Latest Innovations in Roll Forming Technology for R Panel Manufacturing

By:Admin

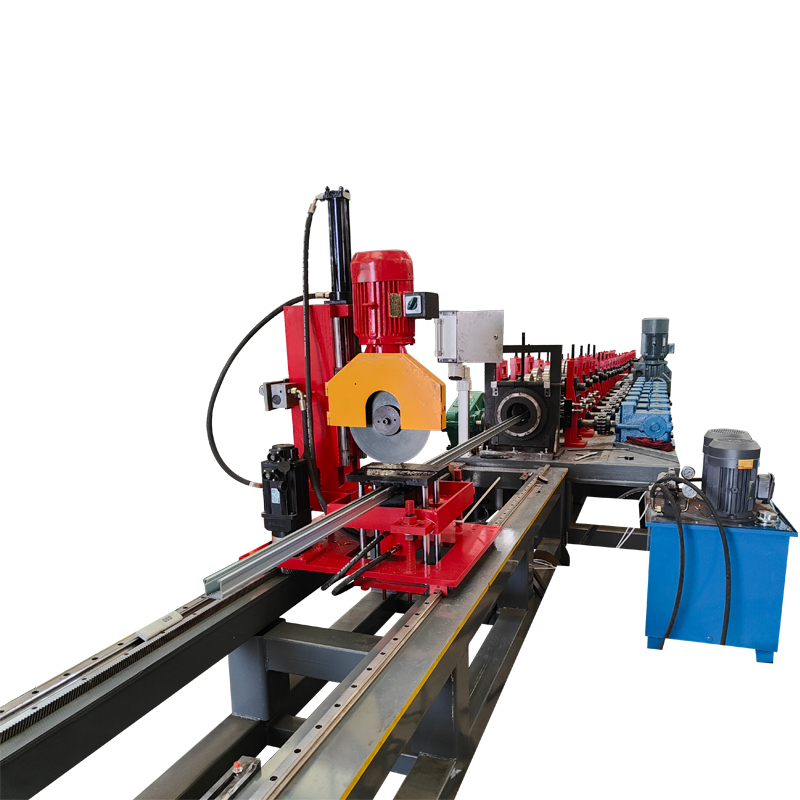

[Company Name] Unveils State-of-the-Art R Panel Roll Former

[City, State] – [Company Name], a leading manufacturer of industrial equipment, has announced the launch of its latest innovation – the R Panel Roll Former. This cutting-edge machine is designed to revolutionize the metal roofing industry, offering advanced features and superior performance.

The R Panel Roll Former is the result of [Company Name]'s commitment to excellence and innovation. With over [number] years of experience in the industry, the company has established itself as a trusted provider of high-quality equipment and machinery. The R Panel Roll Former is the latest addition to its extensive product lineup, and it promises to set new standards in terms of efficiency and reliability.

Featuring a [specific feature], the R Panel Roll Former is capable of producing [number] panels per minute, making it one of the fastest machines on the market. This exceptional speed, combined with its precision engineering, ensures that [Company Name]'s customers will be able to increase their productivity and meet the growing demand for metal roofing products.

In addition to its impressive performance, the R Panel Roll Former is also designed with user-friendliness in mind. [Company Name] has incorporated [specific feature] into the machine, allowing operators to easily adjust settings and monitor the production process. This intuitive design ensures that even those with minimal experience can operate the roll former with ease.

"We are thrilled to introduce the R Panel Roll Former to the market," said [Company Name]'s CEO. "This machine represents a significant leap forward in terms of technology and capability, and we are confident that it will make a positive impact on our customers' operations. We are dedicated to providing innovative solutions that empower our clients to succeed, and the R Panel Roll Former is a testament to that commitment."

The launch of the R Panel Roll Former is a reflection of [Company Name]'s continued investment in research and development. With a team of talented engineers and designers, the company is constantly seeking ways to improve its products and exceed customer expectations. The roll former is the latest example of this dedication, and it is sure to solidify [Company Name]'s position as a leader in the industry.

The R Panel Roll Former is now available for purchase, and [Company Name] is excited to see the impact it will have on the metal roofing market. With its unparalleled speed, precision, and user-friendly design, the roll former is poised to become an indispensable tool for companies looking to optimize their production processes and elevate their competitiveness.

