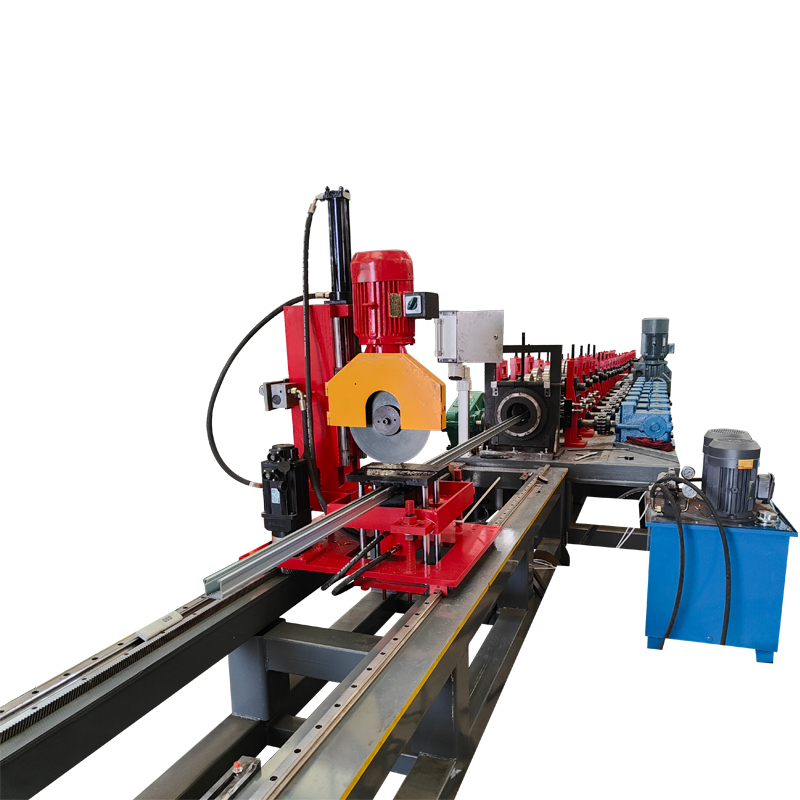

High-quality C Purlin Roll Forming Machine at an affordable price

By:Admin

In the construction industry, the demand for efficient and reliable roll forming machines is constantly increasing. Whether it's for fabricating steel structures or producing metal building materials, roll forming machines are crucial for achieving high precision and productivity. As a leading manufacturer in this field, [Company Name] is dedicated to providing cost-effective and high-quality C Purlin roll forming machines that meet the diverse needs of our customers.

One of the key factors that distinguish our C Purlin roll forming machines is their competitive pricing. We understand the importance of offering affordable solutions without compromising on quality and performance. Our team of engineers and designers has utilized the latest technology and innovative manufacturing processes to ensure that our machines are not only cost-effective but also durable and efficient. This commitment to excellence has positioned us as a trusted name in the industry, with a track record of delivering value to our clients.

When it comes to the price of our C Purlin roll forming machines, we take into consideration various factors such as materials, labor, and overhead costs. By optimizing our production processes and streamlining our operations, we are able to offer competitive prices to our customers without sacrificing the quality of our machines. In addition, our commitment to continuous improvement and cost-efficiency enables us to adapt to market changes and deliver affordable solutions that meet the evolving demands of the construction industry.

Furthermore, our C Purlin roll forming machines are designed to maximize productivity and minimize downtime, which contributes to their cost-effectiveness. With features such as automated controls, high-speed capabilities, and precision engineering, our machines enable our customers to achieve high output and consistent quality in their production processes. This not only enhances their operational efficiency but also contributes to cost savings in the long run.

In addition to competitive pricing, our company is dedicated to providing comprehensive support and services to our customers. From technical assistance to maintenance and training, we strive to be a reliable partner to our clients, ensuring that they get the most value out of our C Purlin roll forming machines. Our goal is to build long-term relationships with our customers based on trust, integrity, and mutual success.

As a global manufacturer and supplier, [Company Name] has a strong presence in the international market, serving the needs of construction companies, steel fabricators, and building material manufacturers around the world. Our commitment to affordable pricing, high-quality products, and customer satisfaction has earned us a reputation for excellence and reliability in the industry.

