High-Quality Glazed Tile Profile Corrugating Machine: Everything You Need to Know

By:Admin

The roofing industry is witnessing a revolutionary transformation with the introduction of the state-of-the-art Color Steel Glazed Tile Profile Corrugating Machine. This cutting-edge technology is set to redefine the standards of roofing, bringing in a new era of efficiency, precision, and high-quality production.

The Color Steel Glazed Tile Profile Corrugating Machine, developed by a leading manufacturing company, is equipped with advanced features that make it stand out in the market. With its high-speed performance, accurate profile shaping, and superior durability, this machine is set to become a game-changer in the roofing industry.

This groundbreaking technology has been specifically designed to meet the growing demand for high-quality roofing materials that not only provide protection but also add an aesthetic appeal to buildings. The Color Steel Glazed Tile Profile Corrugating Machine is capable of producing a wide range of glazed tiles with different profiles, colors, and finishes, offering versatility and flexibility to meet diverse customer requirements.

The company behind this innovative machine has a rich history of expertise and experience in the manufacturing industry. With a strong focus on research and development, they have a track record of introducing cutting-edge technologies that have redefined various sectors. Their commitment to quality and innovation has earned them a reputation as a trusted and reliable partner in the industry.

The Color Steel Glazed Tile Profile Corrugating Machine is a testament to the company's dedication to delivering advanced solutions that cater to the evolving needs of the market. By integrating the latest manufacturing techniques and technologies, they have been able to create a product that not only meets industry standards but also sets new benchmarks for excellence.

One of the key highlights of this machine is its efficiency in production. With its high-speed performance and precision engineering, it is capable of delivering large volumes of high-quality glazed tiles in a short span of time. This not only increases productivity for manufacturers but also ensures timely delivery to meet customer demands.

Moreover, the Color Steel Glazed Tile Profile Corrugating Machine is designed to prioritize durability and longevity. Built with high-quality materials and components, it is capable of withstanding the rigors of continuous operation, making it a reliable investment for manufacturers looking for long-term sustainability.

In addition to its performance and durability, the machine also offers ease of operation and maintenance. It is designed with user-friendly features that make it convenient for operators to set up, monitor, and maintain, reducing downtime and optimizing overall efficiency.

The introduction of the Color Steel Glazed Tile Profile Corrugating Machine is expected to have a significant impact on the roofing industry. Its ability to produce high-quality glazed tiles with precision and efficiency is set to transform the way roofing materials are manufactured, setting new standards for quality and performance.

As the demand for superior roofing solutions continues to grow, the Color Steel Glazed Tile Profile Corrugating Machine is poised to become a sought-after technology for manufacturers striving to meet the evolving needs of the market. With its unparalleled capabilities and advanced features, it is set to lead the way in shaping the future of the roofing industry.