For more information about the R Panel Roll Former and [Company Name]'s other products, interested parties are encouraged to visit the company's website or contact their sales department.

About [Company Name]:

[Company Name] is a renowned manufacturer of industrial equipment, specializing in [specific industry]. With a focus on innovation and quality, the company has earned a reputation for delivering cutting-edge solutions that empower its customers to thrive in a competitive marketplace. For [number] years, [Company Name] has been at the forefront of the industry, providing reliable products and exceptional service to clients around the world.

For media inquiries, please contact:

[Contact Name]

[Company Name]

[Phone Number]

[Email Address]

[Company Website]

Company News & Blog

Durable and Efficient Aluminum Extrusion Bending Machine for Industrial Use

Aluminum Extrusion Bending Machine Revolutionizes Production at Manufacturing CompanyThe manufacturing industry has always been at the forefront of technological innovation, constantly evolving and adapting to the changing demands of the market. In recent years, the use of aluminum extrusion bending machines has become increasingly prevalent in the industry, offering a more efficient and precise method of shaping aluminum extrusions for various applications. One company that has embraced this technology is [Company Name], a leading manufacturer of aluminum products.The [Company Name] has recently invested in a state-of-the-art aluminum extrusion bending machine, which has significantly revolutionized their production processes. This cutting-edge machine has enabled the company to enhance its capabilities and offer a wider range of products to its customers.The aluminum extrusion bending machine has been a game-changer for [Company Name], allowing them to produce complex and intricate designs with a high degree of accuracy and precision. By utilizing advanced CAD/CAM software, the machine is able to create custom shapes and designs, providing a level of flexibility that was previously unattainable with traditional bending methods.Furthermore, the efficiency of the aluminum extrusion bending machine has resulted in a significant reduction in production time, allowing [Company Name] to fulfill orders more quickly and efficiently. This has had a positive impact on the company's bottom line, as well as improving customer satisfaction by delivering products in a timely manner.In addition to the tangible benefits of increased efficiency and precision, the aluminum extrusion bending machine has also allowed [Company Name] to expand its product offerings. The machine's versatility and flexibility have empowered the company to take on a wider variety of projects and meet the diverse needs of its customers.[Company Name] has always prided itself on its commitment to innovation and advancement, and the investment in the aluminum extrusion bending machine is a testament to this ethos. By staying ahead of the curve and embracing the latest technology, the company has been able to maintain its position as a leader in the industry, while also setting new standards for quality and productivity.Furthermore, the company's dedication to excellence doesn't stop at technology – it extends to its skilled workforce as well. The operators and technicians who work with the aluminum extrusion bending machine undergo rigorous training and certification programs to ensure that they are able to maximize the machine's capabilities and deliver the highest quality products to customers.Looking ahead, [Company Name] is committed to leveraging the full potential of the aluminum extrusion bending machine, as well as exploring other cutting-edge technologies that can further elevate its production processes. By continuously seeking out new opportunities for improvement and growth, the company is poised to remain at the forefront of the industry for years to come.In conclusion, the investment in the aluminum extrusion bending machine has been a game-changer for [Company Name], empowering them to elevate their production processes and offer a wider range of products to their customers. By embracing advanced technology and fostering a culture of innovation, the company has solidified its position as a leader in the manufacturing industry, setting new standards for efficiency, precision, and quality. As they continue to push the boundaries of what is possible, [Company Name] is poised for even greater success in the years to come.

High-quality Galvanized Steel Sheet Roof Glazed Tile Roll Forming Machine Available

