C Shape Purlin Forming Machine: Transforming the Construction Industry

By:Admin

C Shape Purlin Forming Machine: The Ultimate Solution for Construction Industry

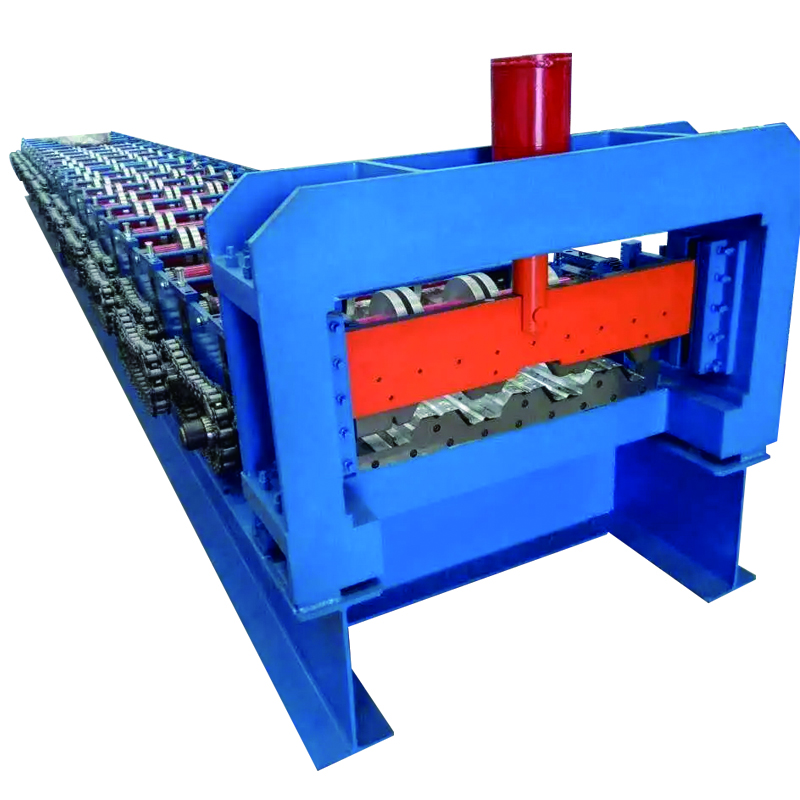

In recent years, the global construction industry has undergone massive creativity and innovation, giving rise to new designs and architectures. One of the critical components of these new designs is the C-shaped purlin, which provides structural support and stability to the buildings. However, the traditional manual production of C-shaped purlin is cumbersome, time-consuming, and sometimes inaccurate.

To address this challenge, many construction companies are turning to C Shape Purlin Forming Machine. This advanced machine offers a fast, efficient, and accurate way to manufacture C-shaped purlins, thus improving the quality of the final product.

One of the leading manufacturers of C shape purlin forming machines in the global market is a reputable manufacturing company (). The company has been in the industry for several years and has built a reputation for producing high-quality and durable machinery to cater to various industrial needs.

The C shape purlin forming machine from the company has a unique design and features that make it ideal for any construction project. It is made of high-grade materials, ensuring durability, longevity, and reliability. Additionally, it has an advanced electronic control system that enables automatic production, further enhancing efficiency.

The machine's versatility allows it to produce different sizes and shapes of purlins, making it an ideal choice for any construction project. Whether you are working on a commercial, residential, or industrial structure, the C shape purlin forming machine will deliver quality and efficiency.

Another critical aspect of the machine is its user-friendly nature. Operators can easily control and adjust the forming parameters, ensuring that the final product meets the required standards. Additionally, the machine has a low maintenance cost, thus allowing business owners to save on expenses.

The C Shape Purlin Forming Machine has revolutionized the construction industry by providing an efficient, cost-effective, and accurate method of producing C-shaped purlins. The machine has been a game-changer, enabling business owners to meet the increasing demand for high-quality and reliable purlins.

Furthermore, the machine's electronic controls and advanced features enable it to produce purlins with high precision and accuracy, further improving the final product's quality. This has led to increased customer satisfaction and repeat business, further boosting profitability.

In conclusion, the C Shape Purlin Forming Machine is the ultimate solution for the construction industry. Its advanced features, durability, and versatility make it an ideal choice for any construction project. Additionally, its user-friendly nature and low maintenance cost make it an excellent investment for business owners. With the increasing demand for high-quality and reliable purlins, investing in this machine is a wise decision for any construction company. Contact reputable manufacturing company () today and take your construction business to the next level.