Company News & Blog

High-Quality Trapezoid Profile Metal Roofing Sheet Machine: A Complete Guide

Metal Roofing Sheet Trapezoid Profile Machine Revolutionizes Roofing IndustryMetal roofing has long been a popular choice for commercial and industrial buildings due to its durability and longevity. However, the process of manufacturing metal roofing sheets has typically been labor-intensive and time-consuming. But that is all about to change, thanks to the innovative Metal Roofing Sheet Trapezoid Profile Machine developed by {Company}.This cutting-edge machine is set to revolutionize the roofing industry with its efficiency, accuracy, and speed. The trapezoid profile machine is capable of producing high-quality metal roofing sheets with a trapezoid shape in a fraction of the time it takes using traditional methods. This is a game-changer for roofing companies who are looking to increase their productivity and reduce production costs.One of the key features of the Metal Roofing Sheet Trapezoid Profile Machine is its versatility. It can accommodate a wide range of materials, including galvanized steel, aluminum, and copper, allowing for the production of a variety of roofing solutions to meet the specific needs of the customers. Additionally, the machine is fully automated, requiring minimal human intervention, which reduces the chance of errors and ensures consistent quality in every sheet produced.The trapezoid profile machine also boasts a high level of precision and accuracy, thanks to its advanced technology and state-of-the-art manufacturing process. This means that the roofing sheets produced are of uniform dimensions and have perfectly formed trapezoid profiles, ensuring a tight fit and a seamless finish when installed on a building. Furthermore, the machine is capable of producing roofing sheets in various lengths, allowing for customization to suit the requirements of different construction projects.With the Metal Roofing Sheet Trapezoid Profile Machine, {Company} is reinforcing its position as a leader in the roofing industry. This machine is a testament to the company's commitment to innovation and its dedication to providing cutting-edge solutions to its customers. By investing in this technology, {Company} is not only improving its own production processes but also supporting the growth and success of the companies that rely on its high-quality roofing products.In addition to the Metal Roofing Sheet Trapezoid Profile Machine, {Company} offers a comprehensive range of roofing solutions to meet the diverse needs of its customers. Whether it's for residential, commercial, or industrial applications, {Company} has a wide selection of metal roofing sheets, accessories, and custom fabrication services to ensure that every project is completed to the highest standard.{Company} has built a strong reputation for delivering superior quality products and exceptional customer service. The company's team of experts and technicians are highly skilled and knowledgeable in all aspects of roofing, and they are committed to providing valuable guidance and support to customers every step of the way. With a focus on innovation, reliability, and customer satisfaction, {Company} has become a trusted partner for businesses and contractors in the roofing industry.In conclusion, the Metal Roofing Sheet Trapezoid Profile Machine is set to bring about a significant transformation in the roofing industry. Its speed, efficiency, and precision will enable roofing companies to streamline their production processes and achieve higher levels of productivity. With a commitment to quality and innovation, {Company} continues to lead the way in providing the roofing industry with state-of-the-art solutions that meet the evolving needs of the market.

High-Quality Metal Roof Panel Roll Forming Machine

Metal Roof Panel Roll Forming Machine Revolutionizes the Roofing IndustryThe roofing industry has witnessed a revolution in recent years with the introduction of the cutting-edge Metal Roof Panel Roll Forming Machine by [Company Name]. This innovative machine has completely transformed the way metal roof panels are manufactured, offering numerous benefits in terms of efficiency, precision, and cost-effectiveness.With over [number of years] years of experience in the metal forming industry, [Company Name] has established itself as a leading provider of advanced roll forming solutions. The Metal Roof Panel Roll Forming Machine is the latest addition to their impressive lineup of machinery, and it has quickly become a game-changer in the roofing sector.Traditionally, the process of manufacturing metal roof panels involved multiple steps and considerable manual labor. However, the Metal Roof Panel Roll Forming Machine has streamlined this process, significantly reducing production time and labor costs. By automating the roll forming process, the machine can produce high-quality metal roof panels with unmatched precision and consistency.One of the key advantages of the Metal Roof Panel Roll Forming Machine is its versatility. It is capable of producing a wide range of metal roof panel profiles, catering to the diverse needs of the roofing industry. Whether it's standing seam panels, corrugated panels, or custom profiles, this machine can handle them all with ease.Moreover, the machine is equipped with advanced controls and monitoring systems that ensure optimal performance and product quality. With precise measurements and adjustments, the Metal Roof Panel Roll Forming Machine can consistently produce panels that meet the highest industry standards.In addition to its efficiency and precision, the machine also offers significant cost savings for manufacturers. The reduced labor and material waste, combined with the increased production capacity, make it a cost-effective investment for companies in the roofing industry. By maximizing productivity and minimizing operational expenses, the Metal Roof Panel Roll Forming Machine helps businesses improve their bottom line.Furthermore, the machine's durable construction and reliable performance make it a long-term asset for any manufacturing facility. With proper maintenance and support from [Company Name]'s experienced team, the Metal Roof Panel Roll Forming Machine is built to withstand the rigors of heavy-duty production and deliver consistent results for years to come.The introduction of the Metal Roof Panel Roll Forming Machine has been met with widespread acclaim from industry professionals. Many manufacturers have adopted this advanced technology to enhance their production capabilities and stay ahead of the competition. The machine has empowered roofing companies to meet the growing demand for high-quality metal roof panels while maintaining a competitive edge in the market.In conclusion, the Metal Roof Panel Roll Forming Machine by [Company Name] has revolutionized the roofing industry by offering a combination of efficiency, precision, and cost-effectiveness. With its versatile capabilities and advanced features, this innovative machine has set a new standard for metal roof panel manufacturing. As the roofing industry continues to evolve, the Metal Roof Panel Roll Forming Machine stands as a testament to [Company Name]'s commitment to pushing the boundaries of roll forming technology and empowering businesses to thrive in a competitive market.

