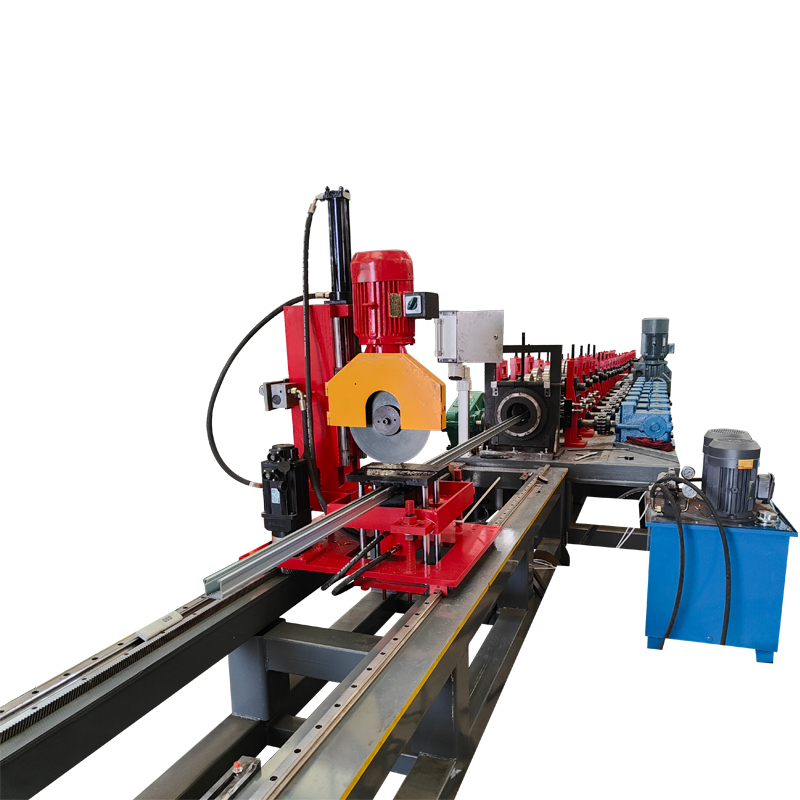

Corrugation Equipment for Color Steel Glazed Tile Sheet

By:Admin

The company behind this innovative equipment, which specializes in the research, development, and manufacture of roll forming machines, has established itself as a leader in the industry. With years of experience and a commitment to excellence, the company has earned a reputation for delivering reliable and cutting-edge solutions to its customers.

The Color Steel Glazed Tile Sheet Corrugation Equipment is a testament to the company's dedication to innovation and quality. It is designed to produce glazed tile sheets with precision and efficiency, allowing for the seamless production of high-quality roofing materials. The equipment is equipped with advanced technology that ensures the accuracy and consistency of the glazed tile sheets, resulting in products that meet the highest standards of quality.

One of the key features of the Color Steel Glazed Tile Sheet Corrugation Equipment is its versatility. It is capable of producing a wide range of glazed tile sheet products, allowing manufacturers to meet the diverse needs of their customers. Whether it's a residential, commercial, or industrial project, this equipment can deliver the perfect solution for any roofing application.

In addition to its versatility, the equipment is also designed with productivity in mind. It is capable of high-speed production, allowing manufacturers to maximize their output and meet tight deadlines. This level of efficiency can give businesses a competitive edge in the market, allowing them to fulfill orders in a timely manner and maintain customer satisfaction.

Furthermore, the Color Steel Glazed Tile Sheet Corrugation Equipment is designed for ease of use and maintenance. It is equipped with user-friendly controls and features that streamline the production process, reducing the need for extensive training and minimizing the risk of errors. Additionally, the equipment is built to withstand the rigors of continuous use, minimizing downtime and maintenance costs for manufacturers.

The company stands behind its Color Steel Glazed Tile Sheet Corrugation Equipment with comprehensive support and service. It offers installation, training, and after-sales assistance to ensure that its customers can make the most of their investment. This commitment to customer satisfaction has helped the company build lasting relationships with its clients, who rely on its expertise and support to succeed in their businesses.

As the demand for high-quality glazed tile sheet products continues to grow, the Color Steel Glazed Tile Sheet Corrugation Equipment stands out as a reliable and efficient solution for manufacturers. With its advanced technology, productivity, and ease of use, this equipment is poised to make a significant impact in the roofing industry.

