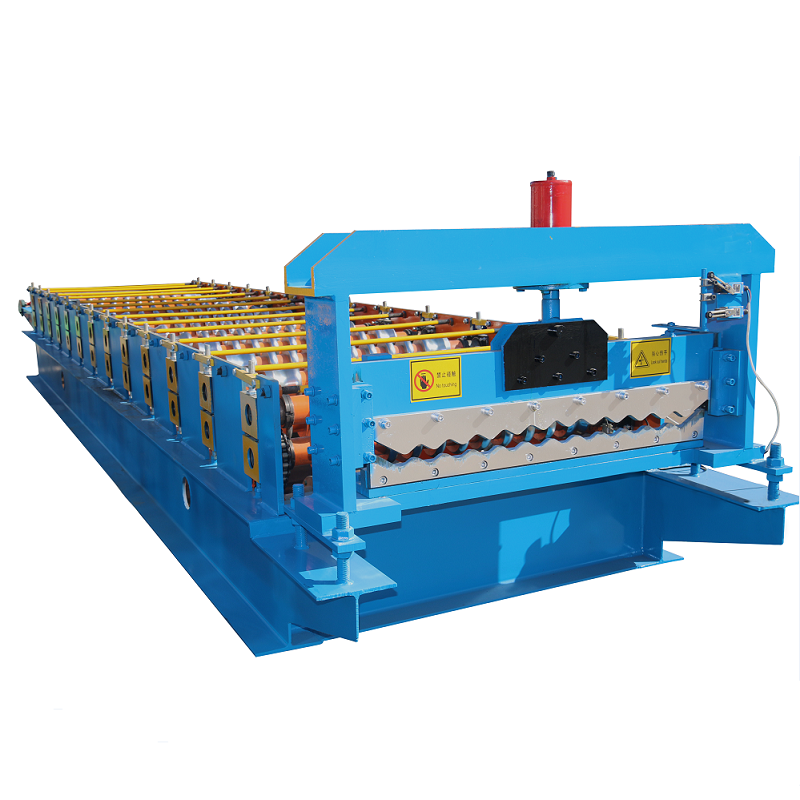

High-Quality Metal Roof Forming Machine for Sale - Get a Quote Now

By:Admin

Metal Roof Forming Machine Market is forecast to reach $49.29 million by 2026, after growing at a CAGR of 3.4% during 2021-2026. Metal roof forming machines are used in the construction industry to produce metal roofing materials. These machines are designed to create different types of metal roofing panels, such as standing seam, corrugated, and ribbed panels, with varying widths, lengths, and depths.

The growing demand for metal roofing in residential and commercial construction projects is a key factor driving the growth of the metal roof forming machine market. Metal roofs are gaining popularity due to their durability, energy efficiency, and low maintenance requirements. In addition, metal roofing materials are available in a wide range of colors and designs, making them a versatile choice for architectural applications.

The construction industry's increasing focus on sustainable building materials is also contributing to the growing adoption of metal roofing. Metal roofs are recyclable and have a longer lifespan compared to traditional asphalt shingles, making them an environmentally friendly choice for building owners. As a result, contractors and builders are investing in metal roof forming machines to meet the demand for high-quality metal roofing materials.

The metal roof forming machine market is highly competitive, with several key players competing for market share. These companies are investing in research and development activities to introduce advanced metal roof forming machines that offer enhanced efficiency and productivity. The market is also witnessing a trend toward the integration of automation and digital technologies in metal roof forming machines, enabling manufacturers to optimize production processes and reduce operational costs.

One of the leading players in the metal roof forming machine market is {Company Name}. Established in 1998, {Company Name} is a renowned manufacturer of metal forming machinery, specializing in the design and production of advanced metal roof forming machines. The company's product portfolio includes a wide range of metal roof forming machines, such as standing seam roll formers, corrugated panel roll formers, and ribbed panel roll formers, designed to meet the diverse requirements of the construction industry.

{Company Name} is known for its commitment to quality and innovation, offering metal roof forming machines that are built to high precision and performance standards. The company's engineering team continuously strives to incorporate the latest technological advancements in its machines, ensuring maximum productivity and reliability for its customers. With a strong focus on customer satisfaction, {Company Name} provides comprehensive after-sales support and technical assistance to help customers optimize the performance of their metal roof forming machines.

