- Home

- Blog

- High-Quality Horizontal Barrel Vault Panel Production Equipment for Efficient Manufacturing

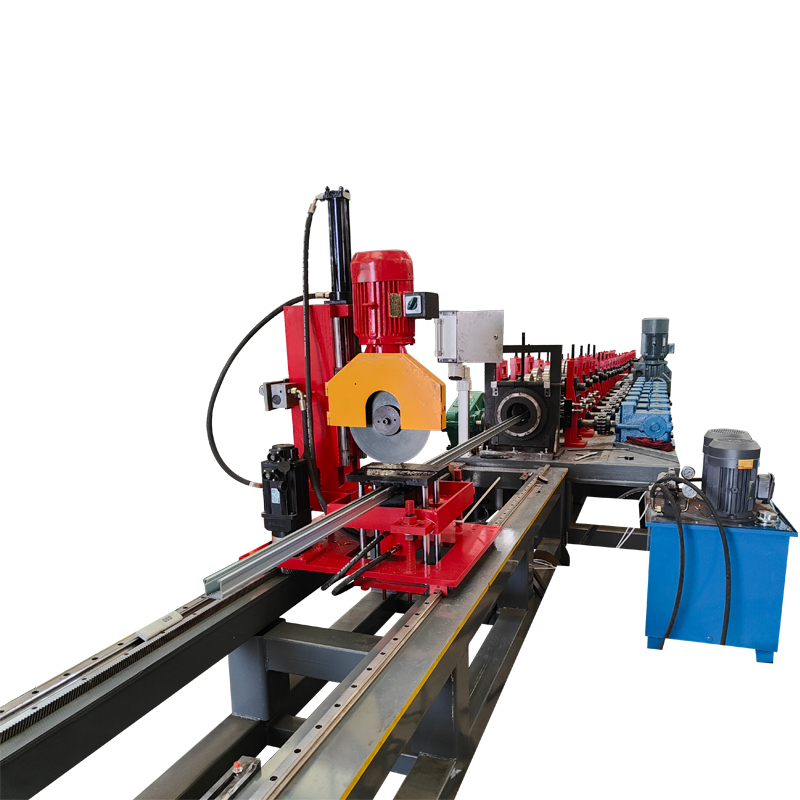

High-Quality Horizontal Barrel Vault Panel Production Equipment for Efficient Manufacturing

By:Admin

The Horizontal Barrel Vault Panels are an essential component of modern building construction, providing strength and support for large structures such as commercial buildings, warehouses, and even some residential properties. The demand for these panels has been steadily increasing, leading to a need for more advanced production techniques to meet the market's requirements.

The new production equipment, which includes cutting, bending, and assembling machines, is designed to streamline the manufacturing process, effectively reducing production times and improving the overall quality of the panels. This breakthrough in production technology is expected to have far-reaching implications for the construction industry, as it will allow for faster and more cost-effective production of Horizontal Barrel Vault Panels, ultimately benefiting both manufacturers and consumers.

In addition to the innovative equipment, the company also boasts a state-of-the-art production facility that is equipped with the latest technology and machinery. This, combined with the company's commitment to quality and innovation, has positioned them as a leader in the manufacturing of construction components such as the Horizontal Barrel Vault Panels.

The company, with its extensive experience in the construction industry, has built a reputation for delivering high-quality products that meet the highest standards of performance and durability. Their team of engineers and technicians are constantly working on developing new and improved manufacturing techniques, with a focus on efficiency, sustainability, and cost-effectiveness.

One of the key advantages of the new production equipment is its ability to produce Horizontal Barrel Vault Panels with greater precision and consistency. This is crucial for ensuring that the panels meet the strict structural requirements of modern building designs, and also for reducing waste and material usage during the production process.

Furthermore, the company's commitment to sustainability is reflected in the design of the production equipment, which incorporates energy-efficient technologies and sustainable manufacturing practices. This demonstrates the company's dedication to reducing its environmental impact while also delivering high-quality products to the market.

The introduction of the new production equipment has already generated significant interest within the construction industry, with many industry experts and professionals recognizing its potential to drive innovation and efficiency in the manufacturing of Horizontal Barrel Vault Panels. In fact, the company has already received inquiries from various construction companies and developers who are keen to explore the use of the new panels in their upcoming projects.