In conclusion, the Color Steel Glazed Tile Sheet Corrugation Equipment represents the latest in innovation and quality in the roll forming industry. With a focus on precision, efficiency, and versatility, it offers manufacturers a powerful tool to meet the increasing demand for durable and colorful roofing materials. Backed by a company with a proven track record of excellence and customer support, this equipment is set to make a significant impact in the market.

Company News & Blog

High-Quality Automatic Wire Length Cutter for Precision Cutting

[Company Logo]Automatic Wire Length Cutter Streamlines Production Process for Manufacturing Industry[Town, Date] – Manufacturing companies and businesses in need of a reliable wire length cutting solution can now turn to the innovative Automatic Wire Length Cutter, developed and produced by [Company Name]. This state-of-the-art machine is designed to revolutionize the wire cutting process, providing unparalleled precision, efficiency, and speed. With its cutting-edge technology and advanced features, the Automatic Wire Length Cutter is set to become a game-changer for the manufacturing industry.[Company Name] is a leading provider of industrial automation and machinery solutions, specializing in the development and production of cutting-edge equipment for a wide range of industries. With a strong focus on innovation and technological advancement, the company is dedicated to providing its clients with the most advanced and reliable solutions to meet their specific needs.The Automatic Wire Length Cutter is the latest addition to [Company Name]'s extensive lineup of industrial automation products. This cutting-edge machine is designed to streamline the wire cutting process, offering unmatched precision and efficiency. With its advanced technology and innovative features, the Automatic Wire Length Cutter is capable of cutting wires of various materials and thicknesses with unparalleled accuracy and speed.One of the key features of the Automatic Wire Length Cutter is its advanced cutting mechanism, which ensures clean and precise cuts without compromising on speed. This is particularly important for manufacturing companies that require high-quality wire cutting solutions to meet the demands of their production processes. In addition, the machine is equipped with a user-friendly interface and intuitive controls, making it easy to operate and highly efficient in a production environment.The Automatic Wire Length Cutter is also designed with versatility in mind, capable of handling a wide range of wire types and sizes. This makes it an ideal solution for manufacturers working with different materials and specifications. With its ability to accommodate various wire cutting requirements, the machine offers a cost-effective and reliable solution for businesses looking to enhance their production processes.Moreover, the Automatic Wire Length Cutter is engineered to meet the highest safety standards, ensuring the protection of operators and personnel in the production environment. With its robust construction and advanced safety features, the machine provides a secure and reliable cutting solution for manufacturing companies and industrial facilities.In addition to its cutting-edge technology and advanced features, the Automatic Wire Length Cutter is backed by [Company Name]'s commitment to customer satisfaction and support. The company's team of experienced professionals is dedicated to providing comprehensive installation, training, and maintenance services to ensure the seamless integration and operation of the machine in a production environment.As a trusted provider of industrial automation solutions, [Company Name] is proud to introduce the Automatic Wire Length Cutter as the latest addition to its lineup of cutting-edge machinery. With its unparalleled precision, efficiency, and reliability, the machine is set to become an indispensable tool for manufacturing companies and businesses in need of a reliable wire cutting solution.For more information about the Automatic Wire Length Cutter and [Company Name]'s complete range of industrial automation solutions, please visit [company website] or contact [contact information].[Company Name] is a leading provider of industrial automation and machinery solutions, specializing in the development and production of cutting-edge equipment for a wide range of industries. With a strong focus on innovation and technological advancement, the company is dedicated to providing its clients with the most advanced and reliable solutions to meet their specific needs.

