Cut to Length: The Latest Advancement in Automatic Cutting Technology

By:Admin

In the constantly evolving world of metal processing, efficiency and precision are crucial factors for success. One company at the forefront of this industry is {}, a leading provider of cutting-edge machinery for metal fabrication. Recognizing the need for advanced solutions to meet the demands of their customers, {} has recently introduced a new Automatic Cut to Length machine that promises to revolutionize the way metal is processed.

The Automatic Cut to Length machine is designed to streamline the production process, offering a range of benefits for metal processing businesses. With its advanced automation and cutting-edge technology, this machine is capable of accurately cutting metal sheets to precise lengths with minimal human intervention. This not only enhances the overall productivity of the operation but also ensures a high degree of precision in the final product, reducing waste and improving the quality of output.

One of the key features of the Automatic Cut to Length machine is its versatility. Equipped with a range of customizable settings, the machine is capable of handling a variety of metal materials, including steel, aluminum, and other alloys. This flexibility makes it an ideal solution for a wide range of metal processing applications, from automotive and aerospace to construction and manufacturing.

The machine’s advanced control system and intelligent software further contribute to its efficiency and accuracy. Operators can easily program the machine to cut metal sheets to specific dimensions, allowing for rapid and precise production according to the requirements of a particular project. This level of control not only saves time but also minimizes the margin for error, ensuring that the finished products meet the highest standards of quality.

In addition to its cutting capabilities, the Automatic Cut to Length machine also offers advanced handling features. The machine is equipped with a robust material feeding system that efficiently moves metal sheets through the cutting process, further optimizing the production workflow. This seamless integration of cutting and handling functions results in a smooth and uninterrupted operation, reducing downtime and maximizing output.

With the introduction of the Automatic Cut to Length machine, {} has once again demonstrated its commitment to innovation and excellence in the field of metal processing machinery. The company’s extensive experience and expertise in this industry have enabled it to develop a cutting-edge solution that addresses the evolving needs of metal fabricators and manufacturers. By leveraging the latest technologies, {} continues to set new standards for productivity, precision, and reliability in metal processing.

For metal processing businesses, the adoption of the Automatic Cut to Length machine represents a valuable investment in their future success. The machine’s ability to enhance productivity and precision offers a competitive advantage in the market, allowing businesses to meet the growing demands of their customers with superior quality and efficiency. Furthermore, the potential cost savings from reduced waste and improved efficiency make this machine a wise long-term investment for any metal processing operation.

As the industry continues to evolve, the demand for advanced metal processing solutions will only continue to grow. With its Automatic Cut to Length machine, {} has positioned itself at the forefront of this trend, offering a game-changing technology that is redefining the way metal is processed. For businesses looking to stay ahead in the competitive world of metal fabrication, this machine is a powerful tool for enhancing productivity and precision, ultimately driving success and profitability in the long run.

