High-Quality Automatic Wire Length Cutter for Precision Cutting

By:Admin

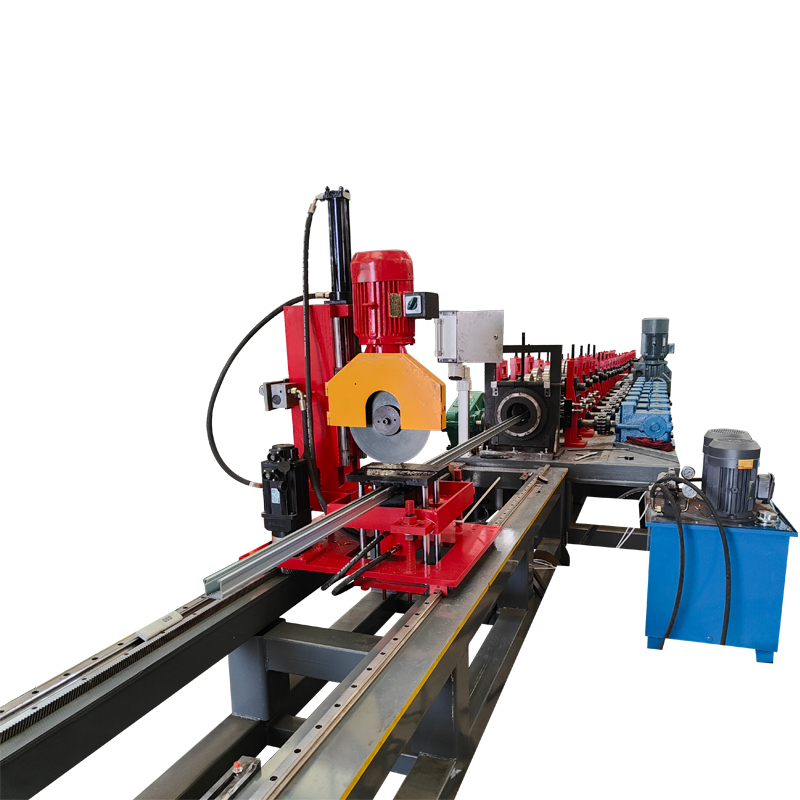

Automatic Wire Length Cutter Streamlines Production Process for Manufacturing Industry

[Town, Date] – Manufacturing companies and businesses in need of a reliable wire length cutting solution can now turn to the innovative Automatic Wire Length Cutter, developed and produced by [Company Name]. This state-of-the-art machine is designed to revolutionize the wire cutting process, providing unparalleled precision, efficiency, and speed. With its cutting-edge technology and advanced features, the Automatic Wire Length Cutter is set to become a game-changer for the manufacturing industry.

[Company Name] is a leading provider of industrial automation and machinery solutions, specializing in the development and production of cutting-edge equipment for a wide range of industries. With a strong focus on innovation and technological advancement, the company is dedicated to providing its clients with the most advanced and reliable solutions to meet their specific needs.

The Automatic Wire Length Cutter is the latest addition to [Company Name]'s extensive lineup of industrial automation products. This cutting-edge machine is designed to streamline the wire cutting process, offering unmatched precision and efficiency. With its advanced technology and innovative features, the Automatic Wire Length Cutter is capable of cutting wires of various materials and thicknesses with unparalleled accuracy and speed.

One of the key features of the Automatic Wire Length Cutter is its advanced cutting mechanism, which ensures clean and precise cuts without compromising on speed. This is particularly important for manufacturing companies that require high-quality wire cutting solutions to meet the demands of their production processes. In addition, the machine is equipped with a user-friendly interface and intuitive controls, making it easy to operate and highly efficient in a production environment.

The Automatic Wire Length Cutter is also designed with versatility in mind, capable of handling a wide range of wire types and sizes. This makes it an ideal solution for manufacturers working with different materials and specifications. With its ability to accommodate various wire cutting requirements, the machine offers a cost-effective and reliable solution for businesses looking to enhance their production processes.

Moreover, the Automatic Wire Length Cutter is engineered to meet the highest safety standards, ensuring the protection of operators and personnel in the production environment. With its robust construction and advanced safety features, the machine provides a secure and reliable cutting solution for manufacturing companies and industrial facilities.