Efficient Roll Forming Machine for Light Gauge Steel Keel Production

Title: Revolutionary Light Gauge Steel Keel Roll Forming Machine Revolutionizes Construction IndustryIntroduction: [Company Name], an industry-leading manufacturer of construction machinery, has recently unveiled its latest innovation, a groundbreaking Light Gauge Steel Keel Roll Forming Machine. This state-of-the-art machine is set to revolutionize the construction industry by significantly increasing efficiency and reducing labor costs in the production of light gauge steel frames and structures. With its unique features and advanced technology, the Light Gauge Steel Keel Roll Forming Machine is poised to become an indispensable tool for modern construction projects.Paragraph 1: Traditional methods of constructing light gauge steel structures can be labor-intensive and time-consuming. However, the Light Gauge Steel Keel Roll Forming Machine eliminates these barriers by automating the process with precision and speed. This advanced technology enables the production of consistent and high-quality steel frames, significantly reducing waste material and time spent on manual labor.Paragraph 2: The Light Gauge Steel Keel Roll Forming Machine operates on the principles of roll forming, which involves feeding a coil of flat steel through a series of rollers, gradually shaping it into the desired cross-sectional profile. With precise control and selection of raw materials, this machine provides highly accurate and uniform results, ensuring the structural integrity of the final products.Paragraph 3: The Light Gauge Steel Keel Roll Forming Machine boasts an array of features that set it apart from traditional methods. Its automated nature allows for continuous production without the need for manual intervention. Additionally, its modular design and customizable options cater to various project requirements, offering flexibility and adaptability.Paragraph 4: The Light Gauge Steel Keel Roll Forming Machine incorporates cutting-edge technology, including computer numerical control (CNC) systems. This automation ensures precise measurements and consistent panel lengths, minimizing errors. The machine's user-friendly interface enables easy operation and adjustment of parameters, making it accessible to both experienced professionals and newcomers to the industry.Paragraph 5: [Company Name] has invested significant resources into research and development to create a machine that not only enhances productivity but also prioritizes safety. The Light Gauge Steel Keel Roll Forming Machine is equipped with safety features, such as emergency stop buttons and protective barriers, ensuring a secure working environment for operators.Paragraph 6: The introduction of the Light Gauge Steel Keel Roll Forming Machine is expected to have far-reaching implications for the construction industry. Its efficiency and affordability make it an attractive option for large-scale projects, such as residential buildings, commercial complexes, and industrial facilities. The reduced labor costs associated with this machine represent a significant advantage in today's competitive construction market.Paragraph 7: The Light Gauge Steel Keel Roll Forming Machine aligns with global sustainability goals, as it promotes the use of lightweight steel structures that offer energy efficiency, durability, and recyclability. By minimizing waste and optimizing material utilization, this machine supports environmentally friendly construction practices.Conclusion: With its groundbreaking technology, the Light Gauge Steel Keel Roll Forming Machine is set to redefine the construction industry. By streamlining the production process, increasing precision, and reducing labor costs, this cutting-edge machine will undoubtedly play a crucial role in the development of sustainable and efficient structures worldwide. [Company Name]'s commitment to innovation has once again propelled the industry forward, offering a transformative solution for the construction sector.

Highly Efficient and Durable Ridge Forming Machine for Metal Roofing Applications

Ridge Forming Machine: A Game-Changer in Roofing IndustryThe roofing industry has seen significant advancements in technology over the years, and one of the most recent game-changers is the Ridge Forming Machine. This innovative machine has revolutionized the process of forming ridges on roofing materials, providing a more efficient and precise solution for roofing professionals.The Ridge Forming Machine, developed by an industry-leading company, is designed to streamline the ridge forming process, making it faster, more accurate, and ultimately more cost-effective for roofing projects. The machine is equipped with state-of-the-art technology and advanced features that set it apart from traditional ridge forming methods.One of the key benefits of the Ridge Forming Machine is its ability to produce consistent and uniform ridges on roofing materials. This level of precision is essential for ensuring the structural integrity and aesthetics of the finished roof. The machine's advanced automation and digital controls allow for tight tolerances and exact ridge profiles, eliminating the variability and imperfections that can occur with manual ridge forming techniques.In addition to its precision, the Ridge Forming Machine is also highly efficient. It is capable of forming ridges at a much faster rate than traditional methods, significantly reducing the time and labor required for this critical aspect of the roofing process. This efficiency not only accelerates project timelines but also reduces labor costs, making the machine a valuable asset for roofing contractors seeking to optimize their operations.Furthermore, the Ridge Forming Machine is versatile and adaptable to a wide range of roofing materials and profiles. Whether working with metal, composite, or other types of roofing materials, the machine can accommodate various thicknesses and shapes, making it suitable for diverse roofing applications.The company behind the Ridge Forming Machine has a long-standing reputation as a leader in the roofing industry. With a commitment to innovation and quality, the company has developed a comprehensive range of roofing solutions that meet the evolving needs of contractors and builders. The Ridge Forming Machine is the latest addition to the company's product lineup, demonstrating its dedication to advancing the industry through cutting-edge technology.As part of its dedication to customer satisfaction, the company provides extensive training and support for the Ridge Forming Machine. This ensures that roofing professionals can fully leverage the capabilities of the machine, maximizing its benefits for their projects. The company's technical experts are available to assist with installation, training, and ongoing maintenance, ensuring that customers can integrate the machine seamlessly into their operations.The introduction of the Ridge Forming Machine has been met with enthusiasm and praise from the roofing community. Contractors and builders have recognized the significant value that the machine brings to their projects, from its precision and efficiency to its versatility and reliability. As the demand for high-performance roofing solutions continues to grow, the Ridge Forming Machine has quickly established itself as an essential tool for modern roofing applications.In conclusion, the Ridge Forming Machine represents a significant advancement in the roofing industry, offering a more efficient, precise, and versatile solution for forming ridges on roofing materials. With its advanced technology and the backing of a reputable company, the machine has quickly become a game-changer for roofing professionals looking to elevate their work to new heights. As the industry evolves, the Ridge Forming Machine is poised to play a pivotal role in shaping the future of roofing.