Overall, the company's investment in advanced production equipment and its dedication to innovation and quality have positioned them as a leading provider of Horizontal Barrel Vault Panels. With their state-of-the-art production facility and commitment to sustainability, they are well-equipped to meet the growing demand for these essential construction components while also driving positive change in the industry. The introduction of the new production equipment marks a significant milestone for the company and is expected to have a profound impact on the construction industry as a whole.

Company News & Blog

Efficient Automatic Length Cutting Machine for Various Applications

Automatic Length Cutting Machine Revolutionizing Precision Cutting in Manufacturing IndustryIn today's fast-paced manufacturing industry, precision cutting plays a crucial role in ensuring the quality and accuracy of the final product. To meet the demand for high-precision cutting in various industries, the introduction of the Automatic Length Cutting Machine has revolutionized the way manufacturers produce cut-to-length products. This state-of-the-art machine, developed and manufactured by {Company Name}, is setting new standards for precision cutting in the manufacturing industry.{Company Name} has been at the forefront of manufacturing innovative machinery and equipment for various industries for over two decades. With a commitment to excellence and a strong focus on technological advancements, the company has established itself as a leading provider of cutting-edge solutions for precision cutting and manufacturing processes. The Automatic Length Cutting Machine is a testament to their dedication to delivering high-quality, efficient, and reliable equipment to their clients.The Automatic Length Cutting Machine is designed to provide unmatched precision and accuracy in cutting various materials, including metal sheets, plastic, rubber, and other industrial materials. The machine's advanced cutting technology ensures consistent and uniform cuts, enabling manufacturers to produce high-quality products with minimal waste and maximum efficiency. This level of precision is critical for industries such as automotive, aerospace, construction, and metal fabrication, where the quality of the cut directly impacts the performance and reliability of the final product.One of the key features of the Automatic Length Cutting Machine is its advanced automation system, which allows for easy programming and set-up of cutting parameters. This significantly reduces the time and effort required for manual adjustments, while also minimizing the risk of human error. Additionally, the machine's intuitive interface and user-friendly controls make it accessible to operators of all skill levels, further streamlining the manufacturing process and increasing overall productivity.The versatility of the Automatic Length Cutting Machine is another standout feature, as it is capable of handling a wide range of materials and dimensions. Whether it's a small batch of custom-sized parts or large-scale production runs, the machine can accommodate varying lengths and thicknesses with precision and consistency. This flexibility makes it an invaluable asset for manufacturers looking to optimize their production processes and meet the diverse demands of their clients.Furthermore, the Automatic Length Cutting Machine is equipped with advanced safety features to ensure the well-being of operators and minimize the risk of accidents. The machine's enclosure and safety interlocks provide a secure operating environment, while its built-in sensors and monitoring systems enhance overall operational safety. This commitment to safety reflects {Company Name}'s dedication to not only providing cutting-edge technology but also prioritizing the well-being of its clients and their personnel.In addition to its technical capabilities, the Automatic Length Cutting Machine is backed by {Company Name}'s comprehensive support and service network. From initial installation and commissioning to ongoing maintenance and technical assistance, the company's team of experts is committed to providing exceptional support to ensure the seamless operation of their equipment. This dedication to customer satisfaction has earned {Company Name} a reputation for reliability and trustworthiness in the manufacturing industry.The introduction of the Automatic Length Cutting Machine by {Company Name} is poised to reshape the landscape of precision cutting in the manufacturing industry. By combining cutting-edge technology, unmatched precision, and exceptional versatility, this machine is redefining the standard for high-quality, efficient, and reliable cutting solutions. As manufacturers continue to seek ways to optimize their production processes and enhance their competitive edge, the Automatic Length Cutting Machine stands as a testament to {Company Name}'s commitment to innovation and excellence in the manufacturing sector.

