Ultimate Guide to Aluminum Profile Cutting: Everything You Need to Know

By:Admin

In today's fast-paced manufacturing industry, precision and efficiency are key factors that can make or break a company's success. With constantly evolving technologies and customer demands, it's crucial for businesses to stay ahead of the game by investing in the latest cutting-edge solutions. This is where [company name] comes in.

[Company name] is a leading provider of aluminium profile cutting services that cater to various industries including construction, automotive, aerospace, and more. With a state-of-the-art facility and a team of skilled professionals, they are well-equipped to handle projects of all sizes and complexities.

Utilizing advanced machinery and techniques, [company name] offers a wide range of cutting services to meet the diverse needs of their clients. Whether it's standard cuts, intricate designs, or custom shapes, their capabilities are virtually limitless. From simple straight cuts to complex miter cuts, their precision and attention to detail are unmatched.

One of the key advantages of choosing [company name] for aluminium profile cutting is their commitment to quality. They understand the importance of delivering products that meet the highest standards, which is why they adhere to strict quality control measures throughout the entire cutting process. This ensures that each piece is accurately cut to the customer's specifications, resulting in a finished product that is precise and reliable.

Furthermore, [company name] prides itself on its ability to provide fast turnaround times without sacrificing quality. They understand that time is of the essence in the manufacturing industry, which is why they have streamlined their processes to minimize lead times and maximize efficiency. This means that clients can expect their orders to be completed and delivered in a timely manner, allowing them to stay on schedule and meet their project deadlines.

In addition to their cutting services, [company name] also offers value-added solutions to further meet the needs of their customers. This includes additional machining, surface finishing, and packaging services, providing a comprehensive and hassle-free experience for clients. By offering these added services, [company name] aims to be a one-stop shop for all of their customers' aluminium cutting and processing needs.

With a strong commitment to customer satisfaction, [company name] is dedicated to providing personalized service and support to each of their clients. From the initial consultation to the final delivery, their team works closely with customers to ensure that their specific requirements are met every step of the way. This personalized approach has earned [company name] a reputation for being a reliable and trusted partner in the industry.

In conclusion, [company name] is a leading provider of aluminium profile cutting services that offers a precision solution for a wide range of manufacturing needs. With their cutting-edge technology, commitment to quality, fast turnaround times, and personalized service, they are well-equipped to handle projects of all sizes and complexities. Whether it's standard cuts, intricate designs, or custom shapes, [company name] is the go-to choice for all aluminium cutting and processing needs.

Company News & Blog

Revolutionary Color Steel Glazed Tile Corrugation Machine Promises Unmatched Performance

