Discover the Benefits of a Roof Tile Roll Forming Machine for Your Construction Business

By:Admin

The Roof Tile Roll Forming Machine is a result of extensive research and development by the industry-leading company, which has a solid reputation for delivering high-quality roll forming machinery. Drawing on their years of experience and expertise in the field, the company has brought forth a machine that is designed to meet the evolving demands of the roofing industry.

One of the key features of this Roof Tile Roll Forming Machine is its ability to produce high-quality roof tiles with precision and speed. The machine is equipped with advanced technology that allows for seamless roll forming, ensuring that each tile is produced with consistent quality and accuracy. This not only enhances the overall efficiency of the manufacturing process but also results in a superior end product.

Furthermore, the Roof Tile Roll Forming Machine is designed to be highly versatile, capable of producing a wide range of roof tile designs and sizes. This flexibility is essential for meeting the diverse needs of different construction projects and allows for customization according to specific requirements. With this machine, roofing companies and contractors can easily cater to a variety of client preferences, thereby enhancing their competitive edge in the market.

In addition to its advanced functionality, the Roof Tile Roll Forming Machine is also built for durability and longevity. Constructed with high-quality materials and precision engineering, the machine is designed to withstand the rigors of continuous production and deliver reliable performance over an extended period of time. This durability not only ensures a consistent output of roof tiles but also minimizes downtime for maintenance and repairs, contributing to overall cost savings for users.

Furthermore, the company behind the Roof Tile Roll Forming Machine is committed to providing comprehensive support and service to its customers. With a team of experienced technicians and engineers, the company offers installation, training, and maintenance services to ensure that users can maximize the potential of the machine. This dedication to customer satisfaction reflects the company's mission to not only deliver cutting-edge machinery but also to foster long-term partnerships with its clients.

As the roofing industry continues to evolve and demand for efficient manufacturing solutions grows, the introduction of the Roof Tile Roll Forming Machine marks a significant advancement in the field. With its advanced technology, versatility, and durability, this machine is set to elevate the standards of roof tile production and empower roofing companies to achieve greater success in their operations.

Overall, the Roof Tile Roll Forming Machine is a testament to the company's commitment to innovation and excellence in roll forming machinery. With its potential to transform the roofing industry, this machine represents a game-changing solution for manufacturers and contractors alike, setting a new benchmark for efficiency and quality in roof tile production.

Company News & Blog

High-Quality Corrugated Metal Roofing Machine for Sale

Corrugated Metal Roofing Machine Revolutionizes Roofing Industry{Company Name} has recently announced the launch of their newest innovation in the roofing industry - the Corrugated Metal Roofing Machine. This state-of-the-art machine is set to revolutionize the way metal roofing is manufactured, offering advanced technology and unparalleled efficiency.The Corrugated Metal Roofing Machine is designed to produce high-quality, corrugated metal roofing panels with speed and precision. The innovative technology used in the machine ensures that the panels are uniform in shape and size, with smooth, accurate corrugations. This not only enhances the aesthetic appeal of the roofing panels but also improves their functionality and durability.The company has invested extensive research and development into the Corrugated Metal Roofing Machine, ensuring that it meets the highest standards of quality and performance. The machine is equipped with cutting-edge automation and control systems, allowing for seamless operation and minimal human intervention. This not only increases productivity but also reduces the margin of error, resulting in consistently superior roofing panels.Additionally, the Corrugated Metal Roofing Machine is designed to be versatile and adaptable, capable of producing a wide range of corrugated metal roofing panels to meet the diverse needs of the market. From different shapes and profiles to varying thicknesses and coatings, the machine can be customized to manufacture roofing panels to exact specifications, catering to the specific requirements of each project.{Company Name} has a long-standing reputation for excellence in the roofing industry, with a commitment to innovation and customer satisfaction. The launch of the Corrugated Metal Roofing Machine is a testament to the company's dedication to pushing the boundaries of technology and delivering cutting-edge solutions to its customers."We are thrilled to introduce the Corrugated Metal Roofing Machine to the market," said {Spokesperson}. "This is a game-changer for the roofing industry, and we believe it will set a new standard for efficiency, quality, and innovation in metal roofing manufacturing. We are confident that this machine will benefit our customers by offering them unmatched precision and productivity, ultimately helping them to achieve superior results with their roofing projects."In addition to its technological advancements, the Corrugated Metal Roofing Machine is also designed with sustainability in mind. By optimizing material usage and reducing waste, the machine minimizes the environmental impact of metal roofing production. Furthermore, the high efficiency of the machine results in lower energy consumption, contributing to overall energy conservation.The launch of the Corrugated Metal Roofing Machine demonstrates {Company Name}'s commitment to driving progress and excellence in the roofing industry. With its cutting-edge technology, superior quality, and sustainable design, the machine is poised to revolutionize the way metal roofing panels are manufactured, setting a new standard for the industry.As the demand for metal roofing continues to grow, driven by its durability, longevity, and aesthetic appeal, the Corrugated Metal Roofing Machine is set to play a pivotal role in meeting this demand. By offering a technologically advanced and efficient solution for metal roofing manufacturing, {Company Name} is poised to strengthen its position as a leader in the roofing industry and capture new opportunities in the market.For more information about the Corrugated Metal Roofing Machine and {Company Name}'s other innovative solutions, visit their website {website}.