Title: Enhance Your Roof's Style and Durability with Galvanized Steel Glazed Tile Sheet Roll FormingIntroduction (100 words):When it comes to roofing, it's crucial to choose materials that strike a balance between aesthetics and durability. One such option is the galvanized steel glazed tile sheet. This innovative roofing solution not only offers exceptional strength and longevity but also enhances the overall appeal of any structure. To bring this fascinating product to life, manufacturers rely on state-of-the-art machinery, like the Color Steel Glazed Tile Sheet Roll Forming and Corrugation Line. In this article, we will delve into the benefits, features, and functionality of this machinery, highlighting its significance in constructing top-quality galvanized steel glazed tile sheet roofs.Section 1: The Advantages of Galvanized Steel Glazed Tile Sheet Roofing (200 words)Galvanized steel glazed tile sheet roofing is quickly gaining popularity across the construction industry, and for good reason. Let's explore the key advantages this product has to offer:1. Durability: Galvanized steel offers exceptional strength and longevity, making it highly resistant to corrosion, impacts, and extreme weather conditions.2. Versatility: The glazed tile pattern adds a touch of elegance to any structure, making it suitable for residential, commercial, and industrial applications alike.3. Low maintenance: With its excellent resistance to rust, rot, and cracks, galvanized steel glazed tile sheet roofing requires minimal maintenance, saving you time and money in the long run.4. Energy efficiency: These roofs provide excellent insulation properties, resulting in reduced heating and cooling costs throughout the year.5. Environmentally friendly: Galvanized steel is 100% recyclable, ensuring a sustainable roofing solution that minimizes environmental impact.Section 2: The Role of the Color Steel Glazed Tile Sheet Roll Forming and Corrugation Line (400 words) The Color Steel Glazed Tile Sheet Roll Forming and Corrugation Line is an essential piece of machinery used to fabricate galvanized steel glazed tile sheet roofing. Let's explore its features and functionality:1. High Precision Manufacturing: This roll forming machine ensures precise and accurate shaping and sizing of the glazed tile sheet roofing. It employs advanced technologies to deliver consistent quality throughout the production process.2. Automated Production Process: The machine operates through a fully automated control system, minimizing manual labor requirements and reducing the chances of errors. This automation streamlines the production process, enhancing efficiency and productivity.3. Customization Options: The Color Steel Glazed Tile Sheet Roll Forming and Corrugation Line allows manufacturers to cater to a wide range of customer preferences by offering customizable options like color, shape, and size.4. Quick and Efficient Operation: This machinery boasts high-speed production capabilities to meet the demands of large-scale projects. It ensures a smooth and uninterrupted workflow, minimizing downtime and maximizing output.5. Easy Maintenance and Longevity: The roll forming machine is built with durability in mind. Equipped with high-quality components and precise engineering, it provides long service life with minimal maintenance requirements.Conclusion (200 words):Investing in a galvanized steel glazed tile sheet roof has numerous benefits. Not only does it elevate the architecture of a structure but also offers unmatched durability, energy efficiency, and low maintenance requirements. To ensure the impeccable quality and precise shaping of these roofs, the Color Steel Glazed Tile Sheet Roll Forming and Corrugation Line plays a vital role. Its automated production process, customization options, and high-speed capabilities are a testament to the importance of advanced machinery in manufacturing such roofing solutions.If you're in search of a reliable roofing material that combines practicality and aesthetic appeal, galvanized steel glazed tile sheet roofing is the answer. And with the Color Steel Glazed Tile Sheet Roll Forming and Corrugation Line, manufacturers can effortlessly produce these roofs to meet the demands of various construction projects. So, enhance your structure's style and longevity by opting for galvanized steel glazed tile sheet roofing, backed by state-of-the-art roll forming machinery.