In addition to its commitment to excellence in product design and manufacturing, {Company Name} is dedicated to sustainability and environmental responsibility. The company's metal roof forming machines are designed to minimize waste and energy consumption, aligning with the industry's emphasis on sustainable construction practices. {Company Name} also emphasizes the importance of safety in its machine designs, implementing robust safety features to protect operators and workers in the production environment.

As a market leader in the metal roof forming machine industry, {Company Name} is well-positioned to capitalize on the growing demand for metal roofing materials. The company's focus on continuous innovation and customer-centric approach has enabled it to establish a strong presence in the global market, serving a diverse customer base across various regions. With a proven track record of delivering high-quality and reliable metal roof forming machines, {Company Name} is poised for continued growth and success in the construction industry.

In conclusion, the metal roof forming machine market is witnessing steady growth, driven by the increasing demand for metal roofing materials in residential and commercial construction projects. {Company Name} stands out as a leading manufacturer of metal roof forming machines, offering innovative and high-quality solutions to meet the evolving needs of the industry. With a strong commitment to quality, innovation, and sustainability, {Company Name} is well-positioned to maintain its position as a key player in the global metal roof forming machine market.

Company News & Blog

Powerful New Forming Machine Poised to Revolutionize the Manufacturing Industry

Forming Machine Revolutionizes the Manufacturing IndustryInnovation has been the driving force behind the manufacturing industry, continually improving the efficiency and quality of production. A recent breakthrough in machinery has once again redefined what is possible in manufacturing. The forming machine, developed by a leading company in the field, has revolutionized the manufacturing industry.The forming machine is a cutting-edge piece of equipment that is used to shape raw materials into the desired form. The process of forming involves using a series of rollers, moulds and dies to turn flat sheets of metal into complex shapes. It has been widely adopted in the automotive, aerospace and construction industries as it significantly reduces production time and increases the precision of the final product.The innovation of the forming machine is that it can now create complex shapes that were not previously possible, allowing manufacturers to easily produce intricate designs and parts. The machine is also highly versatile as it can process a wide range of materials, including aluminium, steel and copper.The development of the forming machine has had a significant impact on efficiency and profitability in the manufacturing industry. Traditionally, complex shapes could only be produced by using a variety of machines, which made the manufacturing process time-consuming and expensive. The forming machine has streamlined this process, allowing parts to be produced faster and more accurately, whilst also reducing the likelihood of mistakes and errors.The company behind the innovation of the forming machine is a leader in its field, with a track record of delivering high-quality machinery to clients across the world. The company has invested heavily in research and development, resulting in a range of products that have changed the face of manufacturing.Founded in 1989, the company has established a reputation for producing high-quality machinery that is tailored to the specific requirements of each client. The company’s team of engineers work closely with clients to develop machinery that is efficient, reliable and cost-effective.The company has developed a range of innovative solutions for the manufacturing industry, including robotics, laser cutting and stamping machines. The forming machine is the latest addition to the company’s portfolio of products that have revolutionized the manufacturing industry.The company has a global presence, with offices in North and South America, Europe, Asia and Africa. Its products are used by manufacturers across a range of industries, including automotive, aerospace, construction, healthcare and food production.The success of the company has been built on its commitment to quality, innovation and customer satisfaction. The forming machine is the perfect example of this commitment, as it represents a technological breakthrough that has changed the way manufacturers operate.The process of forming has been used in manufacturing for centuries, but it was not until the development of the forming machine that it became a truly revolutionary process. The machine has enabled manufacturers to produce complex parts with ease, reducing the time and cost of production whilst increasing accuracy and precision.In conclusion, the forming machine has redefined what is possible in manufacturing, opening up a new world of possibilities for manufacturers across the world. Its impact has been far-reaching, revolutionizing the way complex parts are produced whilst also increasing efficiency and profitability. It is clear that this innovative piece of machinery will continue to shape the manufacturing industry for years to come.