Company News & Blog

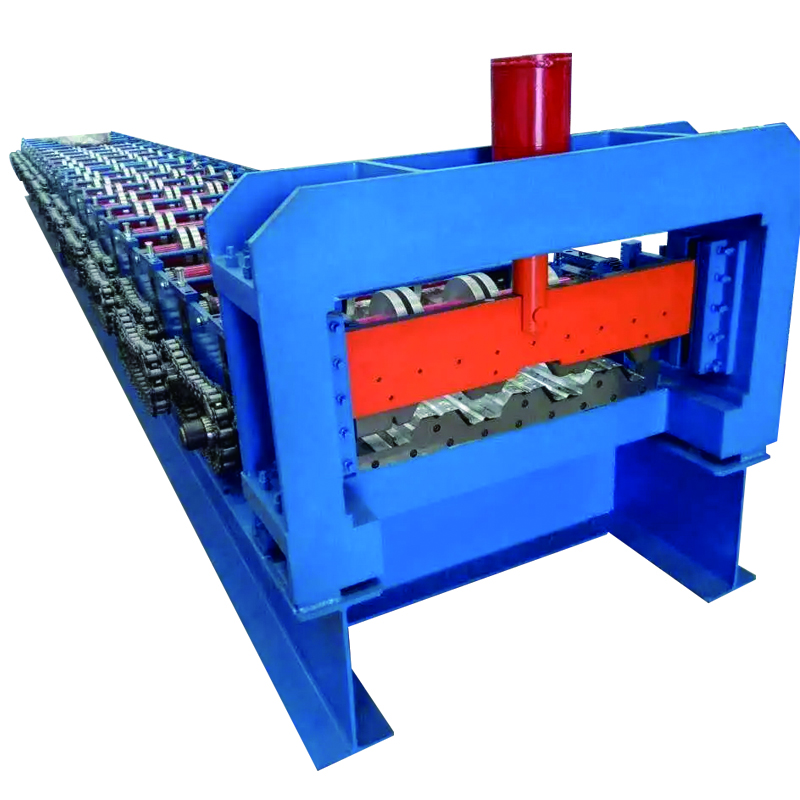

High-Quality Trapezoid Profile Metal Roofing Sheet Machine: A Complete Guide

Metal Roofing Sheet Trapezoid Profile Machine Revolutionizes Roofing IndustryMetal roofing has long been a popular choice for commercial and industrial buildings due to its durability and longevity. However, the process of manufacturing metal roofing sheets has typically been labor-intensive and time-consuming. But that is all about to change, thanks to the innovative Metal Roofing Sheet Trapezoid Profile Machine developed by {Company}.This cutting-edge machine is set to revolutionize the roofing industry with its efficiency, accuracy, and speed. The trapezoid profile machine is capable of producing high-quality metal roofing sheets with a trapezoid shape in a fraction of the time it takes using traditional methods. This is a game-changer for roofing companies who are looking to increase their productivity and reduce production costs.One of the key features of the Metal Roofing Sheet Trapezoid Profile Machine is its versatility. It can accommodate a wide range of materials, including galvanized steel, aluminum, and copper, allowing for the production of a variety of roofing solutions to meet the specific needs of the customers. Additionally, the machine is fully automated, requiring minimal human intervention, which reduces the chance of errors and ensures consistent quality in every sheet produced.The trapezoid profile machine also boasts a high level of precision and accuracy, thanks to its advanced technology and state-of-the-art manufacturing process. This means that the roofing sheets produced are of uniform dimensions and have perfectly formed trapezoid profiles, ensuring a tight fit and a seamless finish when installed on a building. Furthermore, the machine is capable of producing roofing sheets in various lengths, allowing for customization to suit the requirements of different construction projects.With the Metal Roofing Sheet Trapezoid Profile Machine, {Company} is reinforcing its position as a leader in the roofing industry. This machine is a testament to the company's commitment to innovation and its dedication to providing cutting-edge solutions to its customers. By investing in this technology, {Company} is not only improving its own production processes but also supporting the growth and success of the companies that rely on its high-quality roofing products.In addition to the Metal Roofing Sheet Trapezoid Profile Machine, {Company} offers a comprehensive range of roofing solutions to meet the diverse needs of its customers. Whether it's for residential, commercial, or industrial applications, {Company} has a wide selection of metal roofing sheets, accessories, and custom fabrication services to ensure that every project is completed to the highest standard.{Company} has built a strong reputation for delivering superior quality products and exceptional customer service. The company's team of experts and technicians are highly skilled and knowledgeable in all aspects of roofing, and they are committed to providing valuable guidance and support to customers every step of the way. With a focus on innovation, reliability, and customer satisfaction, {Company} has become a trusted partner for businesses and contractors in the roofing industry.In conclusion, the Metal Roofing Sheet Trapezoid Profile Machine is set to bring about a significant transformation in the roofing industry. Its speed, efficiency, and precision will enable roofing companies to streamline their production processes and achieve higher levels of productivity. With a commitment to quality and innovation, {Company} continues to lead the way in providing the roofing industry with state-of-the-art solutions that meet the evolving needs of the market.