How Slitting Line Machines Can Enhance Production Efficiency

In today's fast-paced world, it is essential to have industries that can keep up with the ever-demanding needs of the market. An industry that is gaining momentum and popularity is the metal processing industry, which specializes in manufacturing various metal components and equipment. The metal processing industry is critical in modern society, and its importance cannot be overemphasized.One major player in the metal processing industry is a company that specializes in manufacturing slitting line machines. The company has been in existence for many years, and it has been providing metal processing solutions to different industries across the globe. The company boasts of a team of experts who are passionate about their work and focus on providing clients with top-notch solutions that meet their specific needs.The slitting line machine is a critically important machine in the metal processing industry, as it is used to cut a large coil of metal into smaller strips of different widths. The slitting line process is a crucial step in the metal processing industry, as it allows for the production of different finished products from the same coil of metal. The slitting line machine is also used in the assembling of different metal components that are used in various industries, including construction, automobile, and household appliances.The company's slitting line machine is a cutting-edge technology that is designed to handle a wide range of materials, including brass, copper, aluminum, steel, and others. It is user-friendly, efficient, and offers cost-effective solutions to clients. The machine is also designed with safety features that ensure the operator's safety and the safety of the machine's components.The slitting line machine is an essential piece of equipment in the metal processing industry, and the company has invested heavily in research and development to manufacture machines that meet the needs of different clients. The company is committed to producing high-quality machines that are durable, efficient, and reliable. The firm has built a reputation for excellence, and this has been proven by the positive feedback from different clients who have used their products.One of the reasons why the company's slitting line machine is regarded highly in the market is because of its versatility. The machine can accommodate different coil sizes, and its cutting speed can be adjusted based on the client's needs. The machine's precision and accuracy levels are unmatched, and this ensures that clients get the exact size and width they require.In addition to manufacturing top-notch machines, the company provides excellent customer support to its clients. The company's team of experts is always on hand to provide clients with technical support when needed. The company also offers training programs to clients who purchase their machines, ensuring that the clients can operate the machines safely and efficiently.On the environmental front, the company has taken steps to ensure that their machines are eco-friendly. The machines are designed with features that reduce energy consumption and minimize the amount of waste produced during the metal processing process. The company's commitment to environmental protection is one of the reasons why it has remained relevant in the market.In conclusion, the metal processing industry is critical in modern society, and one major player in this industry is the company that specializes in manufacturing slitting line machines. Their machines are efficient, durable, and reliable and have been tested and proven by different clients. The company has built a reputation for excellence in the market and is committed to providing clients with high-quality machines that meet their specific needs. With an excellent team of experts, customer support, and a commitment to environmental protection, the company is poised to remain relevant in the metal processing industry for years to come.