Company News & Blog

Efficient and Cost-Effective CFS Rollformer for Pods, Modular & Residential Construction

for Pods, Modular and Residential Construction.In the modern age of construction, technology is advancing at an incredible rate. As the demand for affordable and sustainable housing increases, the construction industry is turning to innovative solutions for faster, more efficient building practices. One such solution is the FRAMECAD P325iT CFS Rollformer for Pods, Modular, and Residential Construction, which offers a range of benefits for builders looking to streamline their workflows.One of the key advantages of the P325iT is its ability to produce wall frames and trusses at high speeds. Thanks to its automation and advanced technology, this rollformer is capable of producing frames at a much faster pace than traditional building methods, allowing for increased efficiency and throughput. This makes it a valuable tool for construction companies looking to quickly and economically produce high-quality building components.Another benefit of the P325iT is its versatility. This rollformer is designed to produce frames and trusses for a range of building types, including pods, modular structures, and residential homes. Its flexibility means it can be used across a variety of projects, making it a smart investment for any construction company.One of the standout features of the P325iT is its high level of precision. Thanks to its advanced technology, this rollformer can produce frames with incredibly high accuracy, ensuring a perfect fit every time. This precision is essential for modular construction, where components need to fit together seamlessly to create a fully functioning building.The P325iT is also designed with sustainability in mind. By using lightweight steel framing, this rollformer can help reduce the carbon footprint of construction projects. Steel is a highly recyclable material, making it an ideal choice for builders concerned about their environmental impact.In conclusion, the FRAMECAD P325iT CFS Rollformer for Pods, Modular, and Residential Construction is an incredibly versatile and efficient tool for modern builders. Its automation, precision, speed, and sustainability features make it a smart investment for any construction company looking to streamline their workflows and produce high-quality building components quickly and economically. With the use of this rollformer, builders can enjoy the efficiency of modern construction without sacrificing quality or precision.

Efficient Roll Forming Machine for Color Steel Glazed Roofing Sheets Unveiled

[Dating], [Geographical Location] - The global construction industry is witnessing a major technological breakthrough as [Company Name], a leading manufacturer of machinery and equipment, introduces its state-of-the-art Color Steel Glazed Roofing Sheet Roll Forming Machine. This innovative product is set to revolutionize the production of glazed roofing sheets, enabling builders and contractors to enhance the durability, aesthetic appeal, and cost-effectiveness of their projects.The Color Steel Glazed Roofing Sheet Roll Forming Machine, designed and manufactured by [Company Name], incorporates cutting-edge technology and premium-quality materials to deliver outstanding performance and unparalleled efficiency. The machine is equipped with advanced automation systems and intelligent controls, ensuring precise and accurate sheet formation. This eliminates human error and reduces production time, thereby enhancing productivity and overall project completion rates.With the global construction industry being increasingly mindful of sustainable practices, the Color Steel Glazed Roofing Sheet Roll Forming Machine offers a sustainable solution. It utilizes recycled materials and minimizes waste generation during the production process. This eco-friendly approach not only aligns with environmental regulations but also positions builders and contractors as responsible industry players, meeting the expectations of environmentally conscious consumers.Additionally, the Color Steel Glazed Roofing Sheet Roll Forming Machine caters to the rising demand for energy-efficient buildings. The machine is engineered to create roofing sheets that effectively reflect heat, reducing the need for excessive cooling measures. This not only lowers energy consumption but also translates into substantial cost savings for building owners. Furthermore, the glazed roofing sheets produced by this machine offer superior insulation, enhancing the overall thermal performance of structures.[Company Name] is renowned for delivering cutting-edge solutions in the construction machinery sector, with a history of successful projects and a growing global client base. The company's commitment to quality and innovation has earned it a reputation as an industry leader. By introducing the Color Steel Glazed Roofing Sheet Roll Forming Machine, [Company Name] reaffirms its dedication to providing market-leading products that meet the evolving needs of the construction industry.The machine's user-friendly interface and streamlined operation make it accessible to both experienced manufacturers and newcomers to the industry. It offers customizable settings and efficient production capabilities, ensuring flexibility and versatility for a wide range of roofing sheet designs. The machine's robust construction and reliable performance guarantee longevity and durability, minimizing maintenance and replacement costs for users.Furthermore, [Company Name]'s dedication to customer satisfaction extends beyond the sale of the Color Steel Glazed Roofing Sheet Roll Forming Machine. The company provides comprehensive training programs and ongoing technical support to ensure users can fully utilize the machine's capabilities. This commitment to empowering its clients with the knowledge and resources required to maximize productivity sets [Company Name] apart from its competitors.As the global construction industry continues to grow and evolve, [Company Name] remains at the forefront of technological advancements. With the introduction of the Color Steel Glazed Roofing Sheet Roll Forming Machine, the company is empowering builders and contractors to construct sustainable, energy-efficient, and visually appealing structures. This groundbreaking product reaffirms [Company Name]'s position as a leading manufacturer of machinery and equipment, committed to driving innovation and improving the construction industry as a whole.In conclusion, the Color Steel Glazed Roofing Sheet Roll Forming Machine introduced by [Company Name] is set to revolutionize the production of glazed roofing sheets, providing builders and contractors with a sustainable, energy-efficient, and cost-effective solution. The machine's cutting-edge technology, eco-friendly approach, and comprehensive customer support make it an essential asset for companies looking to stay ahead in an ever-evolving industry. [Company Name]'s commitment to delivering innovative solutions further cements its reputation as a global leader in the construction machinery sector.