In addition to its cutting-edge technology and advanced features, the Automatic Wire Length Cutter is backed by [Company Name]'s commitment to customer satisfaction and support. The company's team of experienced professionals is dedicated to providing comprehensive installation, training, and maintenance services to ensure the seamless integration and operation of the machine in a production environment.

As a trusted provider of industrial automation solutions, [Company Name] is proud to introduce the Automatic Wire Length Cutter as the latest addition to its lineup of cutting-edge machinery. With its unparalleled precision, efficiency, and reliability, the machine is set to become an indispensable tool for manufacturing companies and businesses in need of a reliable wire cutting solution.

For more information about the Automatic Wire Length Cutter and [Company Name]'s complete range of industrial automation solutions, please visit [company website] or contact [contact information].

[Company Name] is a leading provider of industrial automation and machinery solutions, specializing in the development and production of cutting-edge equipment for a wide range of industries. With a strong focus on innovation and technological advancement, the company is dedicated to providing its clients with the most advanced and reliable solutions to meet their specific needs.

Company News & Blog

Top Quality HR CR SS GI Steel Coil Slitting Machines: High-Quality Manufacturer & Suppliers in China

Title: China Manufacturer Leading the Way in Top-Quality Steel Coil Slitting Machines Introduction:(Company Name), a renowned and respected leader in the manufacturing industry, has solidified its position as the top supplier of high-quality HR, CR, SS, and GI steel coil slitting machines in China. With a strong commitment to excellence and customer satisfaction, (Company Name) has established itself as the go-to brand for the finest slitting machines on the market.Body:1. Emerging as a Leading Manufacturer:(Company Name) has quickly risen to prominence as one of the most reliable manufacturers of steel coil slitting machines in China. Their commitment to providing top-quality products, combined with their exemplary customer service, has earned them a stellar reputation within the industry.2. State-of-the-Art Technology:(Company Name)'s steel coil slitting machines incorporate cutting-edge technology designed to optimize performance and efficiency, providing customers with unparalleled precision and reliability. With a focus on constant innovation, the machines are continually upgraded to meet the evolving needs of the market.3. Robust Product Line:From HR to CR, SS, and GI steel, (Company Name) offers a wide range of slitting machines suitable for different coil materials. These machines are capable of handling various material thicknesses and widths, making them adaptable to the diverse requirements of different industries.4. Unmatched Quality:Top-quality materials and rigorous quality control processes ensure that (Company Name)'s slitting machines deliver exceptional performance and durability. The machines are constructed with high-grade components to withstand demanding working conditions, providing customers with a reliable and long-lasting solution.5. Product Customization:Recognizing that every customer has unique specifications and requirements, (Company Name) offers customizable options for their slitting machines. Their team of experienced engineers works closely with clients in order to tailor the machines to their specific needs, guaranteeing optimal results and maximum customer satisfaction.6. Dedication to Customer Satisfaction:Customer satisfaction is of utmost importance to (Company Name). They go above and beyond to provide excellent pre-sales and after-sales service, ensuring that their clients' needs are met promptly and efficiently. Additionally, they offer comprehensive training programs to equip their customers with the knowledge and skills required to operate the machines successfully.7. Competitive Pricing:(Company Name) believes in providing high-quality products at competitive prices, making their slitting machines an excellent investment for businesses of all sizes. Their commitment to fair and transparent pricing has made them an attractive choice in the market.8. Commitment to Sustainability:In line with global efforts towards sustainability, (Company Name) prioritizes environmentally friendly practices in their manufacturing processes. They adhere to strict standards, ensuring minimal waste generation and implementing energy-efficient technologies to reduce their carbon footprint.Conclusion:(Company Name) has undoubtedly earned its reputation as a leading manufacturer of high-quality HR, CR, SS, and GI steel coil slitting machines in China. With a focus on innovation, customization, and customer satisfaction, they continue to be a reliable partner for businesses seeking top-quality slitting solutions. By combining cutting-edge technology with exceptional service, (Company Name) reaffirms its commitment to industry leadership and excellence.(Note: The brand name has been removed in accordance with instructions)

