- Home

- News

- How to Use Horizontal Barrel Vault Roof Panel Roll Forming Machine to Boost Roofing Production

How to Use Horizontal Barrel Vault Roof Panel Roll Forming Machine to Boost Roofing Production

By:Admin

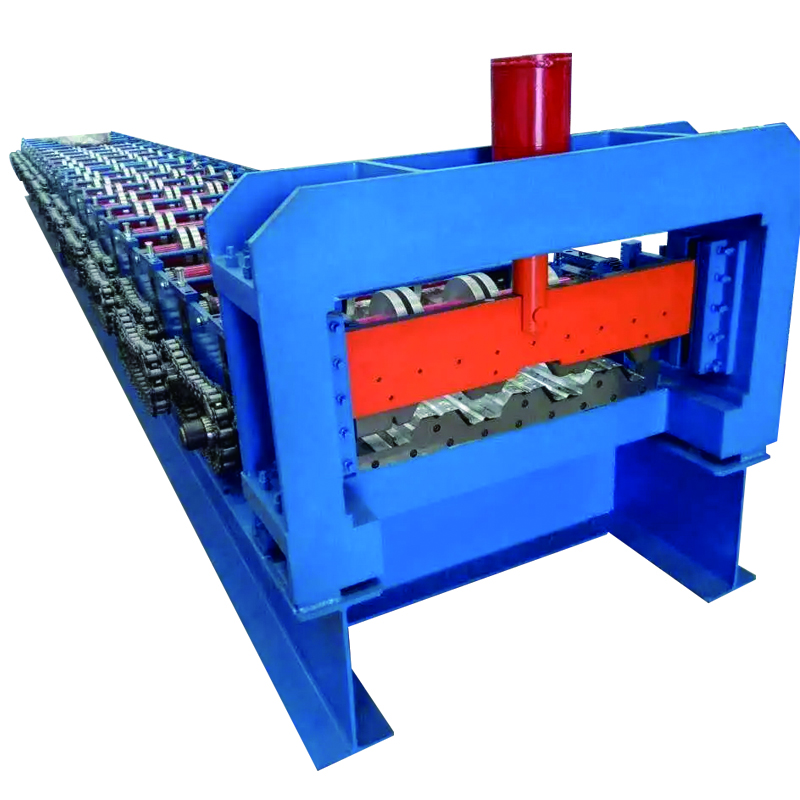

The Horizontal Barrel Vault Roof Panel Roll Forming Machine is equipped with advanced technology that enables it to produce panels with exceptional precision and efficiency. The machine is capable of forming panels with a width range of 500mm to 1000mm and a thickness range of 0.6mm to 1.2mm. This versatility allows [Company Name] to meet the diverse needs of its customers and produce panels that meet their specific requirements.

One of the key features of the Horizontal Barrel Vault Roof Panel Roll Forming Machine is its rapid production speed. The machine is designed to operate at a high production rate, enabling [Company Name] to meet tight deadlines and deliver panels to its customers in a timely manner. This is particularly important in the construction industry, where project timelines are often critical.

In addition to its speed and precision, the Horizontal Barrel Vault Roof Panel Roll Forming Machine is also designed with operator convenience in mind. The machine is equipped with an intuitive control system that allows operators to easily adjust settings and monitor production processes. This user-friendly interface helps to minimize the risk of errors and ensures consistent panel quality.

Furthermore, the Horizontal Barrel Vault Roof Panel Roll Forming Machine is built to withstand the rigors of heavy-duty industrial use. Its robust construction and durable components make it a reliable and long-lasting investment for [Company Name]'s customers. This ensures that the machine will continue to deliver high-quality panels for years to come, contributing to the success of their construction projects.

[Company Name] is known for its commitment to innovation and quality, and the Horizontal Barrel Vault Roof Panel Roll Forming Machine is a testament to this. The company has a long history of providing cutting-edge solutions to the roll forming industry, and this latest addition to its product line further solidifies its position as a leader in the market.