High-quality Corrugated Roof Panel Roll Forming Machine with Adjustable Size

Galvanized Steel Corrugated Roof Panel Roll Forming Machine With Adjustable Size: Revolutionizing the Roofing IndustryIn recent years, the demand for high-quality roofing materials has reached new heights, driven by the growing construction industry around the world. A key component of quality roofing is the corrugated roof panel, which not only provides structural strength and durability but also enhances the aesthetic appeal of a building. China, known for its advanced manufacturing capabilities, has emerged as a leading provider of galvanized steel corrugated roof panels. These panels are produced using state-of-the-art machinery, such as the Galvanized Steel Corrugated Roof Panel Roll Forming Machine with Adjustable Size, which is garnering attention for its innovative features and exceptional quality.The Galvanized Steel Corrugated Roof Panel Roll Forming Machine is designed to meet the specific needs of the roofing industry. It is capable of producing the highest quality galvanized steel corrugated roof panels, thanks to its advanced features and precision engineering. One of the standout features of this machine is its adjustable size functionality, allowing users to produce roof panels of varying dimensions and profiles. This adaptability makes it a versatile solution for roofing material manufacturers, catering to a wide range of customer requirements.Quality is of utmost importance in the roofing industry, and this machine prioritizes it through strict quality control measures. The manufacturers understand that the durability and long lifespan of a roof depend on the strength and corrosion resistance of its materials. Therefore, only high-quality galvanized steel is utilized in the production process. Additionally, the machine undergoes thorough inspections and testing to ensure that the manufactured roof panels meet the highest standards.The Galvanized Steel Corrugated Roof Panel Roll Forming Machine stands out in the market not only for its impeccable quality but also for its efficiency and productivity. Its advanced technology enables high-speed production, significantly reducing manufacturing time and costs. Furthermore, the machine's automated processes minimize the need for manual labor, ensuring consistent quality output while reducing the risk of errors. Its user-friendly interface and intuitive controls also contribute to ease of operation and overall productivity.China has been at the forefront of the manufacturing industry for decades, and its reputation for producing high-quality products has only grown stronger. The Galvanized Steel Corrugated Roof Panel Roll Forming Machine is a prime example of Chinese excellence in manufacturing. China's commitment to innovation and technological advancements has resulted in machines that not only meet but exceed industry standards. Coupled with the expertise and dedication of the manufacturers, these machines are revolutionizing the roofing industry, offering efficient and cost-effective solutions to roofing material manufacturers worldwide.In conclusion, the Galvanized Steel Corrugated Roof Panel Roll Forming Machine with Adjustable Size is a game-changer for the roofing industry. Its exceptional quality, adaptability, and efficiency make it a must-have for manufacturers looking to meet the growing demand for high-quality roofing materials. As China continues to lead the manufacturing sector, its commitment to innovation and excellence guarantees the production of top-notch machinery that revolutionizes industries worldwide.

High-Quality Floor Production Roll Forming Machine for Efficient Manufacturing

Floor Production Roll Forming Machine: Revolutionizing the Manufacturing IndustryIn the competitive world of manufacturing, efficiency and quality are paramount. Manufacturers are constantly seeking state-of-the-art machinery and equipment to streamline their production processes and improve the overall quality of their products. With this in mind, the industry leader in roll forming machine technology, {Company Name}, is proud to introduce its latest innovation - the Floor Production Roll Forming Machine. This cutting-edge machine is set to revolutionize the production of floor panels, offering unparalleled precision, speed, and reliability.The Floor Production Roll Forming Machine is designed to meet the demands of modern manufacturing, offering a range of features that set it apart from traditional roll forming machines. With its advanced technology and innovative design, this machine is capable of producing high-quality floor panels with exceptional speed and accuracy. Its precision-engineered rollers and cutting tools ensure that each panel is produced to exact specifications, with minimal wastage and defects. This level of precision is essential for manufacturers seeking to meet the stringent quality standards of today's market.One of the key advantages of the Floor Production Roll Forming Machine is its versatility. Whether producing standard floor panels or custom-designed components, this machine is capable of handling a wide range of materials, including steel, aluminum, and other alloys. This flexibility makes it an invaluable asset for manufacturers looking to diversify their product range and meet the unique specifications of their clients. In addition, the machine can be easily reconfigured and adapted to accommodate different panel sizes and designs, further enhancing its versatility.The Floor Production Roll Forming Machine is also renowned for its speed and efficiency. Its high-speed production capabilities enable manufacturers to significantly increase their output, reducing the time and resources required to produce floor panels. This improved efficiency not only reduces production costs but also allows manufacturers to meet tight deadlines and satisfy the demands of their clients. Furthermore, the machine's automated operation minimizes the need for manual intervention, further optimizing the production process and reducing the risk of human error.In addition to its technical features, the Floor Production Roll Forming Machine is backed by {Company Name}'s renowned expertise and support. With years of experience in roll forming technology, the company is dedicated to providing comprehensive customer support, including installation, training, and ongoing maintenance services. This ensures that manufacturers can fully optimize the capabilities of the machine and maximize their return on investment. Furthermore, {Company Name}'s commitment to innovation and continuous improvement means that the machine is regularly updated with the latest advancements in technology, keeping it at the forefront of roll forming innovation.The introduction of the Floor Production Roll Forming Machine marks a significant milestone for {Company Name}, reinforcing its position as a leading provider of roll forming technology. With its state-of-the-art features, versatility, and exceptional performance, this machine is set to transform the manufacturing industry, empowering manufacturers to produce high-quality floor panels with unprecedented speed and precision. As the demands of the market continue to evolve, {Company Name} remains committed to driving innovation and delivering cutting-edge solutions that empower manufacturers to succeed in a competitive industry.