Efficient Roof Tin Making Machine Empowers Seamless Roofing Production

Roof Tin Making Machine Revolutionizes the Manufacturing ProcessIn the ever-evolving world of manufacturing, technological advancements continue to reshape industries and revolutionize production processes. One such innovation is the Roof Tin Making Machine, a groundbreaking tool that promises to streamline and improve the manufacturing of roof tins. By integrating cutting-edge technology with efficient design, this machine is set to transform the roofing industry.The Roof Tin Making Machine, developed by an industry-leading company, is an impressive piece of machinery built to enhance productivity, improve output quality, and reduce overall costs. Its state-of-the-art features and functionalities make it an invaluable asset for manufacturers in the roofing sector.This cutting-edge machine is equipped with advanced automation and precision engineering, resulting in enhanced productivity and reduced manual labor. The elimination of manual intervention increases efficiency and minimizes the chance of human errors, resulting in a more streamlined manufacturing process. By automating various steps involved in roof tin production, this machine significantly boosts overall output and eliminates delays caused by manual labor.The Roof Tin Making Machine incorporates sophisticated control systems and software that enable manufacturers to achieve unparalleled precision and accuracy. Precision is crucial in the production of roof tins as even the slightest deviation can compromise the quality and performance of the final product. With this machine, manufacturers can achieve consistent results with minimal variations, ensuring that every roof tin produced meets the highest standards.Moreover, this innovative machine allows for rapid adjustment and customization, enabling manufacturers to cater to diverse client requirements. Its flexible design can adapt to different roof tin sizes, shapes, and specifications, empowering manufacturers to deliver personalized solutions to customers with ease. This versatility not only enhances customer satisfaction but also opens doors for new business opportunities.With sustainability becoming a paramount concern in manufacturing, the Roof Tin Making Machine incorporates eco-friendly features to promote green practices. By optimizing energy consumption and minimizing waste generation, this machine plays a role in reducing the carbon footprint associated with roof tin production. Manufacturers can contribute to a cleaner environment without compromising on quality or efficiency.Additionally, the Roof Tin Making Machine is designed with robust safety features to protect operators and minimize the risk of accidents. This machine adheres to stringent safety standards and is equipped with multiple safety devices. It also includes comprehensive training and support materials to ensure operators are well-versed in operating the machine safely.As a market leader in roof tin manufacturing technology, the company behind the Roof Tin Making Machine prides itself on delivering cutting-edge solutions that drive the industry forward. With a wealth of experience and expertise, the company has developed a strong reputation for delivering high-quality machinery that meets the evolving needs of manufacturers.The Roof Tin Making Machine is a testament to the company's commitment to innovation and customer satisfaction. By combining advanced technology with efficient design, this machine acts as a game-changer in the roofing industry, empowering manufacturers to reach new levels of productivity and excellence.In conclusion, the Roof Tin Making Machine is set to revolutionize the manufacturing process of roof tins. With its automation, precision, customization, sustainability, and safety features, this machine offers a plethora of advantages to manufacturers. By embracing this innovative technology, manufacturers can enhance their production capabilities, stay ahead of the competition, and provide superior products to customers.