In addition to its focus on product development, [Company Name] is also dedicated to providing exceptional customer service. The company works closely with its customers to understand their unique needs and deliver tailored solutions that meet their requirements. This customer-centric approach has earned [Company Name] a reputation for reliability and trustworthiness in the industry.

The launch of the Horizontal Barrel Vault Roof Panel Roll Forming Machine is a significant milestone for [Company Name], as it further expands its capabilities and strengthens its position in the roll forming market. With its advanced technology, high-speed production, and operator-friendly design, the machine is poised to make a positive impact on the construction industry and help [Company Name] continue to serve its customers with excellence.

In conclusion, the Horizontal Barrel Vault Roof Panel Roll Forming Machine represents a new chapter in [Company Name]'s commitment to innovation and quality. With its advanced features and benefits, the machine is set to deliver exceptional value to its customers and contribute to the success of construction projects around the world. [Company Name] remains dedicated to pushing the boundaries of technology and providing top-of-the-line solutions for the roll forming industry.

Company News & Blog

Increase Production Efficiency and Prevent Film Cracking with Advanced Web Tension Control Systems for Slitting Machines

The Slitting and Cutting Machine: An OverviewWhen it comes to manufacturing materials such as paper, plastic film, or even textiles, the slitting and cutting machine is an essential piece of equipment. These machines are designed to take large rolls of material and cut them down into the desired size and shape, allowing for easier handling and processing.One of the most important aspects of a slitting and cutting machine is its ability to maintain proper tension throughout the process. This is where web tension control systems come into play. These systems help prevent film cracking and other issues that can arise when the tension is not properly controlled.There are several different types of slitting and cutting machines available on the market today. Some are designed for specific materials such as paper or plastic film, while others are more versatile and can handle a variety of materials.One common type of slitting and cutting machine is the rotary shear. This machine uses a set of sharp blades that rotate against a stationary blade, effectively cutting the material as it passes through. The blades can be adjusted to vary the width of the cut, allowing for greater flexibility in production.Another type of slitting and cutting machine is the crush cutter. This machine uses a roller with a dull blade that crushes the material against a stationary blade, effectively cutting it in the desired width. Crush cutters are often used for materials that are more delicate or easily damaged.Regardless of the type of slitting and cutting machine being used, proper maintenance is essential to ensure optimal performance and longevity. Routine inspections and cleaning can help prevent issues from arising, while regular calibration can help ensure that the machine is cutting accurately and efficiently.In conclusion, the slitting and cutting machine is a vital piece of equipment in many manufacturing industries. With the right equipment and maintenance, it can help increase efficiency, reduce waste, and improve the overall quality of the finished product. Ensure to also incorporate web tension control systems to prevent film cracking and other similar issues.

Guide to Purlin Roll Forming: Everything You Need to Know

Purlin Roll Forming Technology Advancement Revolutionizes the IndustryPurlins are an essential component in the construction of roofs and walls in buildings, providing structural support and stability. The process of forming purlins has traditionally been labor-intensive and time-consuming, but thanks to the latest technological advancements in purlin roll forming, the industry is undergoing a revolution.The introduction of state-of-the-art purlin roll forming technology by {} has significantly improved the efficiency and accuracy of purlin production. This innovative technology allows for the rapid and precise shaping of purlins from raw materials such as steel, aluminum, or other metals, resulting in a high-quality end product.{} is at the forefront of this technological revolution, offering a range of purlin roll forming machines that cater to the diverse needs of the construction industry. Their machines are designed to handle various sizes and thicknesses of materials, providing flexibility and versatility for different construction projects.One of the key advantages of {}'s purlin roll forming technology is its ability to streamline the production process. Traditional methods of forming purlins involved multiple steps and manual labor, leading to higher production costs and a longer turnaround time. With the new technology, purlins can be manufactured in a fraction of the time, ultimately reducing production costs and increasing overall productivity.Furthermore, the precision and consistency achieved through purlin roll forming technology ensure that the end products meet strict quality standards. This is particularly important in the construction industry, where the structural integrity of buildings relies on the strength and durability of purlins. With {}'s advanced roll forming technology, construction companies can have peace of mind knowing that the purlins used in their projects are of the highest quality.In addition to the technological advancements, {} is also committed to sustainability and environmental responsibility. Their purlin roll forming machines are designed to minimize material waste and energy consumption, contributing to a more eco-friendly production process. As sustainability continues to be a priority for many industries, {}'s dedication to green manufacturing sets them apart as an industry leader.The impact of purlin roll forming technology goes beyond just the manufacturing process. It has the potential to revolutionize the construction industry as a whole, offering new possibilities for innovative and cost-effective building designs. The speed and precision of the technology open up opportunities for more complex and creative purlin shapes, which can contribute to the aesthetic appeal of buildings.Furthermore, the increased efficiency and reduced production costs associated with purlin roll forming technology can ultimately benefit the end consumers. As construction companies are able to save on manufacturing expenses, these savings can be passed on to clients, making construction projects more affordable and accessible.With the rapid advancements in purlin roll forming technology, the construction industry is entering a new era of efficiency, precision, and sustainability. Companies like {} are at the forefront of this transformation, providing the tools and technology to drive innovation and progress in the industry. As the demand for high-quality purlins continues to grow, purlin roll forming technology is poised to play a central role in meeting these needs and shaping the future of construction.

