Top Corrugated Roof Tile Barrel Sheet Profiling Machine for Your Home

By:Admin

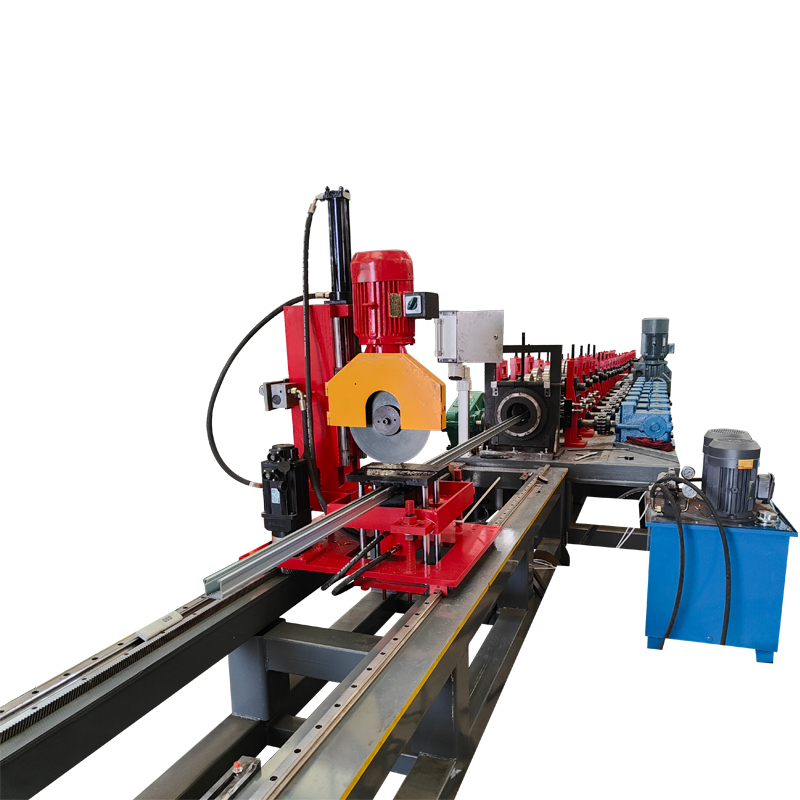

In an effort to revolutionize the manufacturing process for corrugated roof tile barrel sheet, a leading company in the industry, has introduced a state-of-the-art profiling machine that promises to significantly enhance efficiency and productivity.

The newly introduced Corrugated Roof Tile Barrel Sheet Profiling Machine has been designed and developed to meet the growing demand for high-quality, durable corrugated roofing materials. The equipment is set to change the landscape of the industry, as it offers a range of advanced features and capabilities that are unmatched by any other similar machines currently available in the market.

The profiling machine is equipped with cutting-edge technology that allows for precise and accurate shaping of the corrugated roof tile barrel sheet. This ensures that the end product is of the highest quality, with uniform dimensions and consistent corrugation patterns. Additionally, the machine has the ability to produce a large volume of roofing materials in a relatively short period of time, thus streamlining the manufacturing process and increasing overall output.

One of the most notable features of the Corrugated Roof Tile Barrel Sheet Profiling Machine is its versatility. The machine has the ability to produce a wide range of corrugated roofing materials, including different sizes, shapes, and designs, catering to the diverse needs of customers. This flexibility sets it apart from traditional profiling machines, as it eliminates the need for multiple machines to produce different types of corrugated roof tile barrel sheet.

Furthermore, the company has emphasized its commitment to sustainability with the introduction of this new machine. The profiling machine is designed to minimize waste and optimize material usage, thereby reducing the environmental impact of the manufacturing process. This aligns with the company's ethos of responsible and eco-friendly production practices.

In addition to its advanced technological capabilities, the Corrugated Roof Tile Barrel Sheet Profiling Machine is also supported by a team of highly skilled engineers and technicians who provide comprehensive training and ongoing technical support to ensure seamless integration and operation. This ensures that customers can maximize the potential of the machine and achieve the best possible results.