Durable Galvanized Steel Floor Decking Sheet for Construction Projects

Galvanized Steel Floor Decking Sheet is a revolutionary product in the construction industry, offering unparalleled strength, durability, and ease of installation. This innovative flooring solution has quickly gained popularity among builders, developers, and architects, thanks to its superior performance and cost-effectiveness.The Galvanized Steel Floor Decking Sheet is manufactured using high-quality galvanized steel, which is known for its exceptional corrosion resistance and longevity. This ensures that the flooring remains intact and robust even in the harshest of environments, making it suitable for a wide range of applications, including commercial, industrial, and residential projects.One of the key features of the Galvanized Steel Floor Decking Sheet is its unique profile, which is designed to provide optimal structural support and load-bearing capacity. This allows for greater flexibility in design and construction, as the flooring can easily accommodate heavy loads and withstand the rigors of daily use. Additionally, the profile enhances the overall stability and safety of the structure, providing peace of mind to both builders and occupants.Furthermore, the Galvanized Steel Floor Decking Sheet is incredibly easy to install, thanks to its lightweight and modular design. This not only accelerates the construction process but also reduces labor costs, making it an economical choice for builders and developers. In addition, the flooring can be customized to meet specific project requirements, offering versatility and adaptability to various design plans.The company behind the Galvanized Steel Floor Decking Sheet, {COMPANY NAME}, is a leading manufacturer and supplier of high-quality construction materials. With a strong focus on innovation and quality, the company has established itself as a trusted partner for builders and developers seeking top-notch products for their projects.{COMPANY NAME} prides itself on its state-of-the-art manufacturing facilities and cutting-edge technology, which enable the production of superior products that meet and exceed industry standards. In addition, the company boasts a team of experienced engineers and technicians who are dedicated to ensuring the quality and reliability of their products, including the Galvanized Steel Floor Decking Sheet.Moreover, {COMPANY NAME} is committed to sustainability and environmental responsibility, utilizing eco-friendly manufacturing processes and materials whenever possible. This dedication to eco-conscious practices sets the company apart in the industry and resonates with environmentally conscious builders and developers.The Galvanized Steel Floor Decking Sheet is just one of many innovative products offered by {COMPANY NAME}, which also includes a wide range of steel and metal products for various construction applications. As a reliable and reputable supplier, the company has built a strong reputation for delivering exceptional products and outstanding customer service, earning the trust and loyalty of clients across the globe.In conclusion, the Galvanized Steel Floor Decking Sheet is a game-changer in the construction industry, offering unmatched strength, durability, and ease of installation. With {COMPANY NAME} at the helm, builders and developers can be confident in the reliability and performance of this innovative flooring solution. As the demand for high-quality, cost-effective construction materials continues to grow, the Galvanized Steel Floor Decking Sheet is poised to become an indispensable element in modern construction projects, setting new standards for efficiency and sustainability.

Steel Profile Roll Forming Machine: The Ultimate Guide

Color Steel Profile Roll Forming Machine revolutionizes the steel industry with its advanced technology and efficient production capabilities. This state-of-the-art machine is a game-changer for the company, as it significantly improves their manufacturing process and allows them to produce high-quality steel profiles at a much faster pace.The Color Steel Profile Roll Forming Machine is equipped with the latest technology and advanced features, making it the most reliable and efficient machine in the industry. Its precision and accuracy in shaping and forming steel profiles have set a new standard for quality and productivity. The machine is capable of producing a wide range of steel profiles, including C-shaped, U-shaped, and Z-shaped profiles, with exceptional consistency and precision.One of the key advantages of this machine is its high-speed production capabilities. The Color Steel Profile Roll Forming Machine is capable of producing up to 30 meters of steel profiles per minute, which is significantly higher than traditional roll forming machines. This increased production capacity allows the company to meet the growing demand for steel profiles in the market while maintaining high quality and consistency.In addition to its high-speed production capabilities, the Color Steel Profile Roll Forming Machine also offers a high level of flexibility and customization. The machine is equipped with a user-friendly interface that allows operators to easily adjust the settings and parameters for each specific profile, allowing for quick and easy changeovers between different profiles. This flexibility is crucial for the company as it allows them to cater to a wide range of customer needs and requirements.The company behind this innovative machine, {}, is a renowned leader in the steel manufacturing industry. With decades of experience and expertise, they have earned a solid reputation for producing high-quality steel products. The addition of the Color Steel Profile Roll Forming Machine to their production line further solidifies their position as a leader in the industry and demonstrates their commitment to innovation and excellence.{} has always been at the forefront of technology and innovation in the steel industry. The addition of the Color Steel Profile Roll Forming Machine is a testament to their dedication to staying ahead of the curve and providing their customers with the best possible products. This new machine will not only improve their production capabilities but also allow them to offer a wider range of high-quality steel profiles to their customers.The Color Steel Profile Roll Forming Machine has already made a significant impact on the company's production process. With its advanced technology and efficient production capabilities, the machine has allowed {} to increase their production capacity, reduce production times, and improve the overall quality of their steel profiles. This has translated to increased customer satisfaction and has helped the company strengthen its position in the market.The Color Steel Profile Roll Forming Machine has truly revolutionized the steel industry, and {} is proud to be at the forefront of this innovation. With this new machine, they have not only improved their own production process but have also raised the bar for the entire industry. The company is excited about the endless possibilities that this machine offers and looks forward to continuing to lead the way in steel manufacturing with the help of this advanced technology.