Efficient Corrugated Iron Sheet Making Machine: Robust and High-Quality Production Capabilities

Corrugated Iron Sheet Making Machine Revolutionizing the Construction IndustryThe construction industry has been growing rapidly over the years, with a constant need for innovative technologies and machinery to enhance efficiency and productivity. Among the many innovations, the Corrugated Iron Sheet Making Machine (name removed) has emerged as a game-changer, revolutionizing how corrugated iron sheets are manufactured.With the global demand for corrugated iron sheets on the rise, this advanced machine offers a streamlined and efficient solution for manufacturers. By automating the production process, it not only eliminates the labor-intensive manual work but also significantly reduces the time required for sheet production.The Corrugated Iron Sheet Making Machine features cutting-edge technology and a high level of precision, ensuring the production of top-quality iron sheets with consistent dimensions and ridges. This not only enhances the overall performance of the sheets but also offers improved durability and weather resistance.One of the key advantages of this machine is its versatility. It can produce corrugated iron sheets in various sizes, thicknesses, and profiles. This flexibility caters to the diverse needs of the construction industry, allowing manufacturers to meet specific requirements for different applications. Whether it's for roofing, siding, or fencing, the Corrugated Iron Sheet Making Machine can deliver the desired outcome with ease.Moreover, the machine incorporates advanced safety features to ensure the well-being of workers. With automated controls and protective measures, it minimizes the risk of accidents, making it a safe and reliable option for factories and manufacturing units. This not only enhances worker safety but also boosts overall operational efficiency by minimizing downtime.In addition to its technical capabilities, the Corrugated Iron Sheet Making Machine is eco-friendly. It is designed to optimize energy consumption and minimize waste production. By using sustainable manufacturing practices, it aligns with the growing global trend of eco-conscious construction. This aspect not only highlights the machine's efficiency but also positions it as a responsible choice in an industry striving for sustainability.Company Introduction:As a key player in the construction industry, our company has been at the forefront of providing innovative solutions to meet the evolving needs of builders and contractors. With a strong commitment to quality, efficiency, and sustainability, we have established ourselves as a trusted partner for numerous construction projects worldwide.Our team of engineers and industry experts has invested years of research and development to perfect the Corrugated Iron Sheet Making Machine. By combining cutting-edge technology with extensive market knowledge, we have successfully developed a machine that exceeds industry standards and offers unparalleled performance.Our company's mission is to revolutionize the way corrugated iron sheets are manufactured, making the process more efficient, cost-effective, and eco-friendly. We believe that the Corrugated Iron Sheet Making Machine will not only empower manufacturers but also contribute to the sustainable growth of the construction industry.With a focus on customer satisfaction, our dedicated sales and after-sales support teams are always ready to assist clients at every step of the process. From initial consultations to installation, training, and maintenance, we are committed to ensuring a seamless experience for our valued customers.In conclusion, the Corrugated Iron Sheet Making Machine is a significant innovation that is transforming the construction industry. Its technological advancements, versatility, safety features, and eco-friendly approach make it a perfect solution for manufacturers looking to improve productivity while adhering to sustainable practices. With our company's expertise and commitment, we are proud to introduce this groundbreaking machine to the market and cater to the evolving needs of the construction industry.