In conclusion, the price of our C Purlin roll forming machines reflects our dedication to delivering cost-effective solutions that empower our customers to thrive in the competitive construction industry. With a focus on quality, efficiency, and customer value, we continue to set new standards for roll forming technology and contribute to the success of our clients. For more information about our C Purlin roll forming machines and pricing, please contact us [contact information].

Company News & Blog

Ultimate Guide to C Purlin Forming Machine: Types, Uses, and Benefits

C Purlin Forming Machine revolutionizes the steel industry with its remarkable efficiency and precision. This cutting-edge technology is designed and manufactured by a leading machinery company, specializing in metal forming and fabrication equipment.The C Purlin Forming Machine is equipped with state-of-the-art features, making it an essential tool for constructing high-quality steel structures. The machine is designed to produce C-shaped steel purlins with exceptional accuracy and speed, meeting the demands of modern construction projects.One of the key highlights of this advanced machine is its ability to produce a wide range of C purlin sizes, catering to various construction needs. This flexibility is achieved through its adjustable rollers and automated control system, allowing for seamless customization and production.In addition to its versatility, the C Purlin Forming Machine is lauded for its efficiency and reliability. Its robust construction and precision engineering ensure consistent and high-quality output, reducing material wastage and increasing productivity.Furthermore, the machine's user-friendly interface and intuitive controls make operation easy and convenient. Its automated functions streamline the production process, minimizing human error and optimizing workflow.The company behind this groundbreaking technology is renowned for its dedication to innovation and excellence in the metal forming industry. With a strong focus on research and development, they have consistently introduced cutting-edge solutions that meet and exceed the evolving needs of the market.In addition to the C Purlin Forming Machine, the company offers a wide range of metal forming equipment, including roll forming machines, slitting lines, and cut-to-length lines. Their comprehensive product line is backed by a team of skilled engineers and technicians, delivering exceptional customer service and technical support.With a commitment to quality and customer satisfaction, the company has built a strong reputation in the industry, earning the trust of clients worldwide. Their products are widely used in various sectors, including construction, automotive, and industrial manufacturing.As the demand for steel structures continues to grow, the C Purlin Forming Machine is poised to play a pivotal role in meeting this demand. Its advanced capabilities and cutting-edge technology make it an indispensable asset for construction companies and manufacturers, enabling them to achieve superior results with ease and efficiency.In conclusion, the C Purlin Forming Machine represents a significant advancement in the metal forming industry. Its innovative design, precision engineering, and exceptional performance set a new standard for C purlin production, making it a key player in the construction and manufacturing sectors. With the backing of a reputable and forward-thinking company, this technology is poised to make a lasting impact on the steel industry, shaping the future of metal fabrication.

Affordable Roll Forming Machine for C Z Purlin - Get the Best Price!