Could the Universe be Devoured by a Black Hole-Creating Machine?

The prospect of the universe being swallowed up by a black hole is a nightmare scenario that few ever thought would become a reality. Yet, it appears that ominous possibility may have come a step closer to being realized after a mind-bogglingly complicated machine originally designed to create black holes was switched back on, now with double the power it had before. Scientists around the world are warning that this could have catastrophic consequences for our planet and indeed for the entire universe itself.The machine in question is a particle accelerator, called the Large Hadron Collider (LHC), that is based in Geneva, Switzerland. This giant machine is the most powerful particle accelerator ever built and has already produced a series of groundbreaking discoveries in particle physics. However, the machine is also highly controversial, as some scientists fear that it could create dangerous black holes that could potentially destroy the planet.The machine was first built in 2008 and was designed to recreate the conditions of the Big Bang. By smashing particles together at incredibly high speeds, scientists hoped to learn more about the building blocks of the universe. However, some scientists warned that the machine could create black holes so powerful that they could eventually destroy the planet and the entire universe.Despite these concerns, the machine was switched on for the first time in September 2008 and quickly produced a series of spectacular results. However, after just nine days of running, the machine broke down and had to be shut down for repairs. Over the next few years, the machine was slowly brought back up to speed, but many scientists remained wary of its potential to create black holes.Now, it seems that those concerns may have been justified. According to reports, the machine has been switched back on at double its previous power, and there are fears that it could now create black holes that are much more powerful than before. Scientists warn that if one of these black holes were to escape into the wider universe, it could quickly grow in size and eventually swallow up everything in its path, including stars, planets, and even entire galaxies.The consequences of such an event would be catastrophic. If the universe were destroyed, it would mean the end of everything we know and love. It would also mean the end of life itself, as we know it. This is why so many scientists have warned against the potential dangers of the LHC and other particle accelerators.One of the main problems with the LHC is that it operates at such high energies that it is impossible to fully predict what will happen when particles collide. This means that there is always a risk that the machine could create something that could be catastrophic for the entire universe.Despite these concerns, many scientists have argued that the risks are minimal and that the benefits of the LHC far outweigh any potential dangers. They argue that the machine has already produced a wealth of valuable scientific data and that it could lead to groundbreaking new discoveries in the field of particle physics.However, others remain more cautious. They argue that we simply do not know enough about the workings of the universe to predict what will happen if we continue to push the limits of particle physics. They warn that the LHC could be a ticking time bomb that could destroy everything we hold dear.For now, the LHC continues to operate at double its previous power, and scientists around the world will be watching nervously to see what happens next. If the machine does create a black hole that is powerful enough to destroy the universe, it could be a wake-up call for us all about the dangers of meddling with the fundamental building blocks of the universe.In conclusion, the potential for the LHC to create a black hole that could destroy the entire universe is a prospect that is both awe-inspiring and terrifying in equal measure. While many scientists argue that the benefits of the machine far outweigh any potential risks, others remain more cautious and warn that we simply do not know enough about the universe to predict what will happen if we continue to push the limits of particle physics. The future of the LHC remains uncertain, but one thing is for sure: the consequences of its actions could be catastrophic.