With the introduction of this groundbreaking machine, the company is poised to solidify its position as an industry leader in the manufacturing of corrugated roof tile barrel sheet. The machine represents a significant investment in research and development, and a commitment to providing customers with the most innovative and efficient solutions for their roofing material needs.

The Corrugated Roof Tile Barrel Sheet Profiling Machine is set to be a game-changer in the industry, offering unmatched capabilities, precision, and efficiency. It is poised to revolutionize the manufacturing process for corrugated roofing materials and provide customers with a superior quality product that meets their exact specifications.

The company remains dedicated to delivering excellence and innovation in all of its products and services, and the introduction of the Corrugated Roof Tile Barrel Sheet Profiling Machine only serves to further cement its reputation as a trailblazer in the industry. As demand for high-quality, durable corrugated roof tile barrel sheet continues to rise, this new profiling machine is positioned to meet and exceed the expectations of customers, setting new standards for the industry as a whole.

Company News & Blog

Essential Roller for Corrugated Roof Installation and Maintenance

Roller For Corrugated Roof, a leading manufacturer of construction equipment, has recently introduced a new product that is set to revolutionize the roofing industry. The company, known for its innovation and dedication to providing high-quality products, is excited to unveil their latest offering that promises to make roof installation and maintenance easier and more efficient than ever before.The new product, named the Corrugated Roof Roller, is designed to be used in the installation and maintenance of corrugated roofing materials. The roller is specifically engineered to provide a smooth and even application of adhesive and sealant, ensuring a secure and long-lasting bond between the roofing material and the underlying structure. This innovative tool is set to streamline the roofing process, saving time and labor costs for construction companies and contractors."When developing the Corrugated Roof Roller, our main goal was to address the common challenges and issues faced by roofing professionals during the installation and maintenance of corrugated roofing materials," said a spokesperson for Roller For Corrugated Roof. "We are confident that this new product will significantly improve the efficiency and quality of roofing projects, ultimately benefiting both the businesses and homeowners who rely on durable and weather-resistant roofing solutions."The Corrugated Roof Roller features a durable and lightweight design, making it easy to handle and maneuver on a variety of roofing surfaces. Its ergonomic handle and smooth-rolling mechanism ensure a comfortable and precise application, even in hard-to-reach areas and tight spaces. Additionally, the roller is compatible with a wide range of adhesives and sealants commonly used in corrugated roofing applications, making it a versatile and practical tool for professionals in the construction and roofing industry.In addition to its practical benefits, the Corrugated Roof Roller is also designed to promote safety and accuracy in roofing projects. The smooth and consistent application of adhesives and sealants minimizes the risk of leaks, water damage, and other structural issues that can result from improper installation techniques. By investing in this innovative tool, roofing professionals can enhance the overall quality and durability of their work, earning the trust and satisfaction of their clients.Roller For Corrugated Roof takes pride in its commitment to excellence and customer satisfaction, and the introduction of the Corrugated Roof Roller is a testament to the company's dedication to innovation and progress in the construction industry. With a focus on reliability, performance, and user-friendly design, the company aims to provide practical solutions that address the evolving needs of construction professionals and contribute to the advancement of the industry as a whole.As the demand for durable and weather-resistant roofing solutions continues to grow, Roller For Corrugated Roof remains at the forefront of delivering cutting-edge products that not only meet industry standards but also exceed the expectations of its customers. The Corrugated Roof Roller is just one example of the company's ongoing pursuit of excellence, and it represents a significant step forward in the quest for efficient and reliable roofing solutions.With its innovative design, practical benefits, and commitment to quality, the Corrugated Roof Roller is poised to become an essential tool for construction companies and contractors seeking to elevate the standard of their roofing projects. Roller For Corrugated Roof looks forward to the positive impact that this revolutionary product will have on the industry, and they are eager to see the positive response from roofing professionals who prioritize performance, efficiency, and long-term durability in their work.