Photos of Cold Rolling Forming Production Line for Stud Profile C Purlin & U Purlin Roll Forming Machine

Zhiye Cold Forming Machinery Co., Ltd. has launched a new product for the construction industry – the Stud Profile C Purlin Cold Rolling Forming Production Line or more commonly known as the stud U purlin roll forming machine.This machine is designed to produce C purlins and U purlins that are commonly used as framing elements in the construction of roofs, walls, and ceilings. The purlins produced by this machine are known for their high strength, versatility, and cost-effectiveness, making them a popular choice for most building projects.The Stud Profile C Purlin Cold Rolling Forming Production Line operates using advanced technology that ensures the production of high-quality purlins with precise dimensions. Its production process involves feeding raw material into the machine where it is pre-cut and fed into the main roll forming machine. The machine then goes through a series of operations such as leveling, punching, cutting, and stacking, before the final product is produced.The C Purlin Profiles Cold Roll Forming Lines produced by Zhiye Cold Forming Machinery Co., Ltd. are all equipped with state-of-the-art control systems that ensure easy operation, smooth production, and high productivity. The machine can produce purlins of different shapes and sizes, ranging from 100mm to 300mm. It can run at speeds of up to 25 meters per minute, making it possible to produce a large volume of purlins in a short period.The Stud Profile C Purlin Cold Rolling Forming Production Line is made using high-quality components and materials, ensuring its durability and long lifespan. The machine is also flexible and can be easily customized to suit specific customer needs. It is designed for ease of maintenance, with minimal downtime required for repairs and servicing.The launch of this new product by Zhiye Cold Forming Machinery Co., Ltd. is expected to have a significant impact on the construction industry, particularly in the roofing and framing sectors. The machine's ability to produce high-quality purlins quickly and efficiently means that construction companies can save time and money on their projects without compromising the quality of the final product. This is essential, given the increasing demand for construction works globally, where cost and time efficiency are critical.In conclusion, the Stud Profile C Purlin Cold Rolling Forming Production Line/stud U purlin roll forming machine from Zhiye Cold Forming Machinery Co., Ltd. is a significant innovation that will revolutionize the construction industry. The machine's advanced technology, coupled with its efficiency and precision, will ensure that construction companies can produce high-quality purlins quickly and cost-effectively. This will ultimately lead to faster project completion times and reduced costs, making it a popular choice in the industry.