Our company is excited to announce the launch of our new C Z Purlin Roll Forming Machine, a highly efficient and cost-effective solution for creating C and Z shaped steel purlins. With the growing demand for quality steel construction materials, our machine offers a superior level of precision and productivity, making it an essential investment for steel manufacturing companies.The C Z Purlin Roll Forming Machine is designed to produce C and Z shaped purlins with a high level of accuracy and consistency. This is achieved through the use of advanced technology and precision engineering, ensuring that every purlin produced meets the strictest quality standards. The machine can handle a wide range of steel thicknesses and sizes, making it suitable for a variety of construction projects.One of the key features of our C Z Purlin Roll Forming Machine is its exceptional speed and efficiency. The machine is capable of producing purlins at a rapid pace, helping to increase production output and reduce labor costs. This makes it an ideal choice for steel manufacturing companies looking to improve their productivity and competitiveness in the market.In addition to its speed and efficiency, our machine is also incredibly easy to operate and maintain. It is equipped with user-friendly controls and features a durable design that minimizes the need for frequent maintenance. This ensures that our customers can rely on the machine for consistent performance and minimal downtime, ultimately saving time and money.Furthermore, our C Z Purlin Roll Forming Machine is competitively priced, offering exceptional value for money. We understand the importance of cost-effectiveness in the steel manufacturing industry, which is why we have designed our machine to deliver a high return on investment. By investing in our machine, companies can significantly reduce their production costs and improve their overall profitability.As a company, we have a strong reputation for delivering high-quality and reliable machinery. With over [number] years of experience in the industry, we have a proven track record of providing innovative solutions that meet the evolving needs of our customers. Our commitment to excellence, combined with our dedication to customer satisfaction, has earned us the trust and loyalty of numerous steel manufacturing companies around the world.In addition to our C Z Purlin Roll Forming Machine, we offer a comprehensive range of roll forming and metal processing equipment. Our extensive product line includes machines for producing roofing panels, wall cladding, decking, and various other steel profiles. We are committed to staying at the forefront of technology and continuously improving our products to meet the changing demands of the industry.We are dedicated to providing exceptional service and support to our customers. From the initial inquiry to after-sales assistance, our team is committed to ensuring that every customer receives the highest level of care and attention. We offer comprehensive training programs, technical support, and spare parts availability to guarantee the long-term performance and reliability of our machines.In conclusion, the launch of our new C Z Purlin Roll Forming Machine represents a significant advancement in steel manufacturing technology. With its exceptional speed, efficiency, and cost-effectiveness, it is set to revolutionize the production of C and Z shaped purlins. We are confident that our machine will provide our customers with a competitive edge in the market and help them achieve greater success in their business endeavors.For more information about our C Z Purlin Roll Forming Machine and other products, please contact us at [contact information] or visit our website [website address]. We look forward to the opportunity to discuss how our solutions can benefit your company and contribute to your success in the steel manufacturing industry.

High-quality glazed tile roll forming and corrugating machine for sale

**Glazed Tile Roll Forming And Corrugating Machine Revolutionizing the Industry**In recent years, the construction industry has been witnessing a technological revolution, with advancements in machinery and automation paving the way for more efficient and precise construction processes. One such innovation making waves in the industry is the Glazed Tile Roll Forming And Corrugating Machine from {company name}. This revolutionary machine is set to transform the way glazed tiles are manufactured, offering a range of benefits to the construction industry.The Glazed Tile Roll Forming And Corrugating Machine is the latest offering from {company name}, a leading manufacturer of construction machinery and equipment. With years of experience and expertise in the industry, {company name} has earned a reputation for delivering high-quality, innovative solutions to meet the evolving needs of the construction sector.This state-of-the-art machine is designed to produce high-quality glazed tiles with precision and speed. Its advanced roll forming and corrugating technology ensures that the finished tiles are of superior quality, with consistent dimensions and a smooth glazed finish. This level of precision and quality control is unmatched in the industry, setting a new standard for glazed tile manufacturing.One of the key advantages of the Glazed Tile Roll Forming And Corrugating Machine is its ability to significantly increase production efficiency. With its automated processes and high-speed operation, the machine can produce a large volume of tiles in a short amount of time, thereby streamlining the manufacturing process and reducing production costs. This not only benefits manufacturers by improving their bottom line, but also has a positive impact on the overall supply chain, ensuring a steady and reliable source of glazed tiles for construction projects.Additionally, the machine’s versatility allows for the customization of tile dimensions and designs, catering to the specific requirements of different construction projects. This flexibility enables manufacturers to meet the diverse needs of their clients, while also allowing for creativity and innovation in tile design. By giving manufacturers the ability to produce a wide range of glazed tiles, all from one machine, {company name} is empowering the industry to expand its offerings and meet the demands of a dynamic construction market.Furthermore, the Glazed Tile Roll Forming And Corrugating Machine is designed with sustainability in mind. Its energy-efficient operation and minimal material wastage contribute to a greener manufacturing process, aligning with the growing emphasis on sustainable construction practices. By reducing energy consumption and minimizing waste, the machine not only benefits the environment, but also supports the construction industry’s commitment to sustainability and responsible resource management.As the construction industry continues to evolve and adapt to changing market demands, the Glazed Tile Roll Forming And Corrugating Machine is a prime example of the innovation driving this transformation. With its advanced technology, efficiency, and sustainability benefits, this machine is poised to revolutionize the production of glazed tiles, offering a new standard of quality, speed, and customization.In conclusion, the Glazed Tile Roll Forming And Corrugating Machine from {company name} represents a significant leap forward in the construction industry, providing manufacturers with the tools they need to meet the evolving demands of the market. With its precision, efficiency, versatility, and sustainability benefits, this machine is set to play a pivotal role in shaping the future of glazed tile manufacturing. As {company name} continues to lead the way with its innovative solutions, the construction industry can look forward to a new era of excellence in construction machinery and equipment.