[Title]: Innovative Color Steel Glazed Tile Corrugation Machine Revolutionizes Roofing Industry[Subtitle]: {Company Name}'s Cutting-edge Solution Takes Roofing Efficiency to New Heights[Date][City], [State] - {Company Name}, a renowned pioneer in the manufacturing industry, has recently unveiled its revolutionary Color Steel Glazed Tile Corrugation Machine, poised to transform the roofing industry worldwide. This cutting-edge technology promises exceptional efficiency and durability, empowering construction companies and homeowners alike with a game-changing roofing solution.With years of industry experience and a commitment to innovative designs, {Company Name} has overcome previous limitations seen in traditional glazed tile corrugation machines. By leveraging advanced engineering techniques, this new machine raises the bar in terms of speed, precision, and quality of output.The Color Steel Glazed Tile Corrugation Machine boasts an impressive range of features specifically designed to address the demands of modern roofing projects. Equipped with an intelligent control system, it offers heightened automation and precision, ensuring a seamless production process. Operators can effortlessly set parameters such as tile size, thickness, and curvature, thus greatly reducing human errors and increasing overall productivity.One of the key benefits of this state-of-the-art machine is its exceptional speed. With a production capacity of up to [X] tiles per minute, it significantly reduces manufacturing time, leading to shorter project timelines and improved customer satisfaction. This increased efficiency is complemented by the machine's ability to produce tiles of varying shapes and colors, allowing for greater customization to suit clients' specific aesthetic requirements.Moreover, the Color Steel Glazed Tile Corrugation Machine prioritizes durability and longevity. By utilizing high-quality materials such as reinforced steel and wear-resistant components, {Company Name} ensures that the machine can withstand continuous use over extended periods. This durability translates into cost savings for roofing companies, as maintenance costs and the frequency of machine replacement are drastically reduced.{Company Name}, an industry leader known for its commitment to environmental sustainability, has also incorporated eco-friendly elements into the design of their Color Steel Glazed Tile Corrugation Machine. By optimizing energy consumption and reducing waste materials during production, the machine aligns with global efforts to encourage sustainable development practices. This commitment not only benefits the environment but also enhances {Company Name}'s reputation as a socially responsible organization.In addition to its technical superiority, {Company Name} provides exceptional customer support and after-sales service. Their team of qualified technicians is readily available to assist clients with installation, training, and troubleshooting, ensuring a seamless transition to the new technology. Continuous software updates and technological advancements further guarantee that {Company Name} remains at the forefront of the roofing industry, offering the latest innovations to their customers.Looking ahead, {Company Name} is excited about the potential of their Color Steel Glazed Tile Corrugation Machine to disrupt the roofing industry on a global scale. With its streamlined production, exceptional durability, and eco-friendly features, this groundbreaking technology sets a new standard in efficiency, quality, and sustainability. Construction companies and homeowners can now benefit from a roofing solution that combines aesthetics with functionality, providing long-lasting protection for years to come.About {Company Name}:{Company Name} is a leading manufacturer and supplier of industrial machinery, renowned for its commitment to innovation and quality. With a rich history spanning over [X] years, they have earned a stellar reputation for providing cutting-edge solutions that empower businesses across various sectors. Committed to sustainable development, {Company Name} constantly strives to deliver eco-friendly and efficient products that meet the evolving needs of their customers.For more information, please visit: [Website URL]Press Contact:[Contact Name][Title][Company Name][Phone Number][Email Address]

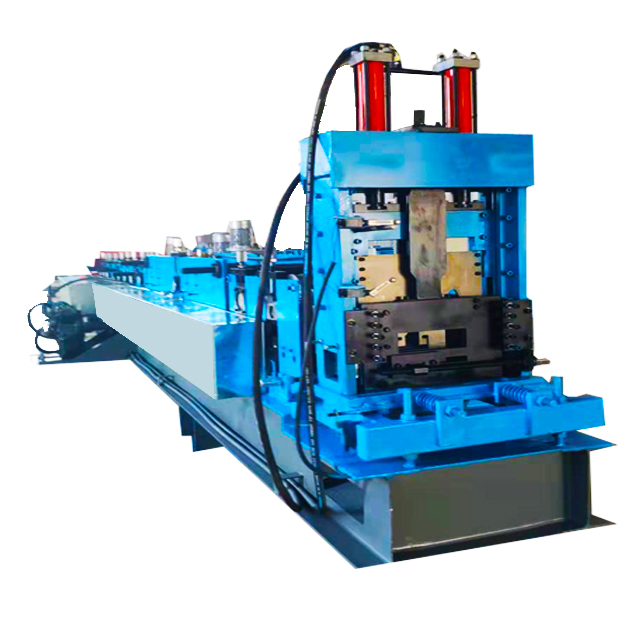

Complete Guide to Purlin Roll Forming Machines: Types, Features, and Applications