High-Quality Portable Roof Panel Rollforming Machine Available for Purchase

Portable Roof Panel Rollforming Machine Allows for Efficient and Fast On-site Production [Company Name] is proud to introduce its latest innovation in rollforming technology – the Portable Roof Panel Rollforming Machine. This cutting-edge equipment is designed to provide the construction industry with a convenient and efficient solution for on-site production of high-quality roof panels.The Portable Roof Panel Rollforming Machine is a game-changer for contractors and builders who require a reliable and cost-effective way to produce custom roof panels at the job site. With its compact and portable design, this machine can be easily transported to any location, allowing for seamless on-site fabrication without the need for expensive and time-consuming off-site manufacturing.One of the key features of the Portable Roof Panel Rollforming Machine is its versatility and customization capabilities. Contractors can easily adjust the machine to produce roof panels of various lengths and widths, making it ideal for projects that require unique and complex roofing designs. This flexibility eliminates the need for pre-fabricated panels, saving both time and money for construction companies.In addition to its customization capabilities, the Portable Roof Panel Rollforming Machine is also known for its speed and efficiency. With its advanced rollforming technology, this machine can produce high-quality roof panels at a rate that far exceeds traditional manufacturing methods. This allows for faster project completion and reduced labor costs, making it an invaluable asset for any construction team.Furthermore, the Portable Roof Panel Rollforming Machine is designed with durability and reliability in mind. Constructed with high-quality materials and precision engineering, this machine is built to withstand the rigors of on-site production, ensuring consistent and reliable performance even in the most demanding work environments.[Company Name] has a proven track record of delivering innovative solutions to the construction industry, and the Portable Roof Panel Rollforming Machine is no exception. With its commitment to quality and customer satisfaction, [Company Name] remains at the forefront of rollforming technology, providing industry-leading equipment and support to its valued clients.The Portable Roof Panel Rollforming Machine is just one example of [Company Name]'s dedication to developing cutting-edge solutions that empower construction professionals to achieve greater efficiency and productivity. With this latest addition to its product lineup, [Company Name] continues to set the standard for rollforming technology, solidifying its position as a trusted partner for the construction industry.In conclusion, the Portable Roof Panel Rollforming Machine is a revolutionary tool that offers unrivaled convenience, efficiency, and customization capabilities for on-site production of high-quality roof panels. With its portable design, speed, and durability, this machine is set to transform the way construction teams approach roof panel fabrication, bringing unprecedented value to projects of all sizes. As [Company Name] continues to drive innovation in rollforming technology, the Portable Roof Panel Rollforming Machine stands as a testament to its unwavering commitment to excellence and customer satisfaction.

