeal. With the Color Steel Glazed Tile Roll Forming Machine, manufacturers can now produce these high-performance materials with greater ease and efficiency, meeting the needs of customers in various sectors such as residential, commercial, and industrial construction.As the roofing industry continues to evolve, technological advancements like the Color Steel Glazed Tile Roll Forming Machine will play a crucial role in shaping its future. With its proven capabilities and the backing of a reputable manufacturer, this innovative machine is set to become an indispensable tool for manufacturers looking to stay competitive in the fast-paced and demanding market.As the demand for high-quality roofing materials continues to rise, manufacturers will undoubtedly turn to advanced solutions like the Color Steel Glazed Tile Roll Forming Machine to meet these demands. With its potential to drive efficiency, productivity, and product innovation, this machine is poised to make a lasting impact on the roofing industry for years to come.

Leading Metal Slitting Machines for Efficient Sheet Cutting

Sheet Metal Slitting Machine Enhances Precision and Efficiency in MetalworkingIn the fast-paced world of manufacturing, precision and efficiency are paramount. It is essential for companies to have reliable and high-performing tools to meet the ever-increasing demands of the industry. Recognizing this need, an innovative solution has emerged in the form of the Sheet Metal Slitting Machine, a game-changer that enhances productivity and accuracy in metalworking.Developed by a leading technology company, this state-of-the-art machine revolutionizes the process of slitting sheet metal into narrower strips, ultimately enabling manufacturers to optimize material usage and streamline their production workflow. Gone are the days of manual labor and imprecise cutting techniques. With the Sheet Metal Slitting Machine, manufacturers can achieve remarkable results with ease.Featuring cutting-edge technology and advanced automation, this machine provides exceptional precision in slitting a wide range of materials, including stainless steel, aluminum, copper, and other alloys. The machine's computerized system ensures consistent and accurate cuts, minimizing material waste and maximizing productivity. Its high-speed operation allows for quick turnaround times, reducing production timelines and meeting tight deadlines.One of the key advantages of the Sheet Metal Slitting Machine is its versatility. It can handle various thicknesses and widths of sheet metal, catering to the specific needs of different industries. Whether it's for automotive, aerospace, construction, or any other sector, this machine can adapt to the required specifications effortlessly. With adjustable settings and customizable features, manufacturers have full control over the slitting process, resulting in superior quality output.In addition to precision and versatility, the Sheet Metal Slitting Machine ensures operator safety. Equipped with advanced safety features, such as emergency stop buttons and protective guards, it prioritizes the well-being of the people operating the machine. This commitment to safety not only instills confidence in the workforce but also helps companies comply with rigorous industry regulations and standards.Furthermore, the company behind this remarkable technology is committed to customer satisfaction and continuous improvement. With years of experience and a solid reputation in the industry, they have earned the trust of manufacturers worldwide. Their team of experts provides comprehensive support, from installation and training to maintenance and troubleshooting. Manufacturers can rely on their expertise to ensure optimal performance and longevity of the Sheet Metal Slitting Machine.As the demand for precision manufacturing continues to rise, the introduction of the Sheet Metal Slitting Machine offers a transformative solution for companies seeking enhanced efficiency and accuracy. By investing in this cutting-edge technology, manufacturers can elevate their production capabilities, reduce costs, and deliver exceptional products to the market.With its emphasis on precision, versatility, and safety, the Sheet Metal Slitting Machine represents the future of metalworking. Its advanced features empower manufacturers to stay ahead of the competition and meet the ever-evolving needs of the industry. As manufacturing processes evolve, this machine stands as a testament to innovation and progress, enabling companies to unlock their full potential and achieve new heights of success in the world of metalworking.