Unlock the Thrills: Cold Formed Steel Extension for Batman: Arkham Origins Game

Cold formed steel is a popular material used in construction and manufacturing industries. It is versatile, strong, and durable, and can be formed into various shapes and sizes, making it an excellent choice for a wide range of applications.One of the most significant advantages of using cold formed steel is its cost-effectiveness. Compared to other traditional construction materials like wood, concrete, or hot-rolled steel, cold formed steel is more affordable and easier to work with. It requires less labor and processing time, which translates to lower operational costs.The manufacturing process for cold formed steel is also relatively straightforward. It involves the use of a Cold Formed Steel Machine, which utilizes a series of rollers and dies to bend and shape the steel to the desired dimensions. This process yields a high-quality, precise product that is consistent in size and shape.Another benefit of cold formed steel is its high strength-to-weight ratio. Cold formed steel structures are lighter and yet stronger than many other building materials used in construction. This makes it an excellent choice for structures that require high strength but limited weight, such as bridges, aircraft hangars, and industrial buildings.Cold formed steel has also been shown to be highly resistant to environmental factors like wind, rain, and seismic forces. It is highly durable and can withstand extreme weather conditions, making it an ideal choice for outdoor structures like sheds, decks, and fencing.In conclusion, cold formed steel is an excellent choice for those looking for a durable, cost-effective, and versatile material for construction and manufacturing purposes. With its numerous benefits, it is no wonder why it has become a popular material in the industry. So, if you are considering using cold formed steel for your next project, make sure to invest in a reliable Cold Formed Steel Machine and get ready to enjoy the many advantages it has to offer.

Tile Sheet Forming And Corrugating Machine: A Breakthrough in Glazed Tile Manufacturing Technology

Glazed Tile Sheet Forming And Corrugating Machine has revolutionized the roofing industry with its advanced technology and efficiency. This state-of-the-art machine has been developed by a leading manufacturing company that specializes in producing high-quality equipment for the construction and roofing sector.The machine is designed to produce glazed tile sheets with precision and accuracy, ensuring uniformity in the shape and size of the tiles. It is equipped with advanced forming and corrugating technology, allowing for seamless production of glazed tile sheets at a faster pace. The machine's high-speed capabilities and automated features make it a game-changer in the industry, increasing productivity and reducing production costs for manufacturers.The company behind this innovative machine has a strong reputation for delivering cutting-edge solutions for the construction and roofing industry. With years of experience in manufacturing and engineering, the company has become a trusted name in the market. They are known for their commitment to quality, reliability, and customer satisfaction. Their team of experts continuously strives to develop innovative solutions that meet the evolving needs of the industry.The Glazed Tile Sheet Forming And Corrugating Machine is a testament to the company's dedication to technological advancement and innovation. By leveraging the latest in engineering and manufacturing techniques, they have created a machine that sets new standards for efficiency and quality in the production of glazed tile sheets. The machine's ability to produce uniform and high-quality tiles is a result of the company's relentless pursuit of excellence and their deep understanding of the industry's requirements.In addition to its advanced technology, the machine is also designed with user convenience in mind. Its user-friendly interface and intuitive controls make it easy to operate, reducing the learning curve for operators and increasing overall efficiency. This focus on usability demonstrates the company's commitment to providing practical and effective solutions for its customers.Furthermore, the Glazed Tile Sheet Forming And Corrugating Machine is built to last, with a durable and robust construction that ensures reliability in long-term use. The company's dedication to quality and craftsmanship is evident in every aspect of the machine's design and manufacturing. This commitment to excellence gives customers confidence in the reliability and performance of their investment.The introduction of this advanced machine signals a new era in the production of glazed tile sheets, setting a new standard for quality, efficiency, and productivity in the roofing industry. Manufacturers can now benefit from increased production capacities, reduced downtime, and improved overall quality of their glazed tile sheets, thanks to this groundbreaking technology.With the Glazed Tile Sheet Forming And Corrugating Machine, the company has once again demonstrated its leadership in the industry and its ability to drive innovation. As the construction and roofing industry continues to evolve, the company remains at the forefront, providing solutions that empower manufacturers to meet the demands of a rapidly changing market.In conclusion, the Glazed Tile Sheet Forming And Corrugating Machine represents a significant advancement in the roofing industry, offering manufacturers a powerful tool to enhance their production capabilities. The machine's advanced technology, user-friendly design, and superior quality make it a game-changer for the industry, and a testament to the company's commitment to excellence and innovation. With this new innovation, the company continues to reinforce its position as a leader in the construction and roofing sector, delivering cutting-edge solutions that drive the industry forward.