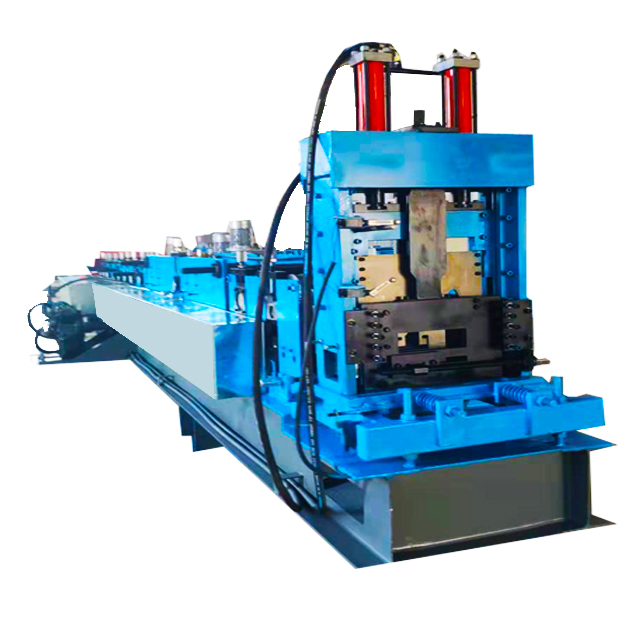

High Speed Steel Roof Truss C Z Purline Making Machinery

High Speed Steel Roof Truss C Z Purline Making Machinery Unveiled by Renowned CompanyThe construction industry is constantly evolving, and with the advancement of technology, new and innovative machinery is constantly being introduced to make the process more efficient and effective. [Company Name], a leading manufacturer of construction machinery, has unveiled its latest offering – the High Speed Steel Roof Truss C Z Purline Making Machinery. This cutting-edge equipment is set to revolutionize the production of roof trusses and purlins, making the process faster, more precise, and more cost-effective.The High Speed Steel Roof Truss C Z Purline Making Machinery is the result of years of research and development by [Company Name]. The company has a strong track record of delivering high-quality construction machinery, and this latest offering is no exception. With its advanced technology and innovative design, this machinery is expected to set a new standard in the industry.One of the key features of the High Speed Steel Roof Truss C Z Purline Making Machinery is its high speed production capability. Equipped with state-of-the-art components and a powerful motor, this machinery is able to produce roof trusses and purlins at a significantly faster rate than traditional methods. This not only increases productivity but also allows for shorter lead times on construction projects, ultimately saving time and money for builders and contractors.In addition to its speed, the High Speed Steel Roof Truss C Z Purline Making Machinery also boasts a high level of precision. The machinery is designed to create trusses and purlins with exact measurements, ensuring a perfect fit and optimal structural integrity. This level of precision is crucial in construction, where even the smallest deviation can lead to significant issues down the line. With this machinery, builders can have confidence in the quality and accuracy of the roof trusses and purlins produced.Furthermore, the High Speed Steel Roof Truss C Z Purline Making Machinery is designed with user-friendliness in mind. It is equipped with intuitive controls and a user-friendly interface, making it easy for operators to set up and operate the machinery. This not only reduces the learning curve for new operators but also minimizes the risk of errors during production.[Company Name] is known for its commitment to quality and reliability, and the High Speed Steel Roof Truss C Z Purline Making Machinery is no exception. The machinery is built to last, with durable materials and robust construction that can withstand the rigors of the construction industry. This ensures that builders and contractors can rely on the machinery for consistent performance and longevity.With the unveiling of the High Speed Steel Roof Truss C Z Purline Making Machinery, [Company Name] is once again demonstrating its leadership in the construction machinery industry. The company is dedicated to continuously pushing the boundaries of innovation, and this latest offering is a testament to that commitment. Builders and contractors can now look forward to a more efficient and effective production process for roof trusses and purlins, thanks to this advanced machinery.In conclusion, the High Speed Steel Roof Truss C Z Purline Making Machinery by [Company Name] is a game-changer for the construction industry. With its high speed production, precision, user-friendliness, and durability, this machinery is set to redefine the production of roof trusses and purlins. Builders and contractors can expect a more efficient and cost-effective production process, ultimately leading to enhanced productivity and quality in construction projects. [Company Name] continues to lead the way in construction machinery, and this latest offering is a clear example of their commitment to innovation and excellence.

Essential Roller for Corrugated Roof Installation and Maintenance

Roller For Corrugated Roof, a leading manufacturer of construction equipment, has recently introduced a new product that is set to revolutionize the roofing industry. The company, known for its innovation and dedication to providing high-quality products, is excited to unveil their latest offering that promises to make roof installation and maintenance easier and more efficient than ever before.The new product, named the Corrugated Roof Roller, is designed to be used in the installation and maintenance of corrugated roofing materials. The roller is specifically engineered to provide a smooth and even application of adhesive and sealant, ensuring a secure and long-lasting bond between the roofing material and the underlying structure. This innovative tool is set to streamline the roofing process, saving time and labor costs for construction companies and contractors."When developing the Corrugated Roof Roller, our main goal was to address the common challenges and issues faced by roofing professionals during the installation and maintenance of corrugated roofing materials," said a spokesperson for Roller For Corrugated Roof. "We are confident that this new product will significantly improve the efficiency and quality of roofing projects, ultimately benefiting both the businesses and homeowners who rely on durable and weather-resistant roofing solutions."The Corrugated Roof Roller features a durable and lightweight design, making it easy to handle and maneuver on a variety of roofing surfaces. Its ergonomic handle and smooth-rolling mechanism ensure a comfortable and precise application, even in hard-to-reach areas and tight spaces. Additionally, the roller is compatible with a wide range of adhesives and sealants commonly used in corrugated roofing applications, making it a versatile and practical tool for professionals in the construction and roofing industry.In addition to its practical benefits, the Corrugated Roof Roller is also designed to promote safety and accuracy in roofing projects. The smooth and consistent application of adhesives and sealants minimizes the risk of leaks, water damage, and other structural issues that can result from improper installation techniques. By investing in this innovative tool, roofing professionals can enhance the overall quality and durability of their work, earning the trust and satisfaction of their clients.Roller For Corrugated Roof takes pride in its commitment to excellence and customer satisfaction, and the introduction of the Corrugated Roof Roller is a testament to the company's dedication to innovation and progress in the construction industry. With a focus on reliability, performance, and user-friendly design, the company aims to provide practical solutions that address the evolving needs of construction professionals and contribute to the advancement of the industry as a whole.As the demand for durable and weather-resistant roofing solutions continues to grow, Roller For Corrugated Roof remains at the forefront of delivering cutting-edge products that not only meet industry standards but also exceed the expectations of its customers. The Corrugated Roof Roller is just one example of the company's ongoing pursuit of excellence, and it represents a significant step forward in the quest for efficient and reliable roofing solutions.With its innovative design, practical benefits, and commitment to quality, the Corrugated Roof Roller is poised to become an essential tool for construction companies and contractors seeking to elevate the standard of their roofing projects. Roller For Corrugated Roof looks forward to the positive impact that this revolutionary product will have on the industry, and they are eager to see the positive response from roofing professionals who prioritize performance, efficiency, and long-term durability in their work.