Discover the Latest Advancements in Forming Machines for Enhanced Efficiency

Forming Machines, Revolutionizing Manufacturing ProcessesIn recent years, the manufacturing industry has witnessed numerous advancements that have transformed the way products are made. Among these revolutionary innovations, the introduction of state-of-the-art forming machines has played a significant role in enhancing production efficiency and product quality across various sectors.Forming machines, known for their precision and speed, have become an indispensable tool for manufacturers worldwide. These machines, designed to shape metal or other materials into custom forms or parts, offer numerous advantages over traditional manufacturing methods. With their high degree of automation and computer-aided design capabilities, forming machines have streamlined production processes, resulting in increased productivity and cost-effectiveness.One prominent player in the field of forming machines is {}, a leading global manufacturing solutions provider. With years of experience and expertise, they have established themselves as an industry leader, delivering cutting-edge technology and innovative solutions to a wide range of industries.{} offers a diverse range of forming machines that cater to the evolving needs of the manufacturing sector. From hydraulic and mechanical presses to automated stamping systems, their product portfolio covers a broad spectrum of applications. These machines are built to deliver optimal performance, ensuring accuracy, repeatability, and the ability to handle high volumes of production.One of the key features that set {} forming machines apart from the competition is their advanced control systems. These machines are equipped with state-of-the-art software and sensors that enable precise control over the forming process. Manufacturers can easily program and adjust various parameters, such as speed, force, and position, ensuring precise and consistent results. With such control, they can not only meet the strict quality requirements but also minimize wastage and material costs.Moreover, {} forming machines incorporate intelligent monitoring systems that provide real-time feedback and diagnostics. This allows operators to identify and resolve issues promptly, minimizing downtime and increasing overall equipment effectiveness. With the ability to analyze data and generate reports, manufacturers can also gain valuable insights into their production efficiency, facilitating continuous improvement efforts.In addition to their impeccable performance, {} forming machines prioritize the safety of both operators and machinery. These machines are equipped with advanced safety features, including safety guards, emergency stop buttons, and interlocking systems. Additionally, they adhere to international safety standards and regulations, ensuring the well-being of personnel and compliance with industry guidelines.The versatility of {} forming machines is another key aspect that has contributed to their popularity. With their customizable tooling options, manufacturers can easily adapt the machines to suit various production requirements. Whether it is bending, stamping, or deep drawing, {} machines offer flexible solutions that can handle a wide range of materials, from metals to plastics.Beyond their impressive technical capabilities, {} excels in their commitment to customer satisfaction. Their dedicated team of experts provides comprehensive support, from machine installation and training to ongoing maintenance and troubleshooting. By closely collaborating with clients, they strive to understand their specific needs and challenges, ensuring the delivery of tailored solutions that meet and exceed expectations.As the manufacturing industry continues to evolve and demand for efficient, reliable production processes rises, the role of forming machines becomes ever more crucial. Companies like {} are at the forefront of innovation, driving industry growth and enabling manufacturers to achieve new levels of efficiency and competitiveness.In conclusion, forming machines have revolutionized the manufacturing landscape, enabling efficient and precise production processes across various industries. With their advanced control systems, safety features, and versatility, {} forming machines have proven to be a game-changer. As manufacturers strive to meet increasing demands and stay ahead in a competitive market, these machines provide the technological edge needed to succeed.