Discover the Art of Aluminium Profile Bending for Enhanced Applications

Aluminium Profile Bending Brings a New Era of ManufacturingThe recent years have seen a drastic rise in the popularity and use of aluminium profiles. They are being extensively used in a diverse range of industries such as automobile, construction, and aerospace. The reason behind the emergence of this trend is the unparalleled advantages that come with using these profiles. They offer high strength, lightness, and durability. They are also easy to manufacture and mould. However, the real challenge arises when it comes to moulding these profiles into the desired shapes and sizes. This is where Aluminium Profile Bending has brought about a revolution in the manufacturing industry.Aluminium Profile Bending (APB), a technique that has been developed by a leading company in the manufacturing industry, has revolutionized the way aluminium profiles are moulded. With the introduction of this technique, manufacturers can now bend the profiles into any desired shape and size. The shapes can vary from simple curves to complex designs. This technique is particularly useful for manufacturing aluminum profiles for the construction industry that require intricate shapes, making it impossible to produce using conventional techniques.Advanced technology and expertise are required to carry out the bending of aluminum profiles, which is where the company that developed APB excels. They have a team of immensely skilled technicians who use cutting-edge equipment to ensure precision in the bending of the profiles. Using this technique, the team can accurately bend even the most intricate shapes.The advantages of APB are numerous. Firstly, it offers a high level of precision which allows for the creation of complex and intricate designs. Secondly, the technique is much more cost-effective, as it reduces the waste material that is produced during the conventional manufacturing process. APB also eliminates the need for additional manufacturing processes that might be required to achieve the desired shape, which again translates to cost savings. Additionally, it provides excellent finish quality and surface appearance, making it ideal for high-quality products such as those required in the automotive and aerospace industries.The use of APB is not limited to aluminum profiles only. The technique can also be used with other metals, including copper, brass, and stainless steel. This versatility means that manufacturers now have even more options when it comes to the manufacturing of complex shapes and designs.The development of APB has had a significant impact on the manufacturing industry. It has not only reduced production costs but has also opened up new possibilities for manufacturers. With this technique, they can now produce complex and intricate designs that were previously not possible.With the increasing demand for aluminium profiles, it is evident that the manufacturing industry needs to embrace new technologies and techniques to stay ahead of the competition. The introduction of Aluminium Profile Bending has provided manufacturers with a game-changing solution to their manufacturing problems. As new and better technologies continue to emerge, it is essential that manufacturers keep an eye out for innovations that could improve their manufacturing processes.In conclusion, Aluminium Profile Bending has revolutionized the way aluminium profiles are moulded, giving manufacturers the ability to produce complex and intricate designs accurately. The technique offers a high level of precision, reduces production costs, and eliminates the need for additional manufacturing processes, making it ideal for a diverse range of industries. As manufacturing technologies continue to evolve, it is essential for manufacturers to stay up-to-date with the latest innovations and techniques to remain competitive in the industry.

High-Quality Ridge Cap Roll Forming Machine for Sale - Ultimate Guide

Ridge Cap Roll Forming Machine is a new addition to the collection of premium roll forming machines offered by {}. This state-of-the-art machine has been designed to produce high-quality ridge caps for roofing applications with precision and efficiency. With the ability to roll form metal sheets into desired ridge cap profiles, this machine is a game-changer for roofing contractors and manufacturers.The Ridge Cap Roll Forming Machine from {} is equipped with advanced technology and features that ensure smooth and accurate production of ridge caps. It has a user-friendly interface that allows for easy operation and control. Additionally, the machine is built with high-quality materials and components, making it durable and long-lasting.One of the key advantages of this roll forming machine is its versatility. It can accommodate a wide range of metal sheet materials, including galvanized steel, aluminum, and stainless steel, allowing for flexibility in ridge cap production. Whether it's a residential, commercial, or industrial roofing project, this machine can meet the demands of various applications.Moreover, the Ridge Cap Roll Forming Machine is designed for high-speed production, enabling manufacturers to increase their output and meet tight deadlines without compromising on quality. This can help businesses improve their efficiency and competitiveness in the market.With a commitment to delivering excellence, {} has ensured that their Ridge Cap Roll Forming Machine complies with industry standards and regulations. The machine undergoes rigorous testing and quality checks to guarantee its performance and reliability. Customers can have peace of mind knowing that they are investing in a top-of-the-line roll forming solution.In addition to the machine itself, {} also provides comprehensive support and services to its customers. From installation and training to maintenance and troubleshooting, the company's team of experts is dedicated to assisting clients every step of the way. This ensures that customers can maximize the potential of the Ridge Cap Roll Forming Machine and achieve the best results.Furthermore, {} takes pride in its continuous innovation and improvement of roll forming technology. The company stays ahead of industry trends and customer needs, constantly enhancing its products to stay at the forefront of the market. This commitment to innovation is reflected in the Ridge Cap Roll Forming Machine, which incorporates the latest advancements in roll forming technology.In summary, the introduction of the Ridge Cap Roll Forming Machine from {} is a significant development for the roofing industry. With its precision, efficiency, versatility, and reliability, this machine offers a competitive edge to businesses involved in ridge cap production. As {} continues to lead the way in roll forming solutions, customers can expect more groundbreaking products that will elevate their manufacturing capabilities.