High-Quality Metal Slitting Line Machines for Sale in Different Gauges

When it comes to metal processing, a slitting line is an essential piece of equipment that is used to cut large coils of metal into narrower widths. A metal slitting line involves a series of operations that include uncoiling, feeding the metal strip through a set of knives, slitting the metal strip into desired widths, and recoiling the strips. The slitting process is widely used in various industries, including automotive, construction, and manufacturing.If you are looking for a high-quality metal slitting line for your business needs, RISHBIN is the right place to go. As one of the leading slitting line manufacturers, RISHBIN offers a range of metal slitting lines that are designed to meet different gauge requirements: light, medium, and heavy gauge.Heavy Gauge Slitting LineA heavy gauge slitting line is typically used for cutting thicker metal strips that range from 2mm to 16mm in thickness. It is an ideal option for industries that require thick materials, such as shipbuilding, bridge construction, and oil and gas pipelines. The heavy gauge slitting line features advanced technology that enables it to handle heavy-duty materials with ease.The heavy gauge slitting line from RISHBIN is designed to handle coils of up to 30 tons and widths of up to 2200mm. The machine features a hydraulic coil car that makes loading and unloading of coils easier and safer. The machine also has a decoiler that ensures smooth feeding of the material to the slitter head.The slitter head of the heavy gauge slitting line features an advanced design that enables it to slit thick materials with high precision. The machine has multiple knife sets that can be easily adjusted to accommodate different width requirements. The slitter head also features a powerful motor that ensures perfect slitting even at high speeds.Once the metal strip has been slit into the desired width, the machine recoils the strips. The recoiling process is also designed to handle heavy-gauge materials without causing any damage. The recoiler is equipped with a tensioning system that ensures uniform rewinding of the strips.In conclusion, a heavy gauge slitting line is an essential machine for any business that requires thick materials. The heavy gauge slitting line from RISHBIN is one of the best on the market, featuring advanced technology that ensures high precision and efficiency. If you are interested in purchasing a heavy gauge slitting line, RISHBIN is the right place to look.

High Speed Light Steel Keel Roll Forming Machine: Efficient Building Material Solution