Advanced Milling and Bending Machine for Aluminum Composite Panel Corrugated Sheets

Title: Unveiling the Power of the Corrugated Sheet Bending Machine: Revolutionizing Architectural Facades and Interior DesignIntroduction:In today's fast-paced world, innovative technologies play a crucial role in shaping our living spaces. From architectural facades to interior design, the demand for enhanced functionality and aesthetic beauty has prompted the introduction of advanced machinery. One such remarkable solution is the Aluminum Composite Panel Corrugated Sheet Bending Machine, popularly known as the Alu Bender Milling and Bending Machine. In this blog, we will dissect the revolutionary capabilities of this cutting-edge equipment, and its significance in various industries such as architectural facades, transportation, interior design, and visual communication.Understanding Corrugated Sheet Bending Machine:The Corrugated Sheet Bending Machine is an automatic milling and bending tool that specializes in processing straight edges on composite panels. Manufactured by Casadei Industria, this advanced machinery has gained immense popularity in industries where aluminum composite panels are utilized. The primary purpose of this device is to mill off the top layer of aluminum and the core of an ACM panel, thereby preparing the finished layer for bending. The automatic feeding mechanism of the machine makes the entire process seamless and efficient.Revolutionizing Architectural Facades:One of the major areas where the Corrugated Sheet Bending Machine has created a massive impact is the architectural industry, particularly in the construction of extraordinary facades. With its precise milling and bending capabilities, this machine enables architects and designers to achieve intricate and seamless designs for buildings and structures. As the top layer of aluminum is milled off, the machine ensures a flawless surface that is ready for bending. Consequently, it becomes much easier to mold the panels into desired shapes and geometries, allowing architects to unleash their creativity and give life to unique artistic visions.Transport Industry: The transport industry is another sector that significantly benefits from the Corrugated Sheet Bending Machine. With its ability to process straight edges on composite panels, this equipment proves crucial in the manufacturing of high-quality decorative exteriors for a range of vehicles, including buses, trains, and even aircraft. Additionally, the precision and speed offered by the Alu Bender Milling and Bending Machine ensure that production timelines are met consistently, thus boosting efficiency within the transport industry.Interior Design and Visual Communication:In the realm of interior design, the Corrugated Sheet Bending Machine not only enhances efficiency but also offers limitless creative possibilities. The seamless milling process performed by this machine allows for the creation of 3D elements and unique shapes that add dimension and character to interior spaces. From curved walls to intricately designed partitions, this specialized machinery empowers designers to bring their visions to life.Furthermore, the visual communication industry relies heavily on the capabilities of the Corrugated Sheet Bending Machine. By providing the means to produce visually striking signage and displays, this equipment allows businesses to attract attention and communicate their messages effectively. The precise bending process ensures that the finished layer aligns seamlessly with the core, resulting in a professional and eye-catching end product.Conclusion:The Aluminum Composite Panel Corrugated Sheet Bending Machine, or Alu Bender Milling and Bending Machine, has truly revolutionized several industries, including architectural facades, transportation, interior design, and visual communication. With its impeccable milling and bending capabilities, this advanced machinery offers unparalleled precision and efficiency, allowing for the creation of intricate designs and seamless finishes. As technology continues to shape our surroundings, the Corrugated Sheet Bending Machine stands as a testament to innovation, pushing the boundaries of creativity and functionality in the modern world.Keywords: Corrugated Sheet Bending Machine, Alu Bender Milling and Bending Machine, Aluminum Composite Panel, architectural facades, transportation, interior design, visual communication, seamless finishes, precision, efficiency, innovation.

High Precision Cut To Length Line Metal Sheet Cutting Machine for Efficient Sheet Metal Slitting