Revolutionizing Manufacturing: Discover the Advanced Metal Panel Production Machine

Profiled Metal Panel Manufacturing Machine Revolutionizes the IndustryIn a groundbreaking development for the metal panel manufacturing industry, a highly reputable company has unveiled its innovative profiled metal panel manufacturing machine. This cutting-edge technology is set to revolutionize the production process, enhance efficiency, and deliver high-quality metal panels like never before.With a commitment to advancing manufacturing capabilities, this state-of-the-art machine is designed to achieve precision and consistency in profiled metal panel production. The company's dedication to research and development has resulted in a game-changing solution that addresses the evolving needs of the industry, while also meeting strict quality standards.The profiled metal panel manufacturing machine boasts an array of advanced features that significantly streamline the production process. The machine's automated functionalities reduce human error, ensuring exceptional product quality and productivity. With minimal manual intervention required, manufacturers can enjoy increased efficiency, saving time and costs in the long run.This revolutionary machine's versatility is another noteworthy aspect that sets it apart from its competitors. It is equipped to process various types of materials, including steel, aluminum, and even composite panels. This adaptability showcases the company's commitment to cater to a wide range of applications and industry requirements.The machine's cutting-edge technology enables manufacturers to produce a variety of profiled metal panels, such as corrugated sheets, standing seam panels, and insulated panels. This diversification in product offerings allows companies to expand their portfolios, cater to different client preferences, and tap into new markets.Furthermore, the machine's precise control system ensures accuracy in panel dimensions, angles, and shapes. Manufacturers can confidently produce panels with intricate designs and complex profiles, meeting the unique specifications of individual projects. This level of precision and customization is highly sought after in industries such as architecture, construction, and automotive manufacturing.Equally important is the machine's emphasis on sustainability and eco-friendliness. With the growing global concern for environmental impact, the company has integrated energy-efficient technologies into the manufacturing process. This not only reduces carbon emissions but also lowers operating costs for manufacturers, contributing to a greener and more sustainable future for the industry.The introduction of this profiled metal panel manufacturing machine signifies the company's commitment to staying at the forefront of technological advancements. By constantly pushing the boundaries of innovation, they ensure that their clients have access to cutting-edge machinery that provides a competitive edge in the marketplace.Additionally, the company's dedication to customer satisfaction is evident in its comprehensive technical support and after-sales services. They offer professional training programs to ensure manufacturers can fully leverage the machine's capabilities, maximizing productivity and profitability. Furthermore, a dedicated customer service network ensures quick response times and assistance whenever needed.Industry professionals have expressed great anticipation for this game-changing machine's impact on the metal panel manufacturing sector. With its advanced features, adaptability, precision, and focus on sustainability, the machine addresses the evolving needs of the industry while optimizing production processes for enhanced efficiency.The profiled metal panel manufacturing machine is set to revolutionize the industry, empowering manufacturers to deliver high-quality panels efficiently and sustainably. It represents a significant milestone in the metal panel manufacturing sector and reinforces the company's commitment to innovation, customer satisfaction, and industry leadership. With this groundbreaking technology, a new era has dawned upon the metal panel manufacturing industry.

High-Quality Aluminium Corrugation Machine for Your Business Needs

Aluminium Corrugation Machine Revolutionizes Manufacturing ProcessThe manufacturing industry is constantly evolving, with new innovations and technologies continuously changing the way products are produced. One such innovation is the Aluminium Corrugation Machine, which has revolutionized the process of shaping and corrugating aluminum sheets.The Aluminium Corrugation Machine, manufactured by an industry-leading company, is a state-of-the-art piece of equipment that has redefined the corrugation process. The machine is designed to increase production efficiency and improve the quality of corrugated aluminum sheets, making it an essential tool for manufacturers in various industries.The Aluminium Corrugation Machine utilizes advanced technology to ensure precise and consistent corrugation of aluminum sheets. This not only improves the overall quality of the final product but also reduces waste and increases productivity. The machine's automated features and user-friendly interface make it easy to operate, allowing for seamless integration into existing manufacturing processes.The company behind the Aluminium Corrugation Machine is a renowned leader in the manufacturing industry, with a long-standing reputation for producing high-quality machinery and equipment. With a focus on innovation and continuous improvement, the company has developed a wide range of cutting-edge products that cater to the diverse needs of manufacturers across various sectors.In addition to the Aluminium Corrugation Machine, the company offers a comprehensive range of solutions for aluminum processing, including roll forming machines, cutting machines, and various other equipment essential for the manufacturing process. With a commitment to delivering superior products and exceptional customer service, the company has established itself as a trusted partner for manufacturers worldwide.The Aluminium Corrugation Machine has already made a significant impact on the manufacturing industry, with many companies adopting this innovative technology to enhance their production capabilities. By incorporating this advanced machine into their operations, manufacturers have been able to streamline their processes, reduce production costs, and ultimately deliver better products to their customers.One of the key advantages of the Aluminium Corrugation Machine is its versatility. The machine is suitable for a wide range of applications, from roofing and cladding to automotive and aerospace components. This flexibility allows manufacturers to expand their product offerings and explore new opportunities in the market, driving growth and innovation within their businesses.Furthermore, the Aluminium Corrugation Machine is designed with sustainability in mind. By improving the efficiency of the corrugation process, the machine helps to minimize material wastage and energy consumption, contributing to a more environmentally friendly manufacturing practice. This aligns with the growing demand for sustainable solutions within the industry and positions the machine as a valuable asset for manufacturers looking to reduce their environmental impact.Looking ahead, the company continues to invest in research and development to further enhance the capabilities of the Aluminium Corrugation Machine. With a focus on continuous improvement and innovation, the company is committed to staying at the forefront of the manufacturing industry and providing cutting-edge solutions that meet the evolving needs of its customers.The Aluminium Corrugation Machine represents a significant leap forward in aluminum processing technology, offering manufacturers a powerful tool to elevate their production capabilities and drive business growth. With its advanced features, precision engineering, and commitment to sustainability, the machine has earned its place as a game-changer in the manufacturing industry, paving the way for a more efficient and sustainable future.

