High-Quality Trapezoid Profile Metal Roofing Sheet Machine: A Complete Guide

By:Admin

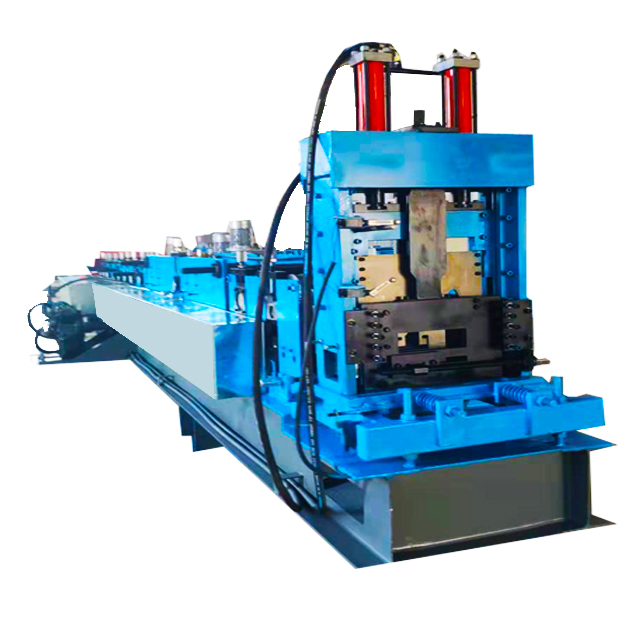

Metal roofing has long been a popular choice for commercial and industrial buildings due to its durability and longevity. However, the process of manufacturing metal roofing sheets has typically been labor-intensive and time-consuming. But that is all about to change, thanks to the innovative Metal Roofing Sheet Trapezoid Profile Machine developed by {Company}.

This cutting-edge machine is set to revolutionize the roofing industry with its efficiency, accuracy, and speed. The trapezoid profile machine is capable of producing high-quality metal roofing sheets with a trapezoid shape in a fraction of the time it takes using traditional methods. This is a game-changer for roofing companies who are looking to increase their productivity and reduce production costs.

One of the key features of the Metal Roofing Sheet Trapezoid Profile Machine is its versatility. It can accommodate a wide range of materials, including galvanized steel, aluminum, and copper, allowing for the production of a variety of roofing solutions to meet the specific needs of the customers. Additionally, the machine is fully automated, requiring minimal human intervention, which reduces the chance of errors and ensures consistent quality in every sheet produced.

The trapezoid profile machine also boasts a high level of precision and accuracy, thanks to its advanced technology and state-of-the-art manufacturing process. This means that the roofing sheets produced are of uniform dimensions and have perfectly formed trapezoid profiles, ensuring a tight fit and a seamless finish when installed on a building. Furthermore, the machine is capable of producing roofing sheets in various lengths, allowing for customization to suit the requirements of different construction projects.

With the Metal Roofing Sheet Trapezoid Profile Machine, {Company} is reinforcing its position as a leader in the roofing industry. This machine is a testament to the company's commitment to innovation and its dedication to providing cutting-edge solutions to its customers. By investing in this technology, {Company} is not only improving its own production processes but also supporting the growth and success of the companies that rely on its high-quality roofing products.

In addition to the Metal Roofing Sheet Trapezoid Profile Machine, {Company} offers a comprehensive range of roofing solutions to meet the diverse needs of its customers. Whether it's for residential, commercial, or industrial applications, {Company} has a wide selection of metal roofing sheets, accessories, and custom fabrication services to ensure that every project is completed to the highest standard.

{Company} has built a strong reputation for delivering superior quality products and exceptional customer service. The company's team of experts and technicians are highly skilled and knowledgeable in all aspects of roofing, and they are committed to providing valuable guidance and support to customers every step of the way. With a focus on innovation, reliability, and customer satisfaction, {Company} has become a trusted partner for businesses and contractors in the roofing industry.