Coil-fed Cutting Machine for Metal and Sheet Metal - Efficient and Precise Solution

Sheet metal coil cutting machines have revolutionized the way sheet metal fabrication was done earlier. These machines use highly advanced laser cutting technology to cut sheet metal coils of various thicknesses with ease. A staunch player in this industry is the DANOBAT LB coil-fed cutting machine, offered by the renowned DANOBATGROUP.The DANOBAT LB coil-fed cutting machine is an efficient and high-quality equipment specially designed for the sheet metal cutting industry. It offers advanced precision in cutting operations, enabling the production of high-quality products with elevated efficiency. The machine can cut coil sheets of various materials such as steel, aluminum, brass, copper, and other alloys.The machine has a cutting speed of up to 150 meters per minute and can handle sheets of thickness ranging from 0.4mm to 16 mm. This coil-fed cutting machine features a robust structure that can withstand intense workload for years, making it one of the most reliable sheet metal cutting machines on the market.Equipped with a fiber laser, the DANOBAT LB coil-fed cutting machine is an extremely precise machine that delivers remarkable cuts on various materials. The laser facilitates high cutting speeds with a minimal kerf width, thus reducing the amount of scrap and maximizing the yield.Moreover, DANOBATGROUP's coil-fed cutting machine is incredibly easy to operate and maintain. The machine's user-friendly interface makes it possible to control the cutting processes and communicate with the machine directly. The intuitive software technology integrated into the machine enables operators to modify cutting parameters and prepare the cutting process quickly and efficiently.The DANOBAT LB coil-fed cutting machine is ideal for the production of various products, including automotive components, industrial equipment, and construction materials, among others. The machine ensures efficient production, improved automation, and enhanced product quality.DANOBATGROUP is not only known for its cutting-edge sheet metal coil cutting machines but also for providing excellent customer service. The company has a team of professionals who are always ready to offer technical support and assistance. With a worldwide presence, DANOBATGROUP ensures that its customers receive timely assistance and a reliable after-sales service.In summary, the DANOBAT LB coil-fed cutting machine is a top-of-the-line equipment that offers high-precision, efficiency, and reliability to the sheet metal cutting industry. Its excellent cutting speed, user-friendly interface, and optimal usage of materials result in minimized production costs and high-quality products. To learn more about this cutting-edge technology and to request a quote, contact DANOBATGROUP, a reputed provider of sheet metal processing solutions.

Top-rated Roof Panel Machine: A Game-Changer in Construction Industry

Roof Panel Machine Revolutionizes the Manufacturing IndustryThe manufacturing industry has seen a significant breakthrough with the introduction of the state-of-the-art Roof Panel Machine by a leading company. This innovative machine has redefined the process of manufacturing roof panels, making it faster, more efficient, and cost-effective.The Roof Panel Machine is designed to streamline the production of roof panels, providing manufacturers with a high-quality and reliable solution for their production needs. With advanced technology and precision engineering, this machine has the capability to produce a wide range of roof panels with varying thickness, length, and design specifications. This level of flexibility allows manufacturers to meet the diverse needs of their customers, while maintaining a high standard of quality and consistency.One of the key features of the Roof Panel Machine is its automated operation, which minimizes the need for manual labor and reduces the risk of errors in the production process. This automated system is equipped with intelligent controls and sensors that ensure the accurate and precise fabrication of roof panels, resulting in a higher level of efficiency and productivity. As a result, manufacturers can increase their output and meet tight production deadlines without compromising on the quality of their products.In addition, the Roof Panel Machine is designed for ease of use, with a user-friendly interface and intuitive controls that make it accessible to operators of varying skill levels. This allows manufacturers to train their staff quickly and efficiently, reducing the time and resources required for onboarding new employees. The simplified operation of the machine also minimizes the risk of human error, resulting in a more consistent and reliable production process.Furthermore, the Roof Panel Machine is engineered for durability and longevity, ensuring a reliable and long-lasting solution for manufacturers. With robust construction and high-quality components, this machine is designed to withstand the rigors of continuous use in a manufacturing environment, providing a dependable and low-maintenance option for production facilities.The introduction of the Roof Panel Machine has significantly impacted the manufacturing industry, offering a transformative solution for the production of roof panels. With its advanced technology, automated operation, ease of use, and durability, this machine has redefined the standards of manufacturing, setting new benchmarks for efficiency, productivity, and quality.Company Introduction:The company behind the Roof Panel Machine is a leading innovator in the field of manufacturing technology. With a strong focus on research and development, this company has consistently introduced cutting-edge solutions that address the evolving needs of the industry. The Roof Panel Machine is the latest addition to their portfolio of advanced machinery, and it reflects their commitment to driving innovation and excellence in manufacturing.In addition to their dedication to technological advancement, the company is also known for their comprehensive support and service network. They offer a range of services, including installation, training, maintenance, and technical support, to ensure that their customers can fully maximize the benefits of their machinery. This level of support reinforces the company's dedication to customer satisfaction and their commitment to delivering value beyond the sale of their products.With a strong track record of success and a reputation for delivering superior technology, the company is poised to continue leading the way in the manufacturing industry. The Roof Panel Machine is just one example of their innovative solutions, and it serves as a testament to their vision of shaping the future of manufacturing with cutting-edge technology and unmatched expertise.In conclusion, the Roof Panel Machine has ushered in a new era of manufacturing, offering a game-changing solution for the production of roof panels. With its advanced technology, automated operation, ease of use, and durability, this machine has set a new standard for efficiency, productivity, and quality in the industry. As a testament to the company's commitment to innovation and excellence, the Roof Panel Machine stands as a pioneering achievement that is revolutionizing the manufacturing landscape.