Key things to know about slitter steel in the industry

Slitter Steel, a leading company in the steel manufacturing industry, has recently announced a significant milestone in their production process. The company, known for its excellence in providing high-quality steel products, has successfully implemented a new technology that has revolutionized their slitting process.With over 50 years of experience in the steel industry, Slitter Steel has established itself as a trusted and reliable source for a wide range of steel products. The company specializes in slitting, cut-to-length, and distribution of various types of steel, including stainless steel, carbon steel, and aluminum. Their state-of-the-art facilities and cutting-edge technology allow them to meet the diverse needs of their customers with precision and efficiency.The recent advancement in Slitter Steel's slitting process is a result of their commitment to continuous improvement and innovation. This new technology has significantly enhanced their capacity to produce high-quality slit steel that meets the strictest industry standards. By implementing this cutting-edge technology, Slitter Steel has further solidified its position as a leader in the steel manufacturing industry.The innovative technology has streamlined the slitting process, enabling Slitter Steel to increase its production capacity while maintaining superior quality. This advancement has also improved the efficiency of their operations, allowing the company to meet the growing demands of their customers in a timely manner.Furthermore, the new technology has enhanced the accuracy and consistency of the slit steel products, making them even more reliable for various applications. This development has positioned Slitter Steel as a preferred supplier for industries that require precision-cut steel products, such as automotive, construction, and manufacturing.In addition to their commitment to technological advancement, Slitter Steel is also dedicated to sustainability and environmental stewardship. The company has implemented eco-friendly practices in their manufacturing processes, ensuring that their operations have minimal impact on the environment. With a focus on sustainability, Slitter Steel continues to prioritize the well-being of the planet while delivering top-quality steel products to their customers.The successful implementation of the new technology in Slitter Steel's slitting process has garnered positive feedback from their customers and partners. The improved efficiency and quality of the slit steel products have reinforced the company's reputation for excellence in the industry. This milestone has also positioned Slitter Steel for continued growth and success in the global market.As Slitter Steel continues to expand its reach and capabilities, the company remains committed to upholding its core values of quality, innovation, and customer satisfaction. With a strong foundation built on decades of expertise and a forward-looking approach to technology, Slitter Steel is poised to lead the way in the steel manufacturing industry for years to come.In conclusion, Slitter Steel's recent achievement in enhancing its slitting process with innovative technology is a testament to the company's unwavering commitment to excellence. With a focus on quality, efficiency, and sustainability, Slitter Steel continues to set the standard for steel manufacturing and remains a trusted partner for businesses worldwide.