In conclusion, the Metal Roofing Sheet Trapezoid Profile Machine is set to bring about a significant transformation in the roofing industry. Its speed, efficiency, and precision will enable roofing companies to streamline their production processes and achieve higher levels of productivity. With a commitment to quality and innovation, {Company} continues to lead the way in providing the roofing industry with state-of-the-art solutions that meet the evolving needs of the market.

Company News & Blog

Color Steel Glazed Tile Manufacturing Machine Enhances Roofing Industry Efficiency

[Company Introduction][Company Name], a leading manufacturer in the field of steel glazed tile manufacturing, is proud to announce the release of its latest innovation - the Color Steel Glazed Tile Manufacturing Machine (name removed according to the query). With a reputation for delivering high-quality products, [Company Name] has been serving the industry for over a decade. Our team of experienced engineers and technicians constantly strive to develop innovative solutions that meet the evolving needs of the market. Our dedication to quality, reliability, and precision has made us a trusted name in the industry.[Company Name] offers a comprehensive range of cutting-edge machinery and equipment designed for the production of color steel glazed tiles. Our customers span across various sectors such as construction, architecture, and infrastructure. We understand the importance of delivering products that not only withstand extreme weather conditions but also provide aesthetic appeal. Our color steel glazed tile manufacturing machines are engineered with great attention to detail, ensuring flawless performance and durability.As a company, we take pride in our commitment to sustainable practices. We prioritize energy efficiency and strive to develop machines that minimize waste and reduce carbon footprint. By embracing eco-friendly manufacturing processes, we aim to contribute positively to the environment and create a greener future.[Company Name] values customer satisfaction above all else. We believe in building strong relationships with our clients by offering exceptional after-sales support and services. Our team of technical experts is always available to address any queries or concerns our customers may have. We provide comprehensive training programs to ensure that our clients can operate our machines with ease and maximize their productivity.[News Content][City, Date] - [Company Name], a renowned leader in steel glazed tile manufacturing, has announced the launch of its latest state-of-the-art machinery - the Color Steel Glazed Tile Manufacturing Machine (name removed). This cutting-edge technology is set to revolutionize the industry with its innovative features and exceptional performance.The newly developed Color Steel Glazed Tile Manufacturing Machine (name removed) combines the latest advancements in engineering and materials science to deliver unmatched precision and efficiency. Its automated operation streamlines the manufacturing process, increasing productivity and reducing labor costs. The machine offers a high level of customization, allowing for the production of tiles in various colors, shapes, and sizes.Designed for durability, the Color Steel Glazed Tile Manufacturing Machine (name removed) is built to withstand the harshest environmental conditions. Its robust construction and advanced quality control mechanisms ensure consistent output and minimal downtime. This machine is engineered to facilitate efficient material utilization, reducing waste and optimizing production efficiency.One of the key features of the Color Steel Glazed Tile Manufacturing Machine (name removed) is its user-friendly interface. With a comprehensive control system, operators can easily monitor and adjust the production parameters, ensuring precise tile dimensions and perfect finishing. The machine's intuitive design simplifies the learning curve, allowing workers to operate it with minimal training.Speaking about the new product, [Company Name]'s spokesperson said, "We are thrilled to introduce the Color Steel Glazed Tile Manufacturing Machine (name removed) to our customers. This machine represents a significant milestone in our commitment to delivering cutting-edge solutions. With its advanced capabilities and unparalleled performance, we are confident it will exceed our customers' expectations."The Color Steel Glazed Tile Manufacturing Machine (name removed) has already gained significant attention from industry experts and potential customers alike. Its impressive features and competitive pricing make it a highly attractive option for businesses looking to enhance their production capabilities.In conclusion, [Company Name] continues to lead the steel glazed tile manufacturing industry with its commitment to innovation and customer satisfaction. The launch of the Color Steel Glazed Tile Manufacturing Machine (name removed) further solidifies their position as a trusted provider of high-quality machinery. As the industry evolves, [Company Name] remains dedicated to meeting and exceeding market demands while upholding their eco-friendly approach to manufacturing.