Leading Metal Slitting Machines for Efficient Sheet Cutting

Sheet Metal Slitting Machine Enhances Precision and Efficiency in MetalworkingIn the fast-paced world of manufacturing, precision and efficiency are paramount. It is essential for companies to have reliable and high-performing tools to meet the ever-increasing demands of the industry. Recognizing this need, an innovative solution has emerged in the form of the Sheet Metal Slitting Machine, a game-changer that enhances productivity and accuracy in metalworking.Developed by a leading technology company, this state-of-the-art machine revolutionizes the process of slitting sheet metal into narrower strips, ultimately enabling manufacturers to optimize material usage and streamline their production workflow. Gone are the days of manual labor and imprecise cutting techniques. With the Sheet Metal Slitting Machine, manufacturers can achieve remarkable results with ease.Featuring cutting-edge technology and advanced automation, this machine provides exceptional precision in slitting a wide range of materials, including stainless steel, aluminum, copper, and other alloys. The machine's computerized system ensures consistent and accurate cuts, minimizing material waste and maximizing productivity. Its high-speed operation allows for quick turnaround times, reducing production timelines and meeting tight deadlines.One of the key advantages of the Sheet Metal Slitting Machine is its versatility. It can handle various thicknesses and widths of sheet metal, catering to the specific needs of different industries. Whether it's for automotive, aerospace, construction, or any other sector, this machine can adapt to the required specifications effortlessly. With adjustable settings and customizable features, manufacturers have full control over the slitting process, resulting in superior quality output.In addition to precision and versatility, the Sheet Metal Slitting Machine ensures operator safety. Equipped with advanced safety features, such as emergency stop buttons and protective guards, it prioritizes the well-being of the people operating the machine. This commitment to safety not only instills confidence in the workforce but also helps companies comply with rigorous industry regulations and standards.Furthermore, the company behind this remarkable technology is committed to customer satisfaction and continuous improvement. With years of experience and a solid reputation in the industry, they have earned the trust of manufacturers worldwide. Their team of experts provides comprehensive support, from installation and training to maintenance and troubleshooting. Manufacturers can rely on their expertise to ensure optimal performance and longevity of the Sheet Metal Slitting Machine.As the demand for precision manufacturing continues to rise, the introduction of the Sheet Metal Slitting Machine offers a transformative solution for companies seeking enhanced efficiency and accuracy. By investing in this cutting-edge technology, manufacturers can elevate their production capabilities, reduce costs, and deliver exceptional products to the market.With its emphasis on precision, versatility, and safety, the Sheet Metal Slitting Machine represents the future of metalworking. Its advanced features empower manufacturers to stay ahead of the competition and meet the ever-evolving needs of the industry. As manufacturing processes evolve, this machine stands as a testament to innovation and progress, enabling companies to unlock their full potential and achieve new heights of success in the world of metalworking.