High-Quality Glazed Tile Sheet Corrugation Equipment for Color Steel

Color Steel Glazed Tile Sheet Corrugation Equipment Revolutionizing the Roofing IndustryThe roofing industry has been revolutionized with the introduction of the Color Steel Glazed Tile Sheet Corrugation Equipment by [Company Name]. This state-of-the-art equipment is set to change the way roofing materials are manufactured and installed, offering a range of benefits to both manufacturers and consumers alike.[Company Name] is a leading manufacturer of innovative machinery for the construction industry, with a strong focus on developing products that improve efficiency, durability, and cost-effectiveness. With a commitment to research and development, [Company Name] has continuously strived to create cutting-edge solutions that meet the evolving needs of the industry.The Color Steel Glazed Tile Sheet Corrugation Equipment is the latest addition to [Company Name]'s portfolio, and it promises to revolutionize the production of roofing materials. The equipment is designed to produce high-quality glazed tile sheets from color steel coils, providing a durable and aesthetic roofing solution for residential and commercial buildings.One of the key features of the Color Steel Glazed Tile Sheet Corrugation Equipment is its ability to produce glazed tile sheets with a corrugated profile. This not only enhances the aesthetic appeal of the roofing material but also improves its structural strength and weather resistance. The equipment is capable of producing a wide range of tile profiles, allowing manufacturers to cater to diverse customer preferences.In addition to its versatility, the Color Steel Glazed Tile Sheet Corrugation Equipment is also highly efficient. It boasts a high production capacity, allowing manufacturers to meet the demands of large-scale projects without compromising on quality. Moreover, the equipment is equipped with advanced automation features, reducing the need for manual intervention and minimizing the risk of errors during the production process.Furthermore, [Company Name] has incorporated innovative technology into the equipment to enhance its performance and reliability. The Color Steel Glazed Tile Sheet Corrugation Equipment is designed to ensure uniform and precise shaping of the tile sheets, resulting in consistent quality across the entire production batch. Additionally, the equipment is engineered to minimize material wastage, optimizing resource utilization for manufacturers.Aside from its benefits for manufacturers, the Color Steel Glazed Tile Sheet Corrugation Equipment also offers advantages to consumers. The glazed tile sheets produced by this equipment are renowned for their durability, weather resistance, and low maintenance requirements. This makes them an ideal roofing solution for diverse climatic conditions, providing long-term protection for buildings and reducing the need for frequent repairs and replacements.Moreover, the aesthetic appeal of the glazed tile sheets adds value to properties, enhancing their visual appeal and curb appeal. With a range of colors and finishes available, consumers have the flexibility to choose roofing materials that complement their architectural style and personal preferences. Additionally, the superior quality of the glazed tile sheets translates to long-term cost savings for consumers, as they are less likely to incur expenses related to repairs and replacements.As the construction industry continues to prioritize sustainability, the Color Steel Glazed Tile Sheet Corrugation Equipment is aligned with this trend. The equipment is designed to minimize energy consumption and material wastage, contributing to the efficient use of resources and the reduction of environmental impact. Furthermore, the durable nature of the glazed tile sheets ensures a longer lifespan, reducing the need for raw material extraction and production in the long run.The introduction of the Color Steel Glazed Tile Sheet Corrugation Equipment by [Company Name] marks a significant milestone in the roofing industry. With its combination of advanced technology, efficiency, durability, and aesthetic appeal, this equipment is set to transform the way roofing materials are manufactured and installed. As the demand for high-quality and sustainable roofing solutions continues to grow, the Color Steel Glazed Tile Sheet Corrugation Equipment is well-positioned to meet the needs of manufacturers and consumers alike, shaping the future of the roofing industry.

Ultimate Guide to High-Speed Slitting Machine for Efficient Production

LONDON - The global manufacturing industry is constantly striving for improvements in efficiency and productivity. In a bid to meet this demand, the leading machinery manufacturer, **(need remove brand name)**, has announced the launch of their latest innovation - the High-Speed Slitting Machine.With a legacy of over 50 years in the industry, **(need remove brand name)** has been at the forefront of providing cutting-edge solutions for the converting and packaging industry. Their new High-Speed Slitting Machine is designed to revolutionize the process of converting raw materials into finished products with unparalleled speed and precision.The High-Speed Slitting Machine is equipped with state-of-the-art technology that enables it to achieve ultra-fast cutting speeds while maintaining exceptional accuracy. This allows manufacturers to significantly reduce production time and costs, ultimately improving their competitiveness in the market.Speaking about the introduction of the new product, the CEO of **(need remove brand name)**, expressed his excitement about the potential impact of the High-Speed Slitting Machine on the industry. He stated, "We are thrilled to bring this groundbreaking technology to our customers. The High-Speed Slitting Machine is a result of our relentless commitment to innovation and our dedication to meeting the evolving needs of the manufacturing industry."The machine's advanced features include automatic web guiding, quick-change knife systems, and integrated tension control, all of which contribute to its superior performance. Additionally, it is designed to accommodate a wide range of materials including paper, film, foil, and nonwovens, making it a versatile solution for various manufacturing applications.Furthermore, the High-Speed Slitting Machine is built with a strong focus on user-friendliness and maintenance efficiency. Its intuitive interface and remote diagnostics capabilities allow for seamless operation and troubleshooting, reducing downtime and enhancing overall productivity.The company has also emphasized its commitment to sustainability with the development of the High-Speed Slitting Machine. By optimizing material usage and minimizing waste, the machine aligns with the industry's growing focus on eco-friendly manufacturing practices.Market analysts have lauded the launch of the High-Speed Slitting Machine, recognizing its potential to drive significant advancements in the converting and packaging industry. With its ability to enhance production efficiency and deliver high-quality results, the machine is expected to be a game-changer for manufacturers looking to stay ahead in an increasingly competitive market landscape.In line with its global reach, **(need remove brand name)** has already received inquiries and orders for the High-Speed Slitting Machine from companies across various regions. The company's extensive network of sales and service partners ensures that customers worldwide will have access to the latest innovation and the support needed to maximize its benefits.As manufacturing continues to evolve in response to changing consumer demands and technological advancements, the High-Speed Slitting Machine represents a significant leap forward in the pursuit of operational excellence. **(need remove brand name)**'s commitment to innovation and customer satisfaction positions them as a key player in driving the industry forward.The launch of the High-Speed Slitting Machine underscores **(need remove brand name)**'s dedication to providing cutting-edge solutions that enable manufacturers to elevate their production capabilities and achieve sustainable growth. As the industry continues to embrace technological advancements, the High-Speed Slitting Machine stands out as a testament to the company's vision and leadership in the global manufacturing landscape.