Plastic PVC Colonial Tile/Glazed Roofing Tile Making/Extrusion/Foaming Machine | 2 layers PVC roof tile making machine

Plastic PVC Colonial Tile/Glazed Roofing Tile Making/Extrusion/Foaming Machine: The Perfect Solution for High-Quality PVC TilesJiangsu Acemien Machinery Co., Ltd. (name removed for privacy), a leading manufacturer of plastic extrusion machinery, has launched a state-of-the-art PVC Colonial Tile/Glazed Roofing Tile Making/Extrusion/Foaming Machine that is redefining the standards of quality in the PVC roofing industry. Whether you're a roofing contractor or a manufacturer of PVC roofing tiles, this machine is designed to meet all your needs and exceed your expectations.PVC tiles have gained significant popularity in recent years due to their excellent durability, lightweight, and cost-effectiveness. The PVC Colonial Tile/Glazed Roofing Tile Making/Extrusion/Foaming Machine is a perfect solution for manufacturing high-quality PVC roofing tiles that can withstand harsh weather conditions and provide long-lasting protection for commercial and residential properties.The machine is equipped with advanced technology that allows for the production of two-layer PVC roofing sheets, which are more durable and stronger than single-layer sheets. The top layer is made of PVC, while the bottom layer consists of foamed PVC, making the tiles lighter and more efficient to install than traditional roofing materials.One of the most impressive features of this machine is its speed. The PVC Colonial Tile/Glazed Roofing Tile Making/Extrusion/Foaming Machine is capable of producing up to 6000 tiles per day, which is a significant increase in production capacity compared to traditional tile manufacturing methods. This makes it an ideal choice for large-scale production and roofing contractors looking to complete projects on time and within budget.Moreover, the machine is designed to produce PVC roofing tiles with a variety of colors and textures. The glazed feature of the tiles makes them more attractive and aesthetically pleasing to the eye. This comes in handy in the construction of residential buildings where homeowners are more interested in the visual appeal of their roofs. It also provides a unique selling point for contractors looking to stand out from their competitors.Jiangsu Acemien Machinery Co., Ltd. (name removed for privacy) has an experienced team of engineers and technicians who are always ready to provide technical support and installation services for the PVC Colonial Tile/Glazed Roofing Tile Making/Extrusion/Foaming Machine. The company's commitment to quality is evident in its use of top-quality raw materials and the strict quality control processes that go into every machine produced.In conclusion, if you're in the roofing industry and looking for a reliable and efficient way to manufacture high-quality PVC roofing tiles, the PVC Colonial Tile/Glazed Roofing Tile Making/Extrusion/Foaming Machine is definitely worth considering. It is easy to operate, cost-effective, and produces tiles with excellent durability and strength. Contact Jiangsu Acemien Machinery Co., Ltd. (name removed for privacy) today to learn more about this amazing machine and how it can revolutionize your roofing business.