Glazed Tile Roof Panel Roll Former: A Complete Guide

Color Steel Glazed Tile Roof Panel Roll Former is a cutting-edge technology that has revolutionized the production of glazed tile roof panels. This innovative machine has been developed by a leading company in the industry, which specializes in manufacturing high-quality and efficient roll forming equipment. The company has a strong track record of delivering state-of-the-art solutions to meet the diverse needs of its clients, and the Color Steel Glazed Tile Roof Panel Roll Former is no exception.The advanced technology of the Color Steel Glazed Tile Roof Panel Roll Former allows for the quick and precise production of glazed tile roof panels. This machine is designed to handle a wide range of materials, including color steel, galvanized steel, and aluminum. It is capable of producing panels of various sizes and shapes, giving manufacturers the flexibility to meet the specific requirements of their customers.One of the key features of the Color Steel Glazed Tile Roof Panel Roll Former is its high level of automation. This machine is equipped with advanced control systems that enable seamless operation and precise panel production. The automated processes not only ensure consistent panel quality but also enhance the overall efficiency of the production line. This results in significant cost savings for manufacturers and allows them to meet the demands of an increasingly competitive market.In addition to its automation capabilities, the Color Steel Glazed Tile Roof Panel Roll Former is also equipped with advanced safety features. The machine is designed with the well-being of operators in mind, incorporating safeguards that minimize the risk of accidents and injuries in the workplace. This emphasis on safety underscores the company's commitment to providing the best possible working environment for its clients.Furthermore, the Color Steel Glazed Tile Roof Panel Roll Former is engineered for durability and reliability. The machine is constructed using high-quality materials and components, ensuring its long-term performance and minimal maintenance requirements. This reliability is a testament to the company's dedication to delivering equipment that is built to last and withstand the rigors of industrial production.The company behind the Color Steel Glazed Tile Roof Panel Roll Former is a renowned industry leader with a rich history of innovation and excellence. With a team of highly skilled engineers and technicians, the company has consistently pushed the boundaries of roll forming technology, delivering cutting-edge solutions that have set new industry standards.The company's commitment to research and development has enabled it to stay ahead of the curve, continuously improving its equipment to meet the evolving needs of the market. The Color Steel Glazed Tile Roof Panel Roll Former is a testament to this dedication, representing the latest in a long line of industry-leading products.Furthermore, the company places a strong emphasis on customer satisfaction, providing comprehensive support and service to ensure the success of its clients. From initial consultation to after-sales support, the company is dedicated to building lasting partnerships with its customers, serving as a trusted ally in their success.In conclusion, the Color Steel Glazed Tile Roof Panel Roll Former represents a significant advancement in roll forming technology, offering manufacturers a powerful and reliable solution for producing high-quality glazed tile roof panels. With its advanced automation, safety features, and durability, this machine is poised to empower manufacturers to meet the demands of a dynamic market. Backed by a company with a proven track record of excellence and innovation, the Color Steel Glazed Tile Roof Panel Roll Former is set to make a lasting impact on the industry for years to come.