Revolutionary rollformer technology advances construction industry

The latest addition to the metal construction industry, an advanced rollformer, is set to revolutionize the way buildings are constructed. This cutting-edge technology, developed by a renowned company, promises to streamline the construction process and deliver superior quality structures in a cost-effective manner.The rollformer, developed by a highly reputable company, takes metal construction to new heights. Its precise engineering and innovative design ensure that buildings are constructed efficiently and with utmost precision. This advanced technology allows for rapid assembly of metal frames, significantly reducing construction time and costs.The rollformer employs state-of-the-art automation features, enabling seamless integration with CAD (Computer-Aided Design) software. The synergy between the rollformer and the company's advanced software allows for precise customization of metal frames, catering to the unique requirements of each project. With the ability to automatically generate accurate measurements and specifications, the rollformer eliminates human error and ensures seamless integration of structural elements.In addition to its superior automation capabilities, the rollformer boasts a durable and robust construction. With high-quality materials used in its manufacturing, the rollformer guarantees a long lifespan, ensuring uninterrupted operation for years to come. Its reliability and consistency make it the preferred choice for large-scale construction projects, where precision and speed are of the essence.The rollformer offers numerous advantages over traditional construction methods. Its ability to fabricate metal frames on-site eliminates the need for transporting pre-fabricated components, reducing transport costs and logistical complexities. Moreover, the rollformer eliminates the need for complex on-site welding, thereby enhancing the safety of the construction process.One of the key features of this rollformer is its adaptability to various types of metal. Whether it's steel, aluminum, or other metal alloys, the rollformer can efficiently fabricate frames using the material of choice for each project. This versatility expands the possibilities for architects and construction companies, enabling them to explore innovative designs without compromising on quality or functionality.The rollformer's impact on the construction industry is not limited to efficiency and quality. Its environmentally friendly design aligns with the global push for sustainable construction practices. By minimizing waste generation and optimizing resource utilization, the rollformer significantly reduces the carbon footprint associated with traditional construction methods. This environmentally conscious approach makes it an ideal choice for companies aiming to contribute towards a greener future.Furthermore, the rollformer's realization of rapid assembly of metal frames opens up opportunities for companies to take on larger projects. The increase in efficiency and cost-effectiveness provided by the rollformer allows construction companies to not only complete projects faster but also take on more contracts simultaneously. This leads to economic growth within the industry by creating more job opportunities and stimulating overall development.With its revolutionary rollformer, this innovative company is set to disrupt the metal construction industry. By combining cutting-edge automation with superior quality materials, the rollformer streamlines the construction process while delivering impeccable structures. Its adaptability, durability, and environmental consciousness make it the go-to choice for construction companies seeking to enhance their operations and contribute towards a sustainable future.In conclusion, the introduction of the rollformer signifies a remarkable advancement in the metal construction industry. The combination of advanced automation, precise engineering, and adaptability to various metals positions it as a game-changer. As construction companies strive to meet increasing demands for efficiency, quality, and sustainability, the rollformer emerges as the perfect solution to stay ahead of the curve.

