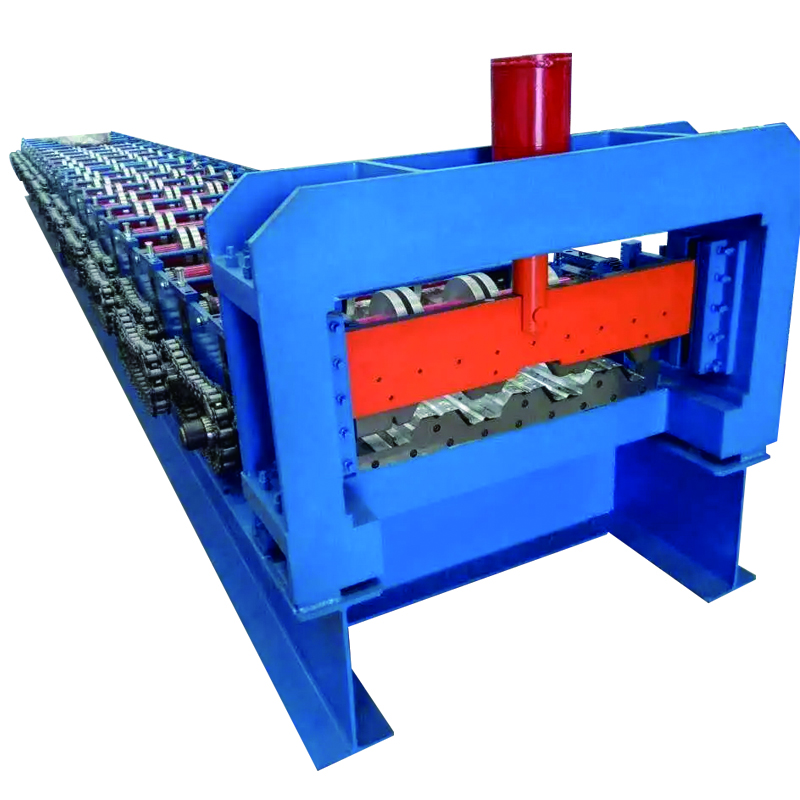

Advanced Forming Machine for Creating Profiles

By:Admin

The newly launched machine has been developed with the latest advancements in technology, resulting in a state-of-the-art and highly efficient production process. The machine is designed to form profiles with extreme precision and accuracy, catering to the specific needs of industries such as automotive, construction, and manufacturing.

The company, founded in 1995, has a proven track record of delivering high-quality machinery and has built a reputation for its commitment to excellence. With a team of experienced engineers and technicians, Profile Forming Machine has consistently set industry standards and has become a trusted partner for businesses seeking reliable and advanced solutions for their production needs.

The new machine is the result of extensive research and development, and it embodies the company's dedication to innovation and customer satisfaction. It has been designed to streamline the production process, reduce energy consumption, and maximize output, making it an ideal choice for businesses looking to enhance their efficiency and productivity.

One of the key features of the new machine is its versatility, allowing it to handle a wide range of profiles and materials. Whether it is aluminum, steel, or other metals, the machine is capable of forming profiles with precision, consistency, and repeatability, meeting the highest quality standards.

In addition to its technical capabilities, the machine also offers user-friendly controls and interface, making it easy to operate and maintain. This ensures that businesses can maximize their production capabilities without compromising on safety or quality.

"We are excited to introduce our latest Profile Forming Machine to the market," said the company's spokesperson. "With its advanced technology and high precision engineering, we believe that it will significantly benefit our customers and help them stay ahead in their respective industries. We are committed to providing the best solutions for our customers, and this machine is a testament to that commitment."

The company also offers comprehensive training and support services to ensure that customers can optimize the performance of the machine and make the most of its capabilities. This personalized approach has been a cornerstone of Profile Forming Machine's success, as it believes in building long-term relationships with its customers and providing ongoing support and assistance.