Guide to Purlin Roll Forming: Everything You Need to Know

Purlin Roll Forming Technology Advancement Revolutionizes the IndustryPurlins are an essential component in the construction of roofs and walls in buildings, providing structural support and stability. The process of forming purlins has traditionally been labor-intensive and time-consuming, but thanks to the latest technological advancements in purlin roll forming, the industry is undergoing a revolution.The introduction of state-of-the-art purlin roll forming technology by {} has significantly improved the efficiency and accuracy of purlin production. This innovative technology allows for the rapid and precise shaping of purlins from raw materials such as steel, aluminum, or other metals, resulting in a high-quality end product.{} is at the forefront of this technological revolution, offering a range of purlin roll forming machines that cater to the diverse needs of the construction industry. Their machines are designed to handle various sizes and thicknesses of materials, providing flexibility and versatility for different construction projects.One of the key advantages of {}'s purlin roll forming technology is its ability to streamline the production process. Traditional methods of forming purlins involved multiple steps and manual labor, leading to higher production costs and a longer turnaround time. With the new technology, purlins can be manufactured in a fraction of the time, ultimately reducing production costs and increasing overall productivity.Furthermore, the precision and consistency achieved through purlin roll forming technology ensure that the end products meet strict quality standards. This is particularly important in the construction industry, where the structural integrity of buildings relies on the strength and durability of purlins. With {}'s advanced roll forming technology, construction companies can have peace of mind knowing that the purlins used in their projects are of the highest quality.In addition to the technological advancements, {} is also committed to sustainability and environmental responsibility. Their purlin roll forming machines are designed to minimize material waste and energy consumption, contributing to a more eco-friendly production process. As sustainability continues to be a priority for many industries, {}'s dedication to green manufacturing sets them apart as an industry leader.The impact of purlin roll forming technology goes beyond just the manufacturing process. It has the potential to revolutionize the construction industry as a whole, offering new possibilities for innovative and cost-effective building designs. The speed and precision of the technology open up opportunities for more complex and creative purlin shapes, which can contribute to the aesthetic appeal of buildings.Furthermore, the increased efficiency and reduced production costs associated with purlin roll forming technology can ultimately benefit the end consumers. As construction companies are able to save on manufacturing expenses, these savings can be passed on to clients, making construction projects more affordable and accessible.With the rapid advancements in purlin roll forming technology, the construction industry is entering a new era of efficiency, precision, and sustainability. Companies like {} are at the forefront of this transformation, providing the tools and technology to drive innovation and progress in the industry. As the demand for high-quality purlins continues to grow, purlin roll forming technology is poised to play a central role in meeting these needs and shaping the future of construction.

6MM Thickness C Purlin Roll Forming Machine for Sigma Shape Steel Purlin - High Quality and Durable