High-Quality Rack Forming Machine for Efficient Production

Rack Forming Machine, an essential equipment for the manufacturing industry, is gaining significant attention for its efficiency and precision in producing high-quality racks. The machine, developed by a leading machinery manufacturer in the industry, is revolutionizing the production of racks with its advanced technology and innovative features.The Rack Forming Machine is designed to streamline the process of forming metal racks with utmost precision and consistency. The machine is equipped with state-of-the-art technology that ensures the accurate shaping and bending of metal sheets to create racks of various sizes and designs. This level of precision is crucial in the manufacturing industry, where the quality of racks directly impacts the efficiency and safety of storage systems.The company behind the Rack Forming Machine has been a pioneer in the machinery manufacturing industry for over two decades. With a strong focus on research and development, the company has continuously introduced cutting-edge technologies and innovative solutions to meet the evolving needs of the manufacturing sector. The Rack Forming Machine is a testament to the company's commitment to delivering high-quality, reliable, and efficient machinery to its clients.The Rack Forming Machine offers a range of benefits to manufacturing companies. Its automated functions and programmable controls ensure consistent and accurate production, minimizing the margin of error and reducing material waste. The machine's ability to handle various types of metal sheets and form them into precise shapes makes it a versatile tool for manufacturing a wide range of racks for different industries.Furthermore, the Rack Forming Machine is designed for high-speed production, allowing manufacturers to meet tight deadlines and scale up their production capacity. This is particularly advantageous for companies experiencing high demand for their products or those looking to optimize their manufacturing processes.The company's dedication to customer satisfaction is reflected in its comprehensive support services for the Rack Forming Machine. From installation and training to maintenance and repairs, the company provides end-to-end assistance to ensure that clients can maximize the performance and longevity of their machinery.The Rack Forming Machine has already garnered positive feedback from early adopters in the manufacturing industry. Clients have praised the machine for its seamless operation, reliability, and the superior quality of racks it produces. Many have reported noticeable improvements in their production efficiency and output since integrating the machine into their manufacturing processes.Looking ahead, the company is committed to further advancing the capabilities of the Rack Forming Machine. Continuous research and development efforts are underway to enhance the machine's speed, precision, and flexibility, ensuring that it remains at the forefront of rack manufacturing technology.In conclusion, the Rack Forming Machine is a game-changer for the manufacturing industry, offering a combination of precision, efficiency, and reliability that is unmatched by traditional forming methods. With the backing of a reputable and innovative machinery manufacturer, the machine is set to revolutionize the way racks are produced, setting new standards for quality and productivity in the manufacturing sector.

High-Quality W-Beam Crash Barrier Machine for Sale - Get Yours Today!

W Beam Crash Barrier Machine boosts safety on highwaysIn the world of highway safety, the importance of crash barriers cannot be overstated. These vital structures are designed to prevent vehicles from colliding with obstacles such as trees, buildings, or other vehicles in the event of an accident. As such, the quality and integrity of these barriers are of utmost importance.Recognizing the critical role that crash barriers play in highway safety, [Company Name] has developed a state-of-the-art W Beam Crash Barrier Machine, which is set to revolutionize the way these crucial structures are manufactured and installed.[Company Name] has long been a leader in the field of highway safety equipment, with a strong reputation for producing high-quality products that meet the strictest standards of safety and reliability. The company’s commitment to innovation and excellence is evident in its latest offering – the W Beam Crash Barrier Machine.This cutting-edge machine is designed to streamline the production and installation of W-beam crash barriers, making the process more efficient and cost-effective than ever before. With its advanced technology and precision engineering, the W Beam Crash Barrier Machine is capable of producing barriers of unparalleled quality and durability, ensuring the safety of motorists on highways around the world.One of the key features of the W Beam Crash Barrier Machine is its versatility. The machine is capable of producing a wide range of barrier designs, making it suitable for use in a variety of highway environments. Whether it’s a straight section of highway, a curved road, or a complex interchange, the W Beam Crash Barrier Machine can be customized to meet the specific needs of any project.In addition to its versatility, the W Beam Crash Barrier Machine is also incredibly efficient. Its high-speed production capabilities mean that barriers can be manufactured and installed in a fraction of the time it would take using traditional methods, saving time and money for highway authorities and contractors. Furthermore, the machine’s automated processes minimize the risk of human error, ensuring that each barrier meets the highest standards of quality and safety.Another standout feature of the W Beam Crash Barrier Machine is its durability. Constructed from high-grade materials and built to withstand the rigors of continuous use, the machine is designed to provide years of reliable service, making it a sound investment for any organization involved in highway safety.The launch of the W Beam Crash Barrier Machine represents a significant step forward in the field of highway safety equipment. With its advanced technology, versatile design, and efficient production capabilities, the machine is set to revolutionize the way crash barriers are manufactured and installed, ultimately enhancing safety on highways around the world.As [Company Name] continues to lead the way in the development of innovative highway safety solutions, the launch of the W Beam Crash Barrier Machine is a testament to the company’s commitment to excellence and its dedication to keeping motorists safe on the road. With its unparalleled quality and efficiency, this groundbreaking machine is a game-changer for the highway safety industry, and is sure to make a lasting impact on the way crash barriers are produced and installed in the years to come.