Innovative Profiling Equipment for Creating Glazed Tiles

Title: Advanced Profiling Equipment Revolutionizes Glazed Tile ManufacturingIntroduction:In a groundbreaking development that is set to transform the glazed tile manufacturing industry, a leading company has unveiled its latest innovation - advanced profiling equipment. This cutting-edge technology eliminates the need for manual profiling, streamlining the production process and ensuring unparalleled precision and efficiency. By leveraging this state-of-the-art machinery, manufacturers can now produce an exquisite range of glazed tiles in a faster, more cost-effective, and sustainable manner.Innovative Technology:The newly-introduced advanced profiling equipment is the result of extensive research and development by a renowned manufacturer. By fusing automation and computer-controlled precision machinery, this equipment allows for the shaping and profiling of glazed tiles in a highly accurate and efficient manner. With superior profiling capabilities, the equipment can achieve intricate designs and impeccable finishing, rendering each glazed tile a work of art.Enhanced Precision:The traditional method of manual profiling often resulted in inconsistencies in tile shape, leading to production delays and significant material wastage. However, with the advent of advanced profiling equipment, such concerns are now a thing of the past. The computerized controls and precise movements of the machinery ensure that each tile is uniform, with perfectly calibrated dimensions as specified by the manufacturer. This increased precision results in a seamless construction process and facilitates easy installation for end-users.Streamlined Production and Increased Efficiency:One of the primary advantages of the new profiling equipment is its ability to significantly boost production capacity while minimizing manufacturing time. The advanced technology automates various stages of the profiling process, including cutting and shaping, thereby reducing the reliance on manual labor. This not only speeds up the production cycle but also reduces costs associated with human errors and worker fatigue. Additionally, the machinery's efficiency ensures a higher output of glazed tiles, meeting market demands effectively.Sustainable Manufacturing:As the global focus on sustainable practices intensifies, the need for eco-friendly manufacturing processes has become more critical than ever. Advanced profiling equipment is a solution to this challenge. By minimizing resource wastage and optimizing the production process, this machinery dramatically reduces the carbon footprint of glazed tile manufacturing. Moreover, it promotes the use of recyclable materials, contributing to the overall sustainability of the industry.Durability and Longevity:The integration of advanced profiling equipment ensures that glazed tiles produced possess exceptional durability and longevity. The precision cutting and shaping techniques employed by the machinery create tiles that fit seamlessly and interlock securely. This eliminates the risks of cracks, breakages, or uneven installation, guaranteeing a reliable, long-lasting flooring or walling solution for customers across various sectors.Revolutionizing Tile Design:The advent of advanced profiling equipment has unlocked a new era of design possibilities for glazed tiles. Manufacturers can now experiment with intricate shapes, beveled edges, and unique aesthetics that were previously difficult to achieve through manual profiling. This has led to an explosion of creativity and innovation in the industry, with customers benefiting from an extensive range of designs and patterns to suit their individual preferences and requirements.Conclusion:The introduction of advanced profiling equipment marks a significant turning point in the glazed tile manufacturing industry. This cutting-edge machinery not only streamlines production processes but also ensures unparalleled precision, efficiency, sustainability, and durability. With limitless design possibilities, the application of this advanced technology promises to revolutionize the realm of glazed tiles, enhancing the quality of construction projects worldwide.

High-quality Corrugated Sheet Forming Machine for Efficient Production

[Company] is excited to announce the launch of its latest innovation, the Corrugated Sheet Forming Machine. This cutting-edge machine is designed to revolutionize the production of corrugated sheets with its advanced technology and efficiency.The Corrugated Sheet Forming Machine is a highly versatile and customizable solution for manufacturers in the packaging, construction, and automotive industries. It is capable of forming corrugated sheets of various sizes and thicknesses, making it an ideal choice for a wide range of applications. With its high-speed production capabilities, the machine is able to meet the demands of even the most fast-paced production environments.One of the key features of the Corrugated Sheet Forming Machine is its precision engineering, which ensures consistently high-quality results with every sheet produced. This level of precision is essential for industries where product integrity and consistency are paramount. The machine also boasts a user-friendly interface, allowing for easy operation and minimal downtime for maintenance and adjustments.In addition to its advanced technology and precision, the Corrugated Sheet Forming Machine is also designed with efficiency in mind. Its streamlined design and intelligent automation reduce the need for manual labor, resulting in lower production costs and higher output. This is a game-changer for manufacturers looking to improve their bottom line without compromising on quality.As a company committed to innovation and customer satisfaction, [Company] has invested significant resources into the development of the Corrugated Sheet Forming Machine. The machine is a testament to the company's dedication to engineering excellence and its ability to anticipate and meet the evolving needs of the manufacturing industry.[Company] has a long-standing reputation for delivering cutting-edge solutions to its customers, and the Corrugated Sheet Forming Machine is the latest example of this commitment. With its high-performance capabilities and user-friendly design, the machine is set to become an essential tool for manufacturers seeking to stay ahead of the competition."We are thrilled to introduce the Corrugated Sheet Forming Machine to the market," said [Company] CEO. "We believe that this machine has the potential to transform the way corrugated sheets are produced, providing our customers with a competitive edge in their respective industries. We are confident that this innovation will set a new standard for efficiency and quality in sheet forming."The introduction of the Corrugated Sheet Forming Machine represents a significant milestone for [Company] as it continues to lead the way in manufacturing technology. With its focus on innovation and customer-driven solutions, the company is poised to maintain its position as a trusted partner for manufacturers seeking to optimize their production processes.For more information about the Corrugated Sheet Forming Machine and other innovative solutions from [Company], visit [Company website] or contact [Company] directly.About [Company]:[Company] is a leading provider of advanced manufacturing solutions for a wide range of industries. With a commitment to innovation and customer satisfaction, the company has established a reputation for delivering cutting-edge technology and engineering excellence. With a focus on efficiency, precision, and reliability, [Company] is dedicated to helping its customers stay ahead of the competition.