High-Quality Ag Panel Roll Forming Machine: A Must-Have for Efficient Farming

Ag Panel Roll Forming Machine Revolutionizes Farming IndustryIn the ever-evolving world of agriculture, technological advancements continue to change the way farmers operate. One such innovation, the Ag Panel Roll Forming Machine, is revolutionizing the farming industry by providing a cost-effective and efficient solution for producing high-quality agricultural panels.The Ag Panel Roll Forming Machine, developed and produced by a leading manufacturing company, is a state-of-the-art piece of equipment designed to streamline the process of manufacturing agricultural panels. These panels are essential for constructing buildings, barns, and other structures on farms, providing much-needed shelter and protection for livestock, equipment, and crops.This innovative machine is equipped with advanced technology and precision engineering, allowing it to produce consistent and precise agricultural panels with minimal waste. Its high-speed production capabilities enable farmers to meet their construction needs in a timely manner, reducing downtime and increasing overall productivity.The company behind this groundbreaking machine has a solid reputation in the manufacturing industry, known for its commitment to producing top-quality equipment that is built to last. With a focus on innovation and customer satisfaction, the company has been a trusted partner for farmers and agricultural businesses for many years.In addition to its cutting-edge technology, the Ag Panel Roll Forming Machine is also designed with user-friendliness in mind. It is easy to operate and requires minimal training, making it accessible to farmers of all experience levels. This accessibility is essential for ensuring that farmers can take advantage of the benefits offered by this innovative equipment.The impact of the Ag Panel Roll Forming Machine extends beyond its immediate users. By increasing the efficiency of agricultural panel production, this machine has the potential to positively influence the entire farming industry. With quicker access to high-quality panels, farmers can expedite construction projects and improve the overall infrastructure of their operations, leading to increased safety and productivity.Furthermore, the machine's ability to minimize waste and optimize material usage contributes to a more sustainable approach to farming. By reducing the environmental impact of panel manufacturing, farmers can align their operations with modern sustainability standards, appealing to environmentally conscious consumers and stakeholders.The Ag Panel Roll Forming Machine is a testament to the ongoing technological advancements in the agriculture sector. Its introduction represents a significant step forward in modernizing farm operations, offering a glimpse into the future of farming technology.With its impressive capabilities and potential to transform the industry, the Ag Panel Roll Forming Machine is set to become a staple in farming operations of all sizes. The company's dedication to innovation and customer satisfaction, combined with its track record of manufacturing excellence, positions it as a key player in shaping the future of agriculture.As the farming industry continues to evolve, it is clear that solutions like the Ag Panel Roll Forming Machine will play a vital role in driving progress and success for farming operations around the world. As more farmers adopt this innovative technology, the industry as a whole stands to benefit from increased efficiency, sustainability, and productivity.

How to Choose the Right Steel Roll Forming Machine for Your Needs?