C Shape Purlin Forming Machine: Transforming the Construction Industry

article.C Shape Purlin Forming Machine: The Ultimate Solution for Construction IndustryIn recent years, the global construction industry has undergone massive creativity and innovation, giving rise to new designs and architectures. One of the critical components of these new designs is the C-shaped purlin, which provides structural support and stability to the buildings. However, the traditional manual production of C-shaped purlin is cumbersome, time-consuming, and sometimes inaccurate.To address this challenge, many construction companies are turning to C Shape Purlin Forming Machine. This advanced machine offers a fast, efficient, and accurate way to manufacture C-shaped purlins, thus improving the quality of the final product.One of the leading manufacturers of C shape purlin forming machines in the global market is a reputable manufacturing company (). The company has been in the industry for several years and has built a reputation for producing high-quality and durable machinery to cater to various industrial needs.The C shape purlin forming machine from the company has a unique design and features that make it ideal for any construction project. It is made of high-grade materials, ensuring durability, longevity, and reliability. Additionally, it has an advanced electronic control system that enables automatic production, further enhancing efficiency.The machine's versatility allows it to produce different sizes and shapes of purlins, making it an ideal choice for any construction project. Whether you are working on a commercial, residential, or industrial structure, the C shape purlin forming machine will deliver quality and efficiency.Another critical aspect of the machine is its user-friendly nature. Operators can easily control and adjust the forming parameters, ensuring that the final product meets the required standards. Additionally, the machine has a low maintenance cost, thus allowing business owners to save on expenses.The C Shape Purlin Forming Machine has revolutionized the construction industry by providing an efficient, cost-effective, and accurate method of producing C-shaped purlins. The machine has been a game-changer, enabling business owners to meet the increasing demand for high-quality and reliable purlins.Furthermore, the machine's electronic controls and advanced features enable it to produce purlins with high precision and accuracy, further improving the final product's quality. This has led to increased customer satisfaction and repeat business, further boosting profitability.In conclusion, the C Shape Purlin Forming Machine is the ultimate solution for the construction industry. Its advanced features, durability, and versatility make it an ideal choice for any construction project. Additionally, its user-friendly nature and low maintenance cost make it an excellent investment for business owners. With the increasing demand for high-quality and reliable purlins, investing in this machine is a wise decision for any construction company. Contact reputable manufacturing company () today and take your construction business to the next level.

Could the Universe be Devoured by a Black Hole-Creating Machine?