Purlin Roll Forming Machine: A Key Component in the Metal Construction IndustryThe purlin roll forming machine is a critical aspect of the metal construction industry, playing a pivotal role in the production of purlins, which are structural support members used in the construction of roofs and walls in buildings. These machines are designed to produce high-quality purlins with precise dimensions and consistent shapes, making them an essential asset for any manufacturing facility in the construction sector.{Company Name} is a renowned manufacturer of purlin roll forming machines, known for their advanced technology, high efficiency, and reliability. With years of experience in the industry, {Company Name} has earned a reputation for delivering top-notch roll forming solutions to clients worldwide. Their machines are widely used in the construction of commercial, industrial, and residential buildings, showcasing their versatility and adaptability to various project requirements.The purlin roll forming machine offered by {Company Name} is built with a robust frame, precision-engineered components, and a user-friendly control system, ensuring seamless operation and consistent production of high-quality purlins. The machine is designed to accommodate a wide range of material thicknesses and coil widths, making it a versatile solution for different project specifications. Additionally, {Company Name} provides customization options to tailor the machine to specific production needs, further enhancing its appeal to customers.One of the key features of the purlin roll forming machine from {Company Name} is its high production speed, which enables efficient and cost-effective manufacturing processes. This, coupled with its low maintenance requirements and energy-efficient operation, makes it a valuable asset for companies looking to streamline their production operations and maximize their output. Furthermore, the superior quality of the purlins produced by the machine ensures structural integrity and longevity in the buildings where they are used.{Company Name} takes great pride in its commitment to innovation and customer satisfaction, continuously striving to enhance the performance and capabilities of its roll forming machines. The company's team of skilled engineers and technicians work rigorously to develop new technologies and features that elevate the efficiency and reliability of their machines, keeping them at the forefront of the industry.In addition to manufacturing purlin roll forming machines, {Company Name} also offers comprehensive technical support, maintenance services, and training programs to ensure that their clients can maximize the potential of their equipment. This dedication to customer service has solidified {Company Name} as a trusted partner for businesses in the metal construction industry, providing them with the tools and resources they need to prosper in a competitive market.With a strong emphasis on quality, performance, and customer satisfaction, {Company Name} has positioned itself as a leading provider of purlin roll forming machines, catering to the diverse needs of construction companies worldwide. The company's unwavering commitment to excellence and innovation continues to drive its success and reinforce its standing as a top-tier supplier in the industry.As the demand for efficient and reliable roll forming solutions in the metal construction industry continues to grow, {Company Name} remains dedicated to meeting the evolving needs of its customers and supporting their success with cutting-edge technology and unparalleled expertise. With a steadfast focus on delivering exceptional value and performance, {Company Name} is poised to remain a driving force in the market, shaping the future of purlin roll forming technology and revolutionizing the way purlins are manufactured for years to come.

Highly Efficient Automatic Cut-To-Length Machine for Improved Productivity

Automatic cut-to-length machine is a revolutionary piece of technology that has been developed by a leading manufacturing company. This cutting-edge machine is designed to provide high precision and efficiency in cutting various materials to the required length.The automatic cut-to-length machine is an essential piece of equipment in industries such as metal fabrication, automotive, construction, and manufacturing. It is capable of cutting a wide range of materials including steel, aluminum, copper, and other alloys with incredible accuracy and speed.The company behind this innovative machine, {remove brand name}, is a respected name in the manufacturing industry. With years of experience and expertise in developing cutting-edge solutions, {remove brand name} has established itself as a pioneer in the field of industrial machinery.The automatic cut-to-length machine is a testament to {remove brand name}'s commitment to innovation and quality. It is equipped with advanced features such as a high-speed cutting mechanism, precision control systems, and an intuitive user interface. This enables operators to easily configure the machine for different cutting requirements while maintaining the highest level of accuracy and consistency.One of the key advantages of the automatic cut-to-length machine is its ability to streamline the production process. By automating the cutting process, it eliminates human error and significantly reduces material waste. This not only improves productivity but also contributes to cost savings for businesses.Furthermore, the machine is designed to be versatile and adaptable to different production environments. Whether it is used for high-volume production or custom fabrication, the automatic cut-to-length machine has the capability to meet the diverse needs of the industry.In addition to its innovative technology, {remove brand name} is also known for its dedication to customer satisfaction. The company provides comprehensive support and training to ensure that its clients are able to maximize the potential of the automatic cut-to-length machine. This includes installation, maintenance, and technical assistance to address any issues that may arise.Moreover, {remove brand name} is committed to environmental sustainability in its manufacturing processes. The automatic cut-to-length machine is designed to be energy-efficient and to minimize the impact on the environment. This aligns with the company's values of responsible and sustainable production practices.The automatic cut-to-length machine from {remove brand name} has already garnered attention and praise within the manufacturing industry. Its combination of cutting-edge technology, precision, and reliability has made it a top choice for businesses looking to enhance their production capabilities.In conclusion, the automatic cut-to-length machine from {remove brand name} represents a significant advancement in industrial machinery. Its innovative features, combined with the company's dedication to quality and customer satisfaction, make it a valuable asset for businesses looking to improve their manufacturing processes. As technology continues to evolve, {remove brand name} is poised to remain at the forefront of the industry, providing cutting-edge solutions that meet the needs of the modern manufacturing world.