High-Quality Glazed Tile Making Machine for Efficient Production

For immediate releaseA New Innovation in Glazed Tile Making Technology: Introducing the Glazed Tile Making MachineAs the demand for high-quality construction materials continues to rise, the need for innovative and efficient manufacturing solutions becomes increasingly important. That’s why we are excited to introduce the new Glazed Tile Making Machine, a revolutionary piece of equipment that is set to change the landscape of the construction industry.The Glazed Tile Making Machine is the latest innovation from our company, a leading manufacturer of industrial machinery and equipment. With a strong focus on research and development, we have been at the forefront of technological advancements in the manufacturing sector for over two decades. Our commitment to excellence and innovation has led us to develop the Glazed Tile Making Machine, a state-of-the-art piece of equipment that promises to revolutionize the way glazed tiles are produced.One of the key features of the Glazed Tile Making Machine is its advanced automation capabilities. Equipped with cutting-edge technology, the machine is capable of carrying out the entire tile production process with minimal human intervention. This not only increases productivity and efficiency but also ensures consistent and high-quality output, meeting the demands of modern construction projects.In addition to its automation capabilities, the Glazed Tile Making Machine also boasts a high level of customization. With the ability to produce a wide range of tile sizes, shapes, and designs, the machine offers unprecedented flexibility to meet the diverse needs of our customers. Whether it’s a small-scale residential project or a large commercial development, the Glazed Tile Making Machine is capable of delivering customized solutions to suit any requirement.Furthermore, the Glazed Tile Making Machine is designed with sustainability in mind. As environmental concerns continue to grow, the machine has been developed to minimize waste and energy consumption, making it an eco-friendly option for manufacturers. By using advanced materials and production techniques, the machine ensures that the manufacturing process is as environmentally friendly as possible, aligning with the global push for sustainable practices.The introduction of the Glazed Tile Making Machine marks a significant milestone in the evolution of the construction industry. With its innovative features and advanced capabilities, the machine is set to redefine the way glazed tiles are manufactured, setting new standards for efficiency, quality, and sustainability.As we look to the future, we remain committed to pushing the boundaries of innovation and technology in the manufacturing sector. The Glazed Tile Making Machine is just one example of our dedication to providing cutting-edge solutions to our customers, and we are excited to see the impact it will have on the industry.In conclusion, the Glazed Tile Making Machine represents a new era in the production of glazed tiles. With its advanced automation, customization, and sustainability features, the machine is set to revolutionize the way tiles are manufactured, providing a cost-effective and environmentally friendly solution for the construction industry. We are proud to introduce this groundbreaking technology and look forward to the positive impact it will have on our customers and the wider industry.For more information about the Glazed Tile Making Machine, please visit our website or contact us directly for inquiries and demonstrations.

Guide to Purlin Roll Forming: Everything You Need to Know

Purlin Roll Forming Technology Advancement Revolutionizes the IndustryPurlins are an essential component in the construction of roofs and walls in buildings, providing structural support and stability. The process of forming purlins has traditionally been labor-intensive and time-consuming, but thanks to the latest technological advancements in purlin roll forming, the industry is undergoing a revolution.The introduction of state-of-the-art purlin roll forming technology by {} has significantly improved the efficiency and accuracy of purlin production. This innovative technology allows for the rapid and precise shaping of purlins from raw materials such as steel, aluminum, or other metals, resulting in a high-quality end product.{} is at the forefront of this technological revolution, offering a range of purlin roll forming machines that cater to the diverse needs of the construction industry. Their machines are designed to handle various sizes and thicknesses of materials, providing flexibility and versatility for different construction projects.One of the key advantages of {}'s purlin roll forming technology is its ability to streamline the production process. Traditional methods of forming purlins involved multiple steps and manual labor, leading to higher production costs and a longer turnaround time. With the new technology, purlins can be manufactured in a fraction of the time, ultimately reducing production costs and increasing overall productivity.Furthermore, the precision and consistency achieved through purlin roll forming technology ensure that the end products meet strict quality standards. This is particularly important in the construction industry, where the structural integrity of buildings relies on the strength and durability of purlins. With {}'s advanced roll forming technology, construction companies can have peace of mind knowing that the purlins used in their projects are of the highest quality.In addition to the technological advancements, {} is also committed to sustainability and environmental responsibility. Their purlin roll forming machines are designed to minimize material waste and energy consumption, contributing to a more eco-friendly production process. As sustainability continues to be a priority for many industries, {}'s dedication to green manufacturing sets them apart as an industry leader.The impact of purlin roll forming technology goes beyond just the manufacturing process. It has the potential to revolutionize the construction industry as a whole, offering new possibilities for innovative and cost-effective building designs. The speed and precision of the technology open up opportunities for more complex and creative purlin shapes, which can contribute to the aesthetic appeal of buildings.Furthermore, the increased efficiency and reduced production costs associated with purlin roll forming technology can ultimately benefit the end consumers. As construction companies are able to save on manufacturing expenses, these savings can be passed on to clients, making construction projects more affordable and accessible.With the rapid advancements in purlin roll forming technology, the construction industry is entering a new era of efficiency, precision, and sustainability. Companies like {} are at the forefront of this transformation, providing the tools and technology to drive innovation and progress in the industry. As the demand for high-quality purlins continues to grow, purlin roll forming technology is poised to play a central role in meeting these needs and shaping the future of construction.