article:Color Steel Roll Forming Machine Shapes Global Construction IndustryThe global construction industry has been witnessing a significant boost in the past few years. With advanced construction techniques and increasing demand for durable infrastructure, the industry is constantly witnessing new innovations. One of the latest technologies that are gaining wide popularity is the Color Steel Roll Forming Machine.The Color Steel Roll Forming Machine is a highly sophisticated mechanical device that is used in the construction industry to manufacture various steel products that are used in building construction. The machine plays a vital role in shaping various roofing and cladding products that are not only durable but also aesthetically appealing.Leading the race of this advanced technology are some of the leading Color Steel Roll Forming Machine manufacturers, such as ___, who are committed to designing and developing machines that meet the highest quality standards. Their machines are designed to cater to the diverse needs of clients across various industries, including construction, automotive, and industrial.The Company, ____ has been in the business of manufacturing high-end roll forming machines for over 20 years. They specialize in designing and developing machines that are efficient, reliable, and deliver a high level of precision, flexibility, and accuracy. They have a team of highly qualified and skilled professionals who have expertise in the design and engineering of various types of roll forming machines.Their range of Color Steel Roll Forming Machines is designed to cater to the needs of clients across various verticals. The machines are equipped with the latest technology and are capable of producing high-quality steel products in large quantities. Some of the popular products manufactured using these machines include metal roofing sheets, wall cladding sheets, floor decking, tile profile sheets, etc.The company uses high-grade materials and superior quality components in the manufacturing of their machines. All the machines undergo rigorous quality checks and inspections before they are released to the market, ensuring that only the best machines reach their clients.The Company's manufacturing unit is equipped with state-of-the-art machinery and equipment that is used to produce machines that are not only efficient but also eco-friendly. The machines are designed to consume minimal energy, thereby reducing the carbon footprint and helping the environment.Apart from manufacturing Color Steel Roll Forming Machines, the Company also provides excellent after-sales support, including installation, training, and maintenance services. Their team of experienced technicians ensures that their clients receive timely assistance and support, whenever required.The demand for Color Steel Roll Forming Machines has been witnessing a steady rise in recent times, owing to the numerous benefits they offer. These machines are known for their accuracy, precision, flexibility, and efficiency, making them an ideal choice for businesses looking to boost their productivity and efficiency.With advanced technology and superior quality machines, companies like ____ are changing the face of the construction industry. Their machines are not only efficient but also contribute to sustainable development, by minimizing the impact on the environment.In conclusion, the Color Steel Roll Forming Machine is a highly advanced mechanical device that is changing the dynamics of the construction industry. Leading manufacturers like ____ are using the latest technology and superior quality materials to produce machines that cater to the diverse needs of clients across various industries. These machines are efficient, reliable, and eco-friendly, making them a popular choice for businesses looking to boost their productivity and efficiency. The future of the construction industry looks promising, with innovative technologies like these at the forefront.

High-quality Corrugated Sheet Forming Machine for Efficient Production

[Company] is excited to announce the launch of its latest innovation, the Corrugated Sheet Forming Machine. This cutting-edge machine is designed to revolutionize the production of corrugated sheets with its advanced technology and efficiency.The Corrugated Sheet Forming Machine is a highly versatile and customizable solution for manufacturers in the packaging, construction, and automotive industries. It is capable of forming corrugated sheets of various sizes and thicknesses, making it an ideal choice for a wide range of applications. With its high-speed production capabilities, the machine is able to meet the demands of even the most fast-paced production environments.One of the key features of the Corrugated Sheet Forming Machine is its precision engineering, which ensures consistently high-quality results with every sheet produced. This level of precision is essential for industries where product integrity and consistency are paramount. The machine also boasts a user-friendly interface, allowing for easy operation and minimal downtime for maintenance and adjustments.In addition to its advanced technology and precision, the Corrugated Sheet Forming Machine is also designed with efficiency in mind. Its streamlined design and intelligent automation reduce the need for manual labor, resulting in lower production costs and higher output. This is a game-changer for manufacturers looking to improve their bottom line without compromising on quality.As a company committed to innovation and customer satisfaction, [Company] has invested significant resources into the development of the Corrugated Sheet Forming Machine. The machine is a testament to the company's dedication to engineering excellence and its ability to anticipate and meet the evolving needs of the manufacturing industry.[Company] has a long-standing reputation for delivering cutting-edge solutions to its customers, and the Corrugated Sheet Forming Machine is the latest example of this commitment. With its high-performance capabilities and user-friendly design, the machine is set to become an essential tool for manufacturers seeking to stay ahead of the competition."We are thrilled to introduce the Corrugated Sheet Forming Machine to the market," said [Company] CEO. "We believe that this machine has the potential to transform the way corrugated sheets are produced, providing our customers with a competitive edge in their respective industries. We are confident that this innovation will set a new standard for efficiency and quality in sheet forming."The introduction of the Corrugated Sheet Forming Machine represents a significant milestone for [Company] as it continues to lead the way in manufacturing technology. With its focus on innovation and customer-driven solutions, the company is poised to maintain its position as a trusted partner for manufacturers seeking to optimize their production processes.For more information about the Corrugated Sheet Forming Machine and other innovative solutions from [Company], visit [Company website] or contact [Company] directly.About [Company]:[Company] is a leading provider of advanced manufacturing solutions for a wide range of industries. With a commitment to innovation and customer satisfaction, the company has established a reputation for delivering cutting-edge technology and engineering excellence. With a focus on efficiency, precision, and reliability, [Company] is dedicated to helping its customers stay ahead of the competition.