High-Quality Roll Forming Machine for Wall Panel Production

Wall Panel Roll Forming MachineInnovative Technology to Revolutionize Construction IndustryThe construction industry has always been at the forefront of technological advancements, and the latest innovation to make waves in the industry is the Wall Panel Roll Forming Machine. This advanced technology is set to revolutionize the way wall panels are produced, offering a wide range of benefits that are set to make a significant impact on the construction sector.The Wall Panel Roll Forming Machine, developed by a leading manufacturer in the industry, is at the cutting edge of precision engineering and automation technology. Its state-of-the-art design and functionality ensure that it can produce high-quality wall panels with unparalleled efficiency and accuracy, meeting the demands of modern construction projects.The machine boasts a number of unique features that set it apart from traditional methods of wall panel production. Its ability to produce panels in large volumes at a rapid pace is a game-changer for construction companies, allowing for greater productivity and reduced lead times on projects. Additionally, the machine can produce panels of varying sizes and specifications, providing flexibility to suit the specific requirements of different construction projects.The Wall Panel Roll Forming Machine also offers cost-saving benefits, thanks to its efficient use of materials and reduced waste production. This is a significant advantage for construction companies looking to minimize their environmental impact and maximize their profitability. With the ability to produce panels with minimal material wastage, the machine provides a sustainable solution for the construction industry.One of the most impressive aspects of the Wall Panel Roll Forming Machine is its adaptability to different types of materials. Whether it's steel, aluminum, or other composite materials, the machine is designed to handle a wide range of materials, opening up opportunities for diverse applications in the construction industry.In addition to its technical capabilities, the Wall Panel Roll Forming Machine is backed by a team of experts who provide comprehensive support to customers. From installation and training to ongoing maintenance and troubleshooting, the company's dedicated team is committed to ensuring that customers get the most out of their investment in the machine. This level of support and expertise is a key factor in the success of the machine, as it gives customers the confidence to integrate this advanced technology into their operations.With an impressive track record of delivering innovative solutions to the construction industry, the company behind the Wall Panel Roll Forming Machine has earned a reputation for excellence and reliability. With a focus on quality, performance, and customer satisfaction, the company continues to push boundaries and set new standards for technological advancements in construction equipment.The introduction of the Wall Panel Roll Forming Machine marks a significant milestone in the evolution of wall panel production. Its advanced technology, combined with the expertise and support of the company, is set to transform the way wall panels are manufactured, ultimately reshaping the construction industry as a whole. As construction companies seek to improve efficiency, reduce costs, and adopt sustainable practices, the Wall Panel Roll Forming Machine offers a compelling solution that meets the evolving needs of the industry.In conclusion, the Wall Panel Roll Forming Machine is a game-changing innovation that is set to make a significant impact on the construction industry. With its advanced technology, cost-saving benefits, and adaptability to different materials, the machine offers a compelling solution for construction companies looking to enhance their operations. Backed by a company with a proven track record of excellence, the Wall Panel Roll Forming Machine is poised to revolutionize the way wall panels are produced, setting new standards for efficiency, sustainability, and quality in the construction sector.

The Future of Coil Fed Punching Cutting Machines Market: A Comprehensive Market Analysis