How Slitting Line Machines Can Enhance Production Efficiency

In today's fast-paced world, it is essential to have industries that can keep up with the ever-demanding needs of the market. An industry that is gaining momentum and popularity is the metal processing industry, which specializes in manufacturing various metal components and equipment. The metal processing industry is critical in modern society, and its importance cannot be overemphasized.One major player in the metal processing industry is a company that specializes in manufacturing slitting line machines. The company has been in existence for many years, and it has been providing metal processing solutions to different industries across the globe. The company boasts of a team of experts who are passionate about their work and focus on providing clients with top-notch solutions that meet their specific needs.The slitting line machine is a critically important machine in the metal processing industry, as it is used to cut a large coil of metal into smaller strips of different widths. The slitting line process is a crucial step in the metal processing industry, as it allows for the production of different finished products from the same coil of metal. The slitting line machine is also used in the assembling of different metal components that are used in various industries, including construction, automobile, and household appliances.The company's slitting line machine is a cutting-edge technology that is designed to handle a wide range of materials, including brass, copper, aluminum, steel, and others. It is user-friendly, efficient, and offers cost-effective solutions to clients. The machine is also designed with safety features that ensure the operator's safety and the safety of the machine's components.The slitting line machine is an essential piece of equipment in the metal processing industry, and the company has invested heavily in research and development to manufacture machines that meet the needs of different clients. The company is committed to producing high-quality machines that are durable, efficient, and reliable. The firm has built a reputation for excellence, and this has been proven by the positive feedback from different clients who have used their products.One of the reasons why the company's slitting line machine is regarded highly in the market is because of its versatility. The machine can accommodate different coil sizes, and its cutting speed can be adjusted based on the client's needs. The machine's precision and accuracy levels are unmatched, and this ensures that clients get the exact size and width they require.In addition to manufacturing top-notch machines, the company provides excellent customer support to its clients. The company's team of experts is always on hand to provide clients with technical support when needed. The company also offers training programs to clients who purchase their machines, ensuring that the clients can operate the machines safely and efficiently.On the environmental front, the company has taken steps to ensure that their machines are eco-friendly. The machines are designed with features that reduce energy consumption and minimize the amount of waste produced during the metal processing process. The company's commitment to environmental protection is one of the reasons why it has remained relevant in the market.In conclusion, the metal processing industry is critical in modern society, and one major player in this industry is the company that specializes in manufacturing slitting line machines. Their machines are efficient, durable, and reliable and have been tested and proven by different clients. The company has built a reputation for excellence in the market and is committed to providing clients with high-quality machines that meet their specific needs. With an excellent team of experts, customer support, and a commitment to environmental protection, the company is poised to remain relevant in the metal processing industry for years to come.

High-Quality Light Gauge Steel Truss Roll Forming Machine for Your Construction Needs