and Sheet Metal Slitter Machine.When it comes to cutting metal sheets, it is imperative to have a reliable and precise Cut-To-Length Machine and Sheet Metal Slitter Machine. These machines are designed to offer efficient precision cutting of metal sheets, which is essential in most metal fabrication industries. The High Precision Cut-To-Length Line Metal Sheet Cutting Machine/Sheet Metal Slitter Machine is among the most sought after machines in the market today.This machine is made using high-quality materials that guarantee its durability and efficiency. The machine is specifically designed to cut metal sheets into specific sizes, lengths, and widths, making it ideal for various metal fabrication projects. It utilizes high precision sensors that measure and cut metal sheets according to the desired lengths.One of the benefits of this machine is its ability to deliver high precision cutting. The machine is designed to deliver accurate and consistent cuts that meet your specifications. This is essential in ensuring that the finished products meet the required standards, and there is no wastage of materials.The High Precision Cut-To-Length Line Metal Sheet Cutting Machine/Sheet Metal Slitter Machine is also versatile. It can be used to cut different types of metal sheets, including aluminum, galvanized, cold-rolled, and stainless steel. This makes it ideal for use in different industries such as construction, automotive, and aerospace.Another advantage of this machine is its efficiency. The machine is designed to operate at high speeds, enabling it to cut several metal sheets within a short period. This not only saves time but also increases production capacity, which is essential in meeting high demand in the market.In conclusion, the High Precision Cut-To-Length Line Metal Sheet Cutting Machine/Sheet Metal Slitter Machine is a vital investment for any metal fabricator. It offers high precision cutting, versatility, and efficiency, which are essential in meeting the demands of the market. If you are looking to enhance your metal fabrication business's productivity, then this machine is a must-have.

High-Quality Automatic Corrugated Tile Roll Forming Machine for Metal Roofing and Colored Steel Sheets

Title: Enhancing Efficiency and Quality with the Colored Metal Corrugated Sheet Roll Forming MachineIntroduction:In the rapidly evolving construction industry, keeping up with the latest technological advancements is crucial. When it comes to roofing materials, the demand for colored metal corrugated sheets has significantly increased due to their durability and aesthetic appeal. To meet the rising need for these sheets, the Automatic Metal Roofing Corrugated Tile Roll Forming Machine, also known as the Colored Steel Sheet Roll Forming Machine, has emerged as a game-changer. This blog post will delve into the key features, benefits, and applications of this advanced machine that has revolutionized the manufacturing process.1. Features of the Automatic Metal Roofing Corrugated Tile Roll Forming Machine:The Automatic Metal Roofing Corrugated Tile Roll Forming Machine is designed with cutting-edge technology to ensure seamless production of colored metal corrugated sheets. Some notable features include:a) High-Speed Performance: This machine boasts an exceptional production speed that enables efficient manufacturing without compromising the product's quality. Its advanced automation capabilities contribute to enhanced productivity and a significant reduction in labor costs.b) Precision and Accuracy: Equipped with advanced PLC control systems and digital displays, the machine guarantees precise and accurate sheet dimensions, angles, and curves. This ensures that the final product meets the required specifications, resulting in superior quality roofing sheets.c) Versatile Design: The machine's versatility allows it to handle various raw materials such as galvanized steel, aluminum, and stainless steel. This flexibility enables manufacturers to cater to a wide range of customer preferences, expanding their market reach.d) Durability and Longevity: The machine is built with robust materials, ensuring its durability and longevity. Its reliable performance minimizes downtime and maintenance, contributing to uninterrupted manufacturing operations.2. Benefits of the Colored Metal Corrugated Sheet Roll Forming Machine:a) Enhanced Efficiency: The high-speed performance of the machine significantly reduces the manufacturing time, enabling manufacturers to meet customer demands promptly. Its precision and accuracy eliminate the need for manual adjustments, resulting in increased productivity.b) Cost-Effectiveness: With its automation capabilities, the machine reduces labor costs and minimizes errors caused by human intervention. Its durable construction ensures longevity, reducing maintenance expenses and enhancing the return on investment.c) Customization and Design Flexibility: The machine's versatility allows manufacturers to produce colored metal corrugated sheets in various sizes, shapes, and colors. This flexibility enables them to cater to the unique design preferences and requirements of their customers.d) Superior Quality: The machine's advanced technology ensures the production of high-quality roofing sheets with accurate dimensions and excellent finishes. This quality assurance leads to satisfied customers and increased brand reputation.3. Applications of the Colored Metal Corrugated Sheet Roll Forming Machine:The Colored Metal Corrugated Sheet Roll Forming Machine finds extensive applications in the construction industry. Some notable uses include:a) Residential Roofing: The machine is used to manufacture corrugated metal roofing sheets for residential buildings. These sheets provide durability, weather resistance, and aesthetically pleasing options for homeowners.b) Commercial and Industrial Roofs: Manufacturing large quantities of colored metal corrugated sheets using this machine is ideal for commercial and industrial roofing projects. The sheets' strength, longevity, and low maintenance make them a cost-effective solution.c) Agricultural Structures: The machine caters to the specific requirements of the agricultural sector, enabling the production of corrugated metal sheets for barns, sheds, and other farm structures. These sheets provide a durable and weather-resistant solution for protecting livestock and equipment.Conclusion:The Automatic Metal Roofing Corrugated Tile Roll Forming Machine, also known as the Colored Metal Corrugated Sheet Roll Forming Machine, is a game-changer in the manufacturing of roofing sheets. Its high-speed performance, precision, versatility, and durability have significantly enhanced the efficiency and quality of production. By investing in this advanced machine, manufacturers can cater to customer demands promptly, reduce costs, and produce high-quality colored metal corrugated sheets for various applications in the construction industry.