Coil-fed punching and cutting machines have witnessed significant growth in recent years, driven by the demand for efficient and automated manufacturing processes. These machines are widely used in various industries, including automotive, aerospace, electronics, and construction. With the increasing need for precision and productivity in these sectors, the coil-fed punching and cutting machines market is expected to experience further innovation and growth.A recent market research report by Persistence Market Research provides insights into the coil-fed punching and cutting machines market. The report highlights the market dynamics, growth factors, challenges, and trends shaping the industry. It presents a comprehensive analysis of the market and its future prospects.The coil-fed punching and cutting machines market is witnessing constant innovation in terms of technology and product development. Manufacturers are focusing on improving the efficiency and accuracy of these machines to meet the growing demands of various industries. Integration of advanced features like computer numerical control (CNC) systems, high-speed punching and cutting capabilities, and robotic automation are some of the latest developments in this market.One of the key drivers for the coil-fed punching and cutting machines market is the increasing demand for lightweight materials in the automotive and aerospace industries. With the need for fuel efficiency and reduced emissions, manufacturers are using advanced materials like aluminum and composites, which require precise and efficient cutting and punching processes. Coil-fed punching and cutting machines offer the flexibility and speed required to handle such materials.Another factor driving the growth of this market is the growing adoption of Industry 4.0 technologies. The integration of IoT (Internet of Things) and smart automation in manufacturing processes has revolutionized the industry. Coil-fed punching and cutting machines equipped with IoT capabilities can communicate with other machines and systems, enabling seamless production flow and real-time monitoring. This reduces downtime, improves efficiency, and enhances overall productivity.However, the coil-fed punching and cutting machines market also faces certain challenges. High initial investment costs, skilled labor requirements, and the need for regular maintenance and calibration are some of the factors that can hinder market growth. Additionally, the market is highly competitive, with several players offering similar products. This makes it crucial for manufacturers to differentiate themselves through innovative features and superior customer service.In terms of regional analysis, Asia Pacific is expected to dominate the coil-fed punching and cutting machines market. The rapid industrialization in countries like China, India, and Japan, coupled with the presence of key automotive and electronics manufacturers, creates a favorable environment for market growth. Moreover, the increased focus on automation and the adoption of advanced technologies in these industries are driving the demand for coil-fed punching and cutting machines in the region.In conclusion, the coil-fed punching and cutting machines market is predicted to witness significant growth in the coming years. Continuous innovation in technology, the adoption of Industry 4.0 solutions, and the demand for lightweight materials fuel the market's expansion. However, challenges like high costs and intense competition need to be addressed for sustained growth. Manufacturers must invest in research and development to enhance machine capabilities and provide efficient solutions to cater to the evolving needs of industries worldwide.

Ultimate Guide to Choosing a C Channel Forming Machine

C Channel Forming Machine Revolutionizes the Metal Fabrication ProcessThe manufacturing industry has seen significant advancements in recent years, particularly in the field of metal fabrication. One such advancement comes in the form of the C Channel Forming Machine, a cutting-edge technology that has revolutionized the way metal C channels are produced.The C Channel Forming Machine, developed by a leading manufacturing company, is designed to streamline and simplify the metal fabrication process. This innovative machine is capable of producing high-quality C channels with precision and efficiency, making it an indispensable tool for manufacturers in various industries.The machine's advanced features and capabilities make it the perfect solution for companies looking to enhance their metal fabrication operations. With its ability to produce C channels in a wide range of sizes and specifications, the machine offers versatility and flexibility, allowing manufacturers to meet the unique demands of their customers.One of the key advantages of the C Channel Forming Machine is its speed and efficiency. By automating the process of forming C channels, the machine significantly reduces production time and labor costs, while also improving overall productivity. This not only benefits manufacturers in terms of cost savings but also allows them to fulfill customer orders in a timely manner.In addition to its speed and efficiency, the machine is also known for its precision and accuracy. Its advanced technology ensures that each C channel produced meets the highest standards of quality and consistency. This is essential for manufacturers who require precise and reliable components for their products.Furthermore, the C Channel Forming Machine is designed with user-friendly features, making it easy for operators to set up and operate the machine. This means that manufacturers can quickly integrate the machine into their production processes without the need for extensive training or technical expertise.The company behind the C Channel Forming Machine has a strong track record of innovation and expertise in the field of metal fabrication. With a commitment to developing cutting-edge solutions for the manufacturing industry, the company has become a trusted partner for businesses seeking to improve their production processes.The company's dedication to research and development has led to the creation of the C Channel Forming Machine, which has already made a significant impact in the metal fabrication industry. Its continued investment in technology and engineering ensures that the company remains at the forefront of innovation, providing manufacturers with the tools they need to stay competitive in today's fast-paced market.With its impressive capabilities and proven performance, the C Channel Forming Machine is set to become an essential asset for manufacturers looking to elevate their metal fabrication capabilities. Its ability to deliver precision, efficiency, and versatility makes it a game-changer in the industry, offering a new standard for metal C channel production.As the manufacturing industry continues to evolve, innovative technologies like the C Channel Forming Machine will play a crucial role in driving progress and transformation. With its potential to optimize production processes and improve product quality, this revolutionary machine represents the future of metal fabrication.