Durable Galvanized Steel Floor Decking Sheet for Construction Projects

Galvanized Steel Floor Decking Sheet is a revolutionary product in the construction industry, offering unparalleled strength, durability, and ease of installation. This innovative flooring solution has quickly gained popularity among builders, developers, and architects, thanks to its superior performance and cost-effectiveness.The Galvanized Steel Floor Decking Sheet is manufactured using high-quality galvanized steel, which is known for its exceptional corrosion resistance and longevity. This ensures that the flooring remains intact and robust even in the harshest of environments, making it suitable for a wide range of applications, including commercial, industrial, and residential projects.One of the key features of the Galvanized Steel Floor Decking Sheet is its unique profile, which is designed to provide optimal structural support and load-bearing capacity. This allows for greater flexibility in design and construction, as the flooring can easily accommodate heavy loads and withstand the rigors of daily use. Additionally, the profile enhances the overall stability and safety of the structure, providing peace of mind to both builders and occupants.Furthermore, the Galvanized Steel Floor Decking Sheet is incredibly easy to install, thanks to its lightweight and modular design. This not only accelerates the construction process but also reduces labor costs, making it an economical choice for builders and developers. In addition, the flooring can be customized to meet specific project requirements, offering versatility and adaptability to various design plans.The company behind the Galvanized Steel Floor Decking Sheet, {COMPANY NAME}, is a leading manufacturer and supplier of high-quality construction materials. With a strong focus on innovation and quality, the company has established itself as a trusted partner for builders and developers seeking top-notch products for their projects.{COMPANY NAME} prides itself on its state-of-the-art manufacturing facilities and cutting-edge technology, which enable the production of superior products that meet and exceed industry standards. In addition, the company boasts a team of experienced engineers and technicians who are dedicated to ensuring the quality and reliability of their products, including the Galvanized Steel Floor Decking Sheet.Moreover, {COMPANY NAME} is committed to sustainability and environmental responsibility, utilizing eco-friendly manufacturing processes and materials whenever possible. This dedication to eco-conscious practices sets the company apart in the industry and resonates with environmentally conscious builders and developers.The Galvanized Steel Floor Decking Sheet is just one of many innovative products offered by {COMPANY NAME}, which also includes a wide range of steel and metal products for various construction applications. As a reliable and reputable supplier, the company has built a strong reputation for delivering exceptional products and outstanding customer service, earning the trust and loyalty of clients across the globe.In conclusion, the Galvanized Steel Floor Decking Sheet is a game-changer in the construction industry, offering unmatched strength, durability, and ease of installation. With {COMPANY NAME} at the helm, builders and developers can be confident in the reliability and performance of this innovative flooring solution. As the demand for high-quality, cost-effective construction materials continues to grow, the Galvanized Steel Floor Decking Sheet is poised to become an indispensable element in modern construction projects, setting new standards for efficiency and sustainability.

Ultimate Guide to Aluminum Profile Cutting: Everything You Need to Know

Aluminium Profile Cutting Services: A Precision Solution for Your Manufacturing NeedsIn today's fast-paced manufacturing industry, precision and efficiency are key factors that can make or break a company's success. With constantly evolving technologies and customer demands, it's crucial for businesses to stay ahead of the game by investing in the latest cutting-edge solutions. This is where [company name] comes in.[Company name] is a leading provider of aluminium profile cutting services that cater to various industries including construction, automotive, aerospace, and more. With a state-of-the-art facility and a team of skilled professionals, they are well-equipped to handle projects of all sizes and complexities.Utilizing advanced machinery and techniques, [company name] offers a wide range of cutting services to meet the diverse needs of their clients. Whether it's standard cuts, intricate designs, or custom shapes, their capabilities are virtually limitless. From simple straight cuts to complex miter cuts, their precision and attention to detail are unmatched.One of the key advantages of choosing [company name] for aluminium profile cutting is their commitment to quality. They understand the importance of delivering products that meet the highest standards, which is why they adhere to strict quality control measures throughout the entire cutting process. This ensures that each piece is accurately cut to the customer's specifications, resulting in a finished product that is precise and reliable.Furthermore, [company name] prides itself on its ability to provide fast turnaround times without sacrificing quality. They understand that time is of the essence in the manufacturing industry, which is why they have streamlined their processes to minimize lead times and maximize efficiency. This means that clients can expect their orders to be completed and delivered in a timely manner, allowing them to stay on schedule and meet their project deadlines.In addition to their cutting services, [company name] also offers value-added solutions to further meet the needs of their customers. This includes additional machining, surface finishing, and packaging services, providing a comprehensive and hassle-free experience for clients. By offering these added services, [company name] aims to be a one-stop shop for all of their customers' aluminium cutting and processing needs.With a strong commitment to customer satisfaction, [company name] is dedicated to providing personalized service and support to each of their clients. From the initial consultation to the final delivery, their team works closely with customers to ensure that their specific requirements are met every step of the way. This personalized approach has earned [company name] a reputation for being a reliable and trusted partner in the industry.In conclusion, [company name] is a leading provider of aluminium profile cutting services that offers a precision solution for a wide range of manufacturing needs. With their cutting-edge technology, commitment to quality, fast turnaround times, and personalized service, they are well-equipped to handle projects of all sizes and complexities. Whether it's standard cuts, intricate designs, or custom shapes, [company name] is the go-to choice for all aluminium cutting and processing needs.