Pros and Cons of All-In-One vs. Multiple Single Layer Roll Forming Machines: A Comprehensive Comparison

, Multiple Roll Forming Machines, All-in-one Roll Forming Machine, Double layer Roll Forming Machine, Roll Forming Machinery.When it comes to roll forming, there are a few different options to consider. One decision that needs to be made is whether to choose an all-in-one roll forming machine or multiple single layer roll forming machines. Both options have their pros and cons, so it ultimately depends on the specific needs and preferences of the user.Single layer roll forming machines are a popular choice for many manufacturers. These machines are designed to create a continuous sheet of metal by bending it into a certain shape. One of the advantages of using a single layer roll forming machine is the ability to produce a high volume of products quickly and efficiently. Since the machine only focuses on one layer at a time, it's easier to control the quality of each product and ensure that each one is consistent.Another advantage of using a single layer roll forming machine is the ability to customize the process based on the specific needs and materials being used. These machines are often designed to be highly flexible, allowing for adjustments to be made based on the thickness and type of material being used.However, one of the downsides of using a single layer roll forming machine is the need for multiple machines if a manufacturer needs to produce multiple layers. This can be a disadvantage if a manufacturer is trying to minimize the number of machines being used in their production process.On the other hand, all-in-one roll forming machines are designed to be highly versatile and efficient. These machines are capable of producing multiple layers of metal at once, which can help streamline the production process. Additionally, all-in-one roll forming machines are often designed to be highly automated, which can help reduce the need for labor and increase overall efficiency.One of the disadvantages of using an all-in-one roll forming machine is the potential for decreased quality control. Since these machines are designed to focus on multiple layers at once, it can be more difficult to ensure that each product is consistent and meets the desired quality standards.Another potential disadvantage of using an all-in-one roll forming machine is the cost. These machines are typically more expensive than single layer roll forming machines, which can be a disadvantage for smaller manufacturers or those with limited budgets.Finally, double layer roll forming machines are another option to consider. These machines are designed to produce two layers of metal at once, which can help increase production efficiency and reduce the need for multiple machines. However, like all-in-one roll forming machines, double layer roll forming machines can be more expensive and may have lower quality control.Ultimately, the decision to choose between an all-in-one roll forming machine and multiple single layer roll forming machines will depend on a variety of factors, including the specific needs and preferences of the manufacturer. Both options have their advantages and disadvantages, so manufacturers should carefully consider their options before making a final decision.

Discover the Benefits of a Roof Tile Roll Forming Machine for Your Construction Business