With its latest offering, Profile Forming Machine is poised to further strengthen its position as a market leader and a preferred choice for businesses seeking cutting-edge solutions for their production needs. The company's dedication to continuous improvement and technological advancement sets it apart in the industry, and its commitment to quality and customer satisfaction is unwavering.

As the market continues to evolve and demand for high-quality products grows, Profile Forming Machine is well-positioned to meet the needs of industries requiring precision and efficiency in their production processes. The company's new machine is a testament to its vision and capability, and it is set to make a significant impact in the global machinery industry.

Company News & Blog

High-Quality Ag Panel Roll Forming Machine: A Must-Have for Efficient Farming

Ag Panel Roll Forming Machine Revolutionizes Farming IndustryIn the ever-evolving world of agriculture, technological advancements continue to change the way farmers operate. One such innovation, the Ag Panel Roll Forming Machine, is revolutionizing the farming industry by providing a cost-effective and efficient solution for producing high-quality agricultural panels.The Ag Panel Roll Forming Machine, developed and produced by a leading manufacturing company, is a state-of-the-art piece of equipment designed to streamline the process of manufacturing agricultural panels. These panels are essential for constructing buildings, barns, and other structures on farms, providing much-needed shelter and protection for livestock, equipment, and crops.This innovative machine is equipped with advanced technology and precision engineering, allowing it to produce consistent and precise agricultural panels with minimal waste. Its high-speed production capabilities enable farmers to meet their construction needs in a timely manner, reducing downtime and increasing overall productivity.The company behind this groundbreaking machine has a solid reputation in the manufacturing industry, known for its commitment to producing top-quality equipment that is built to last. With a focus on innovation and customer satisfaction, the company has been a trusted partner for farmers and agricultural businesses for many years.In addition to its cutting-edge technology, the Ag Panel Roll Forming Machine is also designed with user-friendliness in mind. It is easy to operate and requires minimal training, making it accessible to farmers of all experience levels. This accessibility is essential for ensuring that farmers can take advantage of the benefits offered by this innovative equipment.The impact of the Ag Panel Roll Forming Machine extends beyond its immediate users. By increasing the efficiency of agricultural panel production, this machine has the potential to positively influence the entire farming industry. With quicker access to high-quality panels, farmers can expedite construction projects and improve the overall infrastructure of their operations, leading to increased safety and productivity.Furthermore, the machine's ability to minimize waste and optimize material usage contributes to a more sustainable approach to farming. By reducing the environmental impact of panel manufacturing, farmers can align their operations with modern sustainability standards, appealing to environmentally conscious consumers and stakeholders.The Ag Panel Roll Forming Machine is a testament to the ongoing technological advancements in the agriculture sector. Its introduction represents a significant step forward in modernizing farm operations, offering a glimpse into the future of farming technology.With its impressive capabilities and potential to transform the industry, the Ag Panel Roll Forming Machine is set to become a staple in farming operations of all sizes. The company's dedication to innovation and customer satisfaction, combined with its track record of manufacturing excellence, positions it as a key player in shaping the future of agriculture.As the farming industry continues to evolve, it is clear that solutions like the Ag Panel Roll Forming Machine will play a vital role in driving progress and success for farming operations around the world. As more farmers adopt this innovative technology, the industry as a whole stands to benefit from increased efficiency, sustainability, and productivity.

Designing Auto Glazed Tile Forming Machine for Metal Roofing: Customizable Metal Roofing Roll Forming Machine