New Machine Technology Streamlines Panel Roll Forming Process

Panel Roll Forming Machine Revolutionizes the Manufacturing IndustryPanel roll forming machines have emerged as a game-changer in the manufacturing industry, allowing for faster, more efficient, and cost-effective production of various panel products. These machines eliminate the need for multiple steps and human intervention, automating the entire process and significantly increasing productivity.A panel roll forming machine, also known as a roll former, is a specialized equipment used for shaping metal sheets into desired profiles by continuous bending operations. This technology has revolutionized the manufacturing processes of different industries, including construction, automotive, aerospace, and many others.The use of panel roll forming machines has surged in recent years due to their ability to produce panel products with high precision and quality. By employing highly precise control systems, these machines ensure consistent shaping and bending of metal sheets, resulting in flawless end products. This precision has made them a go-to solution for industries that require uniformity and accuracy in their panel products.One of the key advantages of panel roll forming machines is their high production speed. Unlike traditional manufacturing processes, which involve multiple steps and longer lead times, roll forming machines enable continuous production without interruptions. By feeding metal sheets through the machine, it produces a constant flow of shaped panels, vastly reducing production time and enhancing efficiency.Furthermore, panel roll forming machines offer outstanding versatility. They can be adjusted to produce a wide range of profiles, such as C and Z purlins, roof and wall panels, decking sheets, and more. This flexibility allows manufacturers to cater to diverse customer needs without investing in separate machines for each profile. By simply adjusting the settings, a single roll forming machine can handle different profiles, leading to significant cost savings.The advent of computer numerical control (CNC) technology has further enhanced the capabilities of panel roll forming machines. CNC systems allow for precise control over the entire manufacturing process, ensuring consistent quality and reducing the chances of errors. With the help of CNC, manufacturers can create complex panel designs, intricate patterns, and embossments more accurately than ever before.In addition to increased productivity and versatility, panel roll forming machines contribute to sustainability efforts. By eliminating the need for excessive scrap material and reducing energy consumption, these machines help minimize environmental impacts. Manufacturers can optimize material usage, resulting in less waste generation, while the efficient energy utilization of panel roll forming machines significantly reduces carbon footprints.Company Introduction: {}With its commitment to innovation and excellence, the company has emerged as a leading provider of panel roll forming machines. Its state-of-the-art manufacturing facilities and cutting-edge research and development team ensure the quality and reliability of their products.The company's panel roll forming machines are known for their robust construction and advanced features. Equipped with modern control systems, these machines guarantee precise shaping and bending operations, delivering panel products of superior quality.At the core of the company's philosophy is customer satisfaction. It offers comprehensive after-sales service, including installation, training, and technical support, ensuring the smooth integration of their machines into the customers' production lines. The company's dedication to providing outstanding customer experiences has earned them a strong reputation in the industry.In conclusion, panel roll forming machines have revolutionized the manufacturing industry by automating and streamlining the production of panel products. These machines offer high precision, versatility, and increased production speed, resulting in cost-effective and efficient manufacturing processes. With their commitment to excellence, the company {} has become a reliable provider of panel roll forming machines, helping businesses across various industries thrive.