High-Quality Corrugated Roof Tile Making Machine for Efficient Production

Corrugated Roof Tile Making Machine brings innovation in the roofing industryThe roofing industry has seen a significant shift in recent years, with a growing demand for durable, cost-effective, and eco-friendly roofing solutions. In response to this demand, a leading manufacturer, {company name removed}, has introduced an advanced Corrugated Roof Tile Making Machine that is set to revolutionize the roofing industry.The Corrugated Roof Tile Making Machine is a state-of-the-art equipment that is designed to produce high-quality roofing tiles with precision and efficiency. It is equipped with advanced technology and features that allow for the seamless production of corrugated roof tiles, which are known for their strength, durability, and aesthetic appeal.The machine is capable of producing a wide range of corrugated roof tiles, including various sizes, shapes, and colors, thereby catering to the diverse needs and preferences of customers. Whether it's for residential, commercial, or industrial applications, the machine has the capability to meet the demands of the market.One of the key features of the Corrugated Roof Tile Making Machine is its high production capacity, which enables manufacturers to meet large-scale orders and deadlines. This is particularly beneficial for roofing companies and contractors who require a reliable and efficient production system to fulfill their projects in a timely manner.Furthermore, the machine is designed with user-friendly controls and automation, which not only simplifies the production process but also minimizes the risk of errors and defects. This results in consistent quality and uniformity in the produced tiles, thereby enhancing the overall satisfaction of customers.In addition to its efficiency and productivity, the Corrugated Roof Tile Making Machine is also environmentally friendly. It is designed to minimize waste and energy consumption, thereby aligning with the growing emphasis on sustainable and eco-friendly manufacturing practices.The introduction of this advanced machine signifies a significant advancement in the roofing industry, offering manufacturers and customers alike a reliable and cutting-edge solution for their roofing needs. With its ability to produce high-quality, long-lasting, and visually appealing corrugated roof tiles, the machine is set to significantly impact the market and set new standards for roofing materials.In line with {company name removed}'s commitment to innovation and excellence, the Corrugated Roof Tile Making Machine reflects the company's dedication to providing advanced solutions that meet the evolving needs of the industry. With its extensive experience and expertise in manufacturing equipment for the construction and building materials sector, the company has once again demonstrated its leadership in driving innovation and progress in the market.The introduction of the Corrugated Roof Tile Making Machine is poised to bring about a positive change in the roofing industry, offering a cost-effective, efficient, and sustainable solution for both manufacturers and consumers. As the demand for high-quality and durable roofing materials continues to rise, this innovative machine is expected to play a pivotal role in shaping the future of the industry.In conclusion, the Corrugated Roof Tile Making Machine represents a significant leap forward in the roofing industry, offering a modern, efficient, and sustainable solution for the production of high-quality corrugated roof tiles. With its advanced technology, user-friendly features, and eco-friendly design, the machine is set to transform the way roofing materials are manufactured and used, setting new benchmarks for quality and performance in the market.