High-quality Glazed Tile Roll Forming Machine for Color Steel - Complete Guide

Color Steel Glazed Tile Roll Forming Machine Revolutionizes the Roofing Industry[City, State] - With the continuous advancement of technology, the roofing industry is experiencing a significant transformation. The introduction of the Color Steel Glazed Tile Roll Forming Machine has revolutionized the way roofing materials are manufactured, making the process faster, more efficient, and more cost-effective. This innovative machine, developed by a leading machinery manufacturer, has caught the attention of the construction and roofing industries worldwide.The Color Steel Glazed Tile Roll Forming Machine is designed to produce high-quality glazed tiles made of color steel, which are widely used for roofing and cladding applications. It is capable of forming and cutting the glazed tiles with high precision, ensuring consistency and uniformity in the finished product. This state-of-the-art machine has the ability to produce a wide range of glazed tile profiles, giving manufacturers the flexibility to meet diverse customer demands.One of the key features of this roll forming machine is its advanced control system, which allows for easy operation and monitoring of the production process. With user-friendly controls and automation capabilities, the machine enables manufacturers to maximize productivity and minimize material waste. In addition, the machine is equipped with safety features to ensure the protection of workers and prevent accidents in the workplace.The company behind this groundbreaking innovation, [Company Name], is a renowned manufacturer of roll forming machines and other industrial equipment. With years of experience and expertise in the field, the company has established a reputation for delivering high-quality, reliable, and innovative machinery solutions to its customers. The Color Steel Glazed Tile Roll Forming Machine is a testament to the company's commitment to advancing the industry through technological innovation.In addition to its cutting-edge technology, the company also provides comprehensive services to support its customers, including installation, training, and after-sales support. This ensures that manufacturers can fully optimize the performance of the roll forming machine and achieve the best possible results in their production processes. With a global presence and a dedicated team of professionals, the company is capable of meeting the needs of customers around the world.The introduction of the Color Steel Glazed Tile Roll Forming Machine has already made a significant impact on the roofing industry. Manufacturers who have adopted this technology have reported improvements in their production efficiency, product quality, and overall business performance. The machine's ability to produce high-quality glazed tiles at a faster pace has allowed manufacturers to meet growing market demands and stay ahead of the competition.Furthermore, the use of color steel for roofing and cladding applications offers numerous benefits, including durability, weather resistance, and aesthetic appeal. With the Color Steel Glazed Tile Roll Forming Machine, manufacturers can now produce these high-performance materials with greater ease and efficiency, meeting the needs of customers in various sectors such as residential, commercial, and industrial construction.As the roofing industry continues to evolve, technological advancements like the Color Steel Glazed Tile Roll Forming Machine will play a crucial role in shaping its future. With its proven capabilities and the backing of a reputable manufacturer, this innovative machine is set to become an indispensable tool for manufacturers looking to stay competitive in the fast-paced and demanding market.As the demand for high-quality roofing materials continues to rise, manufacturers will undoubtedly turn to advanced solutions like the Color Steel Glazed Tile Roll Forming Machine to meet these demands. With its potential to drive efficiency, productivity, and product innovation, this machine is poised to make a lasting impact on the roofing industry for years to come.