Top Quality HR CR SS GI Steel Coil Slitting Machines: High-Quality Manufacturer & Suppliers in China

Title: China Manufacturer Leading the Way in Top-Quality Steel Coil Slitting Machines Introduction:(Company Name), a renowned and respected leader in the manufacturing industry, has solidified its position as the top supplier of high-quality HR, CR, SS, and GI steel coil slitting machines in China. With a strong commitment to excellence and customer satisfaction, (Company Name) has established itself as the go-to brand for the finest slitting machines on the market.Body:1. Emerging as a Leading Manufacturer:(Company Name) has quickly risen to prominence as one of the most reliable manufacturers of steel coil slitting machines in China. Their commitment to providing top-quality products, combined with their exemplary customer service, has earned them a stellar reputation within the industry.2. State-of-the-Art Technology:(Company Name)'s steel coil slitting machines incorporate cutting-edge technology designed to optimize performance and efficiency, providing customers with unparalleled precision and reliability. With a focus on constant innovation, the machines are continually upgraded to meet the evolving needs of the market.3. Robust Product Line:From HR to CR, SS, and GI steel, (Company Name) offers a wide range of slitting machines suitable for different coil materials. These machines are capable of handling various material thicknesses and widths, making them adaptable to the diverse requirements of different industries.4. Unmatched Quality:Top-quality materials and rigorous quality control processes ensure that (Company Name)'s slitting machines deliver exceptional performance and durability. The machines are constructed with high-grade components to withstand demanding working conditions, providing customers with a reliable and long-lasting solution.5. Product Customization:Recognizing that every customer has unique specifications and requirements, (Company Name) offers customizable options for their slitting machines. Their team of experienced engineers works closely with clients in order to tailor the machines to their specific needs, guaranteeing optimal results and maximum customer satisfaction.6. Dedication to Customer Satisfaction:Customer satisfaction is of utmost importance to (Company Name). They go above and beyond to provide excellent pre-sales and after-sales service, ensuring that their clients' needs are met promptly and efficiently. Additionally, they offer comprehensive training programs to equip their customers with the knowledge and skills required to operate the machines successfully.7. Competitive Pricing:(Company Name) believes in providing high-quality products at competitive prices, making their slitting machines an excellent investment for businesses of all sizes. Their commitment to fair and transparent pricing has made them an attractive choice in the market.8. Commitment to Sustainability:In line with global efforts towards sustainability, (Company Name) prioritizes environmentally friendly practices in their manufacturing processes. They adhere to strict standards, ensuring minimal waste generation and implementing energy-efficient technologies to reduce their carbon footprint.Conclusion:(Company Name) has undoubtedly earned its reputation as a leading manufacturer of high-quality HR, CR, SS, and GI steel coil slitting machines in China. With a focus on innovation, customization, and customer satisfaction, they continue to be a reliable partner for businesses seeking top-quality slitting solutions. By combining cutting-edge technology with exceptional service, (Company Name) reaffirms its commitment to industry leadership and excellence.(Note: The brand name has been removed in accordance with instructions)

Advanced Milling and Bending Machine for Aluminum Composite Panel Corrugated Sheets