High-Quality Metal Roofing Sheet Corrugated Tile Roll Forming Machine for Custom Applications" Our Wide Range of Roof Roll Forming Machines and Equipment for Efficient Roofing Solutions Enhance Your Roofing Projects with our Corrugated Tile Roof Roll Forming Machine Advanced Maquina De Hacer Calaminas: Perfectly Designed for Customized Metal Roofing Sheets Discover Our Impressive Line of Roofing Machinery: Curve Roof Machines, Shearing/Bending Machines, Light Keel Roll Formers, and More

: Efficiency, Durability, VersatilityA metal roof is one of the most durable and long-lasting roofing systems on the market today. It is highly resistant to weathering and UV damage, which makes it an excellent choice for homeowners who want to protect their homes from extreme weather conditions. For this reason, the demand for metal roofing systems has risen over the past few years.However, installing a metal roof can be a daunting task, especially for those who have no experience in roofing. The good news is that the Metal Corrugated Roof Roll Forming Machine is designed to make the installation of metal roofing systems easier and more efficient.EfficiencyThe Metal Corrugated Roof Roll Forming Machine is a game-changer when it comes to metal roof installation. It can speed up the installation process by producing custom-made metal roofing sheets quickly and accurately. Additionally, it is designed to process different types of roofing materials, including aluminum, copper, and steel, and can produce a variety of profiles, such as corrugated and trapezoidal.The machine is highly automated, which means that it requires minimal human intervention. This makes it very efficient, which can save contractors time and labor costs.DurabilityThe metal roofing sheets produced by the Metal Corrugated Roof Roll Forming Machine are highly durable. This is because the machine forms the sheets from raw materials, which eliminates the need for prefabricated sheets that are prone to damage during transportation and handling. Additionally, the thickness of the metal sheets can be customized to suit the specific requirements of the roofing project.VersatilityThe Metal Corrugated Roof Roll Forming Machine is a versatile machine that is suitable for different types of roofing projects. It can form metal sheets in different sizes and profiles, which makes it suitable for residential, commercial, and industrial roofing projects.The machine's versatility is further enhanced by the fact that it can form metal sheets with different coatings, such as galvanized, painted, and coated. This means that contractors can choose the best-coated metal roofing sheets that will enhance the project's durability and performance.ConclusionIn conclusion, the Metal Corrugated Roof Roll Forming Machine is a game-changer in the metal roofing industry. It provides efficiency, durability, and versatility, which are essential for any successful roofing project. Its advanced technology ensures that contractors can produce custom-made metal roofing sheets quickly and accurately, making metal roofing installation more efficient and cost-effective. Anyone looking to install a metal roofing system should consider using this machine to ensure a seamless roofing project.

High-quality Slitting Line for CR Metal Processing

Cr Slitting Line, a cutting-edge new technology for sheet metal processing, is set to revolutionize the manufacturing industry. With its advanced features and efficient operation, this innovative equipment is already making waves in the market.The Cr Slitting Line is designed and manufactured by a leading company in the field of metal processing equipment. This company has a strong reputation for delivering high-quality, reliable and cost-effective solutions to its customers. With years of experience and expertise in the industry, the company has continuously pushed the boundaries of innovation to meet the evolving needs of its clients.The introduction of the Cr Slitting Line is a significant milestone for the company and for the manufacturing industry as a whole. This state-of-the-art equipment is designed to streamline the process of slitting metal sheets, making it faster, more accurate and highly efficient. Its cutting-edge technology and precision engineering ensure superior performance and consistent results, setting a new benchmark in the industry.One of the key features of the Cr Slitting Line is its ability to handle a wide range of materials and thicknesses, making it a versatile solution for various applications. Whether it's stainless steel, aluminum, carbon steel or other types of metal, this equipment can efficiently process them with ease. Its flexibility and adaptability make it an ideal choice for manufacturers looking to expand their capabilities and improve their production efficiency.Furthermore, the Cr Slitting Line is equipped with advanced automation and control systems, ensuring optimal performance and ease of operation. Its intuitive interface and user-friendly controls allow operators to set up and run the equipment with minimal effort, reducing the risk of errors and increasing productivity. This makes it an ideal solution for both small-scale and large-scale manufacturers, offering a competitive advantage in today's fast-paced and competitive market.In addition to its cutting-edge technology, the Cr Slitting Line is also designed with practicality in mind. Its compact footprint and modular design make it easy to integrate into existing production lines, saving valuable floor space and minimizing installation time. Its robust construction and durable components ensure long-term reliability and low maintenance requirements, maximizing uptime and reducing operational costs for manufacturers.The introduction of the Cr Slitting Line has already garnered widespread attention and positive feedback from industry professionals and customers. Its performance and reliability have been put to the test in real-world applications, demonstrating its ability to deliver consistent and high-quality results. As a result, demand for this innovative equipment is on the rise, with manufacturers keen to take advantage of its benefits and stay ahead of the competition.Looking ahead, the company behind the Cr Slitting Line remains committed to pushing the boundaries of innovation and delivering cutting-edge solutions to its customers. Its ongoing investment in research and development, combined with its strong focus on customer satisfaction, positions it as a leading provider of metal processing equipment. As the manufacturing industry continues to evolve, the company is well-positioned to meet the changing needs of its clients and drive the industry forward with its advanced technologies.In conclusion, the introduction of the Cr Slitting Line marks a significant advancement in sheet metal processing technology. With its advanced features, versatile capabilities and exceptional performance, this innovative equipment is set to revolutionize the manufacturing industry. As demand for efficient and reliable metal processing solutions continues to grow, the company behind the Cr Slitting Line is poised to lead the way with its commitment to innovation and customer satisfaction.