Top-quality Corrugated Iron Roofing Sheet Making Machinery for Your Business Needs" becomes "High-Quality Corrugated Iron Roofing Sheet Making Machine for Your Business.

Corrugated Iron Roofing Sheet Making Machine Revolutionizes Roofing IndustryIn a groundbreaking development, the world-renowned machinery manufacturing company, [company name], has unveiled its latest innovation in the field – the Corrugated Iron Roofing Sheet Making Machine. This state-of-the-art machine promises to revolutionize the roofing industry, making the production of corrugated iron roofing sheets more efficient and cost-effective than ever before. The introduction of this cutting-edge technology is set to greatly benefit both manufacturers and consumers in several ways.Traditionally, the process of manufacturing corrugated iron roofing sheets has been a labor-intensive and time-consuming task. However, with the advent of [company name]'s Corrugated Iron Roofing Sheet Making Machine, this is set to change. This automated machine streamlines the entire production process, significantly reducing the need for human labor and expediting the manufacturing cycle. With its high-speed operation, this machine can produce a larger quantity of roofing sheets in a fraction of the time it would take using conventional methods, without compromising on quality.One of the key advantages of the Corrugated Iron Roofing Sheet Making Machine is its versatility. It is designed to accommodate a wide range of sheet sizes and thicknesses, allowing manufacturers to cater to the diverse needs and preferences of their customers. This flexibility in production capabilities provides businesses with a competitive edge and allows them to meet varying market demands efficiently. Moreover, the machine's adjustable settings ensure precise corrugation, resulting in uniformly shaped and sized sheets, thereby further enhancing the product's quality.Cost-effectiveness is another notable feature of this innovative machine. By automating the production process and optimizing material usage, manufacturers can significantly reduce production costs. The Corrugated Iron Roofing Sheet Making Machine eliminates material wastage, as each sheet is precisely cut and shaped, maximizing the utilization of resources. Additionally, the reduced labor requirement leads to lower operating expenses for manufacturers, ultimately resulting in competitive pricing for consumers.Furthermore, the Corrugated Iron Roofing Sheet Making Machine is equipped with advanced monitoring and control systems. These features ensure that every aspect of the production process is closely monitored, guaranteeing consistent quality and minimizing the chances of defects. This level of precision and quality assurance is of utmost importance when it comes to roofing materials, as substandard products can compromise the integrity of buildings and pose safety risks.Promoting sustainable practices is a key focus in today's era, and the Corrugated Iron Roofing Sheet Making Machine aligns well with this objective. By optimizing material usage and reducing waste, it minimizes the environmental impact associated with traditional manufacturing processes. Additionally, the machine’s energy-efficient operation contributes to reduced carbon emissions, making it a responsible choice for eco-conscious manufacturers."We are thrilled to introduce the Corrugated Iron Roofing Sheet Making Machine to the market," said [company spokesperson]. "This cutting-edge technology will transform the way roofing sheets are produced, offering unparalleled efficiency, quality, and cost-effectiveness."With its ability to augment production, minimize costs, and enhance quality control, the Corrugated Iron Roofing Sheet Making Machine is set to become a game-changer in the roofing industry. Businesses that incorporate this machinery into their operations will enjoy a competitive edge in the market, enabling them to meet the growing demand for roofing materials effectively.As the roofing industry continues to evolve, [company name] remains at the forefront of innovation, consistently delivering state-of-the-art machinery that elevates industry standards. Their Corrugated Iron Roofing Sheet Making Machine, with its unmatched capabilities, will undoubtedly shape the future of roofing production, benefitting manufacturers, consumers, and the environment alike.