The prospect of the universe being swallowed up by a black hole is a nightmare scenario that few ever thought would become a reality. Yet, it appears that ominous possibility may have come a step closer to being realized after a mind-bogglingly complicated machine originally designed to create black holes was switched back on, now with double the power it had before. Scientists around the world are warning that this could have catastrophic consequences for our planet and indeed for the entire universe itself.The machine in question is a particle accelerator, called the Large Hadron Collider (LHC), that is based in Geneva, Switzerland. This giant machine is the most powerful particle accelerator ever built and has already produced a series of groundbreaking discoveries in particle physics. However, the machine is also highly controversial, as some scientists fear that it could create dangerous black holes that could potentially destroy the planet.The machine was first built in 2008 and was designed to recreate the conditions of the Big Bang. By smashing particles together at incredibly high speeds, scientists hoped to learn more about the building blocks of the universe. However, some scientists warned that the machine could create black holes so powerful that they could eventually destroy the planet and the entire universe.Despite these concerns, the machine was switched on for the first time in September 2008 and quickly produced a series of spectacular results. However, after just nine days of running, the machine broke down and had to be shut down for repairs. Over the next few years, the machine was slowly brought back up to speed, but many scientists remained wary of its potential to create black holes.Now, it seems that those concerns may have been justified. According to reports, the machine has been switched back on at double its previous power, and there are fears that it could now create black holes that are much more powerful than before. Scientists warn that if one of these black holes were to escape into the wider universe, it could quickly grow in size and eventually swallow up everything in its path, including stars, planets, and even entire galaxies.The consequences of such an event would be catastrophic. If the universe were destroyed, it would mean the end of everything we know and love. It would also mean the end of life itself, as we know it. This is why so many scientists have warned against the potential dangers of the LHC and other particle accelerators.One of the main problems with the LHC is that it operates at such high energies that it is impossible to fully predict what will happen when particles collide. This means that there is always a risk that the machine could create something that could be catastrophic for the entire universe.Despite these concerns, many scientists have argued that the risks are minimal and that the benefits of the LHC far outweigh any potential dangers. They argue that the machine has already produced a wealth of valuable scientific data and that it could lead to groundbreaking new discoveries in the field of particle physics.However, others remain more cautious. They argue that we simply do not know enough about the workings of the universe to predict what will happen if we continue to push the limits of particle physics. They warn that the LHC could be a ticking time bomb that could destroy everything we hold dear.For now, the LHC continues to operate at double its previous power, and scientists around the world will be watching nervously to see what happens next. If the machine does create a black hole that is powerful enough to destroy the universe, it could be a wake-up call for us all about the dangers of meddling with the fundamental building blocks of the universe.In conclusion, the potential for the LHC to create a black hole that could destroy the entire universe is a prospect that is both awe-inspiring and terrifying in equal measure. While many scientists argue that the benefits of the machine far outweigh any potential risks, others remain more cautious and warn that we simply do not know enough about the universe to predict what will happen if we continue to push the limits of particle physics. The future of the LHC remains uncertain, but one thing is for sure: the consequences of its actions could be catastrophic.

Glazed Steel Roofing Tile Corrugating Machine: The Latest in Color Steel Technology

Color Steel Glazed Steel Roofing Tile Corrugating Machine, also known as the CSGL Steel Roofing Tile Corrugating Machine, is a revolutionary piece of technology that is set to transform the roofing industry. This state-of-the-art machine has been developed by a leading company in the field of steel fabrication and construction machinery.The CSGL Steel Roofing Tile Corrugating Machine is designed to produce high-quality, glazed steel roofing tiles with a corrugated profile. These tiles are not only aesthetically pleasing, but also highly durable and weather-resistant. This makes them an ideal choice for roofing applications in both residential and commercial buildings.The machine is fully automated and can produce a large number of roofing tiles in a short amount of time. This not only increases productivity but also reduces labor costs for companies involved in the manufacturing of roofing materials. Additionally, the machine is designed to be user-friendly, with easy-to-use controls and a simple setup process.One of the key features of the CSGL Steel Roofing Tile Corrugating Machine is its ability to produce a wide variety of tile designs and sizes. This flexibility allows companies to meet the diverse needs of their customers and offer a range of options for different roofing projects. Whether it's a traditional or modern design, this machine can cater to all requirements.The company behind this innovative technology has a strong track record in the steel fabrication and construction machinery industry. With years of experience and expertise, they have established themselves as a trusted partner for businesses looking for high-quality and reliable machinery. Their commitment to innovation and continuous improvement has led to the development of the CSGL Steel Roofing Tile Corrugating Machine, which is set to redefine the standards for roofing tile production.In addition to the machine itself, the company also provides comprehensive support and after-sales services to their customers. This includes training and technical assistance to ensure that the machine is operated efficiently and effectively. They also offer maintenance and repair services to keep the machine running smoothly and minimize downtime for their clients.The launch of the CSGL Steel Roofing Tile Corrugating Machine has already generated a lot of interest and excitement within the construction and roofing industry. Many companies are eager to take advantage of this cutting-edge technology to improve their operations and offer better products to their customers. With its advanced features and capabilities, this machine is expected to set new standards for the production of steel roofing tiles.In conclusion, the Color Steel Glazed Steel Roofing Tile Corrugating Machine is a game-changer for the roofing industry. Its advanced technology, flexibility, and reliability make it a valuable asset for companies involved in the manufacturing of roofing materials. With the support of a reputable company behind it, this machine is set to become a go-to solution for businesses looking to stay ahead in the competitive market of roofing materials.