Title: Unveiling the Versatility of Color Steel Metal Glazed Tile Roll Forming MachineIntroduction:When it comes to roofing solutions, metal roof tiles have emerged as a popular choice due to their durability, versatility, and aesthetic appeal. The advent of advanced machinery, such as the Color Steel Metal Glazed Tile Roll Forming Machine, has revolutionized the production process, enabling efficient and precise manufacturing of glazed tiles for roofing sheets. In this article, we will explore the features, benefits, and applications of this innovative machine, along with its role in enhancing the overall efficiency of the metal roofing industry.1. Understanding the Color Steel Metal Glazed Tile Roll Forming Machine:The Color Steel Metal Glazed Tile Roll Forming Machine is a state-of-the-art equipment that caters to the growing demand for metal roof tiles. Designed by DAHEZB, a renowned leader in the field, this machine creates glazed tiles with exceptional precision and quality. With the ability to handle metal sheets ranging from 0.3mm to 0.6mm thickness, it offers a remarkable level of flexibility and adaptability to meet the diverse requirements of customers.2. Key Features:a) Auto Glazed Tile Forming Capability: The Color Steel Metal Glazed Tile Roll Forming Machine is equipped with an auto-glazing feature, ensuring seamless application of glazed tiles onto roofing sheets. This automated process eliminates manual intervention, maintaining consistency and saving valuable time.b) Aluminum Roofing Step Tile Machine: This advanced machine specializes in producing step-tile patterns, imparting an appealing look to the roofing surface. The unique design capabilities allow for customization, enabling customers to create roofing tiles that perfectly complement their project requirements.c) Robust Build for Enhanced Durability: Manufactured using the highest quality materials, the Color Steel Metal Glazed Tile Roll Forming Machine is built to withstand the most demanding production environments. Its robust construction ensures longevity and reliable performance, reducing downtime and maximizing productivity.3. Benefits and Advantages:a) Versatility in Material Compatibility: The Color Steel Metal Glazed Tile Roll Forming Machine is adept at working with various materials, including color steel, galvanized steel, and aluminum. This versatility allows manufacturers to cater to a wide range of customer demands, ensuring market competitiveness and expanding their product offerings.b) Speed and Efficiency: With its advanced automation features, this machine can produce high volumes of glazed tiles in a short span of time. By streamlining the production process, it significantly enhances efficiency, reducing labor costs and increasing overall output.c) Exceptional Precision and Quality: The Glazed Tile Roll Forming Machine guarantees precise dimensions, accurate designs, and consistent quality of each glazed tile produced. This level of craftsmanship enhances the final product's aesthetics and ensures customer satisfaction.4. Applications:The Color Steel Metal Glazed Tile Roll Forming Machine finds extensive application in the metal roofing industry. It is an ideal solution for commercial and residential projects that demand high-quality, long-lasting roofing systems. Its ability to produce an array of designs, patterns, and colors makes it indispensable for architects, contractors, and homeowners seeking to enrich the visual appeal of their buildings.Conclusion:The Color Steel Metal Glazed Tile Roll Forming Machine is a game-changer in the metal roofing industry, revolutionizing the production process and elevating the quality and efficiency of glazed tiles. Its unmatched versatility, durability, and precision make it the preferred choice for manufacturers and customers alike. With its ability to handle various materials and produce an array of designs, this machine signifies the future of metal roofing, where aesthetics meet functionality seamlessly.