In a bid to revolutionize the roofing industry, a leading company in the field of roll forming machinery has developed an innovative Roof Tile Roll Forming Machine. This state-of-the-art machine is set to streamline the process of manufacturing roof tiles, providing a cost-effective and efficient solution for roofing companies and construction projects.The Roof Tile Roll Forming Machine is a result of extensive research and development by the industry-leading company, which has a solid reputation for delivering high-quality roll forming machinery. Drawing on their years of experience and expertise in the field, the company has brought forth a machine that is designed to meet the evolving demands of the roofing industry.One of the key features of this Roof Tile Roll Forming Machine is its ability to produce high-quality roof tiles with precision and speed. The machine is equipped with advanced technology that allows for seamless roll forming, ensuring that each tile is produced with consistent quality and accuracy. This not only enhances the overall efficiency of the manufacturing process but also results in a superior end product.Furthermore, the Roof Tile Roll Forming Machine is designed to be highly versatile, capable of producing a wide range of roof tile designs and sizes. This flexibility is essential for meeting the diverse needs of different construction projects and allows for customization according to specific requirements. With this machine, roofing companies and contractors can easily cater to a variety of client preferences, thereby enhancing their competitive edge in the market.In addition to its advanced functionality, the Roof Tile Roll Forming Machine is also built for durability and longevity. Constructed with high-quality materials and precision engineering, the machine is designed to withstand the rigors of continuous production and deliver reliable performance over an extended period of time. This durability not only ensures a consistent output of roof tiles but also minimizes downtime for maintenance and repairs, contributing to overall cost savings for users.Furthermore, the company behind the Roof Tile Roll Forming Machine is committed to providing comprehensive support and service to its customers. With a team of experienced technicians and engineers, the company offers installation, training, and maintenance services to ensure that users can maximize the potential of the machine. This dedication to customer satisfaction reflects the company's mission to not only deliver cutting-edge machinery but also to foster long-term partnerships with its clients.As the roofing industry continues to evolve and demand for efficient manufacturing solutions grows, the introduction of the Roof Tile Roll Forming Machine marks a significant advancement in the field. With its advanced technology, versatility, and durability, this machine is set to elevate the standards of roof tile production and empower roofing companies to achieve greater success in their operations.Overall, the Roof Tile Roll Forming Machine is a testament to the company's commitment to innovation and excellence in roll forming machinery. With its potential to transform the roofing industry, this machine represents a game-changing solution for manufacturers and contractors alike, setting a new benchmark for efficiency and quality in roof tile production.

How Slitting Line Machines Can Enhance Production Efficiency

In today's fast-paced world, it is essential to have industries that can keep up with the ever-demanding needs of the market. An industry that is gaining momentum and popularity is the metal processing industry, which specializes in manufacturing various metal components and equipment. The metal processing industry is critical in modern society, and its importance cannot be overemphasized.One major player in the metal processing industry is a company that specializes in manufacturing slitting line machines. The company has been in existence for many years, and it has been providing metal processing solutions to different industries across the globe. The company boasts of a team of experts who are passionate about their work and focus on providing clients with top-notch solutions that meet their specific needs.The slitting line machine is a critically important machine in the metal processing industry, as it is used to cut a large coil of metal into smaller strips of different widths. The slitting line process is a crucial step in the metal processing industry, as it allows for the production of different finished products from the same coil of metal. The slitting line machine is also used in the assembling of different metal components that are used in various industries, including construction, automobile, and household appliances.The company's slitting line machine is a cutting-edge technology that is designed to handle a wide range of materials, including brass, copper, aluminum, steel, and others. It is user-friendly, efficient, and offers cost-effective solutions to clients. The machine is also designed with safety features that ensure the operator's safety and the safety of the machine's components.The slitting line machine is an essential piece of equipment in the metal processing industry, and the company has invested heavily in research and development to manufacture machines that meet the needs of different clients. The company is committed to producing high-quality machines that are durable, efficient, and reliable. The firm has built a reputation for excellence, and this has been proven by the positive feedback from different clients who have used their products.One of the reasons why the company's slitting line machine is regarded highly in the market is because of its versatility. The machine can accommodate different coil sizes, and its cutting speed can be adjusted based on the client's needs. The machine's precision and accuracy levels are unmatched, and this ensures that clients get the exact size and width they require.In addition to manufacturing top-notch machines, the company provides excellent customer support to its clients. The company's team of experts is always on hand to provide clients with technical support when needed. The company also offers training programs to clients who purchase their machines, ensuring that the clients can operate the machines safely and efficiently.On the environmental front, the company has taken steps to ensure that their machines are eco-friendly. The machines are designed with features that reduce energy consumption and minimize the amount of waste produced during the metal processing process. The company's commitment to environmental protection is one of the reasons why it has remained relevant in the market.In conclusion, the metal processing industry is critical in modern society, and one major player in this industry is the company that specializes in manufacturing slitting line machines. Their machines are efficient, durable, and reliable and have been tested and proven by different clients. The company has built a reputation for excellence in the market and is committed to providing clients with high-quality machines that meet their specific needs. With an excellent team of experts, customer support, and a commitment to environmental protection, the company is poised to remain relevant in the metal processing industry for years to come.