Reliable Sheet Metal Fabrication Services: Stainless Steel, Aluminum & Custom Metal

Title: Streamlining Your Business with Steel Sheet Making Machines: Unleashing the Power of Custom Metal FabricationIntroduction:In today's competitive market, businesses across various industries are increasingly turning to custom metal fabrication services to meet their unique manufacturing requirements. Among the many processes involved in metal fabrication, Steel Sheet Making Machines play a critical role in ensuring high-quality stainless steel and aluminum sheet production. This article aims to explore the significance of Steel Sheet Making Machines in the realm of custom metal fabrication and how they contribute to the manufacturing success of businesses across the globe.1. The Essence of Steel Sheet Making Machines:Steel Sheet Making Machines are advanced manufacturing tools designed to accurately shape and cut steel sheets into desired forms. These machines incorporate various components and mechanisms, including hydraulic systems, feeders, rollers, shears, and cutting devices. By utilizing cutting-edge technologies, these machines streamline the metal fabrication process, enhancing efficiency, precision, and overall productivity.2. Precision and Consistency:One significant advantage of Steel Sheet Making Machines is their ability to consistently produce high-quality steel sheets with utmost precision. The intricate mechanisms and cutting-edge technologies integrated into these machines ensure consistent sheet thickness, tight tolerances, smooth edges, and well-defined shapes. Custom metal fabrication companies can deliver products that meet or even exceed the expectations of their clients, reinforcing their reputation in the market.3. Increased Efficiency and Productivity:Steel Sheet Making Machines revolutionize the manufacturing process, significantly reducing production time and increasing efficiency. These machines can perform multiple operations, such as cutting, bending, and shaping, in a single run, eliminating the need for separate machinery or manual labor. The automated processes of these machines enable businesses to produce larger volumes of steel sheets with minimal human intervention, thereby increasing productivity and reducing labor costs.4. Versatility and Customization:Custom metal fabricators often deal with diverse client requirements, necessitating the ability to produce steel sheets in various shapes, sizes, and thicknesses. Steel Sheet Making Machines offer extensive flexibility and adaptability, allowing businesses to cater to these diverse demands. With adjustable settings and versatile tooling options, these machines can fabricate customized steel sheets to match unique specifications, enabling businesses to deliver tailored solutions to their customers.5. Cost and Resource Optimization:By investing in Steel Sheet Making Machines, businesses can optimize their use of resources and reduce costs in the long run. These machines minimize material wastage through precise cutting and shaping capabilities, ensuring minimal scrap and maximizing yield. Additionally, the automated nature of these machines reduces the reliance on manual labor, saving on labor expenses.Conclusion:In conclusion, Steel Sheet Making Machines have emerged as indispensable tools in the realm of custom metal fabrication. Their ability to deliver precision, consistency, efficiency, and customization has revolutionized the manufacturing industry. By investing in these advanced machines, businesses can streamline their metal fabrication processes, cater to diverse client requirements, minimize costs, and stay ahead in the competitive market. Whether it is stainless steel sheet metal fabrication, aluminum sheet metal fabrication, or any other custom metal fabrication needs, the utilization of Steel Sheet Making Machines ensures successful outcomes and drives the growth of businesses across the globe.Keywords: Steel Sheet Making Machine, custom metal fabrication, stainless steel sheet metal fabrication, aluminum sheet metal fabrication, metal fabrication services, precision manufacturing, increased productivity, cost optimization, versatile tooling options.