Discover the Art of Aluminium Profile Bending for Enhanced Applications

Aluminium Profile Bending Brings a New Era of ManufacturingThe recent years have seen a drastic rise in the popularity and use of aluminium profiles. They are being extensively used in a diverse range of industries such as automobile, construction, and aerospace. The reason behind the emergence of this trend is the unparalleled advantages that come with using these profiles. They offer high strength, lightness, and durability. They are also easy to manufacture and mould. However, the real challenge arises when it comes to moulding these profiles into the desired shapes and sizes. This is where Aluminium Profile Bending has brought about a revolution in the manufacturing industry.Aluminium Profile Bending (APB), a technique that has been developed by a leading company in the manufacturing industry, has revolutionized the way aluminium profiles are moulded. With the introduction of this technique, manufacturers can now bend the profiles into any desired shape and size. The shapes can vary from simple curves to complex designs. This technique is particularly useful for manufacturing aluminum profiles for the construction industry that require intricate shapes, making it impossible to produce using conventional techniques.Advanced technology and expertise are required to carry out the bending of aluminum profiles, which is where the company that developed APB excels. They have a team of immensely skilled technicians who use cutting-edge equipment to ensure precision in the bending of the profiles. Using this technique, the team can accurately bend even the most intricate shapes.The advantages of APB are numerous. Firstly, it offers a high level of precision which allows for the creation of complex and intricate designs. Secondly, the technique is much more cost-effective, as it reduces the waste material that is produced during the conventional manufacturing process. APB also eliminates the need for additional manufacturing processes that might be required to achieve the desired shape, which again translates to cost savings. Additionally, it provides excellent finish quality and surface appearance, making it ideal for high-quality products such as those required in the automotive and aerospace industries.The use of APB is not limited to aluminum profiles only. The technique can also be used with other metals, including copper, brass, and stainless steel. This versatility means that manufacturers now have even more options when it comes to the manufacturing of complex shapes and designs.The development of APB has had a significant impact on the manufacturing industry. It has not only reduced production costs but has also opened up new possibilities for manufacturers. With this technique, they can now produce complex and intricate designs that were previously not possible.With the increasing demand for aluminium profiles, it is evident that the manufacturing industry needs to embrace new technologies and techniques to stay ahead of the competition. The introduction of Aluminium Profile Bending has provided manufacturers with a game-changing solution to their manufacturing problems. As new and better technologies continue to emerge, it is essential that manufacturers keep an eye out for innovations that could improve their manufacturing processes.In conclusion, Aluminium Profile Bending has revolutionized the way aluminium profiles are moulded, giving manufacturers the ability to produce complex and intricate designs accurately. The technique offers a high level of precision, reduces production costs, and eliminates the need for additional manufacturing processes, making it ideal for a diverse range of industries. As manufacturing technologies continue to evolve, it is essential for manufacturers to stay up-to-date with the latest innovations and techniques to remain competitive in the industry.

High-Quality Corrugated Metal Sheet Roll Forming Machine for Sale

Corrugated Metal Sheet Roll Forming Machine, a New Milestone in the Field of Metal FormingIn the fast-paced world of metal manufacturing, staying ahead of the competition is crucial. That's why the unveiling of the new Corrugated Metal Sheet Roll Forming Machine by [Company Name] has caused quite a stir in the industry. This state-of-the-art machine promises to revolutionize the way corrugated metal sheets are produced, making the process faster, more efficient, and more cost-effective than ever before.The Corrugated Metal Sheet Roll Forming Machine is the result of years of research and development by the team at [Company Name]. Leveraging their extensive experience in the field of metal forming, the engineers at [Company Name] have come up with a machine that is truly groundbreaking. By incorporating the latest advancements in technology and design, they have created a product that sets a new standard for quality and performance.One of the key features of the Corrugated Metal Sheet Roll Forming Machine is its versatility. It is capable of producing a wide range of corrugated metal sheet profiles, giving manufacturers the flexibility to meet the unique requirements of their customers. Whether it's for roofing, siding, or other applications, this machine can handle the job with ease.But perhaps the most impressive aspect of the Corrugated Metal Sheet Roll Forming Machine is its speed and efficiency. Thanks to its advanced automation and precision engineering, this machine is able to produce corrugated metal sheets at a rate that was previously unheard of. This means that manufacturers can now fulfill large orders in a fraction of the time it would have taken with traditional methods.In addition to its speed, the Corrugated Metal Sheet Roll Forming Machine also boasts an impressive level of accuracy and consistency. This is crucial for ensuring that the finished products meet the highest standards of quality. With this machine, manufacturers can have complete confidence that every corrugated metal sheet produced will be of the utmost precision and uniformity.Of course, an innovative product like the Corrugated Metal Sheet Roll Forming Machine is only as good as the company behind it. In the case of [Company Name], customers can rest assured that they are dealing with a reputable and reliable partner. With a long track record of delivering top-notch metal forming solutions, [Company Name] has earned a strong reputation in the industry.Furthermore, [Company Name] doesn't just stop at selling the Corrugated Metal Sheet Roll Forming Machine. They also offer comprehensive support and service to ensure that their customers get the most out of their investment. From installation and training to ongoing maintenance and technical assistance, [Company Name] is dedicated to helping their clients succeed.With the introduction of the Corrugated Metal Sheet Roll Forming Machine, [Company Name] has truly raised the bar for the entire industry. This machine represents a new milestone in the field of metal forming, offering a level of performance and efficiency that was previously unimaginable. As manufacturers around the world seek to stay competitive in a rapidly evolving market, this innovative product is poised to make a significant impact.In conclusion, the Corrugated Metal Sheet Roll Forming Machine by [Company Name] is a game-changer for the metal forming industry. Its cutting-edge technology, versatility, speed, and precision are testament to the ingenuity and expertise of the team at [Company Name]. With this machine, manufacturers can expect to improve their productivity, reduce costs, and deliver exceptional quality products to their customers. It's clear that the future of metal forming is here, and it's being shaped by the innovative solutions of [Company Name].