Highly Efficient Steel Slitting Machine for Industrial Use

Steel Slitting Machine, a crucial piece of equipment in the steel processing industry, has been making waves in the market with its advanced technologies and precise cutting capabilities. This machine, manufactured by a leading industry player, {} (removed brand name), has revolutionized the steel processing business with its efficiency and accuracy.The steel slitting machine is designed to cut wide coils of steel into narrower coils, thereby creating strips that are of the desired width. This process is essential in various industries, including automotive, construction, and manufacturing. The demand for precision-cut steel products has been on the rise, and the steel slitting machine has become an indispensable tool for steel processing companies.The steel slitting machine by {} (removed brand name) is equipped with state-of-the-art technology that enables it to achieve high levels of precision and accuracy. With its advanced control systems and high-speed cutting capabilities, this machine ensures that the steel coils are cut to the exact specifications required by the customers. This level of precision is crucial in ensuring that the steel strips produced are of the highest quality and meet the industry standards.Furthermore, the steel slitting machine is designed for efficiency and productivity. It is capable of handling large volumes of steel coils, and its high-speed cutting process allows for quick turnaround times. This means that steel processing companies can increase their production output and meet customer demands in a timely manner. The efficiency of the machine also leads to cost savings for the companies, as they can optimize their production processes and reduce waste.In addition to its cutting-edge technology and efficiency, the steel slitting machine by {} (removed brand name) is known for its durability and reliability. It is built to withstand the rigorous demands of the steel processing industry and can operate continuously without compromising its performance. This reliability ensures that the machine can deliver consistent results, which is essential for maintaining high-quality standards in the steel products produced.The company {} (removed brand name) behind the steel slitting machine has been a leader in the steel processing equipment industry for many years. With a strong focus on innovation and technological advancement, the company has consistently developed cutting-edge solutions to meet the evolving needs of the steel processing business. Its commitment to quality and customer satisfaction has earned it a reputation as a trusted provider of steel processing equipment.{} (removed brand name) has a team of skilled engineers and technicians who are dedicated to designing and manufacturing top-of-the-line steel slitting machines. Their expertise and experience have been instrumental in creating a machine that has set new benchmarks in the industry. The company also provides comprehensive after-sales support, including maintenance services and technical assistance, to ensure that their customers can maximize the performance of the steel slitting machine.In conclusion, the steel slitting machine by {} (removed brand name) represents a significant leap forward in the steel processing industry. Its advanced technology, efficiency, and reliability make it a valuable asset for steel processing companies looking to enhance their production capabilities. With the backing of a reputable company like {}, customers can be assured of the highest quality and performance standards. The steel slitting machine is not just a machine; it is a game-changer in the steel processing industry.