Pros and Cons of All-In-One vs. Multiple Single Layer Roll Forming Machines: A Comprehensive Comparison

, Multiple Roll Forming Machines, All-in-one Roll Forming Machine, Double layer Roll Forming Machine, Roll Forming Machinery.When it comes to roll forming, there are a few different options to consider. One decision that needs to be made is whether to choose an all-in-one roll forming machine or multiple single layer roll forming machines. Both options have their pros and cons, so it ultimately depends on the specific needs and preferences of the user.Single layer roll forming machines are a popular choice for many manufacturers. These machines are designed to create a continuous sheet of metal by bending it into a certain shape. One of the advantages of using a single layer roll forming machine is the ability to produce a high volume of products quickly and efficiently. Since the machine only focuses on one layer at a time, it's easier to control the quality of each product and ensure that each one is consistent.Another advantage of using a single layer roll forming machine is the ability to customize the process based on the specific needs and materials being used. These machines are often designed to be highly flexible, allowing for adjustments to be made based on the thickness and type of material being used.However, one of the downsides of using a single layer roll forming machine is the need for multiple machines if a manufacturer needs to produce multiple layers. This can be a disadvantage if a manufacturer is trying to minimize the number of machines being used in their production process.On the other hand, all-in-one roll forming machines are designed to be highly versatile and efficient. These machines are capable of producing multiple layers of metal at once, which can help streamline the production process. Additionally, all-in-one roll forming machines are often designed to be highly automated, which can help reduce the need for labor and increase overall efficiency.One of the disadvantages of using an all-in-one roll forming machine is the potential for decreased quality control. Since these machines are designed to focus on multiple layers at once, it can be more difficult to ensure that each product is consistent and meets the desired quality standards.Another potential disadvantage of using an all-in-one roll forming machine is the cost. These machines are typically more expensive than single layer roll forming machines, which can be a disadvantage for smaller manufacturers or those with limited budgets.Finally, double layer roll forming machines are another option to consider. These machines are designed to produce two layers of metal at once, which can help increase production efficiency and reduce the need for multiple machines. However, like all-in-one roll forming machines, double layer roll forming machines can be more expensive and may have lower quality control.Ultimately, the decision to choose between an all-in-one roll forming machine and multiple single layer roll forming machines will depend on a variety of factors, including the specific needs and preferences of the manufacturer. Both options have their advantages and disadvantages, so manufacturers should carefully consider their options before making a final decision.

High-Quality Aluminum Roofing Sheet Color Steel Glazed Tile Roll Forming Machine Photos Available