, Stud Truss Roll Forming Machine, High Speed Roll Forming Machine, Metal Stud Roll Forming Machine.With the advancement in technology, the construction industry also has advanced equipment and machines to produce high-quality materials. One such essential machine is the stud truss high speed light steel keel roll forming machine. This machine is used to make light keel studs and trusses that are used for constructing the roof and walls of a building. It is known for its efficiency, reliability, and high speed.The light steel keel machine is designed differently based on the model and the customer's specifications. The metal stud roll-forming machine produces rolls of metal that are used as roofing or wall material in places such as factories, warehouses, garages, gymnasiums, and exhibition centers. These products are popular because of their lightweight, high strength, and easy installation.One of the many advantages of using a stud truss high speed light steel keel roll forming machine is its speed. The machine is designed to produce large quantities of metal strips rapidly, therefore, allowing for mass production, this significantly reduces the time taken to construct a building. The machine is also straightforward to operate, reducing the need for large labor forces on construction sites.Another benefit of using the light steel keel machine is the quality of the material produced; the metal strips produced are of a consistent thickness, length, and size, eliminating the possibility of defects that could lead to the loss of material. The machines are also low-maintenance as they are designed to be robust and long-lasting, thus reducing the operators' servicing costs.In conclusion, the stud truss high speed light steel keel roll forming machine is a must-have piece of equipment in the construction industry. It's easy operation, and high-speed production makes it a favorite among operators globally. The machine's accuracy and quality of the material produced make it an indispensable tool in the construction of buildings. For cost-effective construction materials, the light steel keel machine is the way to go. So if you are in the construction industry, it's essential to invest in a high-quality stud truss roll forming machine that will provide the best results.

China's Leading Manufacturer of Roll Forming Machines and Glazed Tile Roll Forming Machines

Title: Steel Tile Forming Machine: Revolutionizing the Construction IndustryIntroduction:In the rapidly evolving construction industry, innovation plays a pivotal role in meeting the needs of modern-day infrastructure projects. One such innovation is the Steel Tile Forming Machine, a game-changer in the manufacturing of roofing materials. Developed and manufactured by leading roll forming machine companies in China, this efficient and versatile equipment has transformed the way steel tiles are produced. In this blog, we will delve into the intricacies of the Steel Tile Forming Machine and explore its numerous benefits for the construction industry.Understanding the Steel Tile Forming Machine:The Steel Tile Forming Machine is a state-of-the-art piece of equipment designed specifically for the high-speed production of steel tiles. With its advanced roll-forming technology, it can quickly convert metal coils into fully formed steel tiles of various shapes and sizes. This machine is often used in the production of roofing materials, where it has gained significant popularity due to its accuracy, efficiency, and cost-effectiveness.Key Features and Advantages:1. High Precision and Versatility:The Steel Tile Forming Machine incorporates advanced CNC systems, ensuring precise and consistent tile production. Its adjustable roller sets allow for the formation of tiles in a wide range of profiles and dimensions, meeting the specific requirements of various architectural designs. This versatility makes it an ideal choice for construction projects of all sizes.2. Speed and Efficiency:Equipped with automated control systems, the machine operates at high speeds, significantly reducing production time. This efficiency not only enhances productivity but also optimizes resource utilization, resulting in increased cost-effectiveness for manufacturers.3. Durability and Reliability:Manufactured using high-quality materials, the Steel Tile Forming Machine is built to withstand the demanding conditions of industrial production. Its robust design and high-quality components ensure durability and reliability, reducing maintenance requirements and enabling consistent operation even in challenging environments.4. Cost-Effective Production:The machine's high-speed production capabilities and reduced labor requirements contribute to cost savings for manufacturers. Additionally, its precision and efficiency minimize material wastage, making it an environmentally friendly option.5. Customization and Design Flexibility:With the Steel Tile Forming Machine, manufacturers can effortlessly create specialized shapes, designs, and patterns for steel tiles. Whether it's creating intricate textures or replicating traditional roofing styles, the machine offers unparalleled design flexibility, allowing builders and architects to bring their creative visions to life.Impact on the Construction Industry:The advent of the Steel Tile Forming Machine has revolutionized the construction industry in several ways. Firstly, it has significantly reduced the lead time for steel tile manufacturing, enabling projects to progress at a faster pace. This increased efficiency has particularly benefited large-scale infrastructure developments.Secondly, the machine's ability to produce high-quality steel tiles at a faster rate has positively influenced the cost of construction. By reducing labor and material costs, it has made steel tiles a more affordable roofing option, widening their adoption among builders and homeowners alike.Furthermore, the design flexibility offered by the machine has ushered in a new era of architectural possibilities. From contemporary designs to traditional aesthetic choices, steel tiles produced by this equipment provide architects and builders limitless design opportunities that enhance the overall visual appeal of structures.Conclusion:The Steel Tile Forming Machine has undoubtedly had a transformative impact on the construction industry. Its precision, speed, cost-effectiveness, and design flexibility position it as an essential tool in the manufacturing of steel tiles. As the demand for sustainable and visually appealing roofing materials increases, the Steel Tile Forming Machine is set to become an indispensable asset for construction companies worldwide. Embracing this innovative technology not only streamlines production processes but also enhances the overall quality and efficiency of construction projects.Keywords: Steel Tile Forming Machine, roll forming machine, construction industry, roofing materials, high precision, versatility, speed, efficiency, durability, cost-effective production, customization, design flexibility, impact, lead time, affordability, architectural possibilities, sustainable roofing materials.