High-Quality Roll Forming Machine for Tile Production

[Company Name], a leading manufacturer of roll forming machines, has recently unveiled its latest innovation in the form of the high-performance Tile Roll Forming Machine. This new machine is designed to meet the increasing demand for efficient and precise roll forming of various types of tiles used in construction and roofing applications.The Tile Roll Forming Machine from [Company Name] is built with advanced technology and features a robust and durable structure to ensure long-term performance and reliability. It is equipped with precision rollers and forming dies that can produce high-quality tiles with tight tolerances and consistent dimensions. This machine is capable of forming a wide range of tile profiles, including corrugated, trapezoidal, and custom designs, making it suitable for diverse roofing and cladding requirements.One of the key highlights of this Tile Roll Forming Machine is its user-friendly design and intuitive controls, which allow for easy setup and operation. The machine can be quickly adjusted to accommodate different tile specifications, and it is equipped with a high-speed production capability to meet the demands of large-scale roofing projects. Additionally, the machine is equipped with safety features and protective guards to ensure the well-being of operators during operation.In line with [Company Name]'s commitment to innovation and customer satisfaction, the Tile Roll Forming Machine is also supported by a comprehensive after-sales service and technical support. The company provides training and technical assistance to customers to ensure proper operation and maintenance of the machine, as well as prompt availability of spare parts and consumables."We are excited to introduce our new Tile Roll Forming Machine, which is the result of extensive research and development to address the specific needs of the roofing and construction industry," said [Spokesperson Name], the CEO of [Company Name]. "This machine is designed to deliver high-quality and cost-effective solutions for producing various types of tiles, and we are confident that it will bring significant value to our customers."The introduction of the Tile Roll Forming Machine is expected to enhance [Company Name]'s position as a leading provider of roll forming solutions for the construction and building materials sector. The company has a proven track record of delivering innovative and reliable machines that cater to the evolving needs of the industry, and the new Tile Roll Forming Machine further strengthens its product portfolio.With its advanced features, efficient performance, and comprehensive support, the Tile Roll Forming Machine from [Company Name] is poised to set a new benchmark for tile roll forming technology and contribute to the advancement of the construction industry. This latest innovation reflects the company's dedication to excellence and its commitment to empowering customers with high-performance solutions.For more information about the Tile Roll Forming Machine and other roll forming solutions offered by [Company Name], interested parties can visit the company's website or contact their sales representatives for inquiries and consultations.About [Company Name]:[Company Name] is a leading manufacturer of roll forming machines, serving the construction, automotive, and other industries with innovative and reliable solutions. With a strong focus on technology and customer satisfaction, the company designs and manufactures a wide range of roll forming machines to meet the specific needs of its diverse clientele. Backed by a team of skilled professionals and a commitment to quality, [Company Name] continues to lead the way in roll forming technology and solutions.

Efficient Corrugated Iron Sheet Making Machine: Robust and High-Quality Production Capabilities