How to Choose a Standing Seam Roof Panel Machine for Your Business

Title: Advanced Standing Seam Roof Panel Machine Revolutionizing Roofing IndustryIntroduction:With the constant need for efficient and innovative solutions in the roofing industry, the introduction of an advanced Standing Seam Roof Panel Machine (name omitted) is set to revolutionize the way roofs are manufactured and installed. Developed by a reputable company known for their dedication to quality and precision engineering, this state-of-the-art machine promises to streamline the roofing process while offering enhanced durability and sustainability. Let's delve into the features and benefits of this cutting-edge technology.1. Efficiency and Precision:The Standing Seam Roof Panel Machine combines years of experience with advanced engineering to deliver a machine that is highly efficient and accurate in its operations. The machine is equipped with an automated control system, allowing for precise and consistent panel measurements, ensuring a perfect fit with minimal waste. With the ability to produce up to 60 feet of roof panel per minute, this innovative technology significantly reduces production time, increasing overall efficiency and productivity.2. Durability and Sustainability:In line with the company's commitment to environmentally friendly practices, the Standing Seam Roof Panel Machine employs sustainable materials and construction methods to produce highly durable roofing panels. The machine's design incorporates high-strength steel and state-of-the-art coatings to ensure resistance against harsh weather conditions, corrosion, and UV radiation. These panels offer exceptional longevity, reducing the need for frequent repairs or replacements, ultimately resulting in cost savings for both homeowners and commercial builders.3. Versatility and Customization:One of the standout features of the Standing Seam Roof Panel Machine is its ability to produce a wide range of panel profiles, allowing for extensive customization options. Clients can choose from a variety of panel widths, seam heights, and surface finishes, catering to their specific architectural requirements and aesthetic preferences. This versatility enables architects and designers to create unique roofing designs that harmonize with the overall style of the structure. Additionally, the machine's versatility ensures compatibility with various installation methods, making it suitable for both residential and commercial applications.4. Safety and Ease of Use:The Standing Seam Roof Panel Machine prioritizes operator safety and ease of use. The machine is equipped with advanced safety features, including emergency stop buttons, safety light curtains, and interlocking systems, ensuring a high level of protection during operation. Additionally, it boasts a user-friendly interface, allowing operators to navigate through different settings and controls with ease. The machine's ergonomic design and intuitive controls enable seamless operation, reducing the risk of errors and accidents.5. Training and Technical Support:Recognizing the importance of proper training and continuous technical support, the company offers comprehensive training programs to ensure operators have the necessary skills to operate the Standing Seam Roof Panel Machine effectively. The training covers machine operation, maintenance, troubleshooting, and safety protocols. Additionally, the company provides ongoing technical support to address any queries or concerns raised by customers, further enhancing the overall user experience.Conclusion:The introduction of the Standing Seam Roof Panel Machine marks a significant leap forward in the roofing industry, revolutionizing the way roofs are manufactured and installed. Its exceptional efficiency, precision, versatility, and sustainability make it a game-changer for architects, builders, and homeowners alike. With an unwavering commitment to quality and customer satisfaction, the company behind this advanced technology continues to innovate, ensuring the continuous improvement and development of the roofing industry.

Innovative Technology Automates Tile Production for Increased Efficiency and Output