China Manufacturers & Suppliers of High-Quality Wall And Roof Panel Roll Forming Machines

Wall Panel Roll Forming Machine: A Game-Changer in Construction IndustryIn the fast-paced construction industry, efficiency and quality play a crucial role. This is where the Wall Panel Roll Forming Machine steps in as a game-changer. Taking China by storm, this innovative machine has gained popularity among manufacturers and contractors, revolutionizing the way wall panels are produced.With the growing demand for energy-efficient and eco-friendly buildings, wall panels have become an integral part of modern construction projects. Traditional construction methods, such as bricklaying and concrete casting, can be time-consuming, labor-intensive, and costly. This is where roll forming technology has stepped in to provide an efficient and economical solution.Wall Panel Roll Forming Machine, developed and manufactured by leading Chinese manufacturers, provides a seamless production process for wall panels. Equipped with advanced technology and precision engineering, this machine enables manufacturers to produce high-quality panels in large quantities within a short period.So, what exactly is a Wall Panel Roll Forming Machine? It is a production line that consists of a series of rollers, forming stations, and cutting systems. It takes raw materials, such as galvanized steel or aluminum coils, and shapes them into precise and uniform profiles. These profiles can be customized according to specific design requirements, including thickness, width, and length.The Wall Panel Roll Forming Machine offers numerous advantages over conventional manufacturing methods. Firstly, it significantly reduces labor costs and human errors. The automated process ensures consistent panel dimensions and eliminates the need for manual intervention, resulting in a fast and efficient production line.Secondly, the Wall Panel Roll Forming Machine optimizes material usage, reducing waste and saving costs. By precisely controlling the amount of raw material fed into the machine and its shaping process, manufacturers can minimize scrap and maximize panel output.Furthermore, this machine allows for customization and flexibility. With adjustable roller stations, manufacturers can create various panel profiles, including flat, corrugated, or trapezoidal shapes, to meet diverse construction needs. This versatility enables architects and designers to unleash their creativity and bring unique architectural visions to life.In addition, the Wall Panel Roll Forming Machine enhances safety on construction sites. With panels produced using this technology, the risk of accidents, such as falling debris or collapses, is minimized. These panels are lightweight yet structurally robust, offering enhanced durability and improved seismic resistance.Lastly, the Wall Panel Roll Forming Machine contributes to green construction practices. By using environmentally friendly materials, such as recyclable metals, and reducing energy consumption through efficient production processes, it supports sustainable building practices. Furthermore, its precision engineering ensures tight joints and insulation, enhancing energy efficiency and reducing carbon footprints.In conclusion, the Wall Panel Roll Forming Machine has brought a revolution to the construction industry. Its time-saving, cost-effective, and customizable features have made it the preferred choice for manufacturers and contractors worldwide. With its technological advancements and eco-friendly production practices, this machine paves the way for modern, energy-efficient, and sustainable buildings. Embrace the future of construction and invest in a Wall Panel Roll Forming Machine today!Keywords: Wall Panel Roll Forming Machine, China manufacturers, suppliers, factory, construction, efficiency, quality, game-changer, traditional methods, roll forming technology, production line, rollers, forming stations, cutting systems, raw materials, galvanized steel, aluminum coils, precise profiles, advantages, labor costs, material usage, customization, flexibility, safety, green construction practices, environmentally friendly materials, sustainable buildings.

The Future of Coil Fed Punching Cutting Machines Market: A Comprehensive Market Analysis