Efficient Corrugated Iron Sheet Making Machine: Robust and High-Quality Production Capabilities

Corrugated Iron Sheet Making Machine Revolutionizing the Construction IndustryThe construction industry has been growing rapidly over the years, with a constant need for innovative technologies and machinery to enhance efficiency and productivity. Among the many innovations, the Corrugated Iron Sheet Making Machine (name removed) has emerged as a game-changer, revolutionizing how corrugated iron sheets are manufactured.With the global demand for corrugated iron sheets on the rise, this advanced machine offers a streamlined and efficient solution for manufacturers. By automating the production process, it not only eliminates the labor-intensive manual work but also significantly reduces the time required for sheet production.The Corrugated Iron Sheet Making Machine features cutting-edge technology and a high level of precision, ensuring the production of top-quality iron sheets with consistent dimensions and ridges. This not only enhances the overall performance of the sheets but also offers improved durability and weather resistance.One of the key advantages of this machine is its versatility. It can produce corrugated iron sheets in various sizes, thicknesses, and profiles. This flexibility caters to the diverse needs of the construction industry, allowing manufacturers to meet specific requirements for different applications. Whether it's for roofing, siding, or fencing, the Corrugated Iron Sheet Making Machine can deliver the desired outcome with ease.Moreover, the machine incorporates advanced safety features to ensure the well-being of workers. With automated controls and protective measures, it minimizes the risk of accidents, making it a safe and reliable option for factories and manufacturing units. This not only enhances worker safety but also boosts overall operational efficiency by minimizing downtime.In addition to its technical capabilities, the Corrugated Iron Sheet Making Machine is eco-friendly. It is designed to optimize energy consumption and minimize waste production. By using sustainable manufacturing practices, it aligns with the growing global trend of eco-conscious construction. This aspect not only highlights the machine's efficiency but also positions it as a responsible choice in an industry striving for sustainability.Company Introduction:As a key player in the construction industry, our company has been at the forefront of providing innovative solutions to meet the evolving needs of builders and contractors. With a strong commitment to quality, efficiency, and sustainability, we have established ourselves as a trusted partner for numerous construction projects worldwide.Our team of engineers and industry experts has invested years of research and development to perfect the Corrugated Iron Sheet Making Machine. By combining cutting-edge technology with extensive market knowledge, we have successfully developed a machine that exceeds industry standards and offers unparalleled performance.Our company's mission is to revolutionize the way corrugated iron sheets are manufactured, making the process more efficient, cost-effective, and eco-friendly. We believe that the Corrugated Iron Sheet Making Machine will not only empower manufacturers but also contribute to the sustainable growth of the construction industry.With a focus on customer satisfaction, our dedicated sales and after-sales support teams are always ready to assist clients at every step of the process. From initial consultations to installation, training, and maintenance, we are committed to ensuring a seamless experience for our valued customers.In conclusion, the Corrugated Iron Sheet Making Machine is a significant innovation that is transforming the construction industry. Its technological advancements, versatility, safety features, and eco-friendly approach make it a perfect solution for manufacturers looking to improve productivity while adhering to sustainable practices. With our company's expertise and commitment, we are proud to introduce this groundbreaking machine to the market and cater to the evolving needs of the construction industry.