Title: Revolutionary Tiles Making Machine Transforms the IndustryIntroduction:In a ground-breaking development for the construction industry, a leading manufacturing company, renowned for its innovation, is set to unveil its latest creation - the Tiles Making Machine (TMM). Designed to revolutionize tile production, this state-of-the-art machinery is poised to streamline manufacturing processes and significantly enhance the efficiency and quality of tile production worldwide.Overview of the Tiles Making Machine (TMM):The Tiles Making Machine, developed by a team of expert engineers at a prominent manufacturing company, has been designed to meet the growing demands of the construction industry. This innovative machine integrates cutting-edge technology, automation, and advanced materials to craft tiles with unmatched precision and performance.Features and Benefits:The TMM boasts several remarkable features and benefits that set it apart from conventional tile manufacturing methods. Incorporating artificial intelligence and machine learning algorithms, this cutting-edge machine offers unparalleled accuracy, speed, and reliability. Its versatility allows for the creation of a wide range of tile designs, shapes, and sizes, ensuring a broad spectrum of options for customers.Moreover, the TMM reduces manual labor significantly, offering an automated solution for tile manufacturing. By minimizing human error and maximizing efficiency, this machine enables manufacturers to streamline their production processes, reducing costs and overall turnaround time. This transformative technology not only enhances the quality and consistency of tiles but also enhances worker safety by minimizing exposure to hazardous materials.Sustainability and Environmental Impact:Recognizing the need for sustainable practices within the construction industry, the Tiles Making Machine incorporates eco-friendly elements. By utilizing recycled materials and minimizing waste during the manufacturing process, the TMM aims to reduce the environmental impact of tile production. Furthermore, the machine operates on energy-efficient principles, ensuring a greener production process while reducing overall power consumption.Market Impact and Global Reach:The introduction of the Tiles Making Machine is expected to have a significant impact on the global tile manufacturing market. As the construction industry continues to grow, there is an increasing demand for efficient, cost-effective, and sustainable tile production. The TMM offers manufacturers the opportunity to enhance their productivity, competitiveness, and market presence.By enabling manufacturers to produce tiles of superior quality and diverse designs, the TMM will cater to a broader customer base, from individual homeowners to large-scale commercial projects. Its automation capabilities and streamlined production processes will allow manufacturers to meet deadlines, mitigate supply chain disruptions, and stay ahead in the highly competitive market.Conclusion:The Tiles Making Machine (TMM) has the potential to redefine tile manufacturing globally. By combining cutting-edge technology, automation, sustainability, and versatility, this revolutionary machine offers tile manufacturers an unparalleled advantage in terms of efficiency, productivity, and quality. With its ability to optimize production processes and reduce costs, the TMM is poised to transform the construction industry, meeting the demands of a rapidly growing market.As manufacturers adopt this state-of-the-art machinery, the TMM will pave the way for a new era in tile production, setting new standards of excellence. Additionally, its sustainable practices and eco-friendly manufacturing process will contribute to a greener construction industry, addressing environmental concerns. Underlining the commitment to innovation and progress, the Tiles Making Machine is set to leave an indelible mark on the future of tile manufacturing.

Steel Sheet Roller Forming Machine: The Ultimate Guide

The Automatic Steel Sheet Roller Forming Machine, also known as metal rolling or roll forming machine, has gained popularity in the manufacturing industry due to its efficiency and precision in producing high-quality steel sheet products. This machine has revolutionized the steel sheet forming process by automating the production line and reducing human intervention, resulting in improved productivity and cost savings for companies.The {Company Name} is a leading manufacturer of the Automatic Steel Sheet Roller Forming Machine, with a strong commitment to innovation and quality in the metal forming industry. The company has a proven track record of delivering state-of-the-art equipment that meets the diverse needs of its customers, and its roller forming machines have been widely adopted by manufacturers around the globe.The Automatic Steel Sheet Roller Forming Machine offered by {Company Name} features advanced technology and intelligent software, allowing for precise control and seamless operation. The machine is designed to handle a wide range of steel sheet materials, including stainless steel, carbon steel, and aluminum, with varying thickness and widths. Its modular design and customizable tooling options make it a versatile solution for manufacturers seeking to streamline their production processes and optimize their product offerings.One of the key advantages of the Automatic Steel Sheet Roller Forming Machine is its speed and accuracy in shaping steel sheets into desired profiles and dimensions. The machine's automated feeding system and precise roll forming stations ensure consistent product quality and dimensional accuracy, reducing material waste and rework. This level of precision is essential for meeting the high standards of the automotive, construction, and aerospace industries, where tight tolerances and smooth surface finishes are critical.In addition to its performance capabilities, the Automatic Steel Sheet Roller Forming Machine is also designed with operator safety and ease of use in mind. The machine is equipped with safety guards, emergency stop buttons, and intuitive controls to minimize the risk of accidents and ensure smooth operation. Its user-friendly interface and quick changeover features further enhance productivity and efficiency, allowing manufacturers to quickly adapt to changing production requirements and market demands.The {Company Name} takes pride in providing comprehensive support and service for its Automatic Steel Sheet Roller Forming Machine, including installation, training, and ongoing maintenance. Its team of experienced engineers and technicians are dedicated to helping customers maximize the potential of their equipment and achieve long-term success in the competitive metal forming industry. This commitment to customer satisfaction has earned {Company Name} a reputation for reliability and excellence in the market.As the demand for high-quality steel sheet products continues to grow across various industries, the Automatic Steel Sheet Roller Forming Machine offered by {Company Name} presents a compelling solution for manufacturers seeking to stay ahead of the curve. Its combination of advanced technology, precision engineering, and comprehensive support makes it a valuable investment for companies looking to enhance their production capabilities and expand their product offerings.In conclusion, the Automatic Steel Sheet Roller Forming Machine offered by {Company Name} is a game-changer in the metal forming industry, delivering unmatched performance, versatility, and safety for manufacturers worldwide. With its innovative features and proven track record, this machine is poised to shape the future of steel sheet production and drive business success for its users.