Top Corrugated Roof Tile Barrel Sheet Profiling Machine for Your Home

Corrugated Roof Tile Barrel Sheet Profiling Machine Transforms Manufacturing ProcessIn an effort to revolutionize the manufacturing process for corrugated roof tile barrel sheet, a leading company in the industry, has introduced a state-of-the-art profiling machine that promises to significantly enhance efficiency and productivity.The newly introduced Corrugated Roof Tile Barrel Sheet Profiling Machine has been designed and developed to meet the growing demand for high-quality, durable corrugated roofing materials. The equipment is set to change the landscape of the industry, as it offers a range of advanced features and capabilities that are unmatched by any other similar machines currently available in the market.The profiling machine is equipped with cutting-edge technology that allows for precise and accurate shaping of the corrugated roof tile barrel sheet. This ensures that the end product is of the highest quality, with uniform dimensions and consistent corrugation patterns. Additionally, the machine has the ability to produce a large volume of roofing materials in a relatively short period of time, thus streamlining the manufacturing process and increasing overall output.One of the most notable features of the Corrugated Roof Tile Barrel Sheet Profiling Machine is its versatility. The machine has the ability to produce a wide range of corrugated roofing materials, including different sizes, shapes, and designs, catering to the diverse needs of customers. This flexibility sets it apart from traditional profiling machines, as it eliminates the need for multiple machines to produce different types of corrugated roof tile barrel sheet.Furthermore, the company has emphasized its commitment to sustainability with the introduction of this new machine. The profiling machine is designed to minimize waste and optimize material usage, thereby reducing the environmental impact of the manufacturing process. This aligns with the company's ethos of responsible and eco-friendly production practices.In addition to its advanced technological capabilities, the Corrugated Roof Tile Barrel Sheet Profiling Machine is also supported by a team of highly skilled engineers and technicians who provide comprehensive training and ongoing technical support to ensure seamless integration and operation. This ensures that customers can maximize the potential of the machine and achieve the best possible results.With the introduction of this groundbreaking machine, the company is poised to solidify its position as an industry leader in the manufacturing of corrugated roof tile barrel sheet. The machine represents a significant investment in research and development, and a commitment to providing customers with the most innovative and efficient solutions for their roofing material needs.The Corrugated Roof Tile Barrel Sheet Profiling Machine is set to be a game-changer in the industry, offering unmatched capabilities, precision, and efficiency. It is poised to revolutionize the manufacturing process for corrugated roofing materials and provide customers with a superior quality product that meets their exact specifications.The company remains dedicated to delivering excellence and innovation in all of its products and services, and the introduction of the Corrugated Roof Tile Barrel Sheet Profiling Machine only serves to further cement its reputation as a trailblazer in the industry. As demand for high-quality, durable corrugated roof tile barrel sheet continues to rise, this new profiling machine is positioned to meet and exceed the expectations of customers, setting new standards for the industry as a whole.