High-Quality Corrugated Roof Tile Making Machine for Efficient Production

Corrugated Roof Tile Making Machine brings innovation in the roofing industryThe roofing industry has seen a significant shift in recent years, with a growing demand for durable, cost-effective, and eco-friendly roofing solutions. In response to this demand, a leading manufacturer, {company name removed}, has introduced an advanced Corrugated Roof Tile Making Machine that is set to revolutionize the roofing industry.The Corrugated Roof Tile Making Machine is a state-of-the-art equipment that is designed to produce high-quality roofing tiles with precision and efficiency. It is equipped with advanced technology and features that allow for the seamless production of corrugated roof tiles, which are known for their strength, durability, and aesthetic appeal.The machine is capable of producing a wide range of corrugated roof tiles, including various sizes, shapes, and colors, thereby catering to the diverse needs and preferences of customers. Whether it's for residential, commercial, or industrial applications, the machine has the capability to meet the demands of the market.One of the key features of the Corrugated Roof Tile Making Machine is its high production capacity, which enables manufacturers to meet large-scale orders and deadlines. This is particularly beneficial for roofing companies and contractors who require a reliable and efficient production system to fulfill their projects in a timely manner.Furthermore, the machine is designed with user-friendly controls and automation, which not only simplifies the production process but also minimizes the risk of errors and defects. This results in consistent quality and uniformity in the produced tiles, thereby enhancing the overall satisfaction of customers.In addition to its efficiency and productivity, the Corrugated Roof Tile Making Machine is also environmentally friendly. It is designed to minimize waste and energy consumption, thereby aligning with the growing emphasis on sustainable and eco-friendly manufacturing practices.The introduction of this advanced machine signifies a significant advancement in the roofing industry, offering manufacturers and customers alike a reliable and cutting-edge solution for their roofing needs. With its ability to produce high-quality, long-lasting, and visually appealing corrugated roof tiles, the machine is set to significantly impact the market and set new standards for roofing materials.In line with {company name removed}'s commitment to innovation and excellence, the Corrugated Roof Tile Making Machine reflects the company's dedication to providing advanced solutions that meet the evolving needs of the industry. With its extensive experience and expertise in manufacturing equipment for the construction and building materials sector, the company has once again demonstrated its leadership in driving innovation and progress in the market.The introduction of the Corrugated Roof Tile Making Machine is poised to bring about a positive change in the roofing industry, offering a cost-effective, efficient, and sustainable solution for both manufacturers and consumers. As the demand for high-quality and durable roofing materials continues to rise, this innovative machine is expected to play a pivotal role in shaping the future of the industry.In conclusion, the Corrugated Roof Tile Making Machine represents a significant leap forward in the roofing industry, offering a modern, efficient, and sustainable solution for the production of high-quality corrugated roof tiles. With its advanced technology, user-friendly features, and eco-friendly design, the machine is set to transform the way roofing materials are manufactured and used, setting new benchmarks for quality and performance in the market.