Durable and Efficient Double Deck Roll Forming Machine for High-Volume Production

The Double Deck Roll Forming Machine has recently gained popularity in the metal forming industry, and {} is at the forefront of this innovative technology. This advanced machine has the capability to produce double-layered metal sheets, which offers significant advantages in terms of cost efficiency and production speed.With a focus on providing high-quality roll forming solutions to meet the evolving needs of the industry, {} has been a key player in the development and deployment of the Double Deck Roll Forming Machine. This state-of-the-art equipment is designed to increase productivity and optimize the production process, making it an essential part of modern metal forming operations.One of the key features of the Double Deck Roll Forming Machine is its ability to produce two different profiles simultaneously. This capability enables manufacturers to achieve greater flexibility in their production processes, as well as the ability to meet diverse customer requirements. With this machine, {} has empowered its clients to deliver a wide range of customized metal products, while also improving their overall production efficiency.In addition to its dual-profile capability, the Double Deck Roll Forming Machine also offers enhanced efficiency through its advanced control system. With precise control over the forming process, this machine ensures consistent quality and accuracy in the production of metal sheets. This level of control not only enhances the overall product quality but also minimizes material waste, ultimately leading to cost savings for manufacturers.Moreover, the Double Deck Roll Forming Machine is designed with a modular configuration, allowing for easy customization to suit specific production needs. This flexibility has been a game-changer for many manufacturers, as it enables them to adapt their production lines to accommodate various design requirements and material specifications. As a result, {} has empowered its clients to expand their product offerings and capture new business opportunities in the competitive metal forming market.Furthermore, {} has positioned itself as a leading provider of turnkey solutions for the roll forming industry, offering comprehensive support and expertise in the implementation of the Double Deck Roll Forming Machine. From initial consultation to installation and training, the company is committed to ensuring that its clients fully maximize the potential of this cutting-edge technology. This customer-centric approach has earned {} a reputation for reliability and excellence in the industry.Looking ahead, {} continues to innovate and develop new technologies to further advance the roll forming industry. With a strong focus on research and development, the company is dedicated to staying ahead of market trends and delivering innovative solutions that meet the evolving needs of manufacturers. As the demand for efficient, high-quality metal forming equipment continues to grow, {} remains committed to providing state-of-the-art solutions that drive success for its clients.In conclusion, the Double Deck Roll Forming Machine is a game-changing technology that has revolutionized the metal forming industry, and {} is at the forefront of this innovation. Through its commitment to excellence and customer satisfaction, the company has cemented its position as a trusted partner for manufacturers seeking to optimize their production processes and achieve new levels of efficiency and productivity. As the industry evolves, {} will continue to lead the way in delivering advanced roll forming solutions that empower manufacturers to thrive in the competitive market.