Cable Tray Pultrusion Machine: Advancements in FRP Technology Shake Up the Industry

Title: Cutting-Edge FRP Cable Tray Pultrusion Machine Revolutionizes the IndustryIntroduction:Pushing the boundaries of innovation, a leading company in the manufacturing sector has recently unveiled its latest breakthrough - an advanced FRP (Fiber Reinforced Plastic) Cable Tray Pultrusion Machine. This cutting-edge technology showcases the company's commitment to providing state-of-the-art machinery solutions for the cable management industry. With a focus on enhanced productivity, efficiency, and durability, this new machine is set to revolutionize the sector in numerous ways.Paragraph 1:The FRP Cable Tray Pultrusion Machine is a result of extensive research and development, combined with the company's years of experience in the field. Pultrusion is a continuous manufacturing process that produces fiber-reinforced polymer composites with superior mechanical properties. By utilizing this innovative approach, the machine is designed to create cable trays with exceptional strength, rigidity, and resistance to environmental factors such as corrosion and fire.Paragraph 2:Implementing this advanced equipment brings forth a multitude of benefits for industries relying on cable management systems. Firstly, the FRP Cable Tray Pultrusion Machine guarantees high productivity due to its continuous and automated manufacturing process. This allows for the production of cable trays at a much faster rate compared to conventional methods, resulting in significant time and cost savings.Paragraph 3:Furthermore, the FRP Cable Tray Pultrusion Machine ensures precise and uniform product dimensions. By controlling variables such as resin content, fiber density, and temperature throughout the manufacturing process, the machine delivers cable trays with consistent quality and reliability. This feature eliminates the need for excess materials or rework, leading to further cost reduction and waste minimization.Paragraph 4:One of the most significant advantages of the FRP Cable Tray Pultrusion Machine is its durability and resistance to external influences. Traditional metal cable trays are prone to rust, corrosion, and degradation over time, affecting their performance and longevity. However, the implementation of FRP materials provides excellent resistance to corrosive substances, moisture, UV radiation, and extreme temperatures. This makes the cable trays suitable for both outdoor and indoor applications, including industrial facilities, power plants, transportation infrastructure, and more.Paragraph 5:Moreover, the FRP Cable Tray Pultrusion Machine promotes environmental sustainability by utilizing lightweight, recyclable, and non-toxic materials. The reduction in weight compared to traditional metal cable trays significantly reduces transportation costs and energy consumption during installation. Additionally, the longevity of FRP cable trays minimizes the need for replacements, preventing unnecessary waste generation.Paragraph 6:The company's commitment to customer satisfaction is reflected in the FRP Cable Tray Pultrusion Machine's user-friendly features. With its intuitive control panel and automated operation, the machine ensures ease of use and minimal training requirements for operators. This not only improves overall efficiency but also reduces human errors during the production process, leading to enhanced product quality.Conclusion:In conclusion, the introduction of the FRP Cable Tray Pultrusion Machine marks a significant milestone in the cable management industry. Through its advanced technology, this innovative machinery brings improved productivity, cost-effectiveness, and durability to cable tray manufacturing. With its ability to withstand diverse environmental conditions and promote sustainability, the FRP Cable Tray Pultrusion Machine is set to redefine the standard for cable management systems across various sectors.