Latest Updates on W Beam Crash Barrier Roll Forming Machine: Breaking News and Key Insights

Title: A Revolutionary W Beam Crash Barrier Machine for Enhanced Road SafetyIntroduction:In an era where road safety is of paramount importance, the development and utilization of the W Beam Crash Barrier Machine have become crucial. Designed to withstand high-impact collisions and prevent vehicles from crossing into opposing lanes, this state-of-the-art machine is revolutionizing the road infrastructure sector. In this blog, we will delve into the concept, manufacturing process, and several benefits of the W Beam Crash Barrier Machine, ensuring safer roads for all.Understanding the W Beam Crash Barrier Machine:The W Beam Crash Barrier Machine is a cutting-edge roll forming machine that plays a vital role in manufacturing W-shaped steel beams, popularly known as W beams. These beams serve as a protective barrier on highways and roads, significantly reducing the risk of fatal accidents. The machine features advanced technology, enabling precise and efficient production of the barriers to meet international safety standards.Manufacturing Process:The manufacturing process of the W Beam Crash Barrier Machine involves several crucial steps. Firstly, high-quality galvanized steel strips are selected for their superior strength and durability. These strips are then fed into the roll forming machine, which shapes them into the distinctive W beam profile.The machine's advanced automation system ensures accurate dimensions and consistent quality during the roll forming process. After the beams are formed, they undergo prompt and reliable galvanization. The galvanizing treatment protects the beams from corrosion caused by harsh weather conditions, thereby extending their lifespan.Advantages of the W Beam Crash Barrier Machine:1. Enhanced Road Safety: The primary purpose of the W Beam Crash Barrier Machine is to create crash barriers that offer robust protection for drivers and passengers. The sturdy W-shaped beams ensure the containment of vehicles, minimizing the chance of crossover accidents and promoting overall road safety.2. Durability and Longevity: The utilization of high-quality galvanized steel strips and effective galvanization techniques equips W beams with exceptional durability. These barriers can withstand high-impact collisions and harsh weather conditions, reducing the need for frequent replacements or maintenance.3. Cost-Effectiveness: The W Beam Crash Barrier Machine optimizes production efficiency, resulting in reduced manufacturing costs. Additionally, the long lifespan of the W beams translates into cost savings by minimizing repair expenses and replacement needs.4. Regulatory Compliance: The W Beam Crash Barrier Machine aligns with international safety standards, ensuring that the produced W beams meet all necessary regulatory guidelines. This compliance provides peace of mind for road authorities and enhances the overall road infrastructure.5. Versatility: The machine can be easily adjusted to produce W beams of various shapes, sizes, and specifications, making it adaptable to different road infrastructure requirements. This versatility makes the machine invaluable for road authorities and construction companies.Conclusion:In conclusion, the W Beam Crash Barrier Machine represents a significant advancement in road safety measures. Its ability to manufacture durable, high-quality crash barriers ensures the protection of drivers, passengers, and road infrastructure alike. By promoting containment and minimizing crossover accidents, these machines have revolutionized the road construction sector. With their exceptional versatility and regulatory compliance, it is evident that the W Beam Crash Barrier Machine will continue to play a vital role in enhancing road safety worldwide.Keywords: W Beam Crash Barrier Machine, road safety, roll forming machine, manufacturing process, highway barriers, galvanization, durability, longevity, cost-effectiveness, regulatory compliance, versatility.