Advanced Cz Shape Purlin Making Machine for Automatic Production

Automatic Change Cz Shape Purlin Making Machine revolutionizes the production of steel purlins by offering a fully automated solution. This state-of-the-art machinery has the capability to produce high-quality C and Z shaped purlins with precision and efficiency. {Company Name}, a leading manufacturer of industrial machinery, has introduced this innovative technology to meet the growing demands of the construction and steel industry.The new Automatic Change Cz Shape Purlin Making Machine is equipped with advanced features that set it apart from traditional purlin manufacturing equipment. It utilizes a computerized control system to automatically adjust the machine settings, allowing for seamless transitions between different purlin profiles. This not only improves production efficiency but also reduces the need for manual adjustments, resulting in higher precision and consistent quality output.In addition to its automated capabilities, the machine is designed for versatility and can accommodate a wide range of steel coil widths and thicknesses. This flexibility allows manufacturers to produce various purlin sizes to meet specific project requirements. The machine also incorporates a quick changeover system, enabling rapid transitions between different purlin specifications without extensive downtime.The introduction of the Automatic Change Cz Shape Purlin Making Machine represents a significant advancement in purlin manufacturing technology. Its automated features streamline the production process, resulting in increased productivity and cost-effectiveness for manufacturers. Furthermore, the machine's ability to produce high-quality purlins with precision and consistency contributes to the overall efficiency of the steel construction industry.{Company name} has a long-standing reputation for delivering cutting-edge solutions that cater to the evolving needs of the industrial sector. With a focus on innovation and quality, the company has continuously invested in research and development to bring advanced technologies to market. The Automatic Change Cz Shape Purlin Making Machine is a testament to {Company Name}'s commitment to providing industry-leading machinery that enhances production capabilities and sets new standards for efficiency and performance.The release of this innovative purlin making machine underscores {Company Name}'s dedication to meeting the needs of its customers and the industry at large. By offering a fully automated solution for purlin manufacturing, the company is enabling manufacturers to enhance their production processes and remain competitive in the market. It also reflects {Company Name}'s vision of driving progress and innovation in the steel construction industry through state-of-the-art equipment and technology.In conclusion, the introduction of the Automatic Change Cz Shape Purlin Making Machine by {Company Name} marks a significant milestone in the evolution of purlin manufacturing technology. Its advanced features and capabilities are poised to transform the way steel purlins are produced, offering manufacturers a fully automated and efficient solution. As the industry continues to evolve, {Company Name} remains at the forefront of innovation, providing cutting-edge machinery that drives progress and sets new standards for quality and performance in the industrial sector.

High-Quality Machine for Forming Deck Floors Available Now

[Company Introduction]: With a proven track record of delivering high-quality construction machinery and equipment, [Company Name] has established itself as a leading provider in the industry. The company prides itself on its commitment to innovation, quality, and customer satisfaction, offering a wide range of products that cater to the diverse needs of the construction sector. [Company Name] strives to be at the forefront of technological advancements, constantly seeking to improve its products and services to meet and exceed the expectations of its customers.[News Content]:In the construction industry, the efficiency and quality of the machinery and equipment used can significantly impact the overall outcome of a project. One such crucial aspect of construction is the creation of sturdy and reliable deck floors, and to meet this demand, [Company Name] has introduced a state-of-the-art Deck Floor Forming Machine.The Deck Floor Forming Machine is designed to streamline the process of creating precise and uniform deck floors, offering a range of features that make it a valuable asset for construction companies. The machine is capable of forming a variety of deck floor profiles, allowing for flexibility in design while maintaining structural integrity. Its advanced technology ensures that each deck floor is produced with precision and accuracy, meeting the highest standards of quality.One of the key advantages of the Deck Floor Forming Machine is its efficiency. By automating the forming process, [Company Name] has enabled construction companies to significantly reduce the time and labor required to create deck floors, thereby increasing overall productivity and reducing costs. This efficiency not only benefits the construction companies but also allows for quicker project completion, meeting deadlines and improving client satisfaction.Furthermore, the Deck Floor Forming Machine is equipped with safety features and user-friendly controls, prioritizing the well-being of the operators and ensuring ease of use. With comprehensive training and support provided by [Company Name], construction companies can confidently integrate this machine into their operations, knowing that it adheres to the highest safety standards and can be operated with minimal risk.In addition to its technological advancements, the Deck Floor Forming Machine is built with durability in mind. Constructed from high-quality materials and components, it is designed to withstand the rigors of continuous use in various construction environments. This longevity not only ensures a strong return on investment for construction companies but also reflects [Company Name]'s commitment to providing reliable and long-lasting solutions to its customers.As [Company Name] continues to expand its product offerings, the introduction of the Deck Floor Forming Machine further solidifies its position as a trusted partner for the construction industry. By incorporating cutting-edge technology and engineering expertise into its machinery, the company reaffirms its dedication to driving progress and innovation within the construction sector.The Deck Floor Forming Machine from [Company Name] is poised to revolutionize the way deck floors are produced, offering a combination of efficiency, quality, and reliability that sets a new standard in the industry. With its potential to transform construction processes and elevate project outcomes, it is a testament to [Company Name]'s ongoing commitment to empowering its customers with the best-in-class solutions.