High-quality Roll Forming Machine Available on Alibaba - Find the Best Deals Now

Roll Forming Machine Becomes the Latest Technology Trend in the Construction IndustryIn recent years, the construction industry has seen a significant shift towards using advanced technology to improve efficiency and productivity. One such technology that has gained popularity is the roll forming machine, a versatile and powerful tool that has revolutionized the way construction materials are produced.The roll forming machine, which is a continuous bending operation in which a long strip of sheet metal is passed through sets of rolls mounted on consecutive stands, can be used to produce a wide variety of products, including steel studs, roofing panels, and metal decking. This technology has proven to be highly efficient and cost-effective, making it an attractive option for construction companies looking to streamline their operations.One company that has been at the forefront of this trend is {}. As a leading manufacturer of roll forming machines, they have been supplying their products to construction companies all over the world. Their roll forming machines are known for their high quality, reliability, and advanced features, making them the go-to choice for many in the industry.With the rise of e-commerce platforms, such as Alibaba, it has become even easier for construction companies to access and purchase the latest roll forming machines. Alibaba, a global online platform that connects buyers and sellers, has become a popular choice for companies looking to source industrial equipment, including roll forming machines. This has helped to make the technology more accessible to a wider range of businesses, further driving its adoption in the industry.One of the key advantages of using a roll forming machine is its ability to produce high volumes of products with minimal waste. The continuous bending process allows for precise and consistent shaping of the material, resulting in products that meet tight tolerances and specifications. This level of precision is essential in the construction industry, where the quality of materials directly impacts the safety and integrity of the structures being built.Another benefit of using a roll forming machine is its versatility. By simply changing the tooling, the same machine can be used to produce a variety of different products, making it a cost-effective solution for companies that need to manufacture multiple types of construction materials. This flexibility has made roll forming machines an indispensable tool for construction companies looking to diversify their product offerings.In addition to their efficiency and versatility, modern roll forming machines also come equipped with advanced automation and control systems. This allows for seamless integration into a company's existing production processes, reducing the need for manual labor and minimizing the risk of errors. This level of automation not only improves efficiency but also enhances safety in the workplace.As the construction industry continues to embrace advanced technology, the demand for roll forming machines is expected to grow. This presents a significant opportunity for companies like {} to expand their reach and offer their innovative solutions to a global market. With the support of platforms like Alibaba, the accessibility of these machines will continue to increase, further driving their adoption in the industry.In conclusion, the rise of roll forming machines marks a significant shift in the construction industry towards advanced technology. Their efficiency, versatility, and advanced features make them an attractive option for companies looking to streamline their production processes and improve their competitiveness. With the support of platforms like Alibaba, the accessibility of these machines will continue to increase, driving their adoption in the industry and shaping the future of construction.

The Future of Coil Fed Punching Cutting Machines Market: A Comprehensive Market Analysis

Coil-fed punching and cutting machines have witnessed significant growth in recent years, driven by the demand for efficient and automated manufacturing processes. These machines are widely used in various industries, including automotive, aerospace, electronics, and construction. With the increasing need for precision and productivity in these sectors, the coil-fed punching and cutting machines market is expected to experience further innovation and growth.A recent market research report by Persistence Market Research provides insights into the coil-fed punching and cutting machines market. The report highlights the market dynamics, growth factors, challenges, and trends shaping the industry. It presents a comprehensive analysis of the market and its future prospects.The coil-fed punching and cutting machines market is witnessing constant innovation in terms of technology and product development. Manufacturers are focusing on improving the efficiency and accuracy of these machines to meet the growing demands of various industries. Integration of advanced features like computer numerical control (CNC) systems, high-speed punching and cutting capabilities, and robotic automation are some of the latest developments in this market.One of the key drivers for the coil-fed punching and cutting machines market is the increasing demand for lightweight materials in the automotive and aerospace industries. With the need for fuel efficiency and reduced emissions, manufacturers are using advanced materials like aluminum and composites, which require precise and efficient cutting and punching processes. Coil-fed punching and cutting machines offer the flexibility and speed required to handle such materials.Another factor driving the growth of this market is the growing adoption of Industry 4.0 technologies. The integration of IoT (Internet of Things) and smart automation in manufacturing processes has revolutionized the industry. Coil-fed punching and cutting machines equipped with IoT capabilities can communicate with other machines and systems, enabling seamless production flow and real-time monitoring. This reduces downtime, improves efficiency, and enhances overall productivity.However, the coil-fed punching and cutting machines market also faces certain challenges. High initial investment costs, skilled labor requirements, and the need for regular maintenance and calibration are some of the factors that can hinder market growth. Additionally, the market is highly competitive, with several players offering similar products. This makes it crucial for manufacturers to differentiate themselves through innovative features and superior customer service.In terms of regional analysis, Asia Pacific is expected to dominate the coil-fed punching and cutting machines market. The rapid industrialization in countries like China, India, and Japan, coupled with the presence of key automotive and electronics manufacturers, creates a favorable environment for market growth. Moreover, the increased focus on automation and the adoption of advanced technologies in these industries are driving the demand for coil-fed punching and cutting machines in the region.In conclusion, the coil-fed punching and cutting machines market is predicted to witness significant growth in the coming years. Continuous innovation in technology, the adoption of Industry 4.0 solutions, and the demand for lightweight materials fuel the market's expansion. However, challenges like high costs and intense competition need to be addressed for sustained growth. Manufacturers must invest in research and development to enhance machine capabilities and provide efficient solutions to cater to the evolving needs of industries worldwide.