Are you in need of a high-quality C Purlin Roll Forming Machine for Sigma Shape Steel Purlin? Look no further! China has got you covered. With their state-of-the-art manufacturing capabilities, Chinese companies offer top-notch machinery that meets your production needs. This blog post aims to provide you with all the information you need about the Q195 - Q235 6MM Thickness C Purlin Roll Forming Machine.When it comes to roll forming machines, it's crucial to choose a reliable and efficient one that can deliver the desired results. The Q195 - Q235 6MM Thickness C Purlin Roll Forming Machine fits the bill perfectly. This machine is specifically designed to ensure high-quality production of Sigma Shape Steel Purlin.One of the key features of this machine is its capability to handle a thickness range of 6mm. This ensures that the desired C Purlin shape is accurately formed with precision. The machine's precision plays a vital role in achieving consistent and reliable results, allowing for smooth production processes.The Q195 - Q235 6MM Thickness C Purlin Roll Forming Machine is manufactured adhering to the strictest quality standards. Chinese manufacturers are known for their commitment to offering top-quality products, and this machine is no exception. When it comes to C Z Purlin Roll Forming Machines, it's reassuring to know that this particular machine undergoes rigorous quality control measures.By investing in this machine, you can expect high-quality production of Sigma Shape Steel Purlins. The resulting products are guaranteed to meet industry standards and exceed your expectations. Chinese manufacturers take pride in their ability to deliver reliable and durable machinery that stands the test of time.In addition to its exceptional quality, the Q195 - Q235 6MM Thickness C Purlin Roll Forming Machine also offers excellent efficiency. This allows for higher productivity, ultimately resulting in reduced manufacturing costs. With this machine, you can streamline your production processes and meet deadlines without compromising on quality.It's worth mentioning that the Q195 - Q235 6MM Thickness C Purlin Roll Forming Machine is ideal for a wide range of manufacturing applications. Whether you're producing purlins for industrial buildings, residential structures, or any other projects in need of Sigma Shape Steel Purlins, this machine will cater to your needs.When it comes to search engine optimization (SEO), including relevant keywords is crucial. By including terms such as "manual shape C Purlin Roll Forming Machine" in this blog, we can attract the attention of potential customers who are specifically looking for machines that require manual operation. This allows us to provide valuable information to those in the market for such equipment.In conclusion, the Q195 - Q235 6MM Thickness C Purlin Roll Forming Machine is an excellent choice for achieving high-quality Sigma Shape Steel Purlin production. Its exceptional precision, efficiency, and reliability make it a top contender in the market. Chinese manufacturers are renowned for their commitment to quality, and this machine is a prime example of their dedication to delivering superior machinery.If you're in the market for a manual shape C Purlin Roll Forming Machine, look no further. China's top-notch manufacturing capabilities ensure that you will find the perfect machine to meet your needs. Don't compromise on quality - choose the Q195 - Q235 6MM Thickness C Purlin Roll Forming Machine for all your Sigma Shape Steel Purlin production requirements.

High-Quality Corrugated Roll Making Machine for Manufacturing Purposes

Corrugated Roll Making Machine: A New Milestone for Manufacturing ExcellenceIn the world of modern industry, the need for efficient and high-quality machinery is paramount. This is especially true in the manufacturing of corrugated rolls, essential components in packaging and shipping. In response to this demand, a leading machinery manufacturer has recently introduced a state-of-the-art Corrugated Roll Making Machine, setting a new milestone for manufacturing excellence.The Corrugated Roll Making Machine, developed by a company with a long-standing reputation for innovation and quality in the industry, represents the latest advancement in corrugated roll manufacturing technology. This machine is designed to streamline the production process, allowing for increased efficiency and consistency in the manufacturing of corrugated rolls. In addition, it incorporates cutting-edge features that ensure the high quality and durability of the final product.With a focus on precision engineering and advanced automation, the Corrugated Roll Making Machine is capable of producing a wide range of corrugated roll sizes and specifications to meet the diverse needs of the industry. Its versatility and flexibility make it an ideal solution for manufacturers seeking to enhance their production capabilities and stay ahead of the competition.Furthermore, the company behind the Corrugated Roll Making Machine has a proven track record of delivering reliable and durable machinery to its customers. With a commitment to continuous research and development, they have consistently pushed the boundaries of innovation in the industry, and the introduction of this new machine is a testament to their dedication to excellence.The company's extensive experience in the manufacturing industry, combined with their in-depth knowledge of customer needs, has enabled them to develop a machine that not only meets the current demands of the market but also anticipates future trends. By investing in the Corrugated Roll Making Machine, manufacturers can be confident that they are acquiring a cutting-edge solution that will support their growth and success for years to come.In addition to the advanced technological capabilities of the Corrugated Roll Making Machine, the company also provides comprehensive support and service to its customers. From installation and training to ongoing maintenance and technical assistance, they ensure that their customers are equipped with the knowledge and resources to maximize the potential of their investment.As the global demand for corrugated rolls continues to rise, the introduction of the Corrugated Roll Making Machine represents a significant opportunity for manufacturers to elevate their production capabilities and meet the evolving needs of the market. By harnessing the power of this innovative machine, manufacturers can improve efficiency, reduce waste, and deliver superior quality products to their customers.In conclusion, the Corrugated Roll Making Machine is a game-changer for the manufacturing industry. With its advanced technology, precision engineering, and unwavering commitment to excellence, it is set to redefine the standards for corrugated roll production. As manufacturers embrace this new milestone in manufacturing excellence, they can look forward to a future of increased productivity, profitability, and success.