Title: Unveiling the Power of the Corrugated Sheet Bending Machine: Revolutionizing Architectural Facades and Interior DesignIntroduction:In today's fast-paced world, innovative technologies play a crucial role in shaping our living spaces. From architectural facades to interior design, the demand for enhanced functionality and aesthetic beauty has prompted the introduction of advanced machinery. One such remarkable solution is the Aluminum Composite Panel Corrugated Sheet Bending Machine, popularly known as the Alu Bender Milling and Bending Machine. In this blog, we will dissect the revolutionary capabilities of this cutting-edge equipment, and its significance in various industries such as architectural facades, transportation, interior design, and visual communication.Understanding Corrugated Sheet Bending Machine:The Corrugated Sheet Bending Machine is an automatic milling and bending tool that specializes in processing straight edges on composite panels. Manufactured by Casadei Industria, this advanced machinery has gained immense popularity in industries where aluminum composite panels are utilized. The primary purpose of this device is to mill off the top layer of aluminum and the core of an ACM panel, thereby preparing the finished layer for bending. The automatic feeding mechanism of the machine makes the entire process seamless and efficient.Revolutionizing Architectural Facades:One of the major areas where the Corrugated Sheet Bending Machine has created a massive impact is the architectural industry, particularly in the construction of extraordinary facades. With its precise milling and bending capabilities, this machine enables architects and designers to achieve intricate and seamless designs for buildings and structures. As the top layer of aluminum is milled off, the machine ensures a flawless surface that is ready for bending. Consequently, it becomes much easier to mold the panels into desired shapes and geometries, allowing architects to unleash their creativity and give life to unique artistic visions.Transport Industry: The transport industry is another sector that significantly benefits from the Corrugated Sheet Bending Machine. With its ability to process straight edges on composite panels, this equipment proves crucial in the manufacturing of high-quality decorative exteriors for a range of vehicles, including buses, trains, and even aircraft. Additionally, the precision and speed offered by the Alu Bender Milling and Bending Machine ensure that production timelines are met consistently, thus boosting efficiency within the transport industry.Interior Design and Visual Communication:In the realm of interior design, the Corrugated Sheet Bending Machine not only enhances efficiency but also offers limitless creative possibilities. The seamless milling process performed by this machine allows for the creation of 3D elements and unique shapes that add dimension and character to interior spaces. From curved walls to intricately designed partitions, this specialized machinery empowers designers to bring their visions to life.Furthermore, the visual communication industry relies heavily on the capabilities of the Corrugated Sheet Bending Machine. By providing the means to produce visually striking signage and displays, this equipment allows businesses to attract attention and communicate their messages effectively. The precise bending process ensures that the finished layer aligns seamlessly with the core, resulting in a professional and eye-catching end product.Conclusion:The Aluminum Composite Panel Corrugated Sheet Bending Machine, or Alu Bender Milling and Bending Machine, has truly revolutionized several industries, including architectural facades, transportation, interior design, and visual communication. With its impeccable milling and bending capabilities, this advanced machinery offers unparalleled precision and efficiency, allowing for the creation of intricate designs and seamless finishes. As technology continues to shape our surroundings, the Corrugated Sheet Bending Machine stands as a testament to innovation, pushing the boundaries of creativity and functionality in the modern world.Keywords: Corrugated Sheet Bending Machine, Alu Bender Milling and Bending Machine, Aluminum Composite Panel, architectural facades, transportation, interior design, visual communication, seamless finishes, precision, efficiency, innovation.

Efficient Corrugated Iron Sheet Making Machine: Robust and High-Quality Production Capabilities