Discover the Art of Aluminium Profile Bending for Enhanced Applications

Aluminium Profile Bending Brings a New Era of ManufacturingThe recent years have seen a drastic rise in the popularity and use of aluminium profiles. They are being extensively used in a diverse range of industries such as automobile, construction, and aerospace. The reason behind the emergence of this trend is the unparalleled advantages that come with using these profiles. They offer high strength, lightness, and durability. They are also easy to manufacture and mould. However, the real challenge arises when it comes to moulding these profiles into the desired shapes and sizes. This is where Aluminium Profile Bending has brought about a revolution in the manufacturing industry.Aluminium Profile Bending (APB), a technique that has been developed by a leading company in the manufacturing industry, has revolutionized the way aluminium profiles are moulded. With the introduction of this technique, manufacturers can now bend the profiles into any desired shape and size. The shapes can vary from simple curves to complex designs. This technique is particularly useful for manufacturing aluminum profiles for the construction industry that require intricate shapes, making it impossible to produce using conventional techniques.Advanced technology and expertise are required to carry out the bending of aluminum profiles, which is where the company that developed APB excels. They have a team of immensely skilled technicians who use cutting-edge equipment to ensure precision in the bending of the profiles. Using this technique, the team can accurately bend even the most intricate shapes.The advantages of APB are numerous. Firstly, it offers a high level of precision which allows for the creation of complex and intricate designs. Secondly, the technique is much more cost-effective, as it reduces the waste material that is produced during the conventional manufacturing process. APB also eliminates the need for additional manufacturing processes that might be required to achieve the desired shape, which again translates to cost savings. Additionally, it provides excellent finish quality and surface appearance, making it ideal for high-quality products such as those required in the automotive and aerospace industries.The use of APB is not limited to aluminum profiles only. The technique can also be used with other metals, including copper, brass, and stainless steel. This versatility means that manufacturers now have even more options when it comes to the manufacturing of complex shapes and designs.The development of APB has had a significant impact on the manufacturing industry. It has not only reduced production costs but has also opened up new possibilities for manufacturers. With this technique, they can now produce complex and intricate designs that were previously not possible.With the increasing demand for aluminium profiles, it is evident that the manufacturing industry needs to embrace new technologies and techniques to stay ahead of the competition. The introduction of Aluminium Profile Bending has provided manufacturers with a game-changing solution to their manufacturing problems. As new and better technologies continue to emerge, it is essential that manufacturers keep an eye out for innovations that could improve their manufacturing processes.In conclusion, Aluminium Profile Bending has revolutionized the way aluminium profiles are moulded, giving manufacturers the ability to produce complex and intricate designs accurately. The technique offers a high level of precision, reduces production costs, and eliminates the need for additional manufacturing processes, making it ideal for a diverse range of industries. As manufacturing technologies continue to evolve, it is essential for manufacturers to stay up-to-date with the latest innovations and techniques to remain competitive in the industry.

High-Quality Heavy Gauge Slitting Line for Efficient Production

Heavy Gauge Slitting Line plays a crucial role in the metal processing industry. It is a highly efficient and versatile machine that is used to cut large coils of metal into narrower strips, which are then used for various purposes in different industries. With its high precision and speed, Heavy Gauge Slitting Line has become an essential tool for metal processing companies around the world.One of the leading manufacturers of Heavy Gauge Slitting Line, is known for producing high-quality and reliable machines that meet the needs of its customers. The company has a strong commitment to research and development, and it continuously strives to improve its products and services to meet the evolving needs of the market. With a focus on innovation and technology, the company has established itself as a trusted name in the metal processing industry.The Heavy Gauge Slitting Line produced by the company is designed to meet the demands of heavy-duty metal processing. It is capable of handling large coils of metal with precision and efficiency, making it an ideal choice for companies that require high-volume production. The machine is equipped with advanced control systems and cutting-edge technology to ensure consistent and accurate slitting of metal coils, resulting in high-quality strips that meet the industry standards.The Heavy Gauge Slitting Line is also known for its versatility and flexibility. It can be customized to meet the specific requirements of different types of metal and can handle a wide range of thickness and width, making it suitable for various applications in the metal processing industry. Whether it is stainless steel, aluminum, or other metals, the Heavy Gauge Slitting Line can deliver superior performance and precision cutting, making it a valuable asset for companies across different sectors.In addition to its technical capabilities, the company also provides excellent after-sales support and services to ensure the smooth operation of its Heavy Gauge Slitting Line. Its team of skilled engineers and technicians are committed to providing prompt and efficient assistance to its customers, offering training, maintenance, and troubleshooting services to maximize the performance and lifespan of the machine.The company’s commitment to quality, innovation, and customer satisfaction has earned it a strong reputation in the metal processing industry. Its Heavy Gauge Slitting Line is trusted by companies around the world for its reliability, efficiency, and precision, making it a preferred choice for businesses looking to enhance their metal processing capabilities.With its dedication to excellence and a strong track record in delivering high-quality machines, the company continues to be a leading player in the metal processing industry. As it continues to innovate and evolve, it remains committed to providing the best solutions for its customers and driving the industry forward with its cutting-edge Heavy Gauge Slitting Line.