High-Quality Metal Slitting Line Machines for Sale in Different Gauges

When it comes to metal processing, a slitting line is an essential piece of equipment that is used to cut large coils of metal into narrower widths. A metal slitting line involves a series of operations that include uncoiling, feeding the metal strip through a set of knives, slitting the metal strip into desired widths, and recoiling the strips. The slitting process is widely used in various industries, including automotive, construction, and manufacturing.If you are looking for a high-quality metal slitting line for your business needs, RISHBIN is the right place to go. As one of the leading slitting line manufacturers, RISHBIN offers a range of metal slitting lines that are designed to meet different gauge requirements: light, medium, and heavy gauge.Heavy Gauge Slitting LineA heavy gauge slitting line is typically used for cutting thicker metal strips that range from 2mm to 16mm in thickness. It is an ideal option for industries that require thick materials, such as shipbuilding, bridge construction, and oil and gas pipelines. The heavy gauge slitting line features advanced technology that enables it to handle heavy-duty materials with ease.The heavy gauge slitting line from RISHBIN is designed to handle coils of up to 30 tons and widths of up to 2200mm. The machine features a hydraulic coil car that makes loading and unloading of coils easier and safer. The machine also has a decoiler that ensures smooth feeding of the material to the slitter head.The slitter head of the heavy gauge slitting line features an advanced design that enables it to slit thick materials with high precision. The machine has multiple knife sets that can be easily adjusted to accommodate different width requirements. The slitter head also features a powerful motor that ensures perfect slitting even at high speeds.Once the metal strip has been slit into the desired width, the machine recoils the strips. The recoiling process is also designed to handle heavy-gauge materials without causing any damage. The recoiler is equipped with a tensioning system that ensures uniform rewinding of the strips.In conclusion, a heavy gauge slitting line is an essential machine for any business that requires thick materials. The heavy gauge slitting line from RISHBIN is one of the best on the market, featuring advanced technology that ensures high precision and efficiency. If you are interested in purchasing a heavy gauge slitting line, RISHBIN is the right place to look.

Glazed Steel Profile Roll Forming Machine for Construction with PLC Control - High-Quality Product

article as follows:China-based steel roll forming machine manufacturer, [Brand Name Removed], has announced the launch of its top-of-the-line product, the Steel Tile 750 glazed steel profile roll forming machine.This innovative roll forming machine is designed to offer a superior solution for all construction materials needs. It is expertly engineered to deliver high-quality glazed tile sheets that are highly durable, strong and capable of offering long-lasting performance that withstands the rigors of construction.With a profound understanding of the construction industry, [Brand Name Removed] has always been committed to providing unparalleled products that cater to the specific needs of its clients. The Steel Tile 750 roll forming machine is a prime example of that dedication.Manufactured using the latest technology, the Steel Tile 750 boasts of a robust design that is guaranteed to withstand heavy-duty usage. This machine is powered by PLC control technology, which delivers optimum automation and efficiency.The Steel Tile 750 roll forming machine comes with an automated hydraulic cutting system that ensures precise cuts and eliminates wastage. The machine can produce versatile, glazed tiles ranging in thickness from 0.3-0.8mm and a width of up to 1000mm.The innovation and quality of the Steel Tile 750 roll forming machine are a testament to [Brand Name Removed]'s reputation as a leading manufacturer of roll-forming and other related steel machines serving the global construction industry.According to the company spokesperson, "we understand the importance of quality and durability in the construction industry, and that's why we ensure that every product we manufacture is made to last. With our Steel Tile 750, our customers can enjoy a solution that will save them both time and money. We take pride in manufacturing machines that can remain in use for years."Designing the Steel Tile 750 roll forming machine took into account the varying construction needs of clients across the globe. The machine's versatility is perhaps its most significant selling point, as it can adapt to different building configurations and designs while still maintaining the same standard of quality.With years of experience in the steel roll-forming and construction industry, [Brand Name Removed] has earned a reputation for quality, reliability and exceptional customer service. Its team of qualified engineers and professionals is dedicated to designing machines that exceed customer expectations and meet the industry's specific needs.The Steel Tile 750 is an excellent example of [Brand Name Removed]'s commitment to offering state-of-the-art machinery at an affordable price while maintaining stringent quality control measures. Every machine's quality is checked and tested thoroughly to ensure optimal performance.The launch of the Steel Tile 750 roll forming machine is set to transform the construction industry, offering architects, contractors, and builders a solution that is both reliable and efficient. With this machine, they can speed up the construction process, reduce downtime and achieve the desired results without sacrificing quality.In conclusion, [Brand Name Removed] has once again demonstrated its expertise and focus on quality and innovation with the launch of the Steel Tile 750 glazed steel profile roll forming machine. It is an excellent addition to the company's portfolio, offering clients reliable and top-quality construction solutions at an affordable price. The industry can now look forward to faster and more efficient construction without compromising on quality.