Light Gauge Steel Truss Roll Forming Machine Revolutionizes the Construction IndustryIn recent years, the construction industry has seen a rapid shift towards the use of light gauge steel trusses in construction projects. This shift has been driven by the numerous benefits that light gauge steel trusses offer, including their high strength-to-weight ratio, long spans, and ability to be quickly and accurately installed. To meet the increasing demand for light gauge steel trusses, {Company Name}, a leading manufacturer of roll forming machines, has introduced its state-of-the-art Light Gauge Steel Truss Roll Forming Machine.The Light Gauge Steel Truss Roll Forming Machine is a game-changer in the construction industry, as it allows for the efficient and precise production of light gauge steel trusses. Unlike traditional methods of truss fabrication, which are labor-intensive and time-consuming, this machine is capable of producing trusses at a rapid pace, while maintaining the highest standards of quality and accuracy. This breakthrough technology has significantly reduced the production time of light gauge steel trusses, enabling construction companies to meet tight project deadlines and reduce overall construction costs.Designed with advanced features and cutting-edge technology, the Light Gauge Steel Truss Roll Forming Machine is versatile and adaptable to various truss designs and specifications. This flexibility allows for the customization of trusses to meet the specific requirements of each construction project, while ensuring uniformity and consistency in the manufacturing process. Furthermore, the machine's user-friendly interface and automated controls make it easy to operate, minimizing the need for extensive training and specialized expertise.{Company Name} has a long-standing reputation for delivering high-quality roll forming machines and providing exceptional customer service. With the introduction of the Light Gauge Steel Truss Roll Forming Machine, the company has once again demonstrated its commitment to innovation and excellence in the construction industry. By investing in this cutting-edge technology, construction firms can enhance their production capabilities, streamline their operations, and ultimately, achieve greater efficiency and profitability.In addition to its technological prowess, {Company Name} distinguishes itself through its dedication to customer satisfaction. The company's team of skilled engineers and technical support staff are readily available to provide comprehensive training, ongoing maintenance, and technical assistance to ensure the seamless integration of the Light Gauge Steel Truss Roll Forming Machine into the production process. This level of support is unmatched in the industry, and underscores {Company Name}'s unwavering commitment to its customers' success.The impact of the Light Gauge Steel Truss Roll Forming Machine on the construction industry cannot be overstated. Beyond its ability to enhance productivity and precision in truss fabrication, this innovative machine also upholds sustainability and environmental consciousness in construction practices. By using light gauge steel trusses, construction projects can significantly reduce material waste, promote energy efficiency, and minimize environmental impact, aligning with global efforts to build a more sustainable future.As the construction industry continues to evolve, the demand for light gauge steel trusses will only grow. The introduction of the Light Gauge Steel Truss Roll Forming Machine by {Company Name} has undoubtedly raised the bar for truss manufacturing, setting a new standard for efficiency, quality, and adaptability. This revolutionary technology is not just a machine; it represents a pivotal advancement in the way structures are built, and a testament to the unwavering dedication of {Company Name} to lead the charge towards a more innovative and sustainable construction industry.

High-Quality Metal Roofing Sheet Corrugated Tile Roll Forming Machine for Custom Applications" Our Wide Range of Roof Roll Forming Machines and Equipment for Efficient Roofing Solutions Enhance Your Roofing Projects with our Corrugated Tile Roof Roll Forming Machine Advanced Maquina De Hacer Calaminas: Perfectly Designed for Customized Metal Roofing Sheets Discover Our Impressive Line of Roofing Machinery: Curve Roof Machines, Shearing/Bending Machines, Light Keel Roll Formers, and More

: Efficiency, Durability, VersatilityA metal roof is one of the most durable and long-lasting roofing systems on the market today. It is highly resistant to weathering and UV damage, which makes it an excellent choice for homeowners who want to protect their homes from extreme weather conditions. For this reason, the demand for metal roofing systems has risen over the past few years.However, installing a metal roof can be a daunting task, especially for those who have no experience in roofing. The good news is that the Metal Corrugated Roof Roll Forming Machine is designed to make the installation of metal roofing systems easier and more efficient.EfficiencyThe Metal Corrugated Roof Roll Forming Machine is a game-changer when it comes to metal roof installation. It can speed up the installation process by producing custom-made metal roofing sheets quickly and accurately. Additionally, it is designed to process different types of roofing materials, including aluminum, copper, and steel, and can produce a variety of profiles, such as corrugated and trapezoidal.The machine is highly automated, which means that it requires minimal human intervention. This makes it very efficient, which can save contractors time and labor costs.DurabilityThe metal roofing sheets produced by the Metal Corrugated Roof Roll Forming Machine are highly durable. This is because the machine forms the sheets from raw materials, which eliminates the need for prefabricated sheets that are prone to damage during transportation and handling. Additionally, the thickness of the metal sheets can be customized to suit the specific requirements of the roofing project.VersatilityThe Metal Corrugated Roof Roll Forming Machine is a versatile machine that is suitable for different types of roofing projects. It can form metal sheets in different sizes and profiles, which makes it suitable for residential, commercial, and industrial roofing projects.The machine's versatility is further enhanced by the fact that it can form metal sheets with different coatings, such as galvanized, painted, and coated. This means that contractors can choose the best-coated metal roofing sheets that will enhance the project's durability and performance.ConclusionIn conclusion, the Metal Corrugated Roof Roll Forming Machine is a game-changer in the metal roofing industry. It provides efficiency, durability, and versatility, which are essential for any successful roofing project. Its advanced technology ensures that contractors can produce custom-made metal roofing sheets quickly and accurately, making metal roofing installation more efficient and cost-effective. Anyone looking to install a metal roofing system should consider using this machine to ensure a seamless roofing project.