Coil-fed punching and cutting machines have witnessed significant growth in recent years, driven by the demand for efficient and automated manufacturing processes. These machines are widely used in various industries, including automotive, aerospace, electronics, and construction. With the increasing need for precision and productivity in these sectors, the coil-fed punching and cutting machines market is expected to experience further innovation and growth.A recent market research report by Persistence Market Research provides insights into the coil-fed punching and cutting machines market. The report highlights the market dynamics, growth factors, challenges, and trends shaping the industry. It presents a comprehensive analysis of the market and its future prospects.The coil-fed punching and cutting machines market is witnessing constant innovation in terms of technology and product development. Manufacturers are focusing on improving the efficiency and accuracy of these machines to meet the growing demands of various industries. Integration of advanced features like computer numerical control (CNC) systems, high-speed punching and cutting capabilities, and robotic automation are some of the latest developments in this market.One of the key drivers for the coil-fed punching and cutting machines market is the increasing demand for lightweight materials in the automotive and aerospace industries. With the need for fuel efficiency and reduced emissions, manufacturers are using advanced materials like aluminum and composites, which require precise and efficient cutting and punching processes. Coil-fed punching and cutting machines offer the flexibility and speed required to handle such materials.Another factor driving the growth of this market is the growing adoption of Industry 4.0 technologies. The integration of IoT (Internet of Things) and smart automation in manufacturing processes has revolutionized the industry. Coil-fed punching and cutting machines equipped with IoT capabilities can communicate with other machines and systems, enabling seamless production flow and real-time monitoring. This reduces downtime, improves efficiency, and enhances overall productivity.However, the coil-fed punching and cutting machines market also faces certain challenges. High initial investment costs, skilled labor requirements, and the need for regular maintenance and calibration are some of the factors that can hinder market growth. Additionally, the market is highly competitive, with several players offering similar products. This makes it crucial for manufacturers to differentiate themselves through innovative features and superior customer service.In terms of regional analysis, Asia Pacific is expected to dominate the coil-fed punching and cutting machines market. The rapid industrialization in countries like China, India, and Japan, coupled with the presence of key automotive and electronics manufacturers, creates a favorable environment for market growth. Moreover, the increased focus on automation and the adoption of advanced technologies in these industries are driving the demand for coil-fed punching and cutting machines in the region.In conclusion, the coil-fed punching and cutting machines market is predicted to witness significant growth in the coming years. Continuous innovation in technology, the adoption of Industry 4.0 solutions, and the demand for lightweight materials fuel the market's expansion. However, challenges like high costs and intense competition need to be addressed for sustained growth. Manufacturers must invest in research and development to enhance machine capabilities and provide efficient solutions to cater to the evolving needs of industries worldwide.

High-Quality Metal Roofing Sheet Corrugated Tile Roll Forming Machine for Custom Applications" Our Wide Range of Roof Roll Forming Machines and Equipment for Efficient Roofing Solutions Enhance Your Roofing Projects with our Corrugated Tile Roof Roll Forming Machine Advanced Maquina De Hacer Calaminas: Perfectly Designed for Customized Metal Roofing Sheets Discover Our Impressive Line of Roofing Machinery: Curve Roof Machines, Shearing/Bending Machines, Light Keel Roll Formers, and More

: Efficiency, Durability, VersatilityA metal roof is one of the most durable and long-lasting roofing systems on the market today. It is highly resistant to weathering and UV damage, which makes it an excellent choice for homeowners who want to protect their homes from extreme weather conditions. For this reason, the demand for metal roofing systems has risen over the past few years.However, installing a metal roof can be a daunting task, especially for those who have no experience in roofing. The good news is that the Metal Corrugated Roof Roll Forming Machine is designed to make the installation of metal roofing systems easier and more efficient.EfficiencyThe Metal Corrugated Roof Roll Forming Machine is a game-changer when it comes to metal roof installation. It can speed up the installation process by producing custom-made metal roofing sheets quickly and accurately. Additionally, it is designed to process different types of roofing materials, including aluminum, copper, and steel, and can produce a variety of profiles, such as corrugated and trapezoidal.The machine is highly automated, which means that it requires minimal human intervention. This makes it very efficient, which can save contractors time and labor costs.DurabilityThe metal roofing sheets produced by the Metal Corrugated Roof Roll Forming Machine are highly durable. This is because the machine forms the sheets from raw materials, which eliminates the need for prefabricated sheets that are prone to damage during transportation and handling. Additionally, the thickness of the metal sheets can be customized to suit the specific requirements of the roofing project.VersatilityThe Metal Corrugated Roof Roll Forming Machine is a versatile machine that is suitable for different types of roofing projects. It can form metal sheets in different sizes and profiles, which makes it suitable for residential, commercial, and industrial roofing projects.The machine's versatility is further enhanced by the fact that it can form metal sheets with different coatings, such as galvanized, painted, and coated. This means that contractors can choose the best-coated metal roofing sheets that will enhance the project's durability and performance.ConclusionIn conclusion, the Metal Corrugated Roof Roll Forming Machine is a game-changer in the metal roofing industry. It provides efficiency, durability, and versatility, which are essential for any successful roofing project. Its advanced technology ensures that contractors can produce custom-made metal roofing sheets quickly and accurately, making metal roofing installation more efficient and cost-effective. Anyone looking to install a metal roofing system should consider using this machine to ensure a seamless roofing project.