High-Quality Corrugated Metal Sheet Roll Forming Machine for Sale

Corrugated Metal Sheet Roll Forming Machine, a New Milestone in the Field of Metal FormingIn the fast-paced world of metal manufacturing, staying ahead of the competition is crucial. That's why the unveiling of the new Corrugated Metal Sheet Roll Forming Machine by [Company Name] has caused quite a stir in the industry. This state-of-the-art machine promises to revolutionize the way corrugated metal sheets are produced, making the process faster, more efficient, and more cost-effective than ever before.The Corrugated Metal Sheet Roll Forming Machine is the result of years of research and development by the team at [Company Name]. Leveraging their extensive experience in the field of metal forming, the engineers at [Company Name] have come up with a machine that is truly groundbreaking. By incorporating the latest advancements in technology and design, they have created a product that sets a new standard for quality and performance.One of the key features of the Corrugated Metal Sheet Roll Forming Machine is its versatility. It is capable of producing a wide range of corrugated metal sheet profiles, giving manufacturers the flexibility to meet the unique requirements of their customers. Whether it's for roofing, siding, or other applications, this machine can handle the job with ease.But perhaps the most impressive aspect of the Corrugated Metal Sheet Roll Forming Machine is its speed and efficiency. Thanks to its advanced automation and precision engineering, this machine is able to produce corrugated metal sheets at a rate that was previously unheard of. This means that manufacturers can now fulfill large orders in a fraction of the time it would have taken with traditional methods.In addition to its speed, the Corrugated Metal Sheet Roll Forming Machine also boasts an impressive level of accuracy and consistency. This is crucial for ensuring that the finished products meet the highest standards of quality. With this machine, manufacturers can have complete confidence that every corrugated metal sheet produced will be of the utmost precision and uniformity.Of course, an innovative product like the Corrugated Metal Sheet Roll Forming Machine is only as good as the company behind it. In the case of [Company Name], customers can rest assured that they are dealing with a reputable and reliable partner. With a long track record of delivering top-notch metal forming solutions, [Company Name] has earned a strong reputation in the industry.Furthermore, [Company Name] doesn't just stop at selling the Corrugated Metal Sheet Roll Forming Machine. They also offer comprehensive support and service to ensure that their customers get the most out of their investment. From installation and training to ongoing maintenance and technical assistance, [Company Name] is dedicated to helping their clients succeed.With the introduction of the Corrugated Metal Sheet Roll Forming Machine, [Company Name] has truly raised the bar for the entire industry. This machine represents a new milestone in the field of metal forming, offering a level of performance and efficiency that was previously unimaginable. As manufacturers around the world seek to stay competitive in a rapidly evolving market, this innovative product is poised to make a significant impact.In conclusion, the Corrugated Metal Sheet Roll Forming Machine by [Company Name] is a game-changer for the metal forming industry. Its cutting-edge technology, versatility, speed, and precision are testament to the ingenuity and expertise of the team at [Company Name]. With this machine, manufacturers can expect to improve their productivity, reduce costs, and deliver exceptional quality products to their customers. It's clear that the future of metal forming is here, and it's being shaped by the innovative solutions of [Company Name].