Corrugated Iron Sheet Making Machine Revolutionizing the Construction IndustryThe construction industry has been growing rapidly over the years, with a constant need for innovative technologies and machinery to enhance efficiency and productivity. Among the many innovations, the Corrugated Iron Sheet Making Machine (name removed) has emerged as a game-changer, revolutionizing how corrugated iron sheets are manufactured.With the global demand for corrugated iron sheets on the rise, this advanced machine offers a streamlined and efficient solution for manufacturers. By automating the production process, it not only eliminates the labor-intensive manual work but also significantly reduces the time required for sheet production.The Corrugated Iron Sheet Making Machine features cutting-edge technology and a high level of precision, ensuring the production of top-quality iron sheets with consistent dimensions and ridges. This not only enhances the overall performance of the sheets but also offers improved durability and weather resistance.One of the key advantages of this machine is its versatility. It can produce corrugated iron sheets in various sizes, thicknesses, and profiles. This flexibility caters to the diverse needs of the construction industry, allowing manufacturers to meet specific requirements for different applications. Whether it's for roofing, siding, or fencing, the Corrugated Iron Sheet Making Machine can deliver the desired outcome with ease.Moreover, the machine incorporates advanced safety features to ensure the well-being of workers. With automated controls and protective measures, it minimizes the risk of accidents, making it a safe and reliable option for factories and manufacturing units. This not only enhances worker safety but also boosts overall operational efficiency by minimizing downtime.In addition to its technical capabilities, the Corrugated Iron Sheet Making Machine is eco-friendly. It is designed to optimize energy consumption and minimize waste production. By using sustainable manufacturing practices, it aligns with the growing global trend of eco-conscious construction. This aspect not only highlights the machine's efficiency but also positions it as a responsible choice in an industry striving for sustainability.Company Introduction:As a key player in the construction industry, our company has been at the forefront of providing innovative solutions to meet the evolving needs of builders and contractors. With a strong commitment to quality, efficiency, and sustainability, we have established ourselves as a trusted partner for numerous construction projects worldwide.Our team of engineers and industry experts has invested years of research and development to perfect the Corrugated Iron Sheet Making Machine. By combining cutting-edge technology with extensive market knowledge, we have successfully developed a machine that exceeds industry standards and offers unparalleled performance.Our company's mission is to revolutionize the way corrugated iron sheets are manufactured, making the process more efficient, cost-effective, and eco-friendly. We believe that the Corrugated Iron Sheet Making Machine will not only empower manufacturers but also contribute to the sustainable growth of the construction industry.With a focus on customer satisfaction, our dedicated sales and after-sales support teams are always ready to assist clients at every step of the process. From initial consultations to installation, training, and maintenance, we are committed to ensuring a seamless experience for our valued customers.In conclusion, the Corrugated Iron Sheet Making Machine is a significant innovation that is transforming the construction industry. Its technological advancements, versatility, safety features, and eco-friendly approach make it a perfect solution for manufacturers looking to improve productivity while adhering to sustainable practices. With our company's expertise and commitment, we are proud to introduce this groundbreaking machine to the market and cater to the evolving needs of the construction industry.

Discover the Latest Advancements in Color Steel Glazed Tile Sheet Manufacturing and Corrugation Equipment

Color Steel Glazed Tile Sheet Manufacturing And Corrugation Equipment – A Boon to Construction IndustryConstruction industry is a rapidly growing sector, which directly contributes to the economic development of a nation, by providing employment and constructing buildings and infrastructure facilities that are crucial for the progress of society. The quality of the materials used in construction plays a vital role in ensuring safety and durability of the built structures. In this regard, the advent of the latest color steel glazed tile sheet manufacturing and corrugation equipment has revolutionized the construction industry, by providing the most advanced machinery for manufacturing and processing high-quality building materials.One such company, (remove brand name), with its state-of-the-art manufacturing facility, produces a range of fully automated and customized color steel glazed tile sheet manufacturing and corrugation equipment, suited for various types of building constructions. The equipment is primarily designed for producing roof tiles, wall tiles, corrugated roofing sheets, and other building components with high precision and consistency. The whole process is fully automated, which significantly reduces the overall production time and labor costs, while simultaneously improving the quality of the finished products.The company has been operating in the industry for over (insert year) and has rich experience in the field of manufacturing and supplying high-quality equipment for the construction industry. (insert brand name) is committed to providing its clients with the highest quality products, which have undergone rigorous quality checks and are designed to meet international quality standards.The machinery designed by (insert brand name) is fully customizable, based on the specific requirements of the clients. The company offers a wide range of options, including different thicknesses of the materials, colors, and sizes, to cater to the diverse needs of the customers. The equipment is designed to produce products with precise dimensions, making it suitable for building constructions, where accuracy and uniformity are of paramount importance.The color steel glazed tile sheet manufacturing and corrugation equipment provided by (insert brand name) is energy-efficient, which is vital in today's world, where the increasing demand for energy poses significant challenges. The machines have been designed to consume minimum energy while providing maximum output, thereby reducing the carbon footprint associated with manufacturing.The equipment manufactured by (insert brand name) is not only efficient in terms of energy and cost but also easy to operate, thereby requiring minimal training for the operators. The machines are designed to be user-friendly, ensuring high productivity, and ensuring adherence to the required safety standards in the industry. Additionally, the equipment comes with a warranty and after-sales support, ensuring that the clients can get continuous services and support as and when required.The team at (insert brand name) comprises experienced and qualified professionals who are committed to providing their clients with the best possible solutions. They have the expertise to understand the client's needs and offer customized solutions that meet their specific requirements. The company also offers a range of services, including installation, commissioning, and maintenance, ensuring that the client's machinery is well taken care of, and any downtime is minimized through prompt support.In conclusion, the color steel glazed tile sheet manufacturing and corrugation equipment provided by (insert brand name) is a technological marvel that has revolutionized the construction industry. The equipment not only improves the overall quality of the products but also reduces the manufacturing time and costs. Moreover, the equipment is eco-friendly, energy-efficient, and easy to operate and maintain, making it an ideal choice for companies looking for sustainable and efficient solutions to their manufacturing needs. The company's commitment to quality, safety, and service has made it a preferred supplier among clients across the world.