High-Quality Ag Panel Roll Forming Machine: A Must-Have for Efficient Farming

Ag Panel Roll Forming Machine Revolutionizes Farming IndustryIn the ever-evolving world of agriculture, technological advancements continue to change the way farmers operate. One such innovation, the Ag Panel Roll Forming Machine, is revolutionizing the farming industry by providing a cost-effective and efficient solution for producing high-quality agricultural panels.The Ag Panel Roll Forming Machine, developed and produced by a leading manufacturing company, is a state-of-the-art piece of equipment designed to streamline the process of manufacturing agricultural panels. These panels are essential for constructing buildings, barns, and other structures on farms, providing much-needed shelter and protection for livestock, equipment, and crops.This innovative machine is equipped with advanced technology and precision engineering, allowing it to produce consistent and precise agricultural panels with minimal waste. Its high-speed production capabilities enable farmers to meet their construction needs in a timely manner, reducing downtime and increasing overall productivity.The company behind this groundbreaking machine has a solid reputation in the manufacturing industry, known for its commitment to producing top-quality equipment that is built to last. With a focus on innovation and customer satisfaction, the company has been a trusted partner for farmers and agricultural businesses for many years.In addition to its cutting-edge technology, the Ag Panel Roll Forming Machine is also designed with user-friendliness in mind. It is easy to operate and requires minimal training, making it accessible to farmers of all experience levels. This accessibility is essential for ensuring that farmers can take advantage of the benefits offered by this innovative equipment.The impact of the Ag Panel Roll Forming Machine extends beyond its immediate users. By increasing the efficiency of agricultural panel production, this machine has the potential to positively influence the entire farming industry. With quicker access to high-quality panels, farmers can expedite construction projects and improve the overall infrastructure of their operations, leading to increased safety and productivity.Furthermore, the machine's ability to minimize waste and optimize material usage contributes to a more sustainable approach to farming. By reducing the environmental impact of panel manufacturing, farmers can align their operations with modern sustainability standards, appealing to environmentally conscious consumers and stakeholders.The Ag Panel Roll Forming Machine is a testament to the ongoing technological advancements in the agriculture sector. Its introduction represents a significant step forward in modernizing farm operations, offering a glimpse into the future of farming technology.With its impressive capabilities and potential to transform the industry, the Ag Panel Roll Forming Machine is set to become a staple in farming operations of all sizes. The company's dedication to innovation and customer satisfaction, combined with its track record of manufacturing excellence, positions it as a key player in shaping the future of agriculture.As the farming industry continues to evolve, it is clear that solutions like the Ag Panel Roll Forming Machine will play a vital role in driving progress and success for farming operations around the world. As more farmers adopt this innovative technology, the industry as a whole stands to benefit from increased efficiency, sustainability, and productivity.

How Slitting Line Machines Can Enhance Production Efficiency

In today's fast-paced world, it is essential to have industries that can keep up with the ever-demanding needs of the market. An industry that is gaining momentum and popularity is the metal processing industry, which specializes in manufacturing various metal components and equipment. The metal processing industry is critical in modern society, and its importance cannot be overemphasized.One major player in the metal processing industry is a company that specializes in manufacturing slitting line machines. The company has been in existence for many years, and it has been providing metal processing solutions to different industries across the globe. The company boasts of a team of experts who are passionate about their work and focus on providing clients with top-notch solutions that meet their specific needs.The slitting line machine is a critically important machine in the metal processing industry, as it is used to cut a large coil of metal into smaller strips of different widths. The slitting line process is a crucial step in the metal processing industry, as it allows for the production of different finished products from the same coil of metal. The slitting line machine is also used in the assembling of different metal components that are used in various industries, including construction, automobile, and household appliances.The company's slitting line machine is a cutting-edge technology that is designed to handle a wide range of materials, including brass, copper, aluminum, steel, and others. It is user-friendly, efficient, and offers cost-effective solutions to clients. The machine is also designed with safety features that ensure the operator's safety and the safety of the machine's components.The slitting line machine is an essential piece of equipment in the metal processing industry, and the company has invested heavily in research and development to manufacture machines that meet the needs of different clients. The company is committed to producing high-quality machines that are durable, efficient, and reliable. The firm has built a reputation for excellence, and this has been proven by the positive feedback from different clients who have used their products.One of the reasons why the company's slitting line machine is regarded highly in the market is because of its versatility. The machine can accommodate different coil sizes, and its cutting speed can be adjusted based on the client's needs. The machine's precision and accuracy levels are unmatched, and this ensures that clients get the exact size and width they require.In addition to manufacturing top-notch machines, the company provides excellent customer support to its clients. The company's team of experts is always on hand to provide clients with technical support when needed. The company also offers training programs to clients who purchase their machines, ensuring that the clients can operate the machines safely and efficiently.On the environmental front, the company has taken steps to ensure that their machines are eco-friendly. The machines are designed with features that reduce energy consumption and minimize the amount of waste produced during the metal processing process. The company's commitment to environmental protection is one of the reasons why it has remained relevant in the market.In conclusion, the metal processing industry is critical in modern society, and one major player in this industry is the company that specializes in manufacturing slitting line machines. Their machines are efficient, durable, and reliable and have been tested and proven by different clients. The company has built a reputation for excellence in the market and is committed to providing clients with high-quality machines that meet their specific needs. With an excellent team of experts, customer support, and a commitment to environmental protection, the company is poised to remain relevant in the metal processing industry for years to come.