Roll Forming and Corrugation Machine for Color Steel Glazed Tile Panels

Title: Innovation in Steel Glazed Tile Panel Roll Forming and Corrugation Machine Revolutionizes Construction IndustryIntroduction:The construction industry has witnessed a remarkable innovation in the form of the Color Steel Glazed Tile Panel Roll Forming and Corrugation Machine. This state-of-the-art machine, developed by a reputable company, is set to transform the way steel glazed tiles are manufactured for roofing applications. With its advanced technology and seamless production process, the machine is poised to revolutionize the industry while offering numerous benefits to construction companies and homeowners alike.Body:1. Industry Challenges and Evolution:The construction industry has always demanded sturdy, efficient, and aesthetically pleasing roofing materials. However, the traditional methods of producing steel glazed tiles posed multiple challenges for manufacturers. These challenges included high production costs, limited design options, and time-consuming installation processes.2. Introducing the Color Steel Glazed Tile Panel Roll Forming and Corrugation Machine:Innovating the market, the Color Steel Glazed Tile Panel Roll Forming and Corrugation Machine eliminates the aforementioned challenges. Developed by a prominent technology company known for its commitment to excellence, this machine streamlines the production process, ensuring cost-effectiveness, flexibility, and enhanced design options.3. Seamless Production Process:The machine's advanced features enable a seamless production process. It is equipped with precision engineering and cutting-edge technology, ensuring high precision in every tile produced. The roll forming and corrugation mechanism guarantees consistent tile dimensions, thus reducing material wastage and costs. With adjustable settings, manufacturers can effortlessly produce a wide range of tile profiles, meeting the diverse design preferences of customers.4. Enhanced Design Options:An exciting aspect of the Color Steel Glazed Tile Panel Roll Forming and Corrugation Machine is its ability to offer an extensive range of design options. Manufacturers can now cater to different architectural styles and market demands. From traditional designs to contemporary aesthetics, this machine facilitates the creation of visually striking steel glazed tiles, making it an attractive choice for builders and homeowners alike.5. Cost-Effective Solution:With its efficient production process and reduced material wastage, the Color Steel Glazed Tile Panel Roll Forming and Corrugation Machine ensures cost-effectiveness for manufacturers. This advantage translates to affordable pricing for consumers without compromising on quality or durability. The machine's productivity significantly increases the overall output, thus enabling companies to meet increased market demands in a shorter timeframe.6. Durability and Longevity:Steel glazed tiles produced using this innovative machine boast exceptional durability and longevity. The use of high-quality materials, combined with precision manufacturing, results in tiles that can withstand harsh weather conditions, UV exposure, and the test of time. This durability ultimately translates into increased customer satisfaction and reduced maintenance costs for homeowners.7. Environmental Sustainability:Recognizing the importance of sustainable practices in the construction industry, the Color Steel Glazed Tile Panel Roll Forming and Corrugation Machine adheres to eco-friendly manufacturing processes. The machine's design ensures minimal energy consumption while reducing the carbon footprint. Additionally, the long lifespan of the tiles reduces the need for frequent replacements, contributing to a more sustainable construction approach.Conclusion:The introduction of the Color Steel Glazed Tile Panel Roll Forming and Corrugation Machine has revolutionized the construction industry. It has addressed the challenges faced by manufacturers, providing them with a cost-effective, flexible, and highly efficient solution to produce high-quality steel glazed tiles. With its seamless production process, enhanced design options, and durability, this innovative machine is set to shape the future of the roofing industry. As construction companies and homeowners continue to seek innovative and sustainable solutions, the machine's technological advancements and environmental benefits position it as a game-changer in the market.

Local Machine Shops & Manufacturing Services in Corman Park - Find Metal Connections and Quality Craftsmanship

Title: Streamlining Metal Profiles: Enhancing Machine Shop ManufacturingIntroduction:In today's ever-evolving industrial landscape, machine shops and manufacturing units play a crucial role in the production of metal profiles. These precise and essential components cater to the diverse needs of various industries. However, finding trustworthy and capable machine shops that specialize in metal profile manufacturing can be a challenge. In this blog, we will explore the significance of metal profile manufacturing, the role of machine shops in the process, and how businesses can benefit from high-quality and efficient services.Understanding Metal Profile Manufacturing:Metal profile manufacturing involves the creation of custom metal profiles using various techniques like cutting, bending, welding, and assembly. These profiles find extensive applications across industries ranging from aerospace and automotive to construction and machinery. Precision, accuracy, and durability are vital aspects of metal profile manufacturing, as these components often withstand demanding conditions and require reliable performance.The Importance of Machine Shops:Machine shops serve as the backbone of metal profile manufacturing, utilizing state-of-the-art machinery and a skilled workforce to craft precision profiles with utmost accuracy. These shops play a critical role in implementing and refining the manufacturing processes, ensuring that the final product meets the specific requirements and industry standards. A well-equipped machine shop possesses the machinery and expertise to handle projects of varying complexities and scales, delivering on time and within budget.Streamlining Manufacturing Processes:Modern machine shops leverage advanced technologies, such as computer numerical control (CNC) machines, to optimize the manufacturing process. CNC machines offer superior precision, consistency, and speed, resulting in reduced lead times, minimized waste, and enhanced product quality. By integrating cutting-edge software solutions, machine shops can create intricate profiles and streamline complex manufacturing procedures, offering clients highly customized and efficient solutions.Delivering Unparalleled Quality:When it comes to metal profile manufacturing, quality is of utmost importance. A reputable machine shop understands this requirement and employs rigorous quality control measures at every stage of the manufacturing process. From material selection and raw material inspection to final finishing and inspection, these shops adhere to strict quality standards, ensuring that the end product meets or exceeds client expectations. By partnering with reliable machine shops, businesses can secure access to high-quality metal profiles that are built to withstand tough conditions and deliver exceptional performance.Collaboration and Customization:Collaboration between machine shops and clients is crucial for successful metal profile manufacturing. Experienced machine shops work closely with businesses to understand their unique needs, providing comprehensive consultation and design assistance. By involving clients throughout the design and manufacturing stages, machine shops can ensure that the end product perfectly aligns with specific project requirements. This collaborative approach results in customized profiles that maximize efficiency, reliability, and cost-effectiveness.Conclusion:Metal profile manufacturing is a specialized field that requires the expertise of machine shops capable of meeting the specific needs of various industries. By embracing advanced technologies, implementing stringent quality control measures, and fostering collaborative relationships with clients, reputable machine shops deliver customized metal profiles that enhance efficiency, durability, and performance. Businesses looking for superior metal profiles must partner with trustworthy machine shops and reap the benefits of streamlined manufacturing processes and unparalleled quality.Keywords:Metal profile manufacturing, machine shops, precision, manufacturing processes, CNC machines, quality control, customization, collaboration, advanced technologies, efficiency, durability, performance.