New roll former for producing drip edge now available

Automated roll forming technology has been making waves in the construction industry, as it significantly improves the efficiency and accuracy of producing various components used in building structures. One such company at the forefront of advancing this technology is {Company Name}, a leading manufacturer of roll forming machines and components.{Company Name} has recently introduced a cutting-edge Drip Edge Roll Former that is set to revolutionize the production of drip edges for roofing systems. This state-of-the-art machine is designed to create custom drip edges with precision and speed, enabling contractors and building professionals to enhance the quality and durability of their roofing installations.The Drip Edge Roll Former utilizes advanced roll forming techniques to transform metal coils into seamless drip edges that provide essential protection against water damage and improve the overall integrity of the roof. With its computer-controlled automation, the machine can produce drip edges of varying sizes and configurations, tailored to fit the specific requirements of different roofing projects.One of the key features of the Drip Edge Roll Former is its ability to handle a wide range of metal materials, including galvanized steel, aluminum, and copper, allowing for versatility in design and durability. This flexibility makes it an ideal solution for contractors and builders working on diverse roofing applications, from residential to commercial and industrial projects.Another advantage of the Drip Edge Roll Former is its high-speed production capabilities, which enable efficient manufacturing of drip edges without compromising on quality. The machine's precision and consistency in forming the metal profiles ensure that each drip edge meets the strictest industry standards and specifications.Furthermore, the Drip Edge Roll Former is designed with user-friendly controls and easy changeover features, reducing downtime and enhancing productivity in the production process. Its intuitive interface and quick setup make it accessible to operators of varying skill levels, making it a valuable asset for construction companies looking to streamline their operations.In addition to its technical capabilities, {Company Name} underscores its commitment to providing exceptional support and service to its customers, ensuring that they receive the necessary training and assistance to maximize the benefits of the Drip Edge Roll Former. The company's team of experts is dedicated to helping clients integrate the machine seamlessly into their production workflows and achieve optimal results.The launch of the Drip Edge Roll Former reflects {Company Name}'s continuous innovation and dedication to advancing roll forming technology to meet the evolving needs of the construction industry. With its focus on precision, efficiency, and reliability, the machine is positioned to become a game-changer in the production of drip edges, offering a competitive edge to businesses seeking to elevate their roofing solutions.As the demand for high-quality roofing components continues to grow, {Company Name} remains at the forefront of delivering cutting-edge roll forming solutions that empower construction professionals to achieve superior results in their projects. The Drip Edge Roll Former stands as a testament to the company's commitment to excellence and its unwavering pursuit of innovation in the field of roll forming technology.In conclusion, with the introduction of the advanced Drip Edge Roll Former, {Company Name} reinforces its position as a leader in the roll forming industry and a trusted partner for businesses seeking to elevate their manufacturing capabilities. The machine's precision, versatility, and efficiency are poised to make a significant impact on the production of drip edges, setting a new standard for quality and performance in roofing systems.

Glazed Steel Profile Roll Forming Machine for Construction with PLC Control - High-Quality Product

article as follows:China-based steel roll forming machine manufacturer, [Brand Name Removed], has announced the launch of its top-of-the-line product, the Steel Tile 750 glazed steel profile roll forming machine.This innovative roll forming machine is designed to offer a superior solution for all construction materials needs. It is expertly engineered to deliver high-quality glazed tile sheets that are highly durable, strong and capable of offering long-lasting performance that withstands the rigors of construction.With a profound understanding of the construction industry, [Brand Name Removed] has always been committed to providing unparalleled products that cater to the specific needs of its clients. The Steel Tile 750 roll forming machine is a prime example of that dedication.Manufactured using the latest technology, the Steel Tile 750 boasts of a robust design that is guaranteed to withstand heavy-duty usage. This machine is powered by PLC control technology, which delivers optimum automation and efficiency.The Steel Tile 750 roll forming machine comes with an automated hydraulic cutting system that ensures precise cuts and eliminates wastage. The machine can produce versatile, glazed tiles ranging in thickness from 0.3-0.8mm and a width of up to 1000mm.The innovation and quality of the Steel Tile 750 roll forming machine are a testament to [Brand Name Removed]'s reputation as a leading manufacturer of roll-forming and other related steel machines serving the global construction industry.According to the company spokesperson, "we understand the importance of quality and durability in the construction industry, and that's why we ensure that every product we manufacture is made to last. With our Steel Tile 750, our customers can enjoy a solution that will save them both time and money. We take pride in manufacturing machines that can remain in use for years."Designing the Steel Tile 750 roll forming machine took into account the varying construction needs of clients across the globe. The machine's versatility is perhaps its most significant selling point, as it can adapt to different building configurations and designs while still maintaining the same standard of quality.With years of experience in the steel roll-forming and construction industry, [Brand Name Removed] has earned a reputation for quality, reliability and exceptional customer service. Its team of qualified engineers and professionals is dedicated to designing machines that exceed customer expectations and meet the industry's specific needs.The Steel Tile 750 is an excellent example of [Brand Name Removed]'s commitment to offering state-of-the-art machinery at an affordable price while maintaining stringent quality control measures. Every machine's quality is checked and tested thoroughly to ensure optimal performance.The launch of the Steel Tile 750 roll forming machine is set to transform the construction industry, offering architects, contractors, and builders a solution that is both reliable and efficient. With this machine, they can speed up the construction process, reduce downtime and achieve the desired results without sacrificing quality.In conclusion, [Brand Name Removed] has once again demonstrated its expertise and focus on quality and innovation with the launch of the Steel Tile 750 glazed steel profile roll forming machine. It is an excellent addition to the company's portfolio, offering clients reliable and top-quality construction solutions at an affordable price. The industry can now look forward to faster and more efficient construction without compromising on quality.