Affordable C Purlin Roll Forming Machine Prices: A Complete Guide

C Purlin Roll Forming Machine Price Sees Increase as Demand SurgesThe demand for C Purlin roll forming machines has seen a sharp increase in recent months, leading to a rise in prices for these essential pieces of equipment. This spike in demand can be attributed to the growing construction industry and the need for high-quality building materials.The current price for a C Purlin roll forming machine is significantly higher than it was just a year ago. This increase in price can be attributed to several factors, including rising production costs, a shortage of raw materials, and an increase in global demand. As a result, many companies that rely on C Purlin roll forming machines are feeling the financial strain of these price hikes.One company that has been affected by these price increases is {}. They are a leading manufacturer of C Purlin roll forming machines, and they have been feeling the impact of the rising prices on their bottom line. Despite this, they remain committed to providing high-quality machinery to their customers at competitive prices.{} has been in the industry for over a decade and has established a strong reputation for producing efficient and reliable C Purlin roll forming machines. They have a team of experienced engineers and technicians who work tirelessly to ensure that their machines meet the highest standards of quality and performance.The company has invested heavily in research and development to improve their machines' efficiency and functionality. This dedication to innovation has allowed them to stay ahead of the competition and continue to meet the growing demand for C Purlin roll forming machines.In addition to their commitment to quality, {} also prioritizes customer satisfaction. They offer comprehensive after-sales service and support, ensuring that their customers get the most out of their investment in a C Purlin roll forming machine. This dedication to customer care has earned them a loyal and satisfied customer base.Despite the current challenges posed by rising prices, {} remains optimistic about the future of the C Purlin roll forming machine market. They are confident that their ongoing commitment to excellence and customer satisfaction will allow them to navigate through these challenging times and emerge even stronger.In the meantime, the company continues to monitor the market and make adjustments to their pricing and production processes as necessary. They understand the importance of remaining competitive in the industry while also maintaining their high standards of quality.As the demand for C Purlin roll forming machines continues to grow, {} is determined to meet this demand while also ensuring that their machines remain accessible to their customers. They are optimistic that the current challenges will eventually subside, and the market will stabilize, allowing for a more balanced pricing environment.In conclusion, the rise in the price of C Purlin roll forming machines reflects the increasing demand for these essential pieces of equipment. Companies like {} are working hard to navigate through these challenges and continue to provide high-quality machines to their customers at competitive prices. As the industry continues to evolve, {} remains dedicated to meeting the needs of their customers while staying ahead of the competition.

Increase Production Efficiency and Prevent Film Cracking with Advanced Web Tension Control Systems for Slitting Machines

The Slitting and Cutting Machine: An OverviewWhen it comes to manufacturing materials such as paper, plastic film, or even textiles, the slitting and cutting machine is an essential piece of equipment. These machines are designed to take large rolls of material and cut them down into the desired size and shape, allowing for easier handling and processing.One of the most important aspects of a slitting and cutting machine is its ability to maintain proper tension throughout the process. This is where web tension control systems come into play. These systems help prevent film cracking and other issues that can arise when the tension is not properly controlled.There are several different types of slitting and cutting machines available on the market today. Some are designed for specific materials such as paper or plastic film, while others are more versatile and can handle a variety of materials.One common type of slitting and cutting machine is the rotary shear. This machine uses a set of sharp blades that rotate against a stationary blade, effectively cutting the material as it passes through. The blades can be adjusted to vary the width of the cut, allowing for greater flexibility in production.Another type of slitting and cutting machine is the crush cutter. This machine uses a roller with a dull blade that crushes the material against a stationary blade, effectively cutting it in the desired width. Crush cutters are often used for materials that are more delicate or easily damaged.Regardless of the type of slitting and cutting machine being used, proper maintenance is essential to ensure optimal performance and longevity. Routine inspections and cleaning can help prevent issues from arising, while regular calibration can help ensure that the machine is cutting accurately and efficiently.In conclusion, the slitting and cutting machine is a vital piece of equipment in many manufacturing industries. With the right equipment and maintenance, it can help increase efficiency, reduce waste, and improve the overall quality of the finished product. Ensure to also incorporate web tension control systems to prevent film cracking and other similar issues.