High-efficiency Slitting Line for Effective Metal Processing

Beijing, China - The modern world is fast-paced and ever-changing, therefore businesses around the globe need to adapt, evolve and innovate to remain competitive in the market. In China, there is a steel sheet manufacturing company that is doing just that. They are investing in a new piece of machinery - a CR slitting line - to meet the growing demand for high-quality, thin steel sheets.This company has been in the steel production industry for over two decades and has gained a reputation for delivering exceptional products and services to their clients. They are known for their commitment to quality, efficiency, and customer satisfaction. Their decision to invest in a cutting-edge CR slitting line is another step in their relentless pursuit of excellence.The CR slitting line is a state-of-the-art machine designed to cut a coil of steel sheet into smaller, more manageable pieces, precisely and quickly. The CR (cold-rolled) slitting line is equipped with advanced technology, which allows it to cut at a much higher speed than traditional slitting machines, while maintaining precision and accuracy.This new equipment is vital to the company's expansion plans and growth strategy, as it enables them to produce thin, lightweight steel sheets - a product that is increasingly in demand in many different industries. The automotive and aerospace industries, for instance, require high-quality steel sheets that are both strong and lightweight, to improve fuel efficiency and other performance metrics. With the CR slitting line, this company can now produce these sheets more efficiently and cost-effectively.According to industry experts, the steel sheet manufacturing market is set to grow significantly in the next few years, as more companies require steel sheets for various applications. As such, the demand for high-quality, thin steel sheets will continue to rise. Therefore, this company's investment in the CR slitting line is not only timely but also strategic.In a statement, the company's CEO emphasized the importance of investing in the latest technologies to stay ahead of the competition. "Our customers are always looking for better quality products and faster delivery times. With the CR slitting line, we can meet those demands and exceed their expectations. We are committed to providing top-notch products and services to our clients, and this investment is proof of that commitment."The CR slitting line is not only beneficial to the company's operations but also the environment. The machine is designed to minimize waste, reduce energy consumption and produce steel sheets with consistent thickness. With the growing concern for global warming and environmental issues, the company's decision to invest in this equipment is commendable.The company's commitment to quality, efficiency, and customer satisfaction has earned them a loyal customer base, and the introduction of the CR slitting line will only serve to strengthen that relationship. With this equipment, they can deliver high-quality products faster, at a more competitive price point.In conclusion, the introduction of the CR slitting line by this steel sheet manufacturing company is a testament to their commitment to innovation and excellence. Their investment in this cutting-edge technology will not only benefit their operations but also their customers and the environment. As they continue to grow and expand their business globally, this equipment will play a vital role in their success.

Affordable Roll Forming Machine for C Z Purlin - Get the Best Price!