Durable and Efficient Aluminum Extrusion Bending Machine for Industrial Use

Aluminum Extrusion Bending Machine Revolutionizes Production at Manufacturing CompanyThe manufacturing industry has always been at the forefront of technological innovation, constantly evolving and adapting to the changing demands of the market. In recent years, the use of aluminum extrusion bending machines has become increasingly prevalent in the industry, offering a more efficient and precise method of shaping aluminum extrusions for various applications. One company that has embraced this technology is [Company Name], a leading manufacturer of aluminum products.The [Company Name] has recently invested in a state-of-the-art aluminum extrusion bending machine, which has significantly revolutionized their production processes. This cutting-edge machine has enabled the company to enhance its capabilities and offer a wider range of products to its customers.The aluminum extrusion bending machine has been a game-changer for [Company Name], allowing them to produce complex and intricate designs with a high degree of accuracy and precision. By utilizing advanced CAD/CAM software, the machine is able to create custom shapes and designs, providing a level of flexibility that was previously unattainable with traditional bending methods.Furthermore, the efficiency of the aluminum extrusion bending machine has resulted in a significant reduction in production time, allowing [Company Name] to fulfill orders more quickly and efficiently. This has had a positive impact on the company's bottom line, as well as improving customer satisfaction by delivering products in a timely manner.In addition to the tangible benefits of increased efficiency and precision, the aluminum extrusion bending machine has also allowed [Company Name] to expand its product offerings. The machine's versatility and flexibility have empowered the company to take on a wider variety of projects and meet the diverse needs of its customers.[Company Name] has always prided itself on its commitment to innovation and advancement, and the investment in the aluminum extrusion bending machine is a testament to this ethos. By staying ahead of the curve and embracing the latest technology, the company has been able to maintain its position as a leader in the industry, while also setting new standards for quality and productivity.Furthermore, the company's dedication to excellence doesn't stop at technology – it extends to its skilled workforce as well. The operators and technicians who work with the aluminum extrusion bending machine undergo rigorous training and certification programs to ensure that they are able to maximize the machine's capabilities and deliver the highest quality products to customers.Looking ahead, [Company Name] is committed to leveraging the full potential of the aluminum extrusion bending machine, as well as exploring other cutting-edge technologies that can further elevate its production processes. By continuously seeking out new opportunities for improvement and growth, the company is poised to remain at the forefront of the industry for years to come.In conclusion, the investment in the aluminum extrusion bending machine has been a game-changer for [Company Name], empowering them to elevate their production processes and offer a wider range of products to their customers. By embracing advanced technology and fostering a culture of innovation, the company has solidified its position as a leader in the manufacturing industry, setting new standards for efficiency, precision, and quality. As they continue to push the boundaries of what is possible, [Company Name] is poised for even greater success in the years to come.