High-quality Aluminum Extrusion Bending Machine for Precision Bends

Aluminum Extrusion Bending Machine Revolutionizing the IndustryThe [Company Name] has recently introduced a cutting-edge aluminum extrusion bending machine that is set to revolutionize the industry. This state-of-the-art machine is designed to streamline the process of bending aluminum extrusions, providing increased efficiency, accuracy, and flexibility in manufacturing operations.The advanced bending machine has the capability to bend aluminum extrusions of various shapes and sizes, offering a wide range of applications in industries such as automotive, aerospace, construction, and more. Its precision bending technology ensures consistent, high-quality results, meeting the demands of the most intricate and complex designs.With a focus on innovation and cutting-edge technology, the [Company Name] is committed to pushing the boundaries of what is possible in the field of aluminum extrusion bending. The new machine represents a significant leap forward in the company's ongoing efforts to provide the most advanced and reliable manufacturing solutions to its clients.The [Company Name] has a long-standing reputation for excellence in the industry, with a track record of delivering top-notch equipment and services to a wide range of clients across the globe. The introduction of the aluminum extrusion bending machine is yet another testament to the company's commitment to driving innovation and pushing the boundaries of what is possible in manufacturing.In addition to its cutting-edge technology, the aluminum extrusion bending machine also offers enhanced efficiency and cost-effectiveness. Its automated features and precision controls enable faster production cycles and reduced material waste, ultimately leading to substantial savings for manufacturers.Moreover, the machine's flexibility allows for rapid reconfiguration to accommodate different bending requirements, making it an ideal solution for businesses with diverse product portfolios. This adaptability ensures that manufacturers can meet the evolving needs of their clients while maintaining high standards of quality and precision.The introduction of the aluminum extrusion bending machine is a clear demonstration of the [Company Name]'s commitment to providing comprehensive solutions that cater to the evolving needs of the industry. By leveraging cutting-edge technology, the company continues to set new standards for excellence in manufacturing and remains at the forefront of innovation in the field.As the demand for high-quality aluminum extrusions continues to grow across various industries, the [Company Name] is well-positioned to meet the needs of its clients with this groundbreaking machine. Its advanced capabilities and unparalleled performance make it a game-changer in the industry, offering manufacturers a competitive edge in an increasingly dynamic market.The [Company Name] remains dedicated to delivering innovative solutions that drive efficiency, reliability, and precision in manufacturing operations. With the introduction of the aluminum extrusion bending machine, the company reaffirms its commitment to excellence and its ability to meet the evolving needs of the industry.In conclusion, the aluminum extrusion bending machine is a game-changer for the industry, offering manufacturers a cutting-edge solution that combines precision, efficiency, and flexibility. With its advanced technology and unmatched capabilities, the [Company Name] continues to lead the way in providing innovative manufacturing solutions that set new standards for excellence. As the demand for high-quality aluminum extrusions continues to rise, the introduction of this groundbreaking machine is set to have a significant impact on the industry, paving the way for a new era of manufacturing excellence.

High Speed Light Steel Keel Roll Forming Machine: Efficient Building Material Solution

, Stud Truss Roll Forming Machine, High Speed Roll Forming Machine, Metal Stud Roll Forming Machine.With the advancement in technology, the construction industry also has advanced equipment and machines to produce high-quality materials. One such essential machine is the stud truss high speed light steel keel roll forming machine. This machine is used to make light keel studs and trusses that are used for constructing the roof and walls of a building. It is known for its efficiency, reliability, and high speed.The light steel keel machine is designed differently based on the model and the customer's specifications. The metal stud roll-forming machine produces rolls of metal that are used as roofing or wall material in places such as factories, warehouses, garages, gymnasiums, and exhibition centers. These products are popular because of their lightweight, high strength, and easy installation.One of the many advantages of using a stud truss high speed light steel keel roll forming machine is its speed. The machine is designed to produce large quantities of metal strips rapidly, therefore, allowing for mass production, this significantly reduces the time taken to construct a building. The machine is also straightforward to operate, reducing the need for large labor forces on construction sites.Another benefit of using the light steel keel machine is the quality of the material produced; the metal strips produced are of a consistent thickness, length, and size, eliminating the possibility of defects that could lead to the loss of material. The machines are also low-maintenance as they are designed to be robust and long-lasting, thus reducing the operators' servicing costs.In conclusion, the stud truss high speed light steel keel roll forming machine is a must-have piece of equipment in the construction industry. It's easy operation, and high-speed production makes it a favorite among operators globally. The machine's accuracy and quality of the material produced make it an indispensable tool in the construction of buildings. For cost-effective construction materials, the light steel keel machine is the way to go. So if you are in the construction industry, it's essential to invest in a high-quality stud truss roll forming machine that will provide the best results.