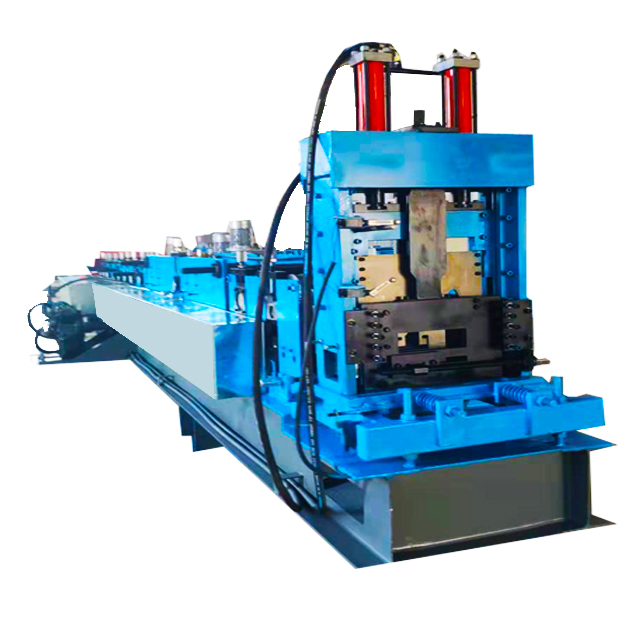

Efficient and Reliable C Shape Purlin Forming Machine for Seamless Construction

In recent news, the C Shape Purlin Forming Machine has been making its rounds, rapidly gaining popularity in the engineering and construction industry. The machine is becoming a go-to solution for engineers and construction companies who are looking to streamline their building process using modern technology. One of the leading companies manufacturing and supplying this machine is {Brand Name Removed}.{Brand Name Removed} is a renowned company that specializes in the manufacturing of high-quality roll-forming machines for the construction industry. The company prides itself on producing machines that help to streamline numerous construction processes and have a positive impact on construction projects' overall efficiency and quality. The C Shape Purlin Forming Machine is one of the machines that exemplify the company's commitment to producing top-of-the-line pieces of equipment.The C Shape Purlin Forming Machine is a roll-forming machine specifically designed for the manufacturing of C-shaped purlins. The machine boasts a high level of automation, which means that it can complete the C-shaped purlin manufacturing process from start to finish with minimal human intervention. This translates to faster production speeds, improved quality control, and reduced labor costs. Additionally, the machine's computerized control system ensures that the finished product is of consistent and precise quality every time.One of the main advantages of the C Shape Purlin Forming Machine is its versatility. The machine can produce purlins of different sizes and shapes, depending on the construction project's needs. This flexibility makes it an excellent machine for construction companies that undertake multiple types of construction projects.Another notable feature of {Brand Name Removed}'s C Shape Purlin Forming Machine is its durability. The machine's frame is made from high-quality steel, which means it can withstand the stress and strain that comes with consistent use. Additionally, the machine's parts are easily replaceable, ensuring the machine's longevity and ease of maintenance.{Brand Name Removed} is a reliable and reputable supplier of the C Shape Purlin Forming Machine. Their machines are manufactured with strict adherence to international quality standards, ensuring consistent quality across all their products. Furthermore, the company provides excellent after-sales service and technical support to ensure their customers' satisfaction.In conclusion, the C Shape Purlin Forming Machine is a revolutionary piece of equipment that streamlines the purlin manufacturing process, while simultaneously maintaining high levels of quality. {Brand Name Removed} is one of the industry leaders in the production of the C Shape Purlin Forming Machine and provides top-notch machines that meet the construction industry's needs. With this machine, construction companies can benefit from increased efficiency, reduced labor costs, and better quality control, leading to a better-built environment.