Steel Sheet Roller Forming Machine: The Ultimate Guide

The Automatic Steel Sheet Roller Forming Machine, also known as metal rolling or roll forming machine, has gained popularity in the manufacturing industry due to its efficiency and precision in producing high-quality steel sheet products. This machine has revolutionized the steel sheet forming process by automating the production line and reducing human intervention, resulting in improved productivity and cost savings for companies.The {Company Name} is a leading manufacturer of the Automatic Steel Sheet Roller Forming Machine, with a strong commitment to innovation and quality in the metal forming industry. The company has a proven track record of delivering state-of-the-art equipment that meets the diverse needs of its customers, and its roller forming machines have been widely adopted by manufacturers around the globe.The Automatic Steel Sheet Roller Forming Machine offered by {Company Name} features advanced technology and intelligent software, allowing for precise control and seamless operation. The machine is designed to handle a wide range of steel sheet materials, including stainless steel, carbon steel, and aluminum, with varying thickness and widths. Its modular design and customizable tooling options make it a versatile solution for manufacturers seeking to streamline their production processes and optimize their product offerings.One of the key advantages of the Automatic Steel Sheet Roller Forming Machine is its speed and accuracy in shaping steel sheets into desired profiles and dimensions. The machine's automated feeding system and precise roll forming stations ensure consistent product quality and dimensional accuracy, reducing material waste and rework. This level of precision is essential for meeting the high standards of the automotive, construction, and aerospace industries, where tight tolerances and smooth surface finishes are critical.In addition to its performance capabilities, the Automatic Steel Sheet Roller Forming Machine is also designed with operator safety and ease of use in mind. The machine is equipped with safety guards, emergency stop buttons, and intuitive controls to minimize the risk of accidents and ensure smooth operation. Its user-friendly interface and quick changeover features further enhance productivity and efficiency, allowing manufacturers to quickly adapt to changing production requirements and market demands.The {Company Name} takes pride in providing comprehensive support and service for its Automatic Steel Sheet Roller Forming Machine, including installation, training, and ongoing maintenance. Its team of experienced engineers and technicians are dedicated to helping customers maximize the potential of their equipment and achieve long-term success in the competitive metal forming industry. This commitment to customer satisfaction has earned {Company Name} a reputation for reliability and excellence in the market.As the demand for high-quality steel sheet products continues to grow across various industries, the Automatic Steel Sheet Roller Forming Machine offered by {Company Name} presents a compelling solution for manufacturers seeking to stay ahead of the curve. Its combination of advanced technology, precision engineering, and comprehensive support makes it a valuable investment for companies looking to enhance their production capabilities and expand their product offerings.In conclusion, the Automatic Steel Sheet Roller Forming Machine offered by {Company Name} is a game-changer in the metal forming industry, delivering unmatched performance, versatility, and safety for manufacturers worldwide. With its innovative features and proven track record, this machine is poised to shape the future of steel sheet production and drive business success for its users.