Our company is excited to announce the launch of our new C Z Purlin Roll Forming Machine, a highly efficient and cost-effective solution for creating C and Z shaped steel purlins. With the growing demand for quality steel construction materials, our machine offers a superior level of precision and productivity, making it an essential investment for steel manufacturing companies.The C Z Purlin Roll Forming Machine is designed to produce C and Z shaped purlins with a high level of accuracy and consistency. This is achieved through the use of advanced technology and precision engineering, ensuring that every purlin produced meets the strictest quality standards. The machine can handle a wide range of steel thicknesses and sizes, making it suitable for a variety of construction projects.One of the key features of our C Z Purlin Roll Forming Machine is its exceptional speed and efficiency. The machine is capable of producing purlins at a rapid pace, helping to increase production output and reduce labor costs. This makes it an ideal choice for steel manufacturing companies looking to improve their productivity and competitiveness in the market.In addition to its speed and efficiency, our machine is also incredibly easy to operate and maintain. It is equipped with user-friendly controls and features a durable design that minimizes the need for frequent maintenance. This ensures that our customers can rely on the machine for consistent performance and minimal downtime, ultimately saving time and money.Furthermore, our C Z Purlin Roll Forming Machine is competitively priced, offering exceptional value for money. We understand the importance of cost-effectiveness in the steel manufacturing industry, which is why we have designed our machine to deliver a high return on investment. By investing in our machine, companies can significantly reduce their production costs and improve their overall profitability.As a company, we have a strong reputation for delivering high-quality and reliable machinery. With over [number] years of experience in the industry, we have a proven track record of providing innovative solutions that meet the evolving needs of our customers. Our commitment to excellence, combined with our dedication to customer satisfaction, has earned us the trust and loyalty of numerous steel manufacturing companies around the world.In addition to our C Z Purlin Roll Forming Machine, we offer a comprehensive range of roll forming and metal processing equipment. Our extensive product line includes machines for producing roofing panels, wall cladding, decking, and various other steel profiles. We are committed to staying at the forefront of technology and continuously improving our products to meet the changing demands of the industry.We are dedicated to providing exceptional service and support to our customers. From the initial inquiry to after-sales assistance, our team is committed to ensuring that every customer receives the highest level of care and attention. We offer comprehensive training programs, technical support, and spare parts availability to guarantee the long-term performance and reliability of our machines.In conclusion, the launch of our new C Z Purlin Roll Forming Machine represents a significant advancement in steel manufacturing technology. With its exceptional speed, efficiency, and cost-effectiveness, it is set to revolutionize the production of C and Z shaped purlins. We are confident that our machine will provide our customers with a competitive edge in the market and help them achieve greater success in their business endeavors.For more information about our C Z Purlin Roll Forming Machine and other products, please contact us at [contact information] or visit our website [website address]. We look forward to the opportunity to discuss how our solutions can benefit your company and contribute to your success in the steel manufacturing industry.

High Precision Cut To Length Line Metal Sheet Cutting Machine for Efficient Sheet Metal Slitting

and Sheet Metal Slitter Machine.When it comes to cutting metal sheets, it is imperative to have a reliable and precise Cut-To-Length Machine and Sheet Metal Slitter Machine. These machines are designed to offer efficient precision cutting of metal sheets, which is essential in most metal fabrication industries. The High Precision Cut-To-Length Line Metal Sheet Cutting Machine/Sheet Metal Slitter Machine is among the most sought after machines in the market today.This machine is made using high-quality materials that guarantee its durability and efficiency. The machine is specifically designed to cut metal sheets into specific sizes, lengths, and widths, making it ideal for various metal fabrication projects. It utilizes high precision sensors that measure and cut metal sheets according to the desired lengths.One of the benefits of this machine is its ability to deliver high precision cutting. The machine is designed to deliver accurate and consistent cuts that meet your specifications. This is essential in ensuring that the finished products meet the required standards, and there is no wastage of materials.The High Precision Cut-To-Length Line Metal Sheet Cutting Machine/Sheet Metal Slitter Machine is also versatile. It can be used to cut different types of metal sheets, including aluminum, galvanized, cold-rolled, and stainless steel. This makes it ideal for use in different industries such as construction, automotive, and aerospace.Another advantage of this machine is its efficiency. The machine is designed to operate at high speeds, enabling it to cut several metal sheets within a short period. This not only saves time but also increases production capacity, which is essential in meeting high demand in the market.In conclusion, the High Precision Cut-To-Length Line Metal Sheet Cutting Machine/Sheet Metal Slitter Machine is a vital investment for any metal fabricator. It offers high precision cutting, versatility, and efficiency, which are essential in meeting the demands of the market. If you are looking to enhance your metal fabrication business's productivity, then this machine is a must-have.