High-Quality Floor Deck Forming Machine for Efficient Construction Projects

Floor Deck Forming Machine Revolutionizes Construction Industry{Company Name}, a leading manufacturer in the construction machinery industry, has recently launched its latest innovation - the Floor Deck Forming Machine. This revolutionary machine is set to transform the way floor decking is produced in the construction industry, bringing about increased efficiency, accuracy, and cost savings.The Floor Deck Forming Machine is designed to streamline the process of manufacturing floor decks, which are essential components in construction projects. Traditionally, floor decks are formed using manual labor or outdated machinery, leading to inconsistencies in production and higher costs. However, with the introduction of {Company Name}'s Floor Deck Forming Machine, these challenges are set to become a thing of the past.The machine is equipped with state-of-the-art technology and the latest advancements in engineering, allowing for the precise production of floor decks in a highly efficient manner. With the ability to produce a wide range of floor deck profiles and sizes, the machine is versatile and adaptable to various construction project requirements.One of the key features of the Floor Deck Forming Machine is its high-speed production capabilities. The machine is capable of producing floor decks at a rapid pace, significantly reducing lead times and increasing overall production output. This not only improves project timelines but also allows for cost savings in labor and resources.In addition to speed, the Floor Deck Forming Machine also boasts exceptional accuracy and consistency in production. The machine's advanced automation ensures that each floor deck is manufactured to precise specifications, resulting in high-quality and uniform products every time. This level of precision is essential in ensuring structural integrity and safety in construction projects.Furthermore, the Floor Deck Forming Machine is designed with user-friendliness in mind. Its intuitive interface and easy-to-use controls make operation straightforward, allowing for seamless integration into existing manufacturing processes. This ease of use minimizes the need for extensive training and reduces the likelihood of errors during production.{Company Name} has a strong reputation for delivering reliable and innovative machinery to the construction industry. With a commitment to quality and customer satisfaction, the company's Floor Deck Forming Machine is backed by comprehensive technical support and after-sales service. This provides peace of mind to customers, knowing that they can rely on {Company Name} for ongoing assistance and maintenance of their machinery.The introduction of the Floor Deck Forming Machine is expected to have a significant impact on the construction industry. Its ability to streamline production, improve efficiency, and deliver high-quality results is set to benefit construction companies, contractors, and builders alike. The machine's cost-effective production process also has the potential to reduce overall project costs, making it an attractive investment for businesses in the construction sector.In conclusion, {Company Name}'s Floor Deck Forming Machine is a game-changer for the construction industry. Its advanced technology, high-speed production capabilities, and precision engineering set a new standard for floor deck manufacturing. With a focus on delivering reliable and innovative solutions, {Company Name} continues to demonstrate its commitment to driving progress and excellence in the construction machinery industry.