Efficient 16 Gauge Sheet Metal Slitter: All You Need to Know

{Insert Company Name}, a leading manufacturer of industrial machinery, is proud to announce the release of its latest innovation, the 16 Gauge Sheet Metal Slitter. This state-of-the-art machine is designed to revolutionize the metal slitting industry, providing customers with unprecedented levels of efficiency and precision.Sheet metal slitting is a crucial process in various industries, including construction, automotive, and manufacturing, where sheets of metal are cut into smaller, more manageable strips. Traditionally, this task has been approached using cumbersome and time-consuming techniques. However, with the introduction of the 16 Gauge Sheet Metal Slitter by {Insert Company Name}, the process has been streamlined and made considerably more efficient.The 16 Gauge Sheet Metal Slitter stands out from the competition due to its exceptional design and advanced features. Made from high-quality materials, this machine offers unparalleled durability, ensuring a long-lasting and reliable solution for businesses. Its precision-engineered components guarantee consistent and accurate cuts, eliminating the risk of errors or irregularities.One of the key highlights of the 16 Gauge Sheet Metal Slitter is its user-friendly interface. Equipped with an intuitive control panel, operators can easily navigate through the various settings and parameters. Additionally, the machine boasts an ergonomic design, prioritizing the comfort and safety of the users. With adjustable settings and quick changeover capabilities, operators can effortlessly switch between different sheet sizes and materials, enhancing overall productivity.Safety is a top priority at {Insert Company Name}, and the 16 Gauge Sheet Metal Slitter reflects this commitment. The machine is equipped with comprehensive safety features, including emergency stop buttons, safety guards, and intelligent sensors that detect any anomalies or potential hazards. This ensures maximum protection for operators and minimizes the risk of accidents or injuries in the workplace.Another key feature of the 16 Gauge Sheet Metal Slitter is its versatility. This machine is capable of handling a wide range of sheet metal materials, including stainless steel, aluminum, and galvanized steel. With adjustable cutting speeds and precision-guided blades, it can easily accommodate different thicknesses and widths of metal, making it suitable for various applications.With the 16 Gauge Sheet Metal Slitter, {Insert Company Name} aims to provide customers with a solution that not only improves efficiency but also saves time and reduces costs. By automating the slitting process, businesses can significantly increase their production output while maintaining consistent quality. This, in turn, leads to higher profitability and a competitive edge in the market.In addition to its exceptional performance, {Insert Company Name} also prides itself on providing excellent customer support. Their team of experienced technicians is available to assist customers with installation, training, and ongoing maintenance, ensuring a smooth and hassle-free experience throughout the lifespan of the machine.As the metal industry continues to evolve and demand for efficient slitting solutions increases, {Insert Company Name} remains at the forefront of innovation. With the introduction of the 16 Gauge Sheet Metal Slitter, they continue to push boundaries and offer cutting-edge solutions to meet the diverse needs of their customers.In conclusion, the 16 Gauge Sheet Metal Slitter by {Insert Company Name} is set to redefine the metal slitting industry. With its advanced features, user-friendly interface, and unmatched versatility, this machine is poised to become an indispensable tool for businesses seeking to improve their productivity and competitiveness. {Insert Company Name} yet again raises the bar with this innovative solution, solidifying its reputation as a leader in the field of industrial machinery.