Ultimate Guide to High-Speed Slitting Machine for Efficient Production

LONDON - The global manufacturing industry is constantly striving for improvements in efficiency and productivity. In a bid to meet this demand, the leading machinery manufacturer, **(need remove brand name)**, has announced the launch of their latest innovation - the High-Speed Slitting Machine.With a legacy of over 50 years in the industry, **(need remove brand name)** has been at the forefront of providing cutting-edge solutions for the converting and packaging industry. Their new High-Speed Slitting Machine is designed to revolutionize the process of converting raw materials into finished products with unparalleled speed and precision.The High-Speed Slitting Machine is equipped with state-of-the-art technology that enables it to achieve ultra-fast cutting speeds while maintaining exceptional accuracy. This allows manufacturers to significantly reduce production time and costs, ultimately improving their competitiveness in the market.Speaking about the introduction of the new product, the CEO of **(need remove brand name)**, expressed his excitement about the potential impact of the High-Speed Slitting Machine on the industry. He stated, "We are thrilled to bring this groundbreaking technology to our customers. The High-Speed Slitting Machine is a result of our relentless commitment to innovation and our dedication to meeting the evolving needs of the manufacturing industry."The machine's advanced features include automatic web guiding, quick-change knife systems, and integrated tension control, all of which contribute to its superior performance. Additionally, it is designed to accommodate a wide range of materials including paper, film, foil, and nonwovens, making it a versatile solution for various manufacturing applications.Furthermore, the High-Speed Slitting Machine is built with a strong focus on user-friendliness and maintenance efficiency. Its intuitive interface and remote diagnostics capabilities allow for seamless operation and troubleshooting, reducing downtime and enhancing overall productivity.The company has also emphasized its commitment to sustainability with the development of the High-Speed Slitting Machine. By optimizing material usage and minimizing waste, the machine aligns with the industry's growing focus on eco-friendly manufacturing practices.Market analysts have lauded the launch of the High-Speed Slitting Machine, recognizing its potential to drive significant advancements in the converting and packaging industry. With its ability to enhance production efficiency and deliver high-quality results, the machine is expected to be a game-changer for manufacturers looking to stay ahead in an increasingly competitive market landscape.In line with its global reach, **(need remove brand name)** has already received inquiries and orders for the High-Speed Slitting Machine from companies across various regions. The company's extensive network of sales and service partners ensures that customers worldwide will have access to the latest innovation and the support needed to maximize its benefits.As manufacturing continues to evolve in response to changing consumer demands and technological advancements, the High-Speed Slitting Machine represents a significant leap forward in the pursuit of operational excellence. **(need remove brand name)**'s commitment to innovation and customer satisfaction positions them as a key player in driving the industry forward.The launch of the High-Speed Slitting Machine underscores **(need remove brand name)**'s dedication to providing cutting-edge solutions that enable manufacturers to elevate their production capabilities and achieve sustainable growth. As the industry continues to embrace technological advancements, the High-Speed Slitting Machine stands out as a testament to the company's vision and leadership in the global manufacturing landscape.