Top-rated Roof Panel Machine: A Game-Changer in Construction Industry

Roof Panel Machine Revolutionizes the Manufacturing IndustryThe manufacturing industry has seen a significant breakthrough with the introduction of the state-of-the-art Roof Panel Machine by a leading company. This innovative machine has redefined the process of manufacturing roof panels, making it faster, more efficient, and cost-effective.The Roof Panel Machine is designed to streamline the production of roof panels, providing manufacturers with a high-quality and reliable solution for their production needs. With advanced technology and precision engineering, this machine has the capability to produce a wide range of roof panels with varying thickness, length, and design specifications. This level of flexibility allows manufacturers to meet the diverse needs of their customers, while maintaining a high standard of quality and consistency.One of the key features of the Roof Panel Machine is its automated operation, which minimizes the need for manual labor and reduces the risk of errors in the production process. This automated system is equipped with intelligent controls and sensors that ensure the accurate and precise fabrication of roof panels, resulting in a higher level of efficiency and productivity. As a result, manufacturers can increase their output and meet tight production deadlines without compromising on the quality of their products.In addition, the Roof Panel Machine is designed for ease of use, with a user-friendly interface and intuitive controls that make it accessible to operators of varying skill levels. This allows manufacturers to train their staff quickly and efficiently, reducing the time and resources required for onboarding new employees. The simplified operation of the machine also minimizes the risk of human error, resulting in a more consistent and reliable production process.Furthermore, the Roof Panel Machine is engineered for durability and longevity, ensuring a reliable and long-lasting solution for manufacturers. With robust construction and high-quality components, this machine is designed to withstand the rigors of continuous use in a manufacturing environment, providing a dependable and low-maintenance option for production facilities.The introduction of the Roof Panel Machine has significantly impacted the manufacturing industry, offering a transformative solution for the production of roof panels. With its advanced technology, automated operation, ease of use, and durability, this machine has redefined the standards of manufacturing, setting new benchmarks for efficiency, productivity, and quality.Company Introduction:The company behind the Roof Panel Machine is a leading innovator in the field of manufacturing technology. With a strong focus on research and development, this company has consistently introduced cutting-edge solutions that address the evolving needs of the industry. The Roof Panel Machine is the latest addition to their portfolio of advanced machinery, and it reflects their commitment to driving innovation and excellence in manufacturing.In addition to their dedication to technological advancement, the company is also known for their comprehensive support and service network. They offer a range of services, including installation, training, maintenance, and technical support, to ensure that their customers can fully maximize the benefits of their machinery. This level of support reinforces the company's dedication to customer satisfaction and their commitment to delivering value beyond the sale of their products.With a strong track record of success and a reputation for delivering superior technology, the company is poised to continue leading the way in the manufacturing industry. The Roof Panel Machine is just one example of their innovative solutions, and it serves as a testament to their vision of shaping the future of manufacturing with cutting-edge technology and unmatched expertise.In conclusion, the Roof Panel Machine has ushered in a new era of manufacturing, offering a game-changing solution for the production of roof panels. With its advanced technology, automated operation, ease of use, and durability, this machine has set a new standard for efficiency, productivity, and quality in the industry. As a testament to the company's commitment to innovation and excellence, the Roof Panel Machine stands as a pioneering achievement that is revolutionizing the manufacturing landscape.