Roll Forming and Corrugation Machine for Color Steel Glazed Tile Panels

Title: Innovation in Steel Glazed Tile Panel Roll Forming and Corrugation Machine Revolutionizes Construction IndustryIntroduction:The construction industry has witnessed a remarkable innovation in the form of the Color Steel Glazed Tile Panel Roll Forming and Corrugation Machine. This state-of-the-art machine, developed by a reputable company, is set to transform the way steel glazed tiles are manufactured for roofing applications. With its advanced technology and seamless production process, the machine is poised to revolutionize the industry while offering numerous benefits to construction companies and homeowners alike.Body:1. Industry Challenges and Evolution:The construction industry has always demanded sturdy, efficient, and aesthetically pleasing roofing materials. However, the traditional methods of producing steel glazed tiles posed multiple challenges for manufacturers. These challenges included high production costs, limited design options, and time-consuming installation processes.2. Introducing the Color Steel Glazed Tile Panel Roll Forming and Corrugation Machine:Innovating the market, the Color Steel Glazed Tile Panel Roll Forming and Corrugation Machine eliminates the aforementioned challenges. Developed by a prominent technology company known for its commitment to excellence, this machine streamlines the production process, ensuring cost-effectiveness, flexibility, and enhanced design options.3. Seamless Production Process:The machine's advanced features enable a seamless production process. It is equipped with precision engineering and cutting-edge technology, ensuring high precision in every tile produced. The roll forming and corrugation mechanism guarantees consistent tile dimensions, thus reducing material wastage and costs. With adjustable settings, manufacturers can effortlessly produce a wide range of tile profiles, meeting the diverse design preferences of customers.4. Enhanced Design Options:An exciting aspect of the Color Steel Glazed Tile Panel Roll Forming and Corrugation Machine is its ability to offer an extensive range of design options. Manufacturers can now cater to different architectural styles and market demands. From traditional designs to contemporary aesthetics, this machine facilitates the creation of visually striking steel glazed tiles, making it an attractive choice for builders and homeowners alike.5. Cost-Effective Solution:With its efficient production process and reduced material wastage, the Color Steel Glazed Tile Panel Roll Forming and Corrugation Machine ensures cost-effectiveness for manufacturers. This advantage translates to affordable pricing for consumers without compromising on quality or durability. The machine's productivity significantly increases the overall output, thus enabling companies to meet increased market demands in a shorter timeframe.6. Durability and Longevity:Steel glazed tiles produced using this innovative machine boast exceptional durability and longevity. The use of high-quality materials, combined with precision manufacturing, results in tiles that can withstand harsh weather conditions, UV exposure, and the test of time. This durability ultimately translates into increased customer satisfaction and reduced maintenance costs for homeowners.7. Environmental Sustainability:Recognizing the importance of sustainable practices in the construction industry, the Color Steel Glazed Tile Panel Roll Forming and Corrugation Machine adheres to eco-friendly manufacturing processes. The machine's design ensures minimal energy consumption while reducing the carbon footprint. Additionally, the long lifespan of the tiles reduces the need for frequent replacements, contributing to a more sustainable construction approach.Conclusion:The introduction of the Color Steel Glazed Tile Panel Roll Forming and Corrugation Machine has revolutionized the construction industry. It has addressed the challenges faced by manufacturers, providing them with a cost-effective, flexible, and highly efficient solution to produce high-quality steel glazed tiles. With its seamless production process, enhanced design options, and durability, this innovative machine is set to shape the future of the roofing industry. As construction companies and homeowners continue to seek innovative and sustainable solutions, the machine's technological advancements and environmental benefits position it as a game-changer in the market.

High-Quality Metal Slitting Line Machines for Sale in Different Gauges

When it comes to metal processing, a slitting line is an essential piece of equipment that is used to cut large coils of metal into narrower widths. A metal slitting line involves a series of operations that include uncoiling, feeding the metal strip through a set of knives, slitting the metal strip into desired widths, and recoiling the strips. The slitting process is widely used in various industries, including automotive, construction, and manufacturing.If you are looking for a high-quality metal slitting line for your business needs, RISHBIN is the right place to go. As one of the leading slitting line manufacturers, RISHBIN offers a range of metal slitting lines that are designed to meet different gauge requirements: light, medium, and heavy gauge.Heavy Gauge Slitting LineA heavy gauge slitting line is typically used for cutting thicker metal strips that range from 2mm to 16mm in thickness. It is an ideal option for industries that require thick materials, such as shipbuilding, bridge construction, and oil and gas pipelines. The heavy gauge slitting line features advanced technology that enables it to handle heavy-duty materials with ease.The heavy gauge slitting line from RISHBIN is designed to handle coils of up to 30 tons and widths of up to 2200mm. The machine features a hydraulic coil car that makes loading and unloading of coils easier and safer. The machine also has a decoiler that ensures smooth feeding of the material to the slitter head.The slitter head of the heavy gauge slitting line features an advanced design that enables it to slit thick materials with high precision. The machine has multiple knife sets that can be easily adjusted to accommodate different width requirements. The slitter head also features a powerful motor that ensures perfect slitting even at high speeds.Once the metal strip has been slit into the desired width, the machine recoils the strips. The recoiling process is also designed to handle heavy-gauge materials without causing any damage. The recoiler is equipped with a tensioning system that ensures uniform rewinding of the strips.In conclusion, a heavy gauge slitting line is an essential machine for any business that requires thick materials. The heavy gauge slitting line from RISHBIN is one of the best on the market, featuring advanced technology that ensures high precision and efficiency. If you are interested in purchasing a heavy gauge slitting line, RISHBIN is the right place to look.