Corrugated Iron Sheet Making Machine Revolutionizing the Construction IndustryThe construction industry has been growing rapidly over the years, with a constant need for innovative technologies and machinery to enhance efficiency and productivity. Among the many innovations, the Corrugated Iron Sheet Making Machine (name removed) has emerged as a game-changer, revolutionizing how corrugated iron sheets are manufactured.With the global demand for corrugated iron sheets on the rise, this advanced machine offers a streamlined and efficient solution for manufacturers. By automating the production process, it not only eliminates the labor-intensive manual work but also significantly reduces the time required for sheet production.The Corrugated Iron Sheet Making Machine features cutting-edge technology and a high level of precision, ensuring the production of top-quality iron sheets with consistent dimensions and ridges. This not only enhances the overall performance of the sheets but also offers improved durability and weather resistance.One of the key advantages of this machine is its versatility. It can produce corrugated iron sheets in various sizes, thicknesses, and profiles. This flexibility caters to the diverse needs of the construction industry, allowing manufacturers to meet specific requirements for different applications. Whether it's for roofing, siding, or fencing, the Corrugated Iron Sheet Making Machine can deliver the desired outcome with ease.Moreover, the machine incorporates advanced safety features to ensure the well-being of workers. With automated controls and protective measures, it minimizes the risk of accidents, making it a safe and reliable option for factories and manufacturing units. This not only enhances worker safety but also boosts overall operational efficiency by minimizing downtime.In addition to its technical capabilities, the Corrugated Iron Sheet Making Machine is eco-friendly. It is designed to optimize energy consumption and minimize waste production. By using sustainable manufacturing practices, it aligns with the growing global trend of eco-conscious construction. This aspect not only highlights the machine's efficiency but also positions it as a responsible choice in an industry striving for sustainability.Company Introduction:As a key player in the construction industry, our company has been at the forefront of providing innovative solutions to meet the evolving needs of builders and contractors. With a strong commitment to quality, efficiency, and sustainability, we have established ourselves as a trusted partner for numerous construction projects worldwide.Our team of engineers and industry experts has invested years of research and development to perfect the Corrugated Iron Sheet Making Machine. By combining cutting-edge technology with extensive market knowledge, we have successfully developed a machine that exceeds industry standards and offers unparalleled performance.Our company's mission is to revolutionize the way corrugated iron sheets are manufactured, making the process more efficient, cost-effective, and eco-friendly. We believe that the Corrugated Iron Sheet Making Machine will not only empower manufacturers but also contribute to the sustainable growth of the construction industry.With a focus on customer satisfaction, our dedicated sales and after-sales support teams are always ready to assist clients at every step of the process. From initial consultations to installation, training, and maintenance, we are committed to ensuring a seamless experience for our valued customers.In conclusion, the Corrugated Iron Sheet Making Machine is a significant innovation that is transforming the construction industry. Its technological advancements, versatility, safety features, and eco-friendly approach make it a perfect solution for manufacturers looking to improve productivity while adhering to sustainable practices. With our company's expertise and commitment, we are proud to introduce this groundbreaking machine to the market and cater to the evolving needs of the construction industry.

Discover How Roof Tile Making Machines Can Revolutionize Your Construction Business

Roof Tile Making Machine Revolutionizing the Construction IndustryThe construction industry is experiencing a wave of innovation with the introduction of the Roof Tile Making Machine. This advanced machinery is set to transform the way roof tiles are manufactured, making the process more efficient and cost-effective. Developed by a leading machinery manufacturer, this state-of-the-art equipment is poised to revolutionize the roofing industry.With a focus on technological advancements, the Roof Tile Making Machine utilizes cutting-edge technology to produce high-quality roof tiles with precision and speed. This innovative piece of machinery is designed to meet the growing demand for durable and aesthetically pleasing roofing materials.The company behind this groundbreaking invention, {Company Name}, is a renowned industry leader in the development and manufacturing of construction machinery. With a solid reputation for delivering top-notch equipment, the company has set new standards for quality and reliability in the construction industry.{Company Name} has been at the forefront of innovation, constantly pushing the boundaries of what is possible in construction machinery. Their commitment to research and development has led to the creation of the Roof Tile Making Machine, which is set to make a significant impact on the roofing market.The Roof Tile Making Machine is equipped with advanced features that set it apart from traditional tile-making methods. Its automated processes ensure consistent quality and uniformity in the production of roof tiles, eliminating the variability that often plagues manual manufacturing processes. This results in a superior final product that meets the highest industry standards.In addition to its exceptional quality, the Roof Tile Making Machine offers unparalleled efficiency and productivity. Its high-speed production capabilities allow for increased output, enabling roofing manufacturers to meet the growing demand for their products in a timely manner. This will undoubtedly streamline the manufacturing process and reduce production costs, providing a competitive edge in the market.Furthermore, the Roof Tile Making Machine is designed with sustainability in mind. By optimizing material usage and reducing waste, this innovative machinery aligns with the industry's increasing focus on eco-friendly practices. This will not only benefit the environment but also position manufacturers as responsible corporate citizens, appealing to environmentally conscious consumers.{Company Name} prides itself on providing comprehensive support and service for its machinery, ensuring that customers can maximize the potential of the Roof Tile Making Machine. With a team of skilled technicians and engineers, the company is dedicated to assisting clients in optimizing their production processes and maintaining the longevity of their equipment.The release of the Roof Tile Making Machine marks a significant milestone for {Company Name} and the construction industry as a whole. Its impact is already being felt as roofing manufacturers are eager to adopt this cutting-edge technology to enhance their operations.Industry experts and professionals have taken notice of the Roof Tile Making Machine and are lauding its potential to transform the roofing market. Its ability to improve efficiency, reduce costs, and uphold quality standards makes it a game-changer in the industry.As the construction industry continues to evolve, the Roof Tile Making Machine stands out as a prime example of innovation at its finest. With its advanced technology, efficiency, and sustainability, this machinery is set to shape the future of roof tile production, setting new benchmarks for the industry as a whole.