Key Considerations in Selecting Forming Machinery for Your Business

Forming Machinery, a leading company in the manufacturing industry, has recently made significant advancements in their machinery technology that is set to revolutionize the industry.With a dedication to innovation and quality, Forming Machinery has been at the forefront of developing high-performance machinery for various applications. Their team of experts and engineers are constantly working on improving their products to meet the evolving needs of their customers.The latest development from Forming Machinery is a state-of-the-art forming machine that is designed to streamline the manufacturing process and improve overall efficiency. This new machinery boasts advanced features such as precision forming capabilities, automated processes, and a user-friendly interface.One of the key highlights of this new forming machine is its ability to work with a wide range of materials, including steel, aluminum, and other metals. This versatility makes it a highly sought-after solution for manufacturers in various industries, including automotive, construction, and aerospace.In addition to its material versatility, the new forming machine also offers precise forming capabilities that ensure high-quality finished products. This level of precision is essential for industries that require intricate and complex metal components.The automation features of the new forming machine further enhance its appeal. By automating certain processes, manufacturers can reduce manual labor and increase production output. This not only leads to cost savings but also allows for faster turnaround times on orders.The user-friendly interface of the new forming machine is another standout feature. Forming Machinery has prioritized usability in their design, making it easy for operators to understand and control the machine. This intuitive interface promotes efficiency and reduces the learning curve for new users.Forming Machinery's commitment to delivering cutting-edge solutions is further demonstrated through their dedication to customer satisfaction. They offer comprehensive support and training for their products, ensuring that their customers can maximize the benefits of their machinery.In addition to their technological advancements, Forming Machinery also places a strong emphasis on sustainability. Their machines are designed to minimize waste and energy consumption, contributing to a more environmentally friendly manufacturing process.Forming Machinery's success in the industry can be attributed to their relentless pursuit of excellence and their ability to adapt to changing market demands. They have built a reputation for delivering reliable and innovative machinery that meets the needs of their diverse customer base.As the manufacturing industry continues to evolve, Forming Machinery remains committed to pushing the boundaries of what is possible. Their latest development in forming machinery is a testament to their ongoing efforts to provide industry-leading solutions.In conclusion, Forming Machinery's new forming machine represents a significant milestone in the manufacturing industry. With its advanced features, versatility, and commitment to customer satisfaction, it is poised to become a game-changer for manufacturers across various sectors. Forming Machinery's dedication to innovation and quality ensures that they will remain a key player in the industry for years to come.

High-Quality Machinery for Making Glazed Roof Tiles at an Affordable Price

[A generic image of a tile making machinery can be added here]In today's fast-paced world, it's crucial for businesses to stay ahead of the game by utilizing the latest technology and machinery. One industry that has seen significant advancements in recent years is the construction industry. With the demand for sustainable and durable building materials on the rise, companies are constantly innovating and improving their manufacturing processes. One such company that is leading the way in this regard is {Company Name}.{Company Name} is a renowned manufacturer of construction machinery and equipment. With a strong focus on innovation and quality, the company has earned a reputation for delivering cutting-edge solutions to its customers. One of its flagship products is the Glazed Roof Tile Making Machinery.The Glazed Roof Tile Making Machinery developed by {Company Name} is a state-of-the-art solution for manufacturing high-quality glazed roof tiles. The machinery is designed to streamline the production process, ensuring efficiency and precision at every stage. With its advanced technology and superior craftsmanship, the machinery is capable of producing a wide range of glazed roof tiles with varying designs and specifications.The key features of the Glazed Roof Tile Making Machinery include its automated operation, high production capacity, and energy efficiency. The machinery is equipped with advanced sensors and control systems that allow for seamless operation without any manual intervention. This not only reduces the labor costs but also ensures consistent output quality. Additionally, the machinery is designed to maximize productivity, with a high production capacity that can meet the demands of large-scale projects. Furthermore, the energy-efficient design of the machinery helps in reducing the overall operational costs, making it an economical choice for businesses.In addition to its technical capabilities, the Glazed Roof Tile Making Machinery is also known for its user-friendly interface and easy maintenance. The machinery is designed with the end-user in mind, with intuitive controls and a user-friendly interface that allows for easy operation. Furthermore, the machinery is built to withstand the rigors of continuous use, with minimal maintenance requirements, ensuring maximum uptime and productivity for the customers.{Company Name}'s Glazed Roof Tile Making Machinery has already gained significant traction in the market, with several successful installations and satisfied customers. The machinery has been widely praised for its performance, reliability, and cost-effectiveness, making it a preferred choice for businesses looking to enhance their production capabilities.With the global construction industry witnessing a surge in demand for sustainable and aesthetically appealing building materials, the Glazed Roof Tile Making Machinery by {Company Name} is well-positioned to capitalize on this trend. The machinery offers a perfect blend of technology, quality, and efficiency, making it an ideal choice for businesses looking to stay ahead of the competition.In conclusion, the Glazed Roof Tile Making Machinery developed by {Company Name} is a testament to the company's commitment to innovation and excellence. With its advanced technology, superior craftsmanship, and customer-centric approach, the machinery has set a new standard in the construction industry. As the demand for high-quality glazed roof tiles continues to grow, {Company Name} is well-positioned to emerge as a key player in the market, offering innovative solutions